Custom gear machining is the backbone of the operation of state-of-the-art machinery and is essential in situations that require sub-millimeter accuracy in repetitive motion of robotic joints and the function of aircraft engines at speeds of tens of thousands of revolutions per minute.

These two fields have almost contradictory and demanding requirements for gear transmission: an extremely high power density, an extremely long service life, an extremely quiet operational level, and an absolute reliability in harsh environments. Those requirements are beyond conventional methods of industrial gear manufacturing.

This article will delve into how JS Precision can elevate CNC gear manufacturing to new heights through its innovative gear manufacturing process, providing core power for your innovative equipment.

Core Answer Table

| Industry Challenges | Core Manufacturing Difficulties | JS Precision's Solution |

| High Precision and Lightweight Robot Joints | Achieving high torque and zero backlash within a small space requires gears with extremely high tooth profile accuracy and an excellent stiffness-to-weight ratio. | Utilizing five-axis CNC gear manufacturing, combined with topology optimization design and special lightweight alloys, ultimate performance integration of joint gears is achieved. |

| Reliability in Extreme Aerospace Environments | Requires compliance with stringent certifications such as AS9100, withstanding extreme temperatures, vacuum, vibration, and shock. Material and process traceability is paramount. | Establishing a fully digital quality archive and applying specialized materials and ultra-precision gear manufacturing processes ensures absolute reliability and traceability for every gear from raw material to finished product. |

| Balancing Cost and Efficiency | High performance means high cost. Optimizing the gear machining process to reduce unit cost while maintaining quality is crucial. | This involves optimizing cutting parameters through process simulation to reduce scrap rates, integrating automated production lines to improve efficiency, and using value engineering analysis to help clients optimize designs and reduce costs. |

Key Findings

- Technical expertise has a direct influence on its performance ceiling: A true expert in custom gear machining must be proficient in the entire process chain from materials science to precision grinding.

- Process optimization is the secret to cost management, where the value addition of an optimal gear manufacturing process comes from minimizing waste and maximizing first-pass yield rather than just cutting costs.

- Certification and compliance are the ticket of entry for the aerospace industry: Choosing a supplier with a mature aerospace quality management system is a prerequisite for project success.

- Having flexible manufacturing capabilities is very important for reacting to market shifts. Your manufacturing capabilities for cnc gear manufacturing should be able to respond to orders for a few pieces of a variety of products to help you shorten the product development cycle.

JS Precision: Custom Gear Machining, Small Batch Rapid Delivery

JS Precision is a professional gear machining manufacturer with many years of experience in this domain. It strictly follows ISO 9001 quality standards. On the basis of this expertise and experience, it has become a model company for custom gear machining.

The core advantage of the company is represented by mastering the whole process chain, starting with material selection and gear design and finishing with precision machining, heat treatment, and testing. Each stage has strict standards and professional technical support.

On small-batch fast delivery, we have gradually reached the top of the industry in single-piece ordering and expedited delivery within 3-5 weeks. Once, we produced a custom articulated gear for a European robotics company with a precision of DIN 4 level. We delivered 20 samples in only 4 weeks, contributing to the client's R&D cycle shortening by 40%.

We have successfully provided customized gear solutions for hundreds of robotics, aerospace, and industrial equipment projects worldwide.

Our gears generally achieve DIN 5-6 precision, and key components can be improved to DIN 4 or higher after process optimization. In addition, with stable quality, efficient service, we have been a core strategic supplier for many high-end clients.

If you are looking for a reliable custom gear machining partner, feel free to contact us and tell us your product needs and lead times to receive a free customized solution and cost estimate.

How Does Custom Gear Machining Meet The Ultra-Precision Demands Of Robotic Joints?

The requirements for gear machining precision for robotic joints are extremely demanding. Custom gear machining is specially designed to take care of such requirements with innovative technology. Right from micron-level control to lightness, every aspect is of crucial importance as far as functioning is concerned.

Micron-Level Accuracy with No Backlash

Precision Tooth Profile and Direction Modification: Using precision grinding technology in CNC gear processing, JS Precision can carry out micron-level modification of the tooth and helical direction, thereby offsetting the deformation of the gears when under load, so as to achieve near-zero backlash in the transmission, thus being able to provide positioning accuracy and repeatability for the robot.

Error Chain from Multiple Setups Eradicated by Integrated Design: As gear bearing mounts, splines, and other related elements are machined simultaneously along with the gear profiles, any errors arising from multiple setup processes are eradicated. This forms a very important foundation block of gear machining at ultra-precision levels by custom gear machining.

Lightweight and High-Rigidity Materials and Processes

Use of Special Alloys: According to the materials selected, special alloys of lightweight aluminum, titanium alloys, or metal-based composite materials, the weight of the joints can be reduced, however, the rigidity and resistance to fatigue of the gears will be improved.

Structure Topology Optimization: Optimization for weight reduction is carried out through scientific weight reduction design for non-critical stress regions of the gear, whereby complicated light structures that cannot be produced through conventional processes are produced via five-axis custom gear machining.

Figure 1 Gears can regulate motion, balance torque, and provide the stability and accuracy required for robots to complete complex tasks.

Selecting The Optimal Heat Treatment In The Gear Manufacturing Process

Heat treatment in gear manufacturing process is a very important step in gear performance and life. Corresponding processes for different applications are needed. JS Precision has extensive experience in gear machining and provides precise heat treatment services for gears of different types.

| Heat Treatment Process | Applicable Scenarios | Core Advantages | Control Points |

| Carburizing & Quenching (Case Hardening) | Gears subjected to high contact stress (e.g., robot RV reducer gears). | High surface hardness, good core toughness. | Controlled atmosphere carburizing furnace and pressure quenching process, precisely controlling deformation and hardness gradient. |

| Induction Hardening (Induction Hardening) | Large module gears or gears requiring localized hardening. | Small heat-affected zone, controllable deformation. | Optimized induction coil design and process parameters to ensure uniform hardening. |

| Nitriding | Precision gears with extremely high dimensional accuracy and minimal deformation requirements (e.g., aerospace servo mechanism gears). | High surface hardness, good anti-galling properties, minimal deformation. | Strict control of nitriding temperature and time to ensure nitrided layer quality. |

Choosing the appropriate heat treatment process can significantly improve gear reliability and reduce the risk of later failures. Please tell us your gear's operating conditions and performance requirements, and our technical team will recommend the optimal heat treatment solution for your gear manufacturing process and provide free process verification advice.

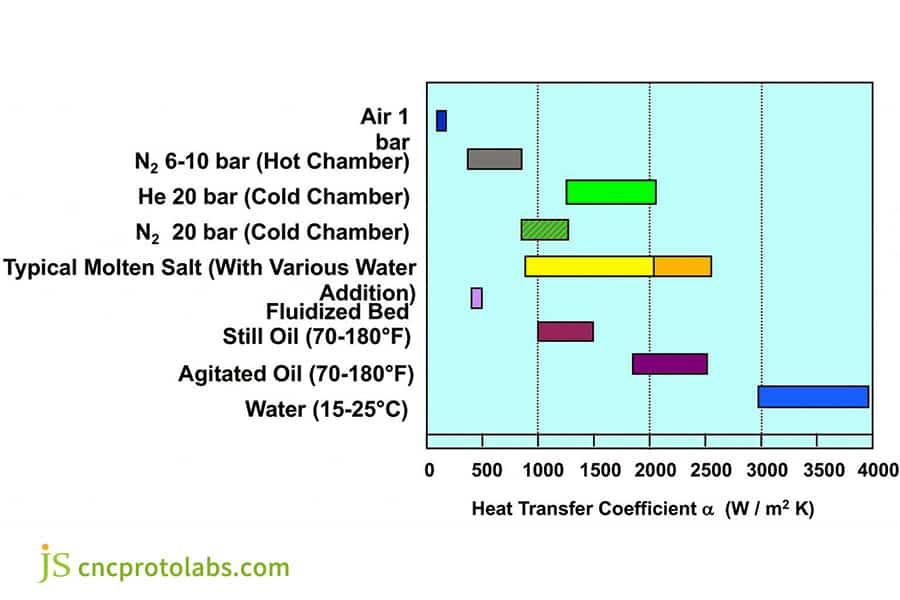

Figure 2 Heat transfer rates of common quench media.

The Special Standards For Custom Gear Machining In Aerospace

The requirements for custom gear machining in the aerospace industry are much higher than those in ordinary industries. The harsh environment and extremely high reliability requirements determine that gear manufacturing must follow special standards.

JS Precision has a complete system and professional skills, which can meet the custom machining requirement of the aerospace industry for manufacturing gears.

Full Implementation of the AS9100 Certification Process

AS9100 is more than just the name on the certification document, it is the quality process traced throughout the entire gear manufacturing process. Starting with the inspection of incoming material to the batch reports on shipment, the process is auditable and traceable to ensure every gea(r) r(g) produced is to aerospace specifications.

Special Material and Process Requirements

Only aerospace-approved grades of materials are allowed. All processes are proven and hardened, and any changes must go through a rigorous PPAP (Pre-production Approval Process). JS Precision provides separate production and management channels for aerospace production jobs in order to maintain professionalism and independence during production.

Extreme Environment Validation

Aerospace gear performance calls for certain environmental verification tests, including high-temperature and low-temperature tests, salt spray tests, and vibration tests. In our design of the gear machining process, the aim is to satisfy the extreme environment right from the start.

How An Optimized Gear Machining Process Lowers Total Cost?

Most companies are under the misconception that minimizing gear costs is achieved via a reduction in prices. In essence, optimizing a gear machining process is fundamental to minimizing a total cost. JS Precision helps customers significantly reduce overall costs through scientific process optimization without compromising quality.

Simulation-driven Process Optimization:

Before the gear machining, professional cutting simulating software is employed for simulating tool loads during the machining processes to minimize waste of materials as well as time during gear machining and optimize machinating parameters to maximize tool longevity.

Automatic and intelligent production lines:

By incorporating robotic automatic load and unload functions and online measurement and compensation, it helps to minimize human involvement, maximize equipment efficiency (OEE), and provide stability to batches of products, as well as decrease rework and customer service expenses related to quality.

How CNC Gear Manufacturing Enables Flexible Response To Low-Volume Orders?

Mini-batching, multi-variety orders are in increasing demand, whereas traditional industrial gear manufacturing is not able to react promptly.

As a result, CNC gear manufacturing, which has superior technological characteristics, has become an essential solution in meeting this requirement, thereby helping JS Precision in meeting the requirements of its customers pertaining to flexible orders.

Quick Changeover Technology

By using a zero-point positioning system, tool change and fixture change take only a few minutes. When combined with a modular tool pre-adjustment library, the time-consuming preparation for gear manufacturing takes relatively lesser time in the traditional process of industrial gear manufacturing. Hence, small order production becomes highly efficient.

Digital Process Library and Intelligent Scheduling

Parameters of the mature gear machining process are programmed and modularly stored. When similar orders come again, they can be immediately retrieved, optimized, and produced. According to intelligent scheduling, urgent or small orders will be opportunely incorporated without affecting the cycle of deliveries.

If you are experiencing difficulties with small batch deliveries and prices for small batch gear orders, let us assist you with our CNC gear manufacturing service. Please provide your order information and desired times for a fast response and low-cost customized manufacturing.

Precision Machining Of Large Gears In Industrial Gear Manufacturing

The machining of large gears, like the yaw gears used in wind turbines, has been a substantial challenge in industrial gear manufacturing.

The large size and the requirement for precision in manufacturing made it a challenge to the equipment and the process used in manufacturing. High precision in the manufacturing of large gears has been accomplished by JS Precision.

Precision Guarantee for Large Equipment: For producing large gears with diameters measuring several meters, it is essential that the geometry and stiffness of the machine tool be accurate. Currently, we are using floor-standing milling and boring machines and large CNC gear hobbing machines equipped with laser interferometers.

Segmented Machining & Assembly Process: For ultra-large-size gears, a high-precision segmented machining process combines with advanced on-site boring and bolting processes to ensure the final gear ring precision requirement.

In-Machine Measurement and On-Site Repair: Because big gears cannot be moved, a portable large gear measuring instrument is used for inspection on site. According to the data of on-site inspection, local fine repair or grinding would be done on the spot to make sure the precision of the gear reaches the requirements of standards.

Do you need large gear machining services of high precision? Please feel free to let our specialized industrial gear team know about your dimensions, your required precision level, and any application scenarios. We will immediately offer you an optimized solution for industrial gear manufacturing, together with a free technical assessment.

Figure 3 With advanced CNC machining and heat treatment capabilities, we produce large gears with excellent durability and performance.

Case Study: From 12 Weeks To 3 Weeks - How Zero Break In Gear Sets Accelerate The Development Of Humanoid Robots

Challenge

In the process of developing a new generation of humanoid robots, the core hip joint reducer of this robotics innovation company needed to be extremely demanding in performance. During transmission, the backlash should be constantly less than 1 arc minute. The time needed from design lock-in to getting a full-function and qualified prototype should not exceed 12 weeks.

The traditional supply chain has multiple rounds of trial production, independent processes, and on-site "run-in" debugging. In this condition, traditional supply chains face dual bottlenecks in terms of cycle time and performance. It is impossible to meet the requirements of the project schedule.

Solution:

JS Precision addresses customer pain points with a systematic engineering approach, providing a four-step key solution:

1. Material and Design Collaborative Optimization:

Participating in the project from the concept confirmation, recommending low-deformation carburized steel decreases tooth profile distortion after heat treatment by 30%, and fundamentally optimizes the design of the tooth profile edge, laying a foundation for further processing.

2. Integrated Process:

Innovatively use the five-axis milling and turning center to realize one-time clamping and integral forming of the planetary carrier and gear blank. It completely avoids datum errors caused by multiple clampings, improving the assembly accuracy of the gear set.

3. Precision Manufacturing and Inspection in a Closed Loop:

Implement a rigorous "machining-measurement-compensation" closed-loop process. Immediately perform a full tooth surface scan after precision grinding via a gear measurement center, with microscopic error data fed back in real time, while automatically correcting the subsequent machining parameters to guarantee that the accuracy of a tooth surface consistently reaches DIN 4 or higher.

4. Digital Selection and Pre-assembly:

According to the full inspection data, the gears are digitally simulated and matched. The gears are pre-assembled, lubricated, and short-run tested in a Class 10,000 cleanroom to verify the performance meets the standards, which can be delivered as "ready to use" and save on-site debugging time for customers.

Results

Ultimately, the gear set delivery cycle, which was foreseen by the customer to take 12 weeks, was reduced to 3 weeks, improving efficiency by 75%. The delivered gear set reached "zero break-in" operation, and transmission backlash consistently stayed within 0.8 arcminutes, fully meeting customer performance requirements.

The customer spoke highly of this collaboration, describing it as a "key pillar of R&D speed." JS Precision was then elevated to a strategic supplier for the company.

Wish to ensure efficient delivery and optimal performance for your gearing? Please upload your gearing designs as well as project requirements with a note “same service as case study,” so that we shall come up with a customer gear machining solution for fast project implementation for you.

Figure 4 Humanoid Robot Joint Reducer

FAQs

Q1: To what gear precision levels are you usually capable?

When it comes to high-end sectors like robotics and aerospace, our gear machining capabilities range between DIN 5-6. However, for critical components, through customized gear machining, precision may even touch DIN 4.

Q2: How can I select the appropriate heat treatment process for my application?

A careful selection of a method for heating treatment is a complex analysis involving the type of loading, rotational speed, and manufacturing materials. Our engineers will provide professional advice on carburizing, nitriding, or induction hardening based on your specific working conditions, matching the optimal gear manufacturing process.

Q3: What is the MOQ for small batch prototype gear orders? How much does it cost?

single-piece orders of small-batch prototype gears. Due to the flexible production capability of CNC gear manufacturing, though more expensive in unit price than mass production, it's much more economic and feasible when considering the whole cost and thus is well suitable in the product development and verification stage.

Q4: How is quality control conducted during machining?

Throughout the process of gear machining, we carry out IPQC quality control, with 100% inspection after the critical process. Prior to the final delivery, a full-dimensional inspection report will be issued by an professional gear measurement center to ensure quality requirements are reached for every batch of gears.

Q5: What is the average time it takes from receipt of drawings to prototype delivery?

The delivery time is 2-3 weeks for simple gear prototypes. It takes 3-5 weeks to process those gear sets with complex structures or high precision. Besides, urgent needs can be met by expedited service.

Q6: What are the aerospace certifications?

The AS 9100 quality system is strictly implemented, with the NADCAP process standards also met. We boast broad experience in accomplishing aerospace custom gear machining projects, thus satisfying all the special requirements of this particular industry.

Q7: Can you machine non-standard tooth profiles or gears with special structures?

Yes, our five-axis CNC equipment and advanced CAM software specialize in machining non-standard tooth profiles such as involute, cycloidal, and circular arcs, composite gear parts with cams and splines integrated, which can definitely meet diverse machining needs.

Q8: How smooth is the communication and the follow-up of the project while cooperating with Chinese suppliers?

We have professional bilingual project managers and professional PLM platforms to ensure real-time project dashboard management. This ensures efficient communication and information transparency. Time zone difference allows for "relay-style" progress tracking, guaranteeing smooth project follow-up throughout.

Summary

Custom gear manufacturing is always more than simple processing and manufacturing—a precise combination of technology, process, experience, and requirements.

Whether it's the precise joints of a robotic system, the highly demanding environments of aerospace, or the stable performance of industrial machinery, selecting a supplier with in-depth technical knowledge, experience, and efficient service can be a defining factor in making gears a huge advantage in performance.

JS Precision, with its profound accumulation in the high-end CNC gear manufacturing field, mature gear manufacturing process control system, and industrial gear manufacturing experience serving top global customers, is committed to providing full support for your innovative projects from concept to flight.

Let your next gear drive transformation happen.

Contact JS Precision team immediately to submit your gear design concept or drawings. What you will receive is not only a quotation, but also a preliminary feasibility analysis and value optimization proposal based on our rich application experience.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com