Brewer machine gear is the "heart" of core equipment in craft breweries and plays a highly important role in every step, from grain conveying and malt grinding to beer mixing.

However, most breweries do have some issues: excessive gear noise affects brewery surroundings, frequent wear means constant downtimes for maintenance, and delivery time is not guaranteed for gears ordered to be tailor-made.

In this fiercely competitive gear manufacturing industry, who is the partner that will give you reliability, cost efficiency, and expertise in food-grade equipment requirements?

This guide will walk through everything, from design and material selection to procurement, showing why global leading brewing equipment brands entrust us with their custom gear cutting.

Core Answer Table

| Dimension of procurement decision-making | Common Challenges and Misconceptions | JS Precision's Professional Solutions and Value |

| Process and Price Transparency | The processes of customization are not transparent, and there is a lot of hidden cost involved with huge price variations. | One-stop customization process: From design support to finished product delivery, clear price structure, no hidden fees, and the most competitive gear manufacturing prices. |

| Quality Assessment and Reliability | Difficulty in assessing the true capabilities of suppliers. Concerns about the consistency of the quality of overseas manufacturing. | Visualized Quality Evidence: From material certification to precision gear grinding services, we provide end-to-end testing reports with accuracy up to AGMA Level 10. |

| Supply Chain and Cost-Effectiveness | Uncertain as to "where can i buy gears for the best value", with considerations between local and overseas suppliers? | Optimum Global Supply Chain Solution: We combine the cost benefits of high-value-added manufacturing in China with equalized quality systems in Europe and America to provide high-value, low-noise gear drive solutions that exceed "low price." |

| Specific Technical Needs | Difficulty finding experts who understand both brewer idler pulleys design and spiral bevel gear manufacturing. | Cross-Disciplinary Technology Integration: Our engineers are proficient in both brewing equipment operating conditions and high-end gear transmission technology, providing optimized solutions from components to systems. |

Why Trust This Guide? Comprehensive Analysis Of The Gear Manufacturing For JS Precision Brewer Machine

Their strength in gear machining is the core of this guide, by experts deeply rooted in the field at JS Precision.

We hold multiple international certifications, including ISO 9001:2015 and ISO 13485:2016, serving more than 500 different beer equipment manufacturers and craft breweries worldwide, with extensive experience in custom brewer machine gear.

We offer more than 80 different materials, from food-grade 316L stainless steel to self-lubricating engineering plastics-all selected for the particular environment of beer production. Employing advanced CNC hobbing, gear shaping, and precision gear grinding services, we continue to produce AGMA 9-10 precision with tolerances controlled within ±0.01mm.

It is not a theoretical guide, but a wrap-up of our experience with more than 1000 brewer machine gear projects. Each recommendation has been tested in real life to help you avoid common mistakes when selecting and procuring.

Want to confirm our brewer machine gear manufacturing capabilities? Provide your equipment parameters, and we'll share three successful case studies and testing reports from similar breweries free, giving you a direct understanding of our craftsmanship standards.

What Is The Process And Cost For Custom Brewer Machine Gear?

The core of the custom brewer machine gear is how to balance precision, lifespan, and cost. Similarly, the processes should be standardized to ensure transparency in costs.

Its quality system must comply with the basic requirements for the design and manufacture of sanitary equipment in the American Society of Mechanical Engineers (ASME) Bioprocessing Equipment Standard (ASME BPE-2022).

Therefore, we will explain in detail JS Precision's full custom gear cutting process and its cost.

Four-Step Transparent Customization Process

1. Design Collaboration and DFM Analysis: Engineers review designs, optimizing gear profiles and materials based on the production environment in beer to avoid defects.

2. Accurate Quoting and Solution Confirmation: A clear quotation will be provided, inclusive of material, machining, and heat treatment along with precision gear grinding services, without any concealed costs.

3. Controlled Manufacturing and Process Inspection: Production throughout the process in our own factory with necessary points of inspection at critical stages, with CNC equipment ensuring consistency.

4. Final Inspection and Certification and On-Time Delivery: 100% factory inspection with test reports and real-time logistics tracking, ensuring on-time delivery.

Detailed Cost Breakdown

The three main factors determining the cost of brewer machine gear are: materials, processes, and batch size:

1. Material Type:

| Material Type | Applicable Scenarios | Unit Price Range (USD/ piece) | Features |

| Food Grade 304 Stainless Steel | Non direct contact parts with alcohol. | 50-150 | Medium corrosion resistance, medium cost. |

| 316L Food Grade Stainless Steel | Direct contact with the liquid parts of the wine. | 80-220 | Optimal corrosion resistance, long service life. |

| POM | Light load and low noise requirements. | 30-80 | Self-lubricating, low noise. |

2. Process Cost:

| Process Type | Processing Content | Unit Price Range USD/piece | Effect |

| Custom Gear Cutting (Gear Hobbing) | General gear profile machining | 20-50 | Meets general precision requirements |

| Custom Gear Cutting (Gear Shaping) | Complex gear profile machining | 30-60 | Adapted to special gear structure |

| Precision Gear Grinding Services | Gear surface grinding + shaping | 30-80 | Precision improvement, noise reduction |

3. Batch Effect:

The unit price of small-batch prototypes (1-10 pieces) will be 30%-50% higher than that of large-scale production (100 pieces or more).

For example, the unit price of 316L stainless steel brewer machine gear is about $180 for less than 10 pieces, and can be reduced to about $120 for more than 100 pieces. It is recommended to plan the purchase volume in conjunction with the annual production plan.

How To Truly Assess A Gear Manufacturing Supplier's Quality?

When choosing a gear manufacturing supplier, you can't just look at the price. The level of precision gear grinding services directly determines the noise and lifespan of brewer machine gear. It is critical to place emphasis on their technical strength and quality control capabilities.

Must-Ask Checklist and Must-See Evidence

Must-Ask Technical Questions

- What AGMA/DIN precision level can be obtained on your brewer machine gear? Is test data available?

- Gear deformation control in heat treatment under high humidity conditions, what are the protections there?

- What are some of the successful low-noise gear drive solutions case studies, possibly with noise test reports?

Key Quality Evidence

Ask for test reports, material quality certificates and heat treatment records from current customers. A true gear manufacturing expert is happy to furnish these details, essential when documenting the precision gear grinding services capabilities.

Equipment and Process Inspection

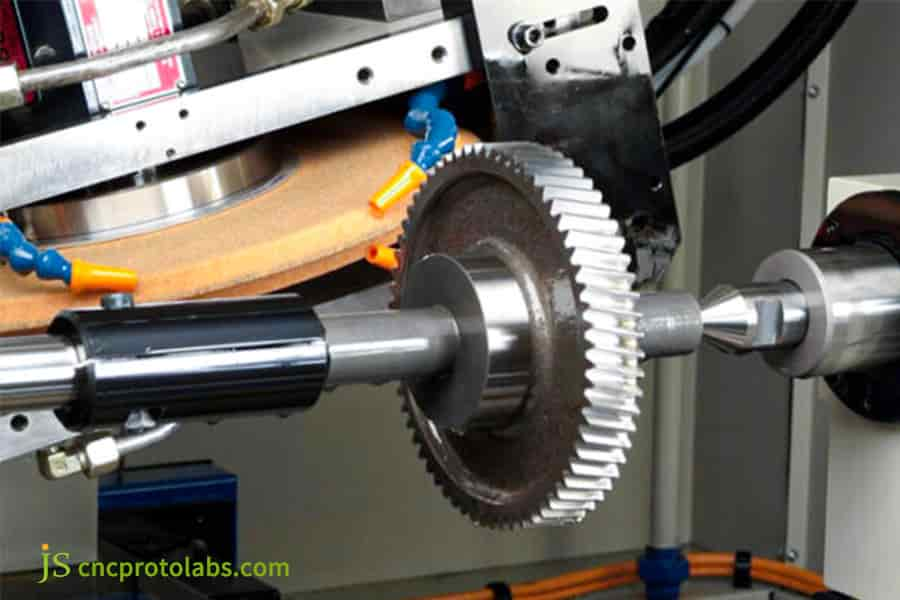

- Main Equipment: Introduce the configuration of CNC gear hobbing machines, gear shaping machines and gear grinding machines. Tooth profile modified by imported gear grinding machines for JS Precision.

- Testing ability: Gear measurement centers, hardness testers, etc. are essential, and each batch of our products undergoes multiple tests.

Want to avoid the pitfalls of supplier selection? Download the free "Gear Manufacturing Supplier Evaluation Checklist" for 10 must-know inspection items that will help you rapidly screen for capable partners.

Figure 1: Check if the supplier is equipped with core gear manufacturing equipment such as high-end precision gear grinding machines.

Material Selection & Cost Guide For Durable Brewer Idler Pulleys

The choice of brewer idler pulleys is directly related to equipment stability and the cost of its maintenance. Common materials and price references are compared in the following tables:

| Material | Applicable Scenarios | Unit Price Range (USD/piece) | Features |

| 316L Stainless Steel | Direct contact with liquids | 60-180 | High corrosion resistance, long lifespan |

| Anodized Aluminium Alloy | Indirect contact with liquids | 40-120 | Lightweight, high cost-performance |

| Engineering Plastics POM | Light load, low noise | 20-60 | Self-lubricating, low noise |

An extremely low price might indicate material downgrades, increasing the risk of corrosion and breakage, with higher maintenance costs.

Figure 2: plastic idler pulley

Where Can I Buy Gears With The Best Overall Value?

When trying to find the answer to "where can I buy gears," do not fall into the trap of low price. The actual value of the gear manufacturing industry has to be factored in conjunction with lifespan, maintenance costs, and losses due to downtime.

Local suppliers have the advantage of convenient communication, short lead time, which can be used for urgent small-batch purchases. Their material and process capability is limited, making it hard to meet the needs of brewer machine gear with high requirements.

As an overseas expert, JS Precision has developed profound expertise in the gear manufacturing industry for many years, with technological depth and scale advantages. They can provide full-process services, including custom gear cutting and precision gear grinding services. Though cross-border lead times are slightly longer, the total cost of ownership is lower.

We focus on high-value, custom gear cutting and provide customized brewer machine gear solutions for breweries.

From Order To Delivery: What Are Realistic Lead Times For Custom Gear Cutting?

The delivery cycle of custom gear cutting is a key consideration for equipment maintenance and upgrades in breweries. Based on years of production experience, JS Precision can break down the real timeline and help you plan a procurement strategy.

Standard Timeline Breakdown

- Process Preparation: 1-3 days for drawing review, programming, process planning. For complex gears, add another 1-2 days to account for DFM analysis.

- Procurement of raw materials: 3-7 days (304 stainless steel and POM are always in stock, whereas special materials like 316L stainless steel take 3-5 days).

- Machining and Heat Treatment: 5-10 days including rough machining, heat treatment, and finish machining. The heat treatment requires 2 to 3 days, which is very critical in gears for harness and life.

- Fine grinding and testing: 3-5 days (precision gear grinding services take 2-3 days, final inspection and report issuance take 1-2 days).

The overall standard delivery cycle is 12-25 days, and the specific time may be affected by the following factors:

- Material Specialties: The purchasing cycle for special alloy materials can be up to 7-10 days.

- Complexity of gearing: The time for machining such complicated structures as spiral bevel gears will be longer by 3-5 days.

- Special heat treatment: carburizing and quenching need an additional 3 days.

- Current Order Schedule: During the peak season that usually occurs from March through May, and again from September through November, the schedule will be considerably longer, orders can be extended by 2-3 days.

For urgent repair or prototype needs, we have an expedited production process, this can deliver within 7-10 days. However, expedited processing will incur a 10%-20% expedited fee. In situations where it is not urgent, we recommend purchasing according to the standard cycle.

Have urgent custom gear cutting needs? Please call our service hotline immediately to inform us of the type and quantity of the gear, as well as the latest date of delivery. We will assess our capacity and provide the best expedited solution to help customers minimize downtime losses.

The Price Premium And ROI Of Low-Noise Gear Drive Solutions

In the production environment of breweries, low-noise gear drive solutions not only improve work comfort, but also bring significant long-term benefits. Although the initial cost of such solutions is higher, the return on investment is considerable.

Noise Sources and Solution Costs

The noise from brewer machine gear mainly comes from the friction on the tooth surface and the shock of transmission. The corresponding solutions and costs are as follows:

- Tooth Profile Modification and High-Precision Grinding: Precision gear grinding services provide microscopic modification to optimize tooth surface contact area and reduce friction noise. Cost increased by about 20-40%, with a noise reduction of about 5-10 dBA, to keep operating noises below 70 dBA.

- Special Lubrication and Material Matching: Adopting food-grade synthetic greases with wear-resistant gear pair materials such as 316L stainless steel + POM reduces wear and noise. Cost increases about 10-15%, with a further reduction of noise by 3-5 dBA and prolongation of lubrication time.

Calculation of Return on Investment (ROI)

Using a medium-sized craft brewery for example, below is the ROI analysis for using the low-noise gear drive solutions:

- Equipment Premium: Reduced noise results in a better production environment, and increases equipment market price by 10%-15%.

- Energy Savings: Optimized Gear Drive Efficiency - 3-5% improvement. For a 10kW unit, this will correspond to an annual saving in electricity of approximately $800-$1200.

- Maintenance Costs: Gear life has been increased from 1 year to 3 years, reducing annual maintenance costs from $2000 to $600, providing total savings of $4200 over the 3-year period.

In general, recuperation of the initial increased costs is possible within 1-2 years while long-term benefits are derived from low noise and low maintenance.

Want to design a low-noise gear drive solutions for your brewery? Please provide your equipment model and current noise data, we will provide you with a free, customized noise reduction solution and ROI analysis report so that you can clearly understand your return on investment cycle.

How To Get A Quote From A Spiral Bevel Gear Manufacturer?

Spiral bevel gears are highly structural and require extreme precision. It is very important to select a professional spiral bevel gear manufacturer for ensuring better transmission performance. Here's a detailed guide to get a quotation from JS Precision, which will help you get an accurate quotation in the shortest possible time.

Provide Valid Inquiry Information

The quotation of spiral bevel gears requires very accurate parameter support. Please prepare the following key drawing parameters in advance:

- Basic Parameters: Module, Gear Ratio, Shaft Angle-commonly 90°, Helix Direction.

- Structural Parameters: Mounting Distance, Tooth Width, Bore Diameter, Keyway Dimensions.

- Performance Requirements: Transmission Power, Speed, Operating Environment Humidity, Corrosion.

- Quantity and Delivery Requirements: Volume to be purchased, expedited service required, delivery address.

Contact Professional Channels Directly

Because ordinary gear factories may not be equipped with enough processing capability and experience in spiral bevel gears, we recommend customers directly connect with our bevel gear expert team through JS Precision's "Engineering Consultation" channel.

The optimization suggestions can be put forward quickly since our experts have more than 10 years of experience in designing and machining spiral bevel gears.

From Inquiry to Collaboration

We can quote you not only, but we can also analyze your application scenario and suggest the best gear type-Gleason or Klingelnberg, and the best manufacturing process. For transmission requirements in beer brewing equipment, we prefer wear-resistant and low-noise solutions to ensure that gears are suitable for humid environments.

Case Study: 55% Noise Reduction Achieved For Craft Brewery Chain's Grain Conveyor Drive

Client Pain Points:

A well-known craft beer chain with 20 stores nationwide experienced two long-standing problems with its brewer machine gear in its grain conveyor system:

- Operating noise reached 85 dBA, impacting the in-store customer experience.

- Gear wear was severe, requiring replacement every 9 months, resulting in high maintenance costs and disruption to normal operations.

JS Precision Solution:

Against this backdrop of pain points, the brand approached JS Precision.

Our engineers first inspected the on-site equipment and found that the original gears used a common hobbing process with a precision of only AGMA 6, resulting in rough tooth surfaces and high friction noise,Furthermore, the material was ordinary carbon steel, which is prone to corrosion and wear in humid environments.

To address these issues, we provided a complete low-noise gear drive solution:

- Redesign the gear pair: Optimize the tooth profile of the brewer machine gear, adopt a modified design, increase the tooth surface contact area, and reduce impact noise.

- Upgraded Manufacturing Process: Adopted precision gear grinding services instead of original precision rolling, further improving precision to AGMA Grade 9 and reducing tooth surface roughness below Ra 0.4μm.

- Optimized Materials and Heat Treatment: Food-grade 316L stainless steel was selected for the gears, and through the controlled nitriding treatment, the surface hardness reached 60HRC. It had great wear resistance and corrosion resistance.

Quantified Results:

After implementation, the following important results were realized:

The operating noise of the store's grain conveyor system was reduced from 85dBA to 70dBA-a 55% reduction in subjective auditory perception-resulting in a significantly improved store environment.

The lifespan of gears has been extended from 9 months to over 3 years, without the need for frequent replacement; The annual maintenance cost of a single transmission system has been reduced from $2500 to $1500, a decrease of 40%.

At present, the brand has completed equipment upgrades for all stores and established a long-term partnership with JS Precision.

Would you like to recreate this noise-reducing and lifespan-enhancing solution? Please let us know about your specific equipment pain points and your needs. Free of charge, we will offer your custom solutions and details of similar case studies that help improve equipment performance and reduce maintenance costs.

Figure 3: Conveyor system gears

FAQs

Q1: What materials are food-grade for brewer machine gears?

We suggest food-grade 304 or 316L stainless steel and FDA-approved POM and UHMW-PE engineering plastics. These are nontoxic, corrosion-resistant, and compliant with beer production hygiene. Leaded brass should be avoided.

Q2: Can you manufacture gears to both metric and imperial standards?

Yes, we are proficient in international standards such as ISO, DIN, and AGMA and can manufacture either metric or imperial standard brewer machine gear according to your drawings with a perfect fit to your equipment.

Q3: What is the typical tolerance for precision ground gears?

Our precision gear grinding services reach the AGMA 9-10 levels of precision, with the tooth profile and direction errors controlled to within 0.005mm. These gears, therefore, offer high stability, with important reductions in transmission noise.

Q4: Do you provide lubrication recommendations for low-noise applications?

Yes. We suggest special food-grade synthetic greases according to the material, speed, and load of your brewer machine gear for reducing friction on tooth surfaces, lowering noise, and meeting hygiene standards.

Q5: What is your minimum order quantity for custom gears?

There is no hard minimum order quantity, we support everything from single-piece prototypes to mass production. Small batch orders also enjoy complete design optimization and quality inspection to meet prototype testing or emergency repair needs.

Q6: Do you supply only gears or complete assembled gearboxes?

The above-mentioned two are all available. We supply brewer machine gear, brewer idler pulleys parts, and gearbox assembly service, offering a one-stop solution to help reduce your procurement cost and assembly cost.

Q7: What is the lead time for a small batch of custom spur gears?

For simple custom spur gears in small batches (<100 pieces), using standard materials such as 304 stainless steel or POM, the standard lead time is 3-4 weeks. Urgent requests can be expedited to 10 days.

Q8: How can I verify your quality claims before placing a large order?

We recommend a small-batch trial production first, allowing you to fully test product quality. You can also schedule an online virtual factory visit to intuitively understand our production equipment, quality control processes, and technological level.

Summary

The core of brewer machine gear manufacturing is "precise fit" and "value balance."

With JS Precision, you are choosing not only a spiral bevel gear manufacturer but also a long-term partner that deeply understands your application scenarios and leverages cutting-edge technology in the gear manufacturing industry to provide you with low-noise gear drive solutions.

Immediately optimize your equipment's transmission performance and cost structure.

→ Send us your gear drawings for a free design review and an accurate quote.

→ Download our FDM White Paper.

→ Book a 15-minute technical call with our gear experts to discuss your project challenges directly.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com