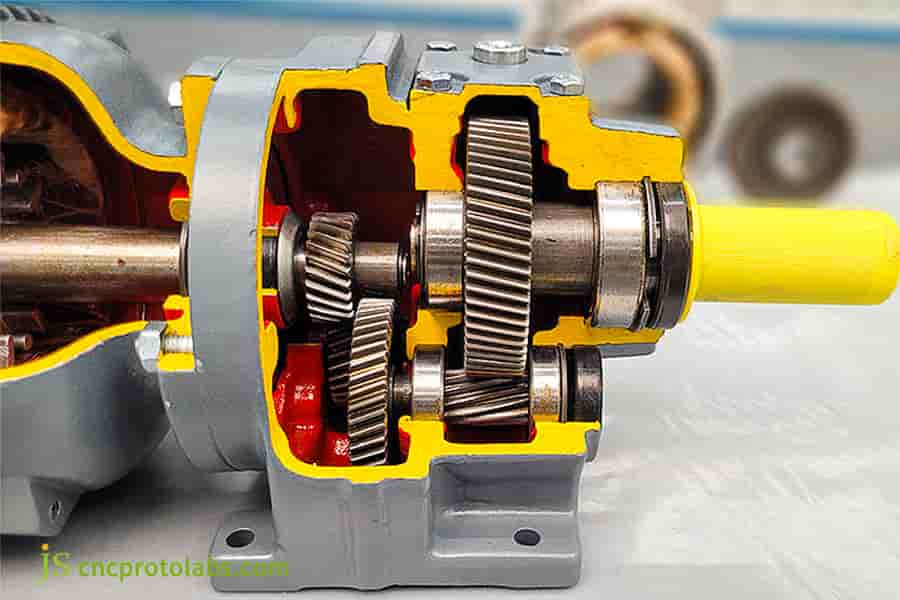

Manufacturing of gear is one of the cornerstones of modern industries, it is the precise functionality of autos, robots, and aircraft that depends on gear transmission. The key question is this: what guarantees that machines function accurately, economically, and reliably? The answer is embedded in well-meshed gears.

Gearing systems are the essence of power transmission, and the production of gears with high performance characteristics is impossible without the integration of different technologies in gearing machining.

This article will lead you through the entire process of gear production, deconstruct the key technologies involved in high precision gear manufacturing, and give you critical guidance on how to choose the best gear manufacturing company. Whether you need precision gear cutting services or high-volume gear production, this article will prove to be a valuable source of insight.

Core Answer Summary

| Core Topics | Key Takeaways | Value to You |

| Gear Manufacturing Fundamentals | The topic covers two main manufacturing processes, namely forming and cutting. The machining of gears has started to witness the advent of digitization and intelligence. The basic material used for gear manufacturing is alloy steel, as well as cast iron. | Understand the process boundary and material characteristics, and clarify the most suitable technical path for one's own product. |

| High Precision Achievement | This is dependent upon highly advanced equipment, processes, and testing. Precision may be as accurate as down to the micron. Key performance indicators are: Tooth Profile Error, DIN Grade. | Make sure that the supplier of your choice meets the highest demands regarding product performance. |

| CNC Hobbing Technology | The core of efficient and highly consistent production of modern gears. Benefits the high-volume gear production. | This is considered an essential parameter used to assess the prowess and technology of the manufacturer. |

| Service Provider Selection | Care must be taken in terms of technical knowhow, quality infrastructure, experience, and time of response. The primary focus should be on technical support and supply chain integrity. | Attempt to overcome procurement hurdles and look for service providers like JS Precision that can be considered strategic business partners. |

Key Takeaways

- Precision is key: True high precision gear manufacturing is defined by specific parameters (such as DIN grade and tooth profile error values). When selecting a supplier, empirical data must be requested.

- Technology is the foundation: High efficiency and high quality can only be established on the basis of advanced CNC gear hobbing techniques and other technologies.

- Scalability and customization are not contradictory: A great gear manufacturing company should be able to cope with the needs of both stable high-volume gear production and custom gear production.

- Choice is strategy: When selecting custom gear manufacturing suppliers , price is secondary in comparison to the partnership needed for engineering assistance and supply chain integrity.

Why Trust JS Precision For Gear Manufacturing?

Building trust with deep technical expertise, stringent quality control, and rich industry experience has made JS Precision one of the most reliable gear manufacturing company among global customers in the highly competitive field of manufacturing of gear.

Our core strengths emanate from our relentless pursuit of excellence in gear machining technology and our profound understanding of customer needs.

JS Precision owns a team of senior engineers with over 12 years of average industry experience, provides full-process engineering support from design optimization to delivery at mass production.

Equipped with more than 20 world-class CNC gear machining machines, with a repeatability accuracy as high as ±2μm, JS Precision will make sure of the realization of high precision gear manufacturing capability covering DIN 3-7 levels.

We company keeps authoritative certifications, including IATF 16949 and ISO 9001. Every batch should be comprehensively tested by equipment, including CMM coordinate measuring machines to ensure the traceability of data.

With more than 1000 successful cases in new energy, aviation, and other industries, we can create more than 5 million sets of high volume gear production annually, which shortened the delivery time for customized gears by 20% compared with the average of the industry.

Our clients include globally renowned new energy vehicle companies and robot manufacturers. A wind power customized gear project has achieved zero defect delivery for three consecutive years with a PPM value of ≤ 30.

If you are looking for custom gear manufacturing suppliers that combine technical expertise, quality assurance, and rapid response capabilities, JS Precision is your ideal choice. Contact our engineering team immediately and inform them of your gear parameters and requirements to receive free DFM manufacturability design analysis and accurate pricing.

How Are Gears Manufactured? ——Overview Of Basic Processes

Gear manufacturing is the production process of precision transformation from raw material to finished product. The understanding of the basic processes in gear manufacturing will help you choose better the technical solution suitable for your products.

Manufacturing of Gears: Raw Material to Finished Product

The essence of gear manufacturing is to process raw materials into gear products that meet the design requirements through a series of processes. In the center of all this is gear machining, which is mainly divided into two categories-the forming and cutting processes.

| Process Type | Representative Technology | Applicable Scenarios | Precision Level (DIN) | Processing Efficiency (pieces/hour) | Process Advantages | Applicable Gear Types |

| Forming Process | Forging, Stamping, Injection Molding | Simple tooth profile, low-volume production. | 8-10 grades | 50-200 | Low cost, fast forming, suitable for mass production of simple parts. | Spur gears, simple worm gears. |

| Cutting Process | Hobbing, Gear Shaping, Gear Grinding | Complex tooth profile, high precision requirements. | 3-7 grades | 10-80 | High precision, complex tooth profile, adaptable to various working conditions. | Spur gears, helical gears, bevel gears, and complex special gears. |

Key material choice has a direct relationship to gear performance because:

- Alloy steel (20CrMnTi, 42CrMo): Used in automobile and construction machinery.

- Cast iron: Used for low-speed, heavy-duty gears.

- Brass: Used for precision instruments.

- Engineering plastics (POM, PA): Home appliances and medical devices.

The entire manufacturing procedure includes blanking, heat treatment (upgrade of material properties), gear machining (process of core gear machining), Finishing (shaving & honing of gear), and Inspection (dimensional test, accuracy, & noise tests).

What is the current evolution of gear manufacturing technology?

With the development of industry technology, manufacturing of gear is undergoing an overall renovation from traditional to modern, with innovation in gear machining technology serving as the driving force:

- Digital Transformation: High precision machining of complex gear profiles is dominated by CNC.

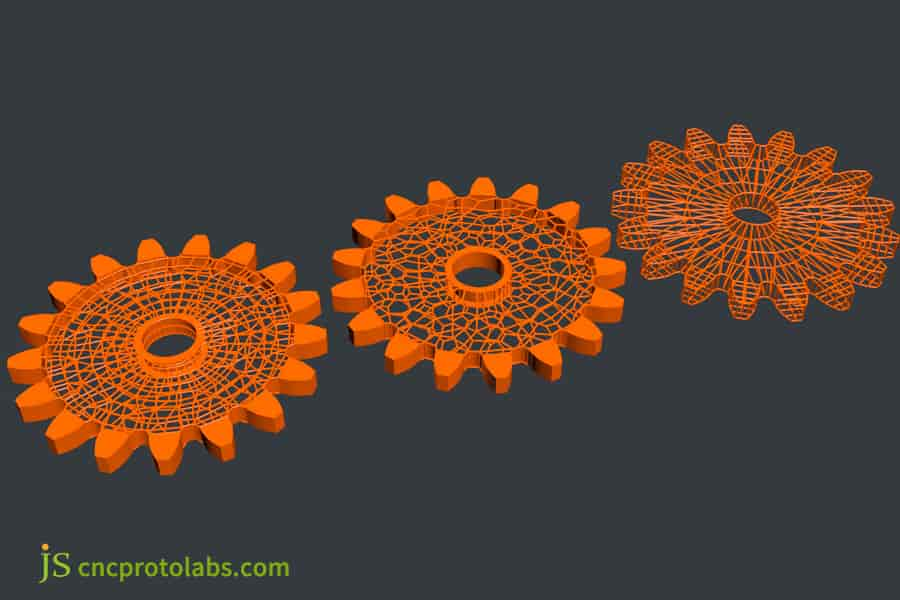

- Additive manufacturing: 3D printing reduces the time to prototype, the cost of customizations.

- Intelligent upgrade: Industry 4.0 facilitates the upgrade of intelligent manufacturing, and this results in the better stability of high-volume gear production through the use of Industry.

How To Define And Implement High Precision Gear Manufacturing?

High precision gear manufacturing is key to the performance of high-end equipment. It not only requires strict dimensional control but also extreme precision in multiple dimensions such as tooth profile and tooth direction.

What is "high precision"? More than just dimensional tolerances

| Precision Grade | Tooth Profile Error (μm) | Cumulative Tooth Pitch Error (μm) | Surface Roughness Ra (μm) | Hardened Layer Depth (mm) |

| Grade 12 (corresponding to DIN Grade 3) | ≤2 | ≤5 | ≤0.4 | 1.5-2.0 |

| Grade 10 (corresponding to DIN Grade 5) | ≤3.5 | ≤8 | ≤0.6 | 1.2-1.8 |

| Grade 8 (corresponding to DIN Grade 6) | ≤5 | ≤12 | ≤0.8 | 0.8-1.5 |

| Grade 6 (corresponding to DIN Grade 7) | ≤8 | ≤18 | ≤1.2 | 0.8-1.2 |

High precision gear manufacturing requires quantitative indicators to support: Tooth profile error should be within 3-5μm, AGMA & DIN standards shall be convertible, selection criteria should be indicated, and the hardness depth should correspond to usage.

How is High Precision Achieved? The Triangular Support of Technology, Equipment, and Process

Precision gear manufacturing involves the combination of three factors:

1. High end CNC machine tools: high rigidity equipment, repeat positioning accuracy < ± 3 μm.

2. Advanced cutting tools and compensation: Custom-coated cutting tools + real-time wear compensation.

3. Environmental control: Environment temperature in the workshops should be 20+/-2.

4. Complete inspection: Using CMM, gear meshing testers, and so on, 100% inspection for critical dimensions.

Should you need advanced support for high precision gear manufacturing, kindly contact JS Precision to ask for our sample data report for precision inspection, learn more about the data that we measure for DIN 3-6 grade gear manufacturing, and arrange for a visit to our precision machining shop to witness the manufacturing process at JS Precision.

Why Are CNC Gear Hobbing Techniques The Cornerstone Of Modern Gear Production?

As one of the essential methods of gear manufacturing, the CNC gear hobbing techniques, characterized by its efficiency, accuracy, and consistency, is considered the current mainstream technology of the gear manufacturing industry.

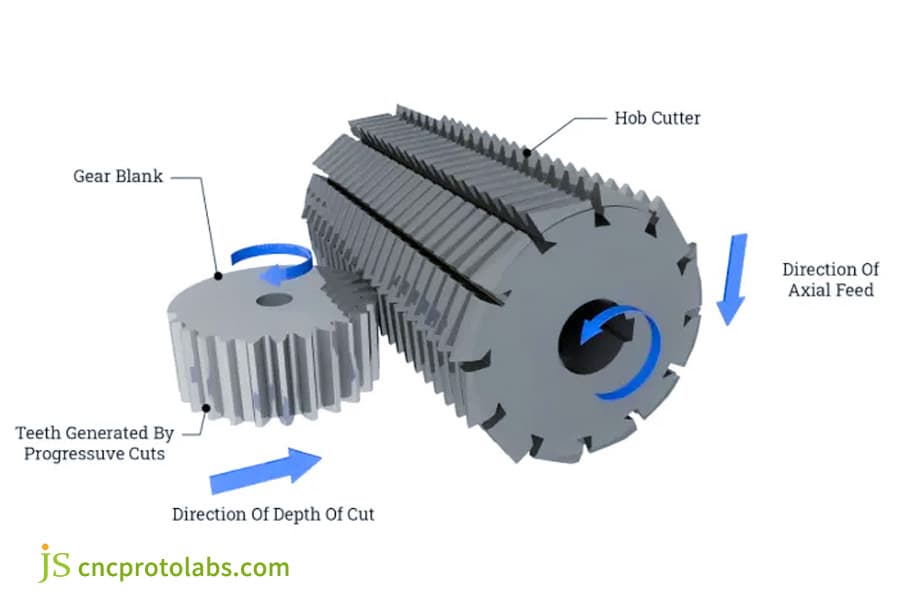

What exactly is CNC gear hobbing? The Art of Continuous Indexing

CNC gear hobbing techniques are the machining methods which involve continuous cutting of the tooth profiles through the helical meshing process of the hob and workpiece:

- Work Principle: The hob rotates and feeds, which simulates the meshing of a gear and a rack, cutting all the tooth profiles in one operation.

- Range of application: Spur gear teeth, Helical gear teeth, etc. Modulus 0.1-20mm, number of teeth 10-1000.

How Does CNC Gear Hobbing Improve Manufacturing Capabilities?

- Efficiency: Continuous cutting reduces machining time considerably, improving efficiency by 30-50% relative to gear shaping, which is beneficial in high-volume gear production.

- High Flexibility: Rapid model changeover on products via CNC programming, with little dependence on complex molds when dealing with small-medium batches customized production needs.

- High Consistency: The CNC system precisely controls cutting parameters, ensuring high uniformity in size and precision for each batch of gears, with a CPK value consistently above 1.67.

Why is it important in modern manufacturing?

CNC gear hobbing techniques play a crucial role in achieving the balance of efficiency and precision by:

- They are able to handle complicated gear designs and tight tolerances, which makes them a primary instrument in high precision gear manufacturing.

- They are easily integrated with automated production lines and thus ensure stable high-volume gear production.

- These can be further finished through other operations of shaving and honing, allowing them to reach DIN 3-7 grades of precision according to industry requirements.

Looking for efficient & precise gear machining solutions? JS Precision has 15 advanced CNC gear hobbing machines & advanced CNC gear hobbing techniques. We can meet your requirements whether it is production in sample quantities or in bulk. Send your gear details now & get free gear machining cycle costs.

What Does Precision Gear Cutting Services Include? How To Choose Suppliers?

Precision gear cutting services play an important role in gear production and include diverse processing methods. Selecting an appropriate service supplier will directly relate to quality.

Introduction to Precision Gear Cutting Services

Professional precision gear cutting services must ensure a one-stop solution.

- Core Machining: Full process machining like hobbing and gear shaping.

- Value-added Services: DFM optimization, heat treatment and other post-processing.

- Customization Support: Machining of non-standard gearsets for special operating conditions.

How to Select Your Precision Gear Cutting Service Provider?

While choosing the precision gear cutting services, attention should be paid to the following:

- Technical Capabilities: Check the equipment list & precision reports.

- Quality Certifications: IATF 16949, ISO 9001.

- Industry Experience: Similar products in the industry, and in the industry for which the product is intended.

- Production Capacity Stability: Evaluate high-volume gear production and secure supply chain strength.

Why are Professional Cutting Services Indispensable to the Industry?

Professional precision gear cutting services come with numerous advantages to the business:

- Less investment capital is needed because there is no requirement to invest in equipment that is quite costly or a professional team that would require a significant salary.

- Technical assistance: Availability of the best process technology and engineering assistance, thereby increasing product competitiveness.

- Flexible Response: Ability to adapt and respond to the changing amounts of orders being received for customization and mass production, respectively.

What Challenges Does High Volume Gear Production Face? How To Ensure Quality?

High-volume gear production requires strict quality control while ensuring efficiency, placing extremely high demands on the manufacturer's process, equipment, and management capabilities.

What are the characteristics of large-scale production?

Characteristics associated with high-volume gear production are these:

- Production of tens of thousands to millions of units per year, with optimal production cycle time.

- Optimizing unit cost and material utilization efficiency.

- Well-organized supply chain collaboration interfaces to enable smooth manufacturing and sales.

How to safeguard the quality lifeline in mass production?

JS Precision uses various quality control processes during high volume gear production:

- Full Process Inspection System: First piece, patrol, and last piece inspection systems, full automatic inspection of critical dimensions.

- Statistical Process Control (SPC): Real-time monitoring of the manufacturing process for detecting any fluctuations, thereby ensuring a value of CPK ≥ 1.67.

- Tool management: Development of the tool life database, application of predictive maintenance to prevent impact on quality due to tool wear.

- Standardized operations: Operating in line with SOPs means that processes are less affected by human factors.

What are the factors driving the growth of large-scale gear production?

The demand for high-volume gear production has surged in recent years, primarily driven by:

- Automotive electrification: Increased demand for gears in new energy vehicle reducers.

- Renewable energy: Expanded demand for wind turbine gearbox gears.

- Widespread automation: Rising demand for industrial robot gears.

Who Is The Ideal Custom Gear Manufacturing Partner? Selection Guide

Custom gear manufacturing suppliers are not only processing plants, but also strategic partners. A thorough analysis of several factors takes place while choosing these suppliers.

What core elements must be analyzed while searching for a custom supplier?

A supplier of high-quality custom gear manufacturing suppliers should have:

- Engineering support: DFM optimization and cost reduction suggestions.

- Quick response: Flexibility concerning design modifications and pressing demands.

- Transparent management: Sync of progress and quality status.

- Quality assurance: High precision gear manufacturing skills and recognized credentials.

How to Establish a Successful Long-Term Partnership with Gear Manufacturers?

A long-term relationship involves cooperation from both the sender and the receiver.

- Technical Agreements should be clearly defined, with the inclusion of factors like the level of accuracy, materials,

- Regular cooperation regarding improvement activities, optimize processes and costs.

- Emphasis on cost of ownership, rather than cost per unit.

Why Choosing the Right Manufacturing Partner is Key to Project Success?

Appropriate custom gear manufacturing suppliers can offer you:

- Decreased risks in R&D and avoided risks in production.

- Reduced R&D time and launch cycles.

- Assured supply chain security along with increased competitiveness.

JS Precision, as one of professional custom gear manufacturing suppliers, always puts customers first, providing full-process support from design to mass production. If you are looking for a long-term partner, feel free to communicate with our engineering team. We will provide you with a free project evaluation and use our professional capabilities to help your project succeed.

Case Study: How JS Precision Helps a New Energy Vehicle Company Achieve Zero Defect Delivery Of Reduction Gears

Customer Issues

A worldwide well-known new energy auto manufacturer was looking for a helical gear in its electric drive system.

Key needs included: manufacturing according to DIN Level 6 high precision gear standards, single-piece weight within ±0.5g, annual demand of more than 500,000 units, approved once via the PPAP production part approval process, single-piece cost controlled within below $12.

JS Precision Solutions

1.Collaborative Design: The JS Precision engineering team was deeply involved in the micro-profile design of gears. By optimizing the parameters of tooth profile and direction, this is highly effective in reducing meshing noise and therefore meeting customer NVH requirements.

2.Process Design: By applying advanced CNC gear hobbing techniques with custom TiAlN-coated tools, the project optimized the cutting parameters to reduce single-piece cut time by 15% and increase material utilization to 92%.

3.Mass Production and Quality Control: An SPC system was deployed for the high-volume gear production line, which can track in real time key dimensions including pitch and tooth profile errors, and CPK is consistently above 1.67, a fully automated inspection station is configured to achieve 100% meshing noise detection and weight screening.

Results

It achieved the project from sample to SOP only in 4 months, beating the customer's target by a month, within the first year of the start of mass production delivery, the customer's assembly defective parts per million (PPM) were below 50, meeting the criteria of zero defective delivery to the customer, the unit cost, kept under $11.2, enabling the customer to lower down the overall procurement expenditures by 8%.

If you have similar difficulties in high precision gear manufacturing or high-volume gear production, you should contact JS Precision and express your project requirements to us. We will offer you tailored solutions based on our successful experience so that your project becomes accomplished.

FAQs

Q1: What are the most commonly used materials for gears?

The most widely used are alloy steels like 20CrMnTi, 42CrMo, because they possess high strength and favorable heat treatment qualities. The other most common ones are cast irons, stainless steel, brass, and engineering plastics.

Q2: What is the difference between gear grinding and gear shaving?

Gear grinding allows for greater precision (up to DIN grade 3) and is employed for the purpose of precision gear manufacturing requirements after the heat treatment process. Gear shaving allows for slightly lower precision (DIN grade 6-7) but is more efficient and is employed for pre-heat treatment finishing.

Q3: What is the typical production cycle for small-batch custom gears?

This is because the time cycle of production varies depending on the level of accuracy needed as well as the complexity of gear production. An estimated time of 4-8 weeks is usually taken before samples can be handed to the client. JS Precision can offer a time cycle of 3-6 weeks.

Q4: How to judge the machining precision level of a gear manufacturer?

It is essential to ask for inspection reports regarding common products, examine the value of essential parameters such as the error of the tooth profile and the cumulative pitch error, and learn about the machine tool positioning accuracy, testing equipment, and certification status of the quality system.

Q5: How to control costs when mass-producing gears?

This can be accomplished by optimizing process parameters focusing on material use, using effective CNC gear hobbing processes, focusing on tool life management, and automation. JS Precision can assist customers in reducing costs associated with mass production by 10-15%.

Q6: Why is finishing necessary after gear heat treatment (such as carburizing and quenching)?

During heat treatment, deformation of the gear occurs, leading to size and precision errors. This deformation can be removed later in the manufacturing process through grinding and honing operations in order for high-precision gears to have high precision and smooth surface finishes of their teeth.

Q7: What key information must be included when providing gear drawings?

The module/pitch diameter pitch, number of teeth, pressure angle, helix angle, displacement coefficient, precision grade, material and heat treatment, critical dimensions, and surface treatment should be clearly defined. These parameters are directly related to the quality of manufacturing of gear.

Q8: As a Chinese gear manufacturing company, what are the core advantages of JS Precision?

JS Precision integrates European-level precision gear machining technology, a localized and efficient supply chain, and advantages in terms of costing, providing a one-stop service for precision gear cutting services from design support to mass production delivery. The company has strengths in difficult, precise, custom, and mass-produced orders.

Summary

Although small, gears bear the core of power transmission in modern industry. Preciseness and efficiency in manufacturing gears have directly ensured the performance and dependability of equipment. Choosing a gear manufacturing company that is matching in technological strength, quality assurance, and service awareness will be the key to success for your products.

Equipped with advanced CNC gear hobbing techniques, high-precision gear manufacturing standards, the flexibility to customize gear manufacturing, and mature high-volume gear production experience, JS Precision will surely provide premium quality products and excellent services for customers around the world.

If you are looking for professional precision gear cutting services or custom gear manufacturing suppliers, feel free to contact JS Precision's engineering team immediately to provide your requirements and drawings. We will provide you with free technical evaluations, DFM analysis, and accurate quotations to drive your next success with precision gears.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com