A gear that operates day and night in mining machinery, absorbing massive impact and wear. Another, a precision part used to replace damaged joints in the human body, must run smoothly without causing toxic side effects.

Both of these seemingly disparate applications have one fundamental question in common: how to choose an engineering plastic that is tough, durable, and affordable?

Choosing the right material is cost-effective, but choosing an incorrect material requires frequent maintenance. The versatility of plastic injection molding processes also becomes a challenge to most engineers.

By reading this guide, you will have a deeper understanding of the logic in choosing between ultra high molecular plastic (UHM) and nylon in terms of cost, performance, and process to enable more precise and cost-effective material selection.

Key Answer Summary

| Comparison Dimensions | Ultra-High Molecular Weight Polyethylene | Nylon |

| Material Family | Thermoplastic (Polyethylene Family) | Thermoplastics (Polyamide Family) |

| Core Characteristics | Extremely high wear resistance, extremely low coefficient of friction, strong impact resistance, chemical resistance. | High mechanical strength, excellent toughness and wear resistance, and good heat resistance. |

| Major Weaknesses | Low melting point, average heat resistance. | High hygroscopicity, dimensional stability affected by humidity. |

| Cost Drivers | High raw material costs, but extremely long service life significantly reduces overall costs. | While the raw material cost is moderate, rigorous drying is required before processing, increasing process costs. |

| Typical Applications | Mine liners, conveyor chains, artificial joints, body armor. | gears, bearings, automotive parts, power tool housings. |

| Processing Methods | Pressing and sintering, extrusion; injection molding is extremely challenging. | Injection molding, extrusion, and blow molding (very mature and versatile) |

Selecting The Most Cost-Effective Material? JS Precision Helps You Decide With Cost-Benefit Analysis

When auto parts engineers are struggling to choose between nylon and ultra high molecular plastic for gears, JS Precision with over 15 years of experience in custom plastic injection molding services has helped over 300 companies solve similar problems.

We have completed over 5,000 custom plastic injection molding orders, 60% of which included comparison of these two materials. These projects encompass a wide array of industries, ranging from warehousing and logistics, to automotive, as well as food machinery.

For example, a car engine plant used nylon for pipe fittings. During hot temperatures, the fittings became deformed in a matter of six months, resulting in monthly maintenance costs of $3,000.

We streamlined the plastic injection molding process and incorporated UHMW-PE (ultra high molecular weight plastic) bushings in the fittings, thus increasing the life of the component from one year to three years and reducing the maintenance cost by 40%.

This handbook is based on such actual project experiences, with real-life verification at all levels, from cost estimating to process optimization. Whether you are interested in initial investment or return on investment, this handbook is a guaranteed reference.

JS Precision employs cost models that are industry-tested and develops material solutions based on your custom plastic injection molding manufacturing needs so you will not fall into "low-cost traps." Call us today and receive a personalized cost calculation report and reduce costs from start to finish.

Busting Myths: Is Nylon An "Ultra High Molecular Plastic"?

Many people may wonder "is nylon plastic?" Nylon belongs to the polyamide family of engineering plastics, but it is completely different from "ultra-high molecular weight plastics".This is a classic classification confusion.

- Ultra high molecular weight plastic is the specific term for polymers, such as UHMW-PE, with molecular weights in the millions. It's a description of performance, not a specific chemical family.

- Nylon belongs to the "polyamide" family, its molecular weight is usually between 20000 and 50000, far from reaching the level of "ultra-high molecular weight".

They are two very different high-performance plastics with very different chemical structures.

Meeting Two "All-Round Players": A Close Examination Of Material Types

We now learn more about the respective material families of UHMP and nylon. Allowing us to learn about their differing performances and their respective application scenarios will allow us to more suitably match them to our needs.

The Large Nylon Family

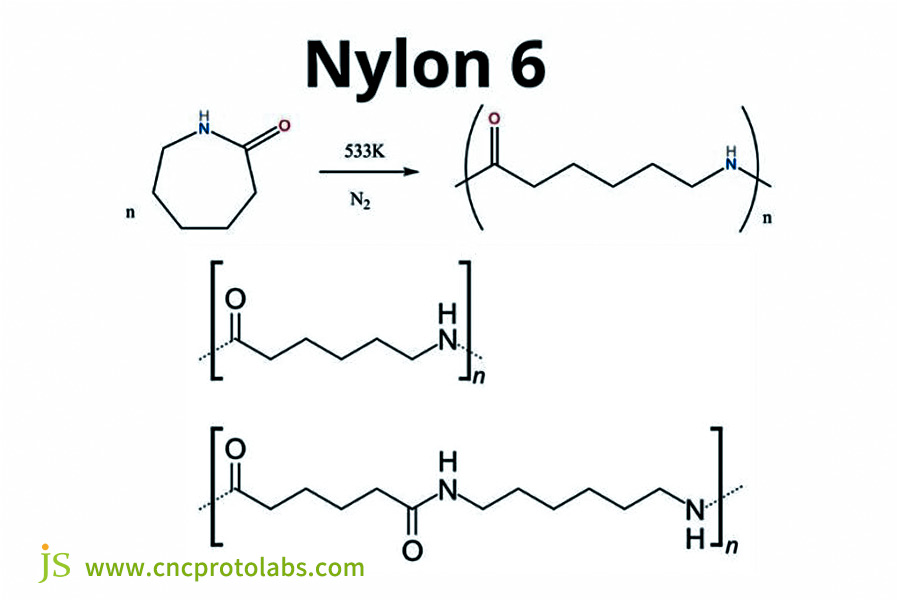

1. Nylon 6: Containing 6 carbon atoms in its monomer, it gives high toughness and fluidity in processing, commonly used for processing gears and bearings.

2. Nylon 66: With 6 carbon atoms in its monomer, it gives hexamethylenediamine and adipic acid. It is stronger and heat-resistant than nylon 6, and is therefore used in automotive engine peripheral components.

3. Nylon 12: With 12 carbon atoms per monomer, it has good low hygroscopicity and exceptional dimensional stability, and is widely used in precision parts.

Ultra High Molecular Weight Polyethylene (UHMW-PE), the "King of Plastics"

UHMW-PE is also known as the "King of Plastics" because of its extremely high molecular weight (typically greater than 1.5 million) and extremely long molecular chains, which give it extremely good wear and impact resistance. Its main forms are standard, antistatic, and flame-retardant, all for different applications.

JS Precision offers online plastic injection molding services, customizing various components to the specifications of various nylon grades and ultra high molecular plastics to enable the full potential of the material and meet your production needs.

Head-To-Head Comparison: The Essential Differences Between Ultra High Molecular Weight Polyethylene And Nylon

Since we now have a preliminary glimpse of the two, let us create a head-to-head comparison based on significant performance characteristics, depicting simply their plus and minus points, and how differences influence practical uses.

| Performance Indicators | Ultra-High Molecular Weight Polyethylene | Nylon (PA) |

| Abrasion Resistance | Top, 8 times that of carbon steel and over 5 times that of nylon. | Good, but significantly lower than UHMW-PE. |

| Coefficient of Friction | Extremely low (0.03-0.08), self-lubricating, lower than ice, suitable for oil-free lubrication. | Medium (0.15-0.3), requires lubrication. |

| Hygroscopicity | Almost non-absorbent (water absorption rate <0.01%), dimensionally stable. | Highly hygroscopic (nylon 6 water absorption rate approximately 3.5%), dimensional and performance changes after moisture absorption. |

| Heat Resistance | Poor, typically upper limit around 80°C, softens easily above 100°C. | Good, long-term operating temperature 80-120°C, reinforced nylon can be raised to 150°C. |

| Mechanical Strength and Rigidity | Low (tensile strength approximately 20-30 MPa), good toughness. | High (tensile strength approximately 60-90MPa), especially reinforced nylon, the rigidity can be increased by more than 50%. |

JS Precision can pick the appropriate material as per your performance requirements and provide you with explicit plastic injection molding price quotes so you understand the performance difference and get to see very clearly what cost implications are involved so you can confidently place your order.

The Truth About Value: A Deep Dive Into Cost Differences

Performance dictates application use, and cost is an important factor in the selection of products. Most individuals pay attention to only the upfront cost of the material and not the total cost. Let us explore this point further.

1. Upfront Material Cost: Ultra high molecular weight plastic (UHMW-PE) will be in the range of $15-20 per kilogram, whereas nylon is $8-12 per kilogram, the former being more expensive upfront.

2. Processing Cost: Nylon injection molding is well-established and affordable with plastic injection molding processing costs of approximately $5 per kilogram. Traditionally, UHMW-PE is difficult to process, at times making use of press sintering, which is less economical, with processing costs of approximately $8-10 per kilogram.

3. Total Lifecycle Cost: Launch of the "cost per operating hour" idea. For example, for a liner in a mining unit, a UHM-PE unit costs $200 per unit and has a lifespan of four years, a nylon unit costs $100 per unit and a lifespan of 0.5 years. This calculates to a cost per operating hour of UHM-PE at $0.11 and nylon at $0.55.

4. Concealed Cost: Nylon requires a drying process, which will cost an additional $200 per batch. UHMW-PE's enhanced chemical resistance will prevent equipment corrosion protection costs by about $1,000 a year.

JS Precision will guide you through extensive calculation of the overall cost of materials, processing, and maintenance, and, with custom plastic injection molding manufacturing service, decide on the most cost-effective option, avoiding concealed costs.

Third Option: When Neither Is Ideal

Sometimes no ultra high molecular plastic or nylon is the best thing for your product. In these cases, other engineering plastics need to be considered. Three common "alternatives" are our recommendation.

1. Polyoxymethylene (POM): Known as "Saigang", it has stable dimensions, high rigidity, and low friction coefficient, making it an excellent candidate for precision gears. However, its acid resistance and toughness are not as good as the first two.

2. Thermoplastic Polyurethane (TPU): It possesses good wear and tear resistance and high elasticity due to which it finds extensive use in soft rollers and screens. However, its compression set and heat resistance are poor.

3. Polyetheretherketone (PEEK): High-performance plastic used in industry with excellent heat resistance, chemical corrosion resistance, and mechanical strength. But at a price of dozens of times more than the first two materials, some $100-150 per kilogram, making it the ultimate choice.

Molding Process Selection: A Comparison Of Mainstream Processing Methods

After the suitable material has been selected, proper processing techniques are required in order to produce qualified parts. Nylon and ultra high molecular weight plastic (UHMWPE) are somewhat disparate in molding operations, so let us explore these in detail.

Nylon Applications

Nylon is typically processed with injection molding to make complex, precise size plastic injection molding parts, such as car pipe fittings.

However, critical drying is required to get quality and prevent silver streaks and embrittlement. Nylon is extremely hygroscopic, and if not dried, the final parts can be defective. When processing nylon, JS Precision dry pellets at 80-100°C for 4-6 hours to attain moisture content of less than 0.1%.

UHMW-PE Challenges and Mainstream Processes

Challenges: UHMW-PE is a bad dream for injection molding equipment with its extremely high melt viscosity, like a sticky rice ball, which makes it incapable of flowing and filling the mold well in normal injection molding.

Mainstream Processes:

1. Hot Compression Molding: This is the main method for manufacturing plates and bars, which involves placing UHMW-PE powder into an injection mold, heating and pressing it, and then cooling it to form.

2. Plunger Extrusion: This is used to produce profiles, such as rails, by extruding the material through a plunger.

Spark of Innovation: So far, UHMW-PE injection molding has been achieved to some extent through modification (reduction of molecular weight) or high-end injection molding machines but not yet in the mainstream.

Case Study: 6 Months To 4 Years! UHMW-PE Composite Solution Saves 70% Total Nylon Gear Costs

Theory alone is not sufficient. Let's consider an example of how ultra high molecular plastics can help customers remove issues as well as reduce total cost.

Customer Pain Point

A 5,000 units/month food packaging equipment factory, with excessive wear and noise in its conveyor system, was operating in a dusty and humid climate.

Within half a year, the reinforced nylon injection-molded gears in their conveyor system were experiencing excessive wear and noise, resulting in product positioning variation over 0.5mm. This needed two monthly stoppages to change the gears, costing each stoppage about $5,000.

Problem Analysis

JS Precision engineers conducted in-field studies and discovered that ambient humidity above 60% enhanced the hygroscopicity of the nylon, lowering the strength of the gears and enhancing wear. Moreover, dust entered the gear meshing space and acted as abrasives, further lowering gear life. The customer required urgently a more wear-resistant material that was humidity-proof.

JS Precision's Innovative Solution

As the gear consists of three meshing teeth and a center hole, its complex structure cannot be directly extruded from extruded UHMW-PE. We introduced a composite structure that combined its advantages and shunned its disadvantages:

1. Core wear-resistant area: A pre-molded UHMW-PE wear-resistant bushing (3mm thick) was used as the contact surface, which used its extremely low coefficient of friction and ultra high wear resistance.

2. Gear structure: PA12, a more water-resistant polymer, was precision-injected around the UHMW-PE bushing in a secondary injection molding operation at 180-200°C to produce a tough gear skeleton.

3. Detailed treatment: The PA12 was pre-dried for 5 hours before it was injected, and both the bushing and the PA12 interface was roughened to enhance adhesion.

Final Results

The lifespan of this composite gear increased to over four years, eight times greater than the initial nylon gear. Monthly downtime decreased from two to zero, preserving $120,000 of annual production loss.

While the cost of a single gear increased from $20 to $30 (a 50% increase), annual maintenance costs reduced from $24,000 to $7,200, reducing total costs by 70% and subsequent customer orders by 30%.

Green Choice: Recyclability And Sustainability

With sustainable development increasing in importance, the recycling and greenness of the material are increasingly crucial considerations for the selection of material. Let's find out how ultra high molecular plastic and nylon perform on these parameters.

1. Chemical Nature: Both are thermoplastics materials and theoretically recyclable.

2. Recycling Status: The recycling industry chain for nylon is rather mature with recycled material priced at about $5-8 per kilogram and appropriate for manufacturing components of low strengths. But due to its extremely specialized processing technology and relatively niche use, the recycling system and economic benefit of UHMW-PE remain underdeveloped.

3. Bio-based Trend: The bio-based nylon (e.g., PA410 from castor oil) has been picked up gradually with a 30% lower carbon footprint compared to traditional nylon. Bio-based UHMW-PE is still at the development stage in the labs.

Application Map: Where Do They Shine?

Now that we know about performance, cost, process, and environmental performance, let's find out the "main battlefields" of each and see where each one can best display its strengths.

Absolute Field of Ultra High Molecular Plastic (UHMW-PE)

Any "hardcore" application requiring extreme wear resistance, shock resistance, and low friction, such as:

- Conveyor line guides in computerized warehousing, with a life expectancy of over 5 years.

- Papermaking machinery dewatering plates, impact and corrosion resistant.

- Low friction skiing soles for sports equipment, for increased speed.

- Medical applications of artificial joints, good biocompatibility.

Wide Range of Nylon

Structural components requiring a good balance of mechanical strength, toughness, and heat resistance, such as:

- Automotive engine surrounding fans and pipe fittings, requiring temperature resistance equal to operating conditions.

- Mechanical manufacturing gears and bearings with a capacity to support some loads.

- Structural frames of consumer electronics where rigidity of high order to protect internal components is required.

Decision Guide: Find Your Mr. Right In Five Steps

Having read the above section, you might still be uncertain. Don't worry, we have distilled five main questions to enable you to quickly select the best material.

1. Is impact, wear, or friction your biggest issue? If so, highly prioritize ultra high molecular plastic, which is far superior in these categories.

2. Does the application require the part to withstand high rigidity or high structural loads? If so, nylon (especially the reinforced grades) is a better choice with higher support.

3. Will the service environment be humid or with chemical solvents? If so, handle nylon with care, UHMW-PE offers stronger chemical resistance and dimensional stability.

4. Will the service temperature consistently be over 80°C? If so, choose nylon or higher grades, UHMW-PE has very poor heat resistance.

5. Does your budget prioritize initial investment or long-term overall cost of ownership? If your budget prioritizes initial investment, choose nylon, if your budget prioritizes long-term cost, consider ultra high molecular plastic carefully.

JS Precision is available to provide one-on-one choice consulting on these five questions. With plastic injection molding prices and processing capabilities, we can help you quickly choose the right material and avoid selection errors.

FAQs

Q1: Which is harder, UHMW-PE or nylon?

Unfilled nylon is typically harder and stiffer than UHMW-PE. Nylon gears, for example, can withstand particular structural loads without deformation. UHMW-PE strength does not result from stiffness but from extremely high toughness. It withstands impact breakage and is thus well suited for impact-resistant cushioning components such as conveyor bumpers and mine cushioning pads.

Q2: Which of these is more wear-resistant, ultra high molecular weight polyethylene or nylon?

Beyond question, ultra high molecular weight polyethylene. It is possibly the most abrasion-resistant plastic in existence today, eight times as abrasion-resistant as carbon steel and over five times as high as nylon. For example, mining equipment wear linings from it could enjoy a predictable service life of four years, while nylon liners need to be replaced at eight months.

Q3: Why become my nylon parts brittle after use?

This is likely to happen because the nylon absorbs moisture from the air and is not properly dried during high-temperature processing, resulting in hydrolysis and degradation, which causes damage to the internal structure of the part. Nylon pellets need to be dried at 80-100°C for 4-6 hours before processing to obtain a moisture level of less than 0.1%. Otherwise, parts are prone to silver streaks and cracking.

Q4: Is ultra high molecular weight polyethylene readily dyeable?

It is very difficult. Because ultra high molecular weight polyethylene is very chemically inert and has very low surface energy, dyes do not adhere well. Despite being treated specially to color it, color fastness is poor and the material flakes readily. It is generally supplied in its own natural white or cream color. In the event of coloring, there are specialized modification alternatives that must be arranged with the producer in advance.

Summary

Choosing between ultra high molecular plastic (UHMW-PE) and nylon is not strictly a matter of price comparison, it's a complete analysis of performance, lifespan, and operating expense.

UHMW-PE offers long-term value with its phenomenal durability, whereas nylon is supreme in a wide range of applications with its balance of performance and proven process. Your choice begins with an intimate familiarity with your application.

JS Precision provides one-stop online plastic injection molding services, including material selection and cost estimation through to processing and manufacturing, and an open plastic injection molding price system. We help thousands of customers solve material problems and improve the competitiveness of products. Request a tailored selection report now!

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com