CNC milling services can represent a critical element of precision manufacturing.

When the success or failure of your project depends on supply chain selection, a wrong decision can lead to significant losses. Choosing the right CNC milling supplier for your critical project is a decisive step in ensuring ultimate success, whether it's urgent delivery of key components for drones within 72 hours, precision parts for medical equipment requiring extremely high tolerances of ± 0.005mm, or controlling costs while ensuring quality for large quantities of shell components.

With many CNC milling manufacturers available in the market, how would you be able to determine their actual capability and ensure that your CNC milling parts meet the required accuracy and performance?

This guide will examine the whole process from technical analysis to decision-making to see why a true solutions provider can be your trusted manufacturing extension.

Key Answer Summary

| Core consideration dimensions | Common Challenges Misconceptions | JS Precision's Professional Solutions |

| Technical Capability Evaluation | Concentrating exclusively on machine quantity, without consideration of process technology and engineering expertise. | Outfitted with advanced machine tools with 3 to 5-axis capability. Paired with best-possible processes to ensure successful production of complex parts on the very first try. |

| Precision and Quality Assurance | Confusing machine tool capability and specifications with actual machining prowess, and failure to consider overall quality control from start to finish. | With our CAM simulation and high rigidity precision CNC milling to Coordinate Measuring Machine inspection, we can assure predictable tolerances and traced quality. |

| Cost and Response Efficiency | Only compare the initial quotation, ignoring hidden costs and delay risks | We have a complete analysis of the CNC milling machine cost breakdown with a quick response link for urgent inquiries. |

| Depth of Collaboration Value | Treating suppliers as order executors and failing to utilize their engineering optimization potential. | Early involvement in DFM analysis, optimizing design to enhance manufacturability, reduce total costs, and provide overall value beyond processing. |

Key Takeaways

- Actual capability is found in process know-how, or experience in engineering, rather than simply looking at machines.

- Stable high precision is due to a methodical process involving hi-tech CAM, high-quality machine tools, and inspection.

- Optimization of total cost needs to take into account factors like production efficiency, quality, and supplier response.

- The best way to manage risks and CNC milling machine cost would be collaboration between design and manufacturing in the early stages.

How To Choose CNC Milling Services? Full Analysis Of JS Precision Practical Experience

As a company with 15 years of experience in CNC milling, JS Precision has served over 5000 clients across 12 core industries including aerospace, medical equipment, and consumer electronics.

Our service standards strictly follow the requirements of ISO 9001:2015 quality management system, which is an internationally recognized authoritative specification for manufacturing quality control.

Now, we have finished processing aerospace parts made of complex titanium alloy with a processing accuracy of ±0.008mm, and overcome difficulties in high-efficiency machining of aluminum alloy shells for a new energy automobile customer, shortening processing times by 30%.

All of these experiences have also allowed us to gain a profound comprehension of the requirements and pain points of each industry. This tutorial is the fruit of our knowledge accumulated over a thousand successful projects.

Everything mentioned here, be it technical evaluation or budget management, or timely delivery or long-term collaboration, can be proved in actual projects.If you are having trouble selecting the CNC milling services, then this guide, infused with prudent advice, is definitely to be trusted.

Are you looking for a quick match for your CNC milling services? Now, you can share the part and the technical specifications of the part, and the team at JS Precision will perform a free analysis and give you the required quote.

What Core Areas Should Be Focused On When Evaluating CNC Milling Services?

While evaluating or considering a partnership, equipment is essential, but the success factor is in the underlying system of technology. While you are considering CNC milling manufacturers, read the equipment specs in brochures, but go further than that into the depth of the technology.

True manifestation of technological depth: process engineering support capability

Process Engineering Capabilities: JS Precision’s engineers will be able to provide solutions for tooling, fixturing, and cutting conditions depending on the material and geometry of the part to be made.

We can provide machining conditions that will be optimized depending on the material to be machined, such as stainless steel, by varying the machining speed and feed rate using appropriately coated tools.

Multi-Axis Programming and Simulation Expertise: For complex parts, we use advanced CAM software such as Mastercam and HyperMill to perform collision free, efficient path planning and fully realistic simulation, in order to avoid machining risks in advance.

Systematic Support for Quality Culture

- Metrology and Testing Resources: Our company is equipped with testing equipment such as coordinate measuring machines and laser interferometers because we have a first piece through last piece inspection process that ensures the CNC milling parts will meet the required standards with respect to quality.

- Standardization and Documentation: The processes and procedures for inspection for quality are well specified and traceable. This is possible for mass production.

Conquering Complex Geometry: How Can Professional CNC Milling Services Handle Complex Multi Axis Machining?

Ranging from impellers to fully integrated housings, complex part production is where a supplier's skills are truly put to the test to turn high-end machines into actual end products. Expert CNC milling services are able to counteract machining difficulties in complex geometry parts.

A Precision Chain from Programming to Execution

1. Enhanced CAM Techniques and Optimized ToolPaths: Through methods like continuous five-axis connection and trochoidal milling, we maintain the smoothness of surfaces and ensure efficient removal of materials.

2. Fixtures for Irregular Workpieces & In-Machine Cues: We use dedicated fixtures for irregular workpieces and in-machine cues for workpiece location verification prior to machining, ensuring dimensions are correct.

Dealing with Material and Vibration Challenges

1. Special Processing for Difficult-to-Machine Materials: For difficulty-to-machine materials like titanium alloys and high-temperature alloys, we use high-pressure cooling and variable-speed cutting processes to control the cutting heat and cutting force, thereby preventing deformation of the material.

2. Dynamic Stability Control: We use axial depth-of-cut compensation and tool holders with vibration-damping properties to eliminate chatter while machining thin-walled components.

Figure 1 CNC milling machines can run on multiple axes, making it possible to machine parts with complex shapes and features.

What Tolerance Level Can Your CNC Milling Parts Typically Achieve?

Tolerances represent a kind of contract between design and manufacturing. To effectively design with a reasonable understanding, it’s a good idea to know these typical ranges of capabilities. Various CNC milling parts, along with precise CNC milling options, can differ considerably in terms of tolerance.

The ASME Y14.5-2009 standard, which is a publication of the American Society of Mechanical Engineers (ASME) and sets specific standards for mechanical part tolerances labeling and inspection tolerances, is abided by fully in our process for tolerance control.

Standard and Achievable Tolerance Range

| Machining Type | Material Used | Typical Range of Tolerance | Special Tolerance Feature |

| General Milling | Aluminum Alloy | ±0.025mm | ±0.0125mm |

| High-Precision Milling | Various Metals/Plastics | ±0.005mm | ±0.003mm |

Important Factors Influencing Final Tolerance Levels

- Properties of Materials and Heat Management: Deformation during cutting differs significantly from one type of material to another. The cutting tolerance of stainless steel is wider than that of aluminum alloy since stainless steel has high cutting friction and low heat dissipation.

- Feature Geometry and Tool Accessibility: It is harder to precisely control the inner walls of deep holes and cavities compared with the outer walls because the longer tool lengths make the tool more flexible and susceptible to vibrations.

Do you want to know if your part design can achieve high-precision machining? Upload your part drawings to JS Precision, and they will offer you a full plan of action regarding the application of tolerances related to the type of materials and structures used in CNC milling parts.

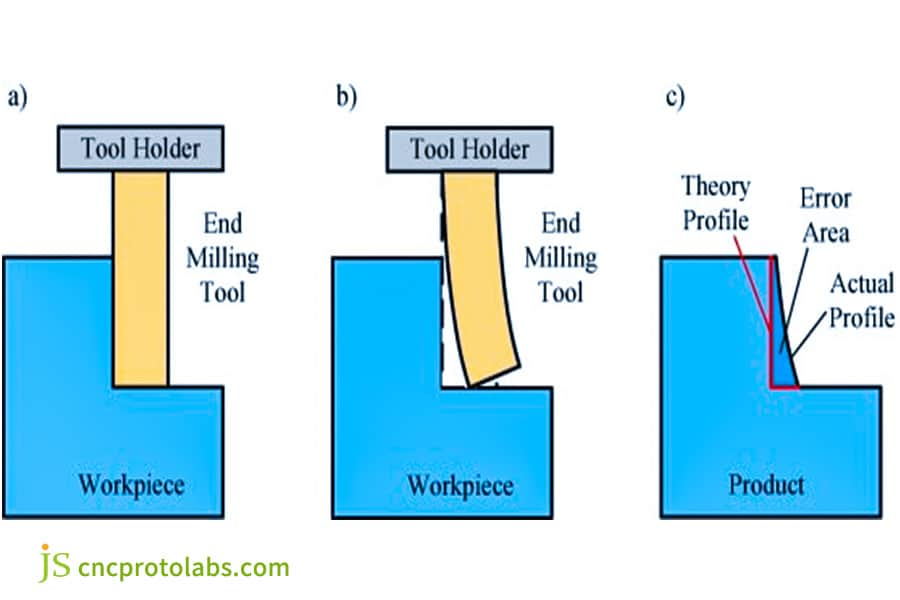

Figure 2 When the cutting force causes slight bending of the tool or workpiece, dimensional errors will occur.

What Are The Behind The Scenes Technologies For Achieving Reliable Precision CNC Milling?

Quality is not an accident but requires a number of deliberate technological interventions. Good precision CNC milling not only requires technological help but is also linked to the CNC milling machine cost.

The Core Role of Machine Tool Performance

- High Rigidity Structure and Thermal Stability: These are the physical bases for establishing precision stability. High rigidity machining reduces cutting vibrations, while heat stability prevents precision degradation with changes in temperature. This has relevance to the value that the machine may offer in the long term and the CNC milling machine cost.

- Advanced CNC and Feedback System: The highly dynamic response CNC system, linear motors, and fully closed-loop optical grating are combined in the "nervous system" which ensures contour accuracy in a quick response to programming commands.

Advanced Management of the Process Chain

- Full lifecycle of tool management: Right from choosing quality tools and performing dynamic balancing to tool wear monitoring, every process is meticulously regulated to make sure that the cutting process remains ever-optimal.

- Full-Process Digital Simulation: Verifying a full process, ranging from programming to machine motion and cutting forces in a virtual simulation environment, mitigating risks such as collisions and overcuts in a proactive manner.

Do you want to know how to obtain stable precision CNC milling services through technological optimization? We organize a technical demonstration by JS Precision. We will brief you on the actual application effect of our core technologies, as well as offer expert advice on cost saving and enhancement of efficiency.

Figure 3 Regularly maintain and upgrade cutting tools to ensure their sharpness and efficiency, and reduce errors caused by tool wear.

Racing Against Time: How Reliable CNC Milling Manufacturers Can Respond To Urgent Needs?

There is a constantly evolving marketplace, meaning the demand for rapid prototyping or production replenishment is a growing requirement. A supplier's flexibility is crucial to the sustainability of the supply chain, a good CNC milling manufacturers can promise delivery during a disaster.

Systematic rapid response mechanism to ensure emergency CNC machining needs

- Reserved Fast Track Capacity: Machine tool capacity and engineering windows are set aside specifically for small-batch high-priority orders, enabling fast tracking of high-priority orders.

- Standardized Processes and Materials Library: Off-the-shelf solutions for standardized materials and standardized processes reduce the time required for process preparation, as the processes for standardized materials no longer have to be designed.

Internal and External Collaboration Done Effectively

- Flat Project Communication: Assign an urgent order project manager who communicates directly with respective production and quality control units of the company and therefore requires fewer levels of decision making.

- Stable Supply Chain Network: Fast procurement networks and partnerships with suppliers for high-quality materials and tooling suppliers enable efficient delivery of materials and prevent production delays.

Behind The Quotation: How To Compare Proposals From Different CNC Milling Manufacturers?

An expert quote encompasses an overall vision of technical expertise and business integrity. Mastering quote analysis is essential for making well-informed decisions within various CNC milling manufacturers and discovering the most cost-effective CNC milling services.

Understanding In-Depth Information Presented in Quotes

- Cost Breakdowns: Clear breakdown of materials, programming, processing, post-processing, and management fees reflects the standardized operating model of suppliers and allows you to clearly understand the direction of each expense.

- Detailed Process Descriptions: It directly relates to the supplier’s level of technological excellence whether a quotation describes well machine strategies, clamping techniques, and inspection techniques.

Value Assessment Beyond Numbers

- Risk Control Commitment: A factor that is indicative of a supplier’s optimism about its capabilities is its level of commitment to risk control, as expressed by its promises or guarantees of success rates and on-time delivery.

- Added Service Value: Free DFM analysis, progress updates, and technical support are all key elements of the value of a CNC milling service.

Comparing quotes from multiple CNC milling manufacturers? After obtaining competitive quotations, JS Precision's cost analysis team can provide you with free interpretation services to help you identify hidden values and potential risks in the quotation.

Case Study: 72 Hour Extreme Delivery: How JS Precision Saves Key R&D Nodes Through 5-Axis CNC Milling

Within the CNC milling services sector, emergency delivery capability is an essential criterion to measure the competitiveness of each supplier. JS Precision, with the aid of professional technology and prompt feedback, successfully achieved the 72-hour limitless delivery mission, thus protecting an important R&D milestone for one of its clients.

Crisis: Damage to Critical Test Component, Project on Brink of Weeks of Delay

One of the drone clients inadvertently damaged a metal insert for the basic carbon fiber composite airframe mold before the final flight test. This metal insert had a complex geometry with irregular curved surfaces and precision position holes that included many deep holes.

Originally, the time for this manufacturing process was two weeks. However, the testing opportunity was only three days, otherwise the project would be delayed for several weeks.

JS Precision's Rapid Response and Precise Execution

After receipt of the client's order, JS Precision initiated its alert response. The production and programming team was able to secure the CAD data from the client within two hours. The team was also able to optimize routes using a standardized procedure and verify the entire production process.

We entrusted the job to our five-axis precision CNC milling center with high performance, setting up shifts to keep the machine tools running continuously, meaning the machine tools would operate 24/7.

The quality control department was responsible for conducting sampling checks after each key process to ensure that the precision machining accuracy was attained.

Results: Not only on time, but exceeding expectations

The time taken for JS Precision to accomplish the task from receiving the data to delivering the precision CNC milling parts was 72 hours, which perfectly matched the testing time frame of the client. The inserts supplied to them were in accordance with their dimensional and geometric tolerances, and their flight testing of carbon fiber components was also a success.

Need urgent CNC milling service support? Let JS Precision develop an exclusive delivery plan for your project and use our professional experience to ensure the smooth progress of your project. Please submit your urgent request.

Figure 4 Customized metal mold for drone body

Why Should JS Precision Be Your First Choice For Your Next CNC Milling Parts Project?

We not only provide milling, but also manufacturing solutions based on deep engineering understanding, ensuring that every project you undertake becomes a reliable success story. In CNC milling parts and CNC milling service, JS Precision's prime strengths reside within its overall commitments to technology, quality, and services.

Highly Integrated Technology & Engineering

- Application-Oriented Team of Process Experts: Engineers at JS Precision have application-oriented know-how in Aerospace, Medical, and other fields, making it possible for us to aptly understand your application requirements and offer expert advice right from the design phase.

- Continuously Invested Advanced Manufacturing Ecosystem: Our machining cell ranges from high-speed milling and five-axis machining to composite machining and is developed to address the most intricate challenges in manufacturing based on different requirements of precision and capacity.

Customer-Centric Quality and Delivery Culture

- Zero Defect Oriented quality loop: We consider quality our lifeline at our organization. Our strong control at each level, whether at the material stage, at the processing level, or at the finished product level, ensures zero defect supply of our CNC milling parts.

- Project-Based Full-Lifecycle Management: From the point of inquiry to completion, your assigned account manager will follow through on every stage of the process to ensure proper information flow, controllable progression, and adequate results.

FAQs

Q1. What is the difference between CNC milling and turning?

The machining process in CNC milling entails the cutter revolving for cutting, with the object stationary, ideal for machining cuboid and shell-shaped parts. The machining process in CNC turning entails the object turning for cutting, with the cutter moving, ideal for machining shafts and disc-shaped parts.

Q2: What is the range of surface roughness that can be expected?

The surface roughness of the conventional finishing process is normally limited to Ra 0.8μm. By optimization of high speed milling and other processes, some components are able to achieve a surface finish of Ra 0.4μm or better.

Q3: Are there significant differences in unit prices for single-piece prototypes and mass production?

The difference of unit price is substantial. To mass produce is to spread one-off costs such as programming and clamping preparation. With increased production volume, processing costs are substantially reduced per unit.

Q4: What are the differences in processing costs and times for aluminum, steel, and plastic materials?

Steel has a more difficult cutting process compared to aluminum, thus requiring lower speeds of cutting. Steel also has higher tool wear rates, thus higher costs of processing. Plastic has a tendency of being easily deformed. Special processing parameters are required. The cost of processing depends on the type of material.

Q5: How can I ensure the security of my intellectual property?

In our company, we shall make a legal and binding Non-Disclosure Agreement contract with our clients. Moreover, our company uses encrypted file transfer. This ensures the confidentiality of the design information of our clients.This commitment is part of our ISO 9001 certification management system.

Q6: What is the procedure when the design is altered?

Please provide the updated complete drawings and we can reassess your Design Flow Assessment and cost quotation based on complete drawings and revert to you regarding changes to our delivery schedule and quotation.

Q7: On what do I have to focus while marking the tolerances on drawings?

International standards such as ISO should be followed regarding marking of tolerance, specification of datum surfaces and datum axes, and specification of tolerance requirements of critical and secondary features. This is also essential for optimizing process cost.Clear drawing annotations help us provide accurate quotations and DFM analysis more quickly.

Q8: Are you able to provide assistance with assembly verification?

We can offer machining services to adjacent mating components, including testing the compatibility of the assembly in order to facilitate a smooth process when assembling.

Summary

The core of choosing CNC milling services is never simply comparing equipment or prices, but finding the best balance between technology, quality, efficiency, and cost.

A manufacturing collaborator with advanced technology, quality, and agility is a priceless business asset. JS Precision, with the diligence of our engineers and the honesty of our collaborators, is dedicated to turning each design idea of yours into a precise truth, a truth that leads to the success of the product.

Start efficient and reliable collaboration now:

→【Upload Drawings, Get Exact Solutions】Upload your 3D files for a precise quote analysis in 24 hours, which includes DFM analysis, analysis of CNC milling machine cost, and shipping time.

→ 【Schedule a Technical Meeting】 To address complicated projects, engage in direct talks on the most appropriate technical solutions and partnership strategy with our application engineers.Share your processing difficulties and win free DFM analysis.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com