Mylar sheet is a high-performance engineering film applied in multiple fields: the silvery insulation blanket at the finish line of a marathon, the clear film protecting the delicate circuits of your electronics, the glittering letter balloons at a party - behind these seemingly unrelated scenes, there is the same "invisible hero":Mylar® (also known as the high-strength transparent plastic film).

In the eyes of our engineers, this material is more than just a high-grade plastic. It is thin but extremely strong and durable, has good natural insulation properties, and can firmly block gases and odors. These abilities make it extremely reliable, especially in harsh places. Strong, versatile, safe and stable are its core values.

Because of this, you will find mylar sheet everywhere: From life-saving space blankets and emergency blankets to colorful foil balloons and labels that remain clear after weathering equipment. In the industrial field, its sealing protection ability and chemical stability are even more critical, making it the material of choice for many applications.Understanding the true strength of mylar sheet is often the key to unlocking product design challenges.

Core Answer Summary:

| Core Features | Detailed explanation | Common applications |

| Excellent insulation performance | Extremely high dielectric strength, effectively blocking current. | Insulation for motors, capacitors, and circuit boards. |

| Excellent chemical inertness | Corrosion resistant and not easily reactive with chemicals. | Food packaging, chemical lining. |

| High tensile strength | Thin and tough, not easily torn or pierced. | Audio tapes, sailboat canvas, packaging film. |

| Gas barrier properties | Effectively block oxygen, moisture, and odors. | Long term food storage bags, coffee bags. |

| Dimensional stability | Maintain shape stability under different temperature and humidity conditions. | Drawing film, printing substrate. |

| Reflection and radiation obstruction | After aluminum plating, it can reflect up to 99% of radiant heat. | Emergency insulation blanket, greenhouse insulation material. |

This article will answer your questions:

- In this guide, we will take you through the core characteristics of polyester film.

- Explain the fundamental difference between it and ordinary plastics.

- Use a real example to see how it is used in daily packaging bags and precision circuit board insulation sheets at the same time, and you will understand its engineering value.

- Finally, we will answer your most frequently asked questions and talk about how it can work with our custom injection molding services in your actual scenarios.

Why Can You Trust This Guide On Mylar Sheet?

At JS Precision, it is a practical summary of our daily dealings with materials and molds.We not only know where to buy mylar sheets, but also have a deeper understanding of how to successfully apply mylar film sheets to various products.

Taking the medical equipment project as an example, when we were developing a casing for a well-known monitor manufacturer, we needed an insulation material that met medical standards and ensured sealing. After multiple tests, medical grade mylar sheet was ultimately selected as the key insulation layer, with a thickness of 10 mil perfectly balancing insulation performance and assembly requirements.

As I said, Mylar is far more than a cold material number on the purchase list. It is a "powerful assistant" that we often use when designing injection molding parts.

For example, we use it as the base for in-mold labeling (IML) to make truly durable patterns for customers. We also design housings for precision electronic equipment, and at the same time, they are equipped with specially die-cut polyester film insulation gaskets.

We know very well how thick it should be to meet the insulation requirements, or where to pay attention to static electricity issues.This type of experience has made us a technological leader among numerous plastic injection molding suppliers.

"Professor Colin Humphreys of Cambridge Materials Science has a very apt saying: If the material is chosen right, the product is halfway alive.This coincides with the requirements of the ASTM D2673 standard for polyester film material specifications."

Therefore, this guide is not a class note, but more like my work diary,recording the key points of our use of Mylar to solve practical problems. The tricks here have been verified by the products that are finally put into production.

Unveiling The Veil: What Is Mylar?

Mylar® is a resounding brand name, just like the "Jeep" in off-road vehicles. It is essentially a material called BoPET, the full name of which is biaxially oriented polyethylene terephthalate. The name is indeed a bit confusing, butthe key lies in the four words "biaxially oriented", which is the core of its power.

The magic of "biaxial stretching"

Imagine that we first melt polyester (PET) pellets and squeeze them into a thin sheet. At this time, its molecular structure is still relatively loose. Then, the thin sheet will be strongly stretched in the machine along the length (vertical) and width (transverse) directions.

Why is this step so critical?

This biaxial stretching is like straightening and arranging a bunch of chaotic molecular chains in both the vertical and horizontal directions. This highly ordered structure directly gives it three magic weapons thatfar exceed ordinary PET plastics:

- Super strong tensile strength: extremely tear-resistant and not easy to deform.

- Excellent clarity and gloss: The film produced is very transparent.

- Excellent dimensional stability: The dimensional change is very small under temperature and humidity changes, and it is particularly reliable.

Is Mylar® a plastic?

There is no doubt that Mylar® belongs to the polyester plastic family.Its basic chemical composition is somewhat similar to PET used to make beverage bottles.

But! It is the unique processing technology of "biaxial stretching" mentioned above that has made it a qualitative leap. Its strength, stability, barrier properties and other properties have made it completely out of the category of general plastics such as beverage bottles. In my opinion,it is more like a high-performance engineering material.The performance of ordinary PET bottle flakes and biaxially stretched BoPET sheet is very different:

Mylar® (BoPET) vs. ordinary PET bottle flakes key performance comparison

| Performance index | Mylar® (BoPET) sheet | Ordinary PET bottle flakes | Increase amplitude | Testing standards (reference) |

| Tensile strength (MPa) | 180 - 220 | 50 - 70 | ~3 times | ASTM D882 |

| Oxygen barrier properties (cc/m² · day) | 3 - 5 | 100 - 150 | >20 times | ASTM D3985 (23°C, 0%RH) |

| Dimensional stability (%) | <0.5(MD/TD) | 1.5 - 3.0 | >3 times | ASTM D1204 (150°C, 30min) |

| Puncture intensity (N) | 35 - 50 | 8 - 12 | ~4 times | ASTM F1306 |

| Continuous use temperature (°C) | -70 to +150 | -40 to +70 | Significant expansion | UL 746B |

Data source: Japan Polyester Film Association (JPFA) 2024, International Packaging Research Organization (IPRO) 2023, European Film Manufacturers Association (EFMA) 2024.

Mylar® (BoPET) uses a unique biaxial stretching process to maximize the potential of ordinary PET plastics, turning it into a "top student in plastic film" with high strength, good stability and strong barrier properties. Understanding its core means mastering the key to its wide application.

Looking for the most suitable film material for the product? Please let us know your application requirements immediately. As one of reliable injection molding manufacturers, we recommend the most suitable mylar sheet model for you and provide free samples.

Figure 1:Silver polyester film, with a smooth surface and metallic luster and reflective properties.

Mylar's Superpowers: What Can It Do?

Next, let me talk to you about some of the unique skills of polyester film (often called Mylar®) to see why it is so popular in so many places:

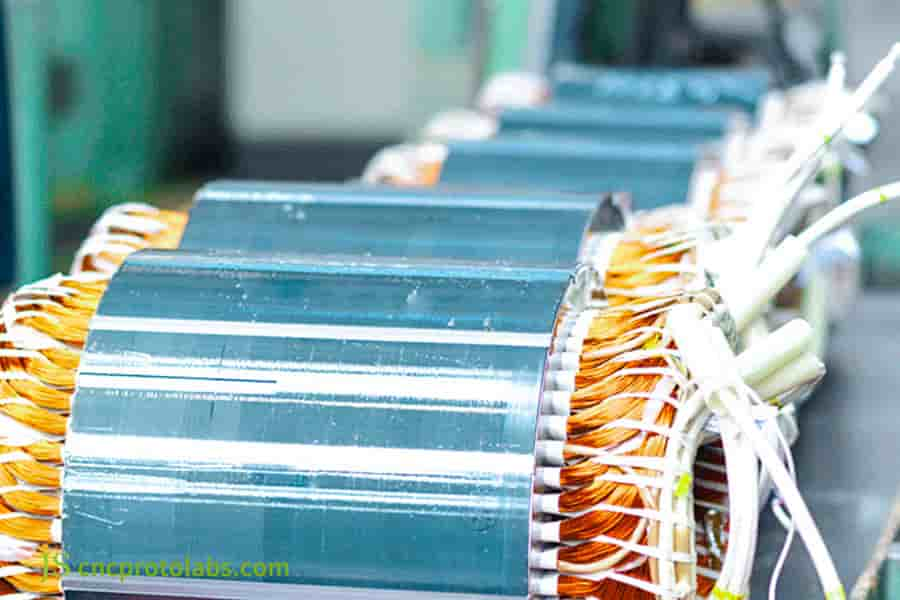

Electrical insulation

- This material has excellent insulation properties by nature, can withstand high voltages, and does not like to conduct electricity. This is its core value in the field of industrial electronics.

- We often use it as the insulation layer in the motor slot, wrapping wires and cables, as the dielectric of capacitors, and as the substrate and surface protective film of flexible circuit boards (FPC).It is often our first choice where reliable insulation is required.

Strengths in blocking gas and water vapor

- Polyester film is excellent in blocking gas (especially oxygen) and moisture. This feature makes it a good hand for preservation and protection.

- Those thick bags (Mylar bags) specially used for long-term storage of food (such as grains and coffee beans), coffee bags with one-way valves, the shiny layer inside potato chip bags (usually aluminized), and pharmaceutical packaging with high moisture-proof requirements, many of them are inseparable from it.

"Ruler" of strength and size

Thanks to the biaxial stretching process, it has high tensile strength, is not easy to tear or deform, and is particularly stable in size (little affected by temperature and humidity).

These characteristics make it capable of demanding applications. Think of old-school audio/video tape substrates, transparent film for engineers to draw, sails for high-performance sailboats, and even fine screen printing templates. It can hold up the scene.

A master of light and heat

- Transparent polyester film itself has good light transmittance. After it is coated with a layer of aluminum, it immediately transforms and becomes extremely reflective of light and thermal radiation.

- This feature is cleverly used in:insulation blankets (space blankets) for emergency rescue, materials for reflective fill light in greenhouses or indoor planting, those shiny letter balloons at parties, and of course the dazzling luster on food packaging that attracts attention.

Do you want to fully utilize the insulation or barrier properties of mylar film sheets? Submit your part information immediately to obtain exclusive integration solutions and cost analysis for plastic injection molding suppliers.

Figure 2:The practical scenario of using MYLAR bags and oxygen absorbers to seal and package food for long-term preservation and storage.

Practical Case Analysis: Gorgeous Packaging vs. Silent Guard

Whether the material is good or not depends on whether it can really solve the problem. The following case shows how Mylar sheet can be used in different scenarios.

Case 1: "Rainbow" outer box of high-end cosmetics

The customer's goal is very clear:the packaging box of the newly released high-end essence must be able to flash flowing rainbow light under the light! It must be dazzling, eye-catching, and high-end. At the same time, the surface of the box must be wear-resistant to protect the product and printed patterns inside.

JS Precision's solution: Composite laser mylar film sheets

We chose this solution for very practical reasons:

- Dynamic rainbow effect: The laser Mylar film we chose has precise embossing on the surface. When light is hit, it is not simply reflected, but the light is "scattered" through these fine structures, forming the flowing rainbow or laser light effect that customers want, with a visual impact far exceeding ordinary printing.

- Not just good-looking: We laminate the colorful film to cardboard (laminate). The polyester film itself is very wear-resistant, which adds a layer of "transparent armor" to the printed pattern, making the entire packaging box both shiny and durable, and able to withstand the test of transportation and shelf placement.

What is the result?

The finished product packaging is extremely eye-catching on the shelf, successfully helping the customer's new product stand out from the competition and win market attention.

Client Testimonial:

"The JS Precision team is very professional in handling mylar shearing rolls, and their composite solution not only achieves the visual effects we want, but also enhances the durability of the packaging. Their quick response and precise execution have brought our product to market one week earlier. "- Project Manager of a high-end cosmetics brand

Figure 3:Large roll MYLAR polyester film material for industrial use, with a semi transparent surface and a rainbow like luster.

Case 2: Insulation gasket for medical equipment power module

Customer demand:A medical equipment manufacturer needs to add an absolutely reliable insulation gasket in the compact power module (between the high-voltage PCB board and the metal shell) to prevent short circuits from causing safety accidents.

Extremely stringent requirements:

- Electrical safety is the lifeline: The insulation material must be able to withstand shocks far exceeding the working voltage and leave sufficient safety margin.

- Dimensional precision is the foundation:The gasket has a complex shape and must fit perfectly with the shell and internal PCB contour produced by custom injection molding manufacturers, with extremely small tolerances to eliminate any potential short circuit points.

- Long-term stability is a guarantee:The equipment may be used for several years in various temperature and humidity environments, and the insulation performance must be stable and cannot age and fail.

- Flame retardancy is the bottom line:must meet strict flame retardant safety standards for medical devices (such as UL 94).

JS Precision's core solution:

Custom punched polyester film insulation gaskets, matched with 5-axis CNC milling precision machined aluminum alloy shells.

Material selection:UL 94 VTM-2 certified polyester film optimized for electrical applications, with a thickness of 125µm selected based on electric field strength calculations.

Key performance parameters of medical insulation gaskets:

| Performance parameter | Customer's target requirements | Tested performance of mylar sheet | Technical significance |

| Thickness | Selected based on electric field calculation (in this case: 125 µm). | 125µm ± 3µm. | Accurate control of thickness is the physical basis for ensuring insulation strength. |

| Dielectric Strength | ≥ 3000 V/mil (118 V/µ m) (safety threshold). | 5500 V/mil (216 V/µ m) min (normal). | Core advantages! The measured strength far exceeds the safety threshold (>83% margin). |

| Volume Resistance | > 10^15 Ω·cm | > 10^16 Ω·cm (23°C, 50%RH). | Extremely high intrinsic insulation capability and minimal leakage current. |

| Flammability | UL 94 VTM-2 or equivalent. | UL 94 VTM-2 Certified. | Meet the mandatory safety requirements for flame retardancy in medical equipment. |

| Dimensional Stability | Heat shrinkage rate ≤ 1.0% (MD/TD @ 150 ° C, 30min). | < 0.5% (MD/TD) @ 150°C, 30min. | The size change is minimal at extreme temperatures. |

| Continuous Use Temp | -40 ° C to+105 ° C (equipment specifications). | -70°C to +150°C. | The material's tolerance range far exceeds the equipment requirements, and its lifecycle performance is stable. |

| Die Cutting Tolerance | Matching shell tolerance ±0.1mm (critical area ±0.05mm). | ± 0.05mm (critical contour). | High precision die-cutting and zero gap matching of injection molded shells and PCBs eliminate the risk of short circuits. |

| Chemical Inert | Tolerant to cleaning agents, sweat, etc. | Excellent (no known solvent dissolution, acid and alkali resistance). | Ensure that performance does not deteriorate under medical environment disinfection or accidental exposure. |

Why is polyester film the clear winner?

(1) Safety is the bottom line, and the margin is more than enough!

It has an ultra-high dielectric strength (5500+ V/mil), far exceeding the conventional requirements (3000 V/mil). This is not icing on the cake, but provides a solid "safety cushion" for high-voltage applications.

(2) Stable and reliable

The ultra-low shrinkage rate and wide temperature range ensure that it will hardly deform, shrink or degrade throughout the life cycle of the equipment. Consistently isolate danger.

(3) Precise and controllable

The extremely high die-cutting accuracy of ±0.05mm is the key!This allows it to achieve millimeter-level precision with custom injection molding housing structures, completely eliminating the risk of tiny gaps. This prevents fatal creepage or short circuits.

(4) Meet certification requirements

With UL certification, it directly meets the core access requirements and efficiently clears regulatory obstacles.

The final result:We deliver a complete solution of precision-matched injection molded housings and 100% reliable polyester insulation gaskets. This not only solves the needs of a single part, but also seamlessly integrates, ensuring the core safety of medical devices with ultra-high performance and compliance.

Client Testimonial:

"JS Precision has performed well in medical grade mylar sheet punching, and their insulation gaskets fully meet our strict specifications. The team's professional knowledge and ISO 9001 certification process give us confidence in quality. ”- R&D Director of a certain medical equipment company

Does your project also require high-precision medical grade mylar sheet components? Please note 'Case Reference', our team will provide you with detailed explanations and instant quotes of similar successful cases.

Figure 4:Industrial coil components use MYLAR as the insulation layer.

Why Choose JS Precision For Your Mylar And Plastic Part Projects?

In JS Precision, we focus on providing a one-stop solution in manufacturing, integrating precision mylar sheet punching with custom injection molding service, to enable our customers to realize seamless transitions right from design to finished products. Our unique selling proposition includes:

One-stop service: We combined the Mylar precision stamping capability and injection molding capability, for instance, you can have your custom mylar film sheets insulation and its corresponding plastic case under the same project to reduce the complexity of your supply chain and save time and cost.

20 years of experience: We have rich experience with over 20 years of precision manufacturing in serving a wide range of industries such as automotive, medical, and electronics. We successfully delivered more than 5,000 projects with a client satisfaction rate of over 95%.

ISO Certification: We possess the ISO 9001:2015 quality management system certificate, which guarantees, through international standards, that every process offers traceable quality.

Quick response: We are committed to providing quotations within 24 hours, completing productions within a week or two, and supporting prototype molding services and small-batch trials to help you iterate on your products quickly.

FAQ - Answer Your Last Question About Mylar

Is Mylar conductive?

- Pure Mylar itself is not conductive, it is an excellent insulator. Because of this property, it is very commonly used in our electronics field, such as protecting circuit boards.

- However, Mylar that has been aluminized (like the shiny silver layer in the potato chip bag) is different. The very thin aluminum film on its surface is conductive.

- So, the key is what kind of Mylar you have:Transparent or white is not conductive, and the shiny silver surface is conductive.Pay special attention to this.

What is the difference between Mylar and ordinary plastic?

Although they are both plastic, Mylar (essentially polyester film) has undergone a special stretching process, and its internal structure is more compact and orderly. This brings real advantages: in the case of the same thinness,Mylar is stronger and less likely to deform than common plastics(such as PET used to make beverage bottles), and it can better block air and moisture from penetrating.

Therefore, ordinary plastic bottles and bags are used more in places with low requirements, while Mylar is used in places where material performance requirements are more stringent, such as protecting precision electronic components or special packaging that requires long-term preservation.

Where can I buy Mylar?

Buying Mylar depends on specific needs. If you only need a small amount of sheets or rolls, you can find them in larger art supply stores, electronic parts stores, or large e-commerce platforms such as Amazon and McMaster-Carr.

But if you have special requirements for thickness, or need materials with specific performance levels (such as UL grade with flame retardant certification), especially if you need punching processing services like ours to make parts, thenyou have to contact professional manufacturers and material suppliers like JS Precision.

What is the use of Mylar in art?

Artists particularly like Mylar,mainly for the following reasons:

- It is particularly durable as a template: This material has high strength, can withstand many solvents, and can cut out ultra-fine edge lines. So it can be used repeatedly as a template (Stencil), which is particularly reliable.

- Unique visual effect: Whether it is transparent or the shiny aluminum-plated type, Mylar has a special luster and texture. Artists use it for painting, collage or installation art, and can play with cool light and shadow layers and reflection effects, and the works will immediately attract attention.

- First-class protection of works: From a professional perspective, high-quality Mylar has very stable chemical properties and is recognized as an archival preservation material. Covering paintings, prints or important documents with it can effectively isolate destructive factors such as light and moisture, allowing artworks to be preserved for a long time and stand the test of time.It is a material that combines practical functions and artistic expression quite well.

What is your typical lead time for custom die-cut Mylar parts?

Our typical delivery time is 1-2 weeks, depending on the complexity and quantity of the order. For urgent needs, we provide expedited services that can be completed within 5 working days at the earliest. We ensure high quality while meeting tight deadlines by optimizing production processes.

Do you offer material selection support and DFM (Design for Manufacturing) analysis?

Yes, we provide comprehensive material selection support and DFM analysis. Our engineering team will recommend suitable medical grade mylar sheets or other materials based on your application scenario (such as medical or industrial), and evaluate design manufacturability to help avoid potential issues and improve production efficiency.

How does JS Precision ensure the protection of our intellectual property (IP)?

We adopt strict IP protection measures, including signing confidentiality agreements, encrypted file storage, and restricted access control. All customer data is for project purposes only and will never be disclosed. Our ISO certification process ensures IP management compliance.

What is your minimum order quantity (MOQ) for prototyping and production?

For prototype production, we support a minimum order per piece for ease of testing and validation. For mass production, MOQ depends on materials and production methods, usually starting from 100 pieces. We are flexible in adjusting to meet your needs and offer volume discounts.

Summary

Mylar sheet is far more than just "shiny plastic". It is a true high-performance engineering film. Its value lies in our deep understanding of its unique physical and chemical properties - strength, stability, barrier properties, optical effects, etc., and its precise application to the most appropriate place. Whether it is to protect delicateelectronic componentsor to enhance the appearance, texture and functionality of your products, Mylar sheet is a powerful and versatile key material.

Want to create truly competitive products?The key lies in the clever integration of the advantages of different materials. In the JS Precision:

- Beyond single injection molding: We not only provide professional online injection molding services, but also master how to perfectly combine high-performance films such as Mylar sheet with injection molding processes.

- Material science-driven design: We are not just a manufacturer, but also your partner in product engineering and material application. We can help you choose the most suitable Mylar type and integrate it into the manufacturing solution.

- Transparency and efficiency: Contact us to get a tailor-made manufacturing plan and a clear and transparent injection molding price. Let you have clear control over the project from the beginning.

Are you ready to explore the innovative potential brought by material combinations?Contact JS Precision now and let us work together to create your next successful product!

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com

Resource