Gear manufacturing is key to production within the company.

When the "Made in America" label brings a premium to industrial gears, have customers considered the value behind it? The rather ironic reality is that the core manufacturing process of gears for many high-end equipment brands touting "American design" is migrating to Chinese precision gear manufacturers like JS Precision.

That is not just a cost transfer but a result brought about by the deepening division of labor in global manufacturing, whereby Chinese manufacturing has moved from "being able to manufacture" to "precision manufacturing," establishing unique advantages in the speed of technological iteration, supply chain efficiency, and overall cost.

This article objectively compares the gear-manufacturing landscape in China and the US and brings to light how JS Precision, having engineering capabilities that transcend geographical boundaries, offers optimum solutions to clientele around the world.

Core Answer Table

| Dimension of Comparison | Common Perceptions regarding American Gear Manufacturing | JS Precision's Actual Advantages |

| Precision and Technology | Depends on historical accumulation and brand reputation, while technological dissemination and iteration speed are restricted due to high cost. | Based on high-quality German and Japanese equipment, supplemented with rich process data from large-scale applications, it realizes fast technological iteration and stable ultra-high precision. |

| Cost and Efficiency | High labor and operational costs inflate unit prices, complicated manufacturing processes for prototype gears extend R&D cycles. | The full-industry-chain cluster brings extreme efficiency, prolonging the cost advantages of mass-produced gears to customized gear manufacturing services and prototype projects. |

| Supply Chain and Response | The local supply chains are complete yet slow, while overseas procurement involves logistical and communicational risks. | A deeply integrated local supply chain provides agile response. A digitalized gear manufacturing process supports transparent collaboration with global clients, realizing "Serving the world from China." |

Why Trust This Guide? JS Precision's Practical gear manufacturing Experience

In gear manufacturing, practical experience is the core standard to judge professionalism, and the accumulated expertise of JS Precision in gear machining allows you to fully trust this guide.

We provide more than 80 material options for multiple industries, including aerospace, medical, and automotive. Additionally, we offer more than 50 surface treatments to meet various durability needs in different scenarios.

We have received numerous international certifications, including ISO 9001:2015, ISO 13485:2016, AS9100D, and IATF 16949:2016, and also the ITAR registration to ensure that every gear is manufactured to a high standard of quality.

In one such project, we solved an emergency for a US-based agricultural machinery OEM:

We completed the drawing review within 24 hours, allocated AMS standard steel on the same day, and employed a combination of gear hobbing with rapid nitriding processes. Qualified gears were airlifted to the customer's warehouse within 28 days at a cost 35% lower than the alternative solution from the US.

Moreover, our gear machining accuracy reaches ±0.01mm and supports high precision grades such as AGMA 8 to AGMA 13, DIN 5 to DIN 9, which allows us to maintain consistent quality for both mass production and prototype manufacturing.

This guide summarizes our practical experience. Each piece of advice has been at least partially tested on real projects to help you avoid common pitfalls in gear manufacturing and to find efficient solutions.

Want to avoid common risks in your gear manufacturing project? Contact us now and tell us your gear needs for free, experience-based process advice to improve your project success rate.

From Blank To Finished Product: How Are Gears Manufactured?

Understanding how are gears manufactured is the key to selecting precision gear manufacturers. Modern precision gear manufacturing has seven key steps, each of which contributes to the gear strength, precision, and noise level directly.

- Design and Modeling: Design the gear on the CAD, decide on the type of teeth and number of teeth, and verify the design flaws through modeling.

- Material Selection and Preparation: The selection of materials should be done according to application scenarios, pre-treated by forging or casting to optimize the material grain structure.

- Rough Machining (Turning, Milling): The machining of the gear blank done by CNC to keep basic dimensional accuracy and leave machining allowance for the teeth.

- Gear Forming (Hobbing, Shaping): Hobbing can be applied for external gears in terms of high efficiency. Shaping is preferred for internal gears to ensure high precision and smooth meshing.

- Heat Treatment(Carburizing, Nitriding): Carburizing and quenching increase surface hardness with toughness at the core. Induction hardening provides localized strengthening to control deformation while allowing for allowances.

- Finishing (Gear Grinding, Honing): Gear grinding improves precision in tooth surface, reduces noise, and optimizes surface quality for long-time stable operation.

- Inspection and Quality Control: Inspection using CMM and gear measuring instruments ensures that standards such as AGMA, DIN, and others are met, no defective products leave the factory.

These seven steps are closely related. Poor material selection can cause cracking during heat treatment, and low precision in gear forming can increase noise. As one of precision gear manufacturers, JS Precision strictly controls each step to ensure the final product meets standards.

Core Forming Processes : Hobbing vs. Shaping vs. Grinding

Gear forming is the core of gear manufacturing. JS Precision selects processes based on the part:

- Hobbing: Only for external gears, high efficiency, suitable for high-volume production of gears, up to AGMA 13 precision.

- Shaping: Used for the machining of internal parallel gears, precision as high as hobbing, efficiency is a bit lower. Suitable for small batches.

- Grinding: Grinding after heat treatment, highest precision - AGMA 16, corrects deformation, thus suitable for high precision applications.

We combine processes according to need, balancing efficiency and precision.

Heat treatment: how to balance gear hardness and toughness?

Heat treatment determines the lifespan of gears, and JS Precision's heat treatment process is strictly controlled according to the AMS 2750 high-temperature measurement standard. Our commonly used processes include:

- Carburizing and quenching: Surface hardness of 58-62 HRC, core hardness of 25-35 HRC. Suitable for high-load gears. Controls the deformation and allows a machining allowance.

- Induction hardening: Local strengthening, small deformation, high efficiency, suitable for gears that require surface wear resistance.

We adjust processes according to the property of the material to ensure gear wear resistance and impact resistance.

Figure 1: Vacuum hardening or carburizing of gears.

How Does Agile Manufacturing Reshape custom gear manufacturing services?

Fast response is needed during the process of custom gear manufacturing services in a rapidly iterating market today. Agile manufacturing allows a seamless transition from prototype gear manufacturing into mass production. Being one of precision gear manufacturers, JS Precision integrates agile concepts at every stage.

Seamless "Prototype-Mass Production" pipeline

In the traditional model, data loss and differences in process are apt to emerge between prototyping and mass production. JS Precision integrates the two into the same quality control system, reusing CAD models and material specifications from the prototyping stage.

The CNC equipment can flexibly switch parameters, avoiding accuracy deviation to shorten the prototyping-to-mass production cycle by more than 30%.

Collaborative Design Driven by a Digital Thread

Customized gears are prone to disconnect between design and manufacturing. JS Precision uses an online platform to build a digital thread: after the customer submits drawings, we feedback DFM analysis and improvement suggestions within 24 hours to reduce problems at the source and improve the efficiency of custom gear manufacturing services.

Flexible Production Lines for Small-Batch Diversity

Prototype gear manufacturing and multi-variety, small-batch production are characterized by slow changeovers and high costs. Our flexible production line, which is equipped with 5-axis CNC and a fast tool change system, achieves changeovers in less than 30 minutes.

It also includes standardized process templates that economically meet the needs for design changes and helps customers move quickly to validate their ideas.

Need to expedite prototype gear manufacturing or custom gear manufacturing services projects? Submit your design requirements now, and within 24 hours our agile team will provide DFM analysis that will help you shorten your development cycle.

What Gets Lost In The “USA Vs China” Price Comparison For gear manufacturing?

Many customers base their selection of gear manufacturing partners on unit price alone. There are some clear differences in total cost of ownership and speed of value realization between the USA and China. China enjoys a greater advantage in the high volume gear production.

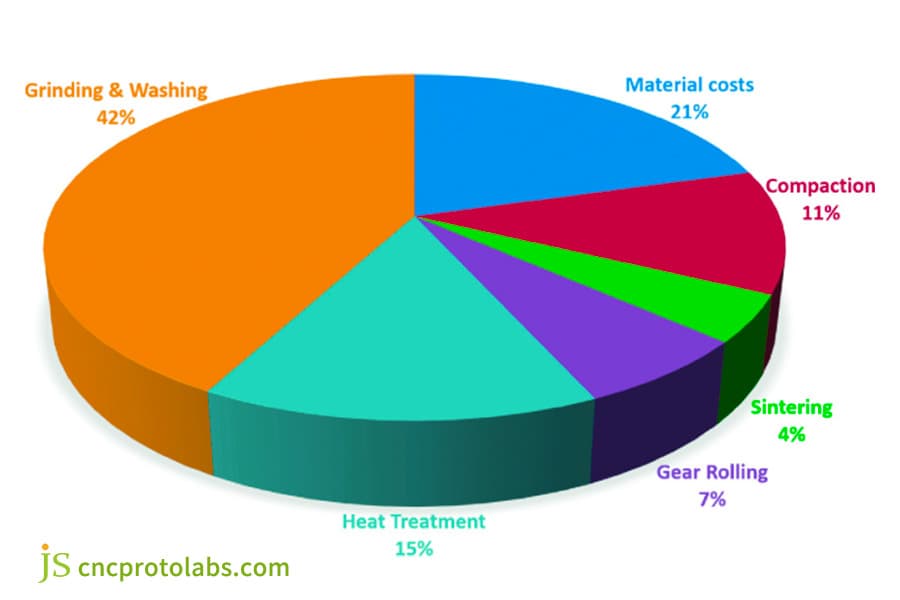

Detailed Cost Breakdown: Various material, labor, and management rates

Take 4140 alloy steel gears for example, an explicit cost comparison between China and the US:

| Cost Item | USA (USD/Unit) | China (USD/Unit) | Reason for Difference |

| Raw Materials (4140 Steel) | 5.2 | 4.8 | Lower Purchasing Costs in China |

| Single Piece Processing Labor Costs | 35 | 18 | Lower Depreciation of Labor and Equipment in China |

| Overall Management Rate | 12% | 8% | Lower Operating Costs in China |

The explicit costs of China are about 30% less, but for high-volume gear production, the difference is even greater.

The Hidden Costs Revealed: R&D Cycle, Inventory, and Opportunity Cost

Hidden costs have a greater effect:

US suppliers deliver prototypes in 6-8 weeks while JS Precision delivers in 1-5 days, thus shortening the R&D cycle by 4-6 weeks, US MOQ is often over 500 units while our MOQ is as low as 10 units, reducing capital tied up, delivery delays result in later product launches, hence lost sales far exceed unit price savings.

The Ultimate Path to Cost Reduction Through Scale

The efficiency of high volume gear production in China is the result of specialized division of labor. With a complete supply chain, JS Precision has professional heat treatment and surface treatment plants nearby, enabling mass production to reduce costs while maintaining quality and delivery speed.

Figure 2: Disassemble the cost of Gear Manufacturing to provide reference for selecting Gear Manufacturing partners.

Challenges In custom gear manufacturing services: How To Ensure Consistency In The Final Product?

One of the major challenges facing custom gear manufacturing services during the transition from prototype gear manufacturing to high volume gear production is consistency. JS Precision addresses the challenge through four key measures, including:

1. Standardized Process Package: There is an independent process package for every project, which contains the materials, parameters, and standards. The procedures should be strictly conducted for each batch.

2. Tool Life Management: Equipment with a management system that has real-time tool monitoring and an early warning system for replacement will improve machining accuracy.

3. Statistical Process Control (SPC): The sampling and measurement of critical dimensions, the analysis for systematic trends, the appropriate adjustment of parameters in a timely manner combine to prevent batches of defective products from being created.

4. Equipment and Tool Calibration: Equipment and tools are calibrated on a monthly basis by using standard parts for accuracy.

These will ensure that gears in mass production are the same as the prototype, so that customers do not have to worry about differences.

What Module Hobbing Capability Do You Need For Your Project? Learn About The Limits Of Gear Hobbing Services

Gear hobbing services account for one of the most common processes in high volume gear production, and their applicability and capability limits affect project feasibility directly.

As one of precision gear manufacturers, JS Precision's gear hobbing services caters to most industrial needs and will suggest alternative processes depending on the project.

Key competencies in gear hobbing services include:

- Maximum module up to 12, capable to machine heavy-duty gears such as mining machinery gears.

- Maximum machining diameter 500mm, meeting the needs of small and medium-sized gears such as automotive transmissions, robot joint gears.

- It covers the machining of carbon steel, alloy steel, stainless steel, titanium alloys, and some engineering plastics, the machining parameters are adjusted according to the material.

- Accuracy to range from AGMA 13 to DIN 7 for highly precise applications in both the aerospace and automobile industries.

When these are beyond our capabilities, we suggest the following alternative processes:

Module form milling for modules over 12, gear shaping for internal gears, and more complicated tooth profile CNC milling. In actual projects, we first check whether the parameters of the gears are compatible. If they are compatible, we quote the solution, if not, we suggest other processes and explain the advantages and disadvantages of each process.

Would you like to know whether your gear project is suitable for gear hobbing services? Please upload your gear parameters, like module and diameter, etc., and we will offer a free assessment, recommending the best machining process to ensure the smooth progress of your projects.

Review Of Practical Cases:How JS Precision Saved A US OEM From 12-Week Delays

In the gear manufacturing industry, sometimes delivery speed determines the success or failure of the project. Well, this case is a real example to explain how JS Precision utilized custom gear manufacturing services in order to help a US client who was facing a crisis.

Customer Crisis

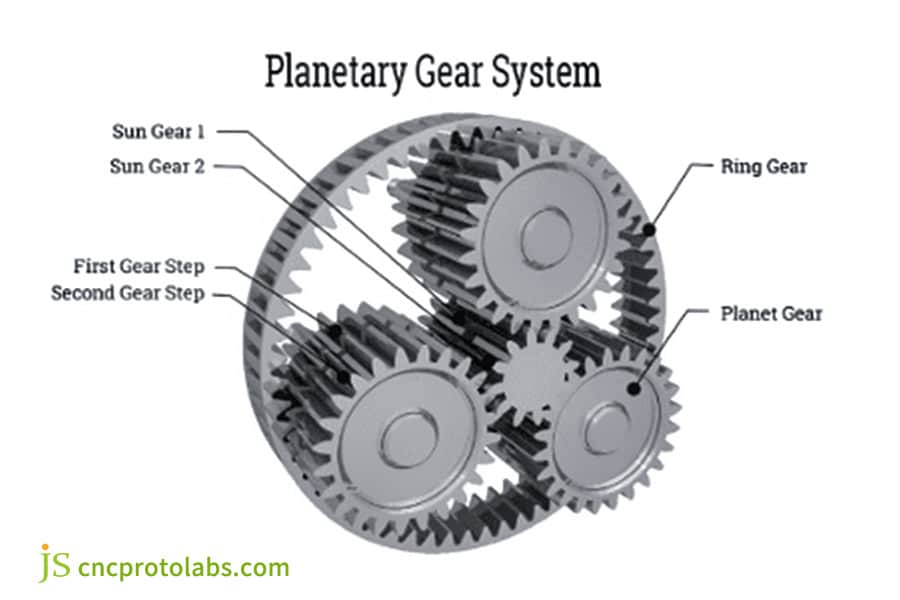

A US agricultural machinery OEM was confronted with a crisis in production: the critical planetary gear set required for its tractors, which a local supplier was supposed to deliver in 6 weeks, was delayed to 18 weeks (12 weeks later), due to capacity constraints. It would shut down the final assembly line in 3 weeks, and estimated total losses were over $2 million.

Also, the US-based alternative suppliers either quoted 50 percent higher prices or still needed 8-10 weeks for delivery, leaving the customer in a dilemma.

China-US Capability Comparison

The customer faced the crisis and, through industry recommendations, contacted JS Precision. Our first step was to compare our offer to the US-based alternatives:

- Delivery Time: While the fastest delivery by the US supplier was 8 weeks, we, after evaluation and comparison, promised delivery within 28 days (4 weeks).

- Price: the US supplier was quoting a price 50% higher than the original supplier's price, whereas our price was 15% less than the original and 35% less than the US alternatives.

- Quality: The US supplier was promising AGMA level 12 precision, whereas we could achieve AGMA level 13. Increased precision increases gear life and reduces related maintenance costs in the future.

- Besides, the MOQ requested from the US supplier was 500 pieces, while we supported production based on customers' actual needs, accordingly, only 300 pieces were produced to avoid inventory buildup. These comparisons gave the customer hope and led to their decision to cooperate with us.

Implementation and Outcomes

By working together, we launched an emergency response: the same-day allocation of 8620H steel to the AMS 2910 standard avoided material delays, gear hobbing and rapid nitriding processes ran parallel, reducing the cycle time by a week, every process was inspected by CMM and gear-measuring instruments to ensure accuracy to AGMA Level 13.

Eventually, 300 gears were produced and inspected within 28 days, airlifted, and delivered to the customer's US warehouse within 48 hours. Customer inspection showed that the gear parameters were comprehensively superior to the original specifications, assembly line operation was normal, and millions of dollars of losses were avoided.

Are you looking for custom gear manufacturing services that can solve the delivery crisis? Immediately call our emergency hotline to tell us your needs, and we will give you a solution within 24 hours to avoid the risk of line downtime.

Figure 3: planetary gear system

Why Should JS Precision Be Your Next gear manufacturing Partner?

As one of precision gear manufacturers, core advantages for JS Precision include "localized response speed + world-class precision manufacturing capabilities", making the company not only a machining workshop but also a gear engineering solution partner.

The precision of gear machining can be up to ±0.01mm. We support AGMA 8-16 and DIN 5-9 grades. There are many material options and surface treatment methods, and we have passed many international certifications and ITAR registration, ensuring high-quality products.

Our speed of response is comparable with local suppliers. US working hours are covered by a bilingual team, prototype delivery in as little as 1 day, and mass production in as little as 2 weeks. Projects labelled urgent receive 24-hour response, and progress is shared in real time on our online platform.

We also provide end-to-end services right from design to inspection, starting with DFM analysis for structure optimization during the design phase, SPC to control consistency in the production phase, and up to full-size reports during the inspection phase.

Whether you need prototype gear manufacturing or high volume gear production, we at JS Precision can tailor a gear manufacturing solution to fit your needs.

FAQs

Q1: How are we to ensure that gears sourced from China would be up to U.S. military or aerospace standard requirements?

Materials meeting the specifications of AMS and ASTM are used, and processes are according to NADCAP. Full-size inspection reports are delivered with material certifications, and a number of clients have added our company to their qualified supplier lists.

Q2: Will there be major communication and time zone problems?

No, we have a bilingual project team to provide communication channels covering your working hours and an online collaboration platform to guarantee transparent and traceable technical requirements and drawing iterations.

Q3: What is the minimum order quantity?

We support single-piece prototype gear manufacturing with no rigid MOQ, offering your R&D flexibility unmatched in the US.

Q4: How are quality issues resolved?

We guarantee "zero disputes" after-sales service. Once the problem is confirmed, we will take on all rework or reproduction costs, prioritize expedited processing, and provide an 8D analysis report.

Q5: Do you do gear matching and component assembly?

Yes, we can match small gears to your large gear data and also provide simple component assembly services, including pressure shafts and lubrication.

Q6: Does it include all the fees? What about international shipping and customs duties?

The price in the quotation is EXW. We can help you arrange door-to-door logistics, DDP terms, to give you the total CIF price and provide complete transparency in all shipping and customs duties.

Q7: What is the biggest surprise about working with Chinese suppliers?

Many clients have reported that, aside from cost savings, the greatest surprise is engineering responsiveness and proactive problem-solving on the part of JS Precision that has far exceeded any prior partner.

Q8: How to handle exchange rate fluctuation risks?

Usually, our quotations are settled in USD, which allows us to lock in the exchange rate for some time. In long-term cooperation, we would work out a more stable price mechanism with our customers to reduce the impact caused by the fluctuation of the exchange rate.

Conclusion

Partner selection in the globalized arena of precision manufacturing can no longer be constrained by geographical labels. True strategic choices are based on comprehensive judgments related to technological capabilities, cost structure, supply chain resilience, and the potential for value co-creation.

As one of reliable precision gear manufacturers to US customers, JS Precision has shown, in practice, that we are able to supply solutions that will meet your expectations-whether it be the cost advantages from high volume gear production or the agile response of custom gear manufacturing services.

It is time for you to rethink your supply chain strategy.

Experience a new generation of global gear manufacturing today! Please visit the JS Precision website to upload your gear drawings for a free and detailed feasibility analysis, transparent quote, and data-driven comparison of US and Chinese manufacturing for your project-all within 24 hours. Let us prove that the best choice often lies outside of conventional thinking.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com