CNC milling services will be a core demand when OEM engineers and purchasing managers outsource complex structural parts.

You can imagine this: urgently needing to produce a batch of precision parts in the launch of new products, the surface quality of the selected supplier is so bad that modification after modification drags on.

The machining capability is not sufficient for complex features, resulting in a high scrap rate, delivery delays disrupt the whole project schedule. Tedious communication wastes a lot of energy, which will influence the comprehensive performance of the product and also the progress of the project at the same time.

This guide is designed to respond to such pains. It elaborates on the basics of the CNC milling processes in great detail and covers practical experience in selecting suppliers, processing materials, and controlling cost for the successful outsourcing of precision CNC milling parts.

Figure 1 CNC milling is controlled by a computer for cutting

Why JS Precision's CNC Milling Guide Is Trustworthy

JS Precision has over 15 years of experience in the field of CNC milling, having completed projects for more than 2,000 customers across various industries such as automotive, aerospace, medical, and consumer electronics.

It has done more than 5,000 precision machining projects down to stringent tolerances of ±0.005mm for aero-engine components and complex parts like the highly biocompatibility required medical device housings.

Our team is staffed with more than 30 professional engineers who have vast experience in material performance, multi-axis machining technology, and DFM optimization. Besides, we employ more than 50 advanced machines, including 20 five-axis CNC milling machines, to guarantee the stability and efficiency of production.

This guide summarizes years of practical experience and professional knowledge, every suggestion and method has been validated in real-world projects.

The internationally accepted ABCM, in COB09-1220, highlights that a proper utilization of design tools, like DFMA, would be able to greatly minimize the cost of CNC machining without compromising its quality. We are in precise alignment with that approach, considering process optimization principles pointed out by our guide.

If you are interested in having a quick check on the applicability of our guide's methods to your project, then just in moments, with your initial project requirements, you will get an absolutely free one-to-one process adaptation assessment service from our pool of expertise.

What Are The 8 Key Processes Included In a Top-Notch CNC Milling Service?

The best CNC milling service is not a straightforward and one-step process, instead, it is a complete quality assurance system. At JS Precision, the following 8 key processes are included in our CNC milling services:

1. In-depth DFM analysis -> 2. Intelligent CAM programming -> 3. Precision fixture design -> 4. High-quality material selection -> 5. Multi-axis machining operation -> 6. Intermediate quality inspection -> 7. Surface treatment (if required) -> 8. Final inspection and report issuance.

Each process has its own important role: DFM analysis lays the foundation for cost reduction and efficiency improvement, while multi-axis machining ensures the precision of complex parts. Ultimately, all these processes work together toward the quality, delivery time, and performance of the finished product.Mastering standardized CNC milling processes is an important basis for selecting high-quality suppliers.

Interested in how these processes apply to your parts? Send us your part drawings and specifications, and we will send you a free process diagnostic report to help solidify the key elements of your project's CNC milling processes.

How To Optimize Milling Part Design From The Source Through Deep DFM Analysis?

DFM analysis is a free core value-added service offered by JS Precision and is a crucial step in optimizing milled part design. It has been demonstrated through extensive practice that high-quality DFM analysis can reduce more than 80% of machining risks beforehand.

Our DFM analysis focuses on three core aspects to create value for clients:

- First, part structure optimization, for instance, a proposal should be presented on replacing sharp corners with rounded corners to enhance part strength and prevent stress concentration during machining.We also recommend modifying excessively thin wall thicknesses, which are generally not less than 1mm for metal parts, in order to avoid distortion during machining.

- Secondly, we assist clients in choosing appropriate datum points. Suitable datum selection improves machining accuracy and reduces cumulative errors.

- Finally, DFM analysis enables the optimization of machining paths: some operations are removed because they are useless. It saves machining time and cost.

What Scenarios Are Three-Axis, Four Axis, And Five Axis Linked Milling Suitable For?

Different types of CNC milling machines have different characteristics and applicable scenarios. The following table summarizes some of the main differences:

| Axis Type | Characteristics | Accuracy | Efficiency | Applicable Part Types |

| Three Axis Milling | Simple structure, easy to operate | ±0.01 - ±0.03mm | Simple workpieces with high processing efficiency. | Simple plates, blocks, and shafts without complex surfaces. |

| Four Axis Milling | Can rotate around one additional axis | ±0.008-0.02mm | Balanced machining efficiency for semi-complex parts. | Parts with cylindrical features : gears, sleeves & simple impellers. |

| Five Axis Milling | It can rotate around two more axes, so it has great flexibility when dealing with materials. | ±0.005mm - ±0.01mm | High machining efficiency for complex parts. | Parts with curved surfaces: Complicated curved surface, aerospace components, turbine blades, turbocharger housing in automotive. |

The equipment matrix of JS Precision covers three-axis, four-axis, and five-axis CNC milling machines. Based on the complexity of your parts, precision requirements, and production volume, we will provide you with an appropriate machining solution to balance cost and performance for the best precision CNC milling service.

Note that our precision control standards are all strictly implemented according to the international tolerance standard of ISO 286. The classification and calculation methods of tolerance grade in this standard ensure precise cooperation and parts interchangeability between manufacturers in different countries and regions.

For example, when machining aerospace components, we set the ranges of tolerance in accordance with the ISO 286 standard, which ensures assembly accuracy and reliability when parts are put into high-altitude, high-pressure environments. This is one of our core advantages that helps us to serve aerospace clients for a long period of time.

Please note that if unsure which axis type is suitable for machining your parts, just tell us the structure of the part, precision requirements, as well as the quantity of production, our team will provide you with a detailed explanation of the differences in types of CNC milling and recommend the most cost-effective multi axis linkage machining solution.

Figure 2: 5-axis milling is used for more complex geometric shapes, such as turbine blades, integral discs, and complex surface treatments.

Figure 2: 5-axis milling is used for more complex geometric shapes, such as turbine blades, integral discs, and complex surface treatments.

What Core Dimensions Must Be Considered When Choosing a Precision CNC Milling Supplier?

Given the nature of the relationships, selecting a reliable CNC milling supplier is one of the most significant factors affecting project success. In the process of evaluating suppliers, the following key dimensions should be considered:

1. Equipment brand and age/usefulness. Advanced and well-maintained equipment, such as Haas and DMG Mori, ensures processing stability. JS Precision's equipment is updated every 3-5 years and consists of world-renowned brands.

2. Measuring instruments and certifications. Suppliers should be equipped with professional measuring equipment, such as CMMs, and hold ISO 9001 certification. We have a complete quality test lab and strictly implement the ISO 9001 quality management system.

3. Experienced engineering team. An experienced engineering team can solve complex technical problems. The average experience of our engineers is 8 years in the industry.

4. Case studies. The more case studies a supplier has successfully completed in the industry, the better. We have numerous successful projects in automotive, aerospace, and other fields.

5. Communication response speed and after-sales service. Timely communication and all-round after-sales service will avoid delays in the projects. We provide 24-hour online technical support and one-year warranty service.

Want to reduce risk when selecting a CNC milling supplier? Let us help by providing a comprehensive list of precision machining manufacturers. This would be an ideal opportunity for detailed evaluation of potential suppliers.

Figure 3 Choosing a precision CNC milling supplier should consider their equipment.

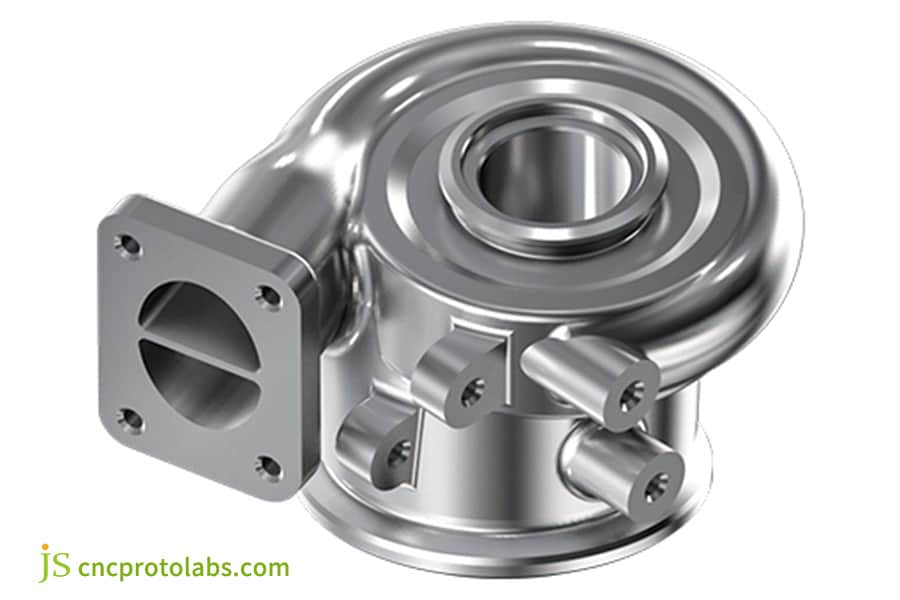

Successful Case-Automotive Engine Industry: Five Axis Precision Milling Of Aluminum Alloy Turbocharger Shell

Customer Issues

In the automotive power plant, the performance of turbocharger housings directly influences the engine power and fuel economy.

The major automotive parts supplier was confronted with a challenge: the need to mass-produce aluminum alloy turbocharger housings that had complex internal flow channels. The existing supplier was unable to guarantee the smoothness of gas flow channels and the flatness of critical mounting surfaces.

This resulted in unstable product performance, frequent malfunctions during use, and a high risk of air leakage, thus greatly affecting the cooperation of this supplier with automakers.

JS Precision Solution

Understanding the customer's challenges, JS Precision developed a custom 5-axis precision milling solution.

- All the machining processes of the turbocharger housing were completed on a high-precision 5-axis CNC milling machine in one clamping. By doing so, the turbocharger casing will not suffer from the accumulated errors caused by multiple clampings, so that each of the parts produced will be identical.

- At the same time, we avoided tool wear and material deformation by professional CAM programming to optimize the toolpaths and utilized targeted cooling processes, ensuring that flow channels would be smooth.

- Moreover, every part must go through a 100% inspection by using a marble platform and coordinate measuring machine to strictly control every critical dimension.

Results and Value

It's done, and the result even exceeded customer expectations: 100% pass rate for turbocharger housing critical dimensions, flow channel surface finish Ra < 0.8μm, critical mounting surfaces, with high-grade flatness, reached the best level in the industry.

This helped the customer completely eliminate the performance fluctuation problem and increase the yield rate from 92% to 99.5%. We also achieved stable monthly batch deliveries, ensuring the customer's production schedule.

If you are also facing challenges in the manufacturing of such complicated parts in the automotive or any other industry, please don't hesitate to present your specific needs. We will provide you with a professional CNC milling solution tailor-made for you, guaranteeing the highest quality of production.

Figure 4 Milling turbocharger housing

What Are The Characteristics And Processing Points Of Common Materials Such As Aluminum Alloy And Stainless Steel In CNC Milling?

Different materials have great differences in CNC milling performance. Mastering their characteristics and machining points is of great importance to ensure product quality, addressing common challenges such as tool wear and insufficient surface finish.

The following are some machining details of three commonly used materials, including targeted solutions to common problems:

6061 Aluminum Alloy:

Features good corrosion resistance and machinability, while tool sticking is common in the process of machining. JS Precision uses carbide tools with special coatings, suitably increases the cutting speeds, applies sufficient amount of cutting fluid for less tool sticking, and controls feed rate to avoid large material deformation.

304/316 Stainless Steel:

Characterized by high strength and toughness, the work hardening tendency is serious when machining. We choose tools with high hardness and wear resistance, adopt low cutting speed and reduced feed rate, adopt the method of layered cutting to avoid excessive tool load, and choose a cutting fluid with excellent cooling and lubrication properties to reduce the machining temperature.

POM Steel:

Material has good rigidity and wear resistance, but it suffers from thermal deformation. We try to use sharp tools to reduce the cutting forces and accordingly the heat generation, control the machining temperature by reducing the cutting speed, and select a clamping method with evenly distributed force to avoid deformation due to clamping.

What Are The Main Factors Affecting The Quotation Of CNC Milling Services? How To Control Costs?

Several factors will come in when it comes to determining how much to pay for the CNC milling service. Understanding them may mean better cost control.

- Programming and debugging time. The more complex a part is, the longer the time it takes to program and debug, which only increases the price.

- Machining time. Material removal rate, part size, and complexity determine the machining time.

- Material cost. The cost for different materials can vary significantly: high-performance materials like the alloys of titanium will be more expensive.

- Tolerance and surface finish requirements. With the increase of tolerance and surface finish requirements, the machining difficulty and cost will increase.

- Quantity ordered. The per-unit cost is lower when larger quantities, or batches, are used to purchase the item because economies of scale are achieved.

Several measures can be done to control the cost of CNC milling:

- Use DFM analysis to optimize the design with reduced or no unnecessary machining steps.

- Loosen non-critical tolerances appropriately while maintaining product performance requirements.

- Consolidate multiple orders to increase batch size.

- Choose cost-effective materials with respect to the operating environment of the part.

Want an accurate quotation with cost-saving suggestions for your project? Note that our cost control solutions are precisely tailored according to the actual needs of the parts. That is, in the case of small batches of orders, we would minimize unit costs through process optimization rather than simply relying on the batch size.

You are welcome to provide us with part drawings and material requirements and inform us about the order quantity. We will give you a transparent quote and a professional cost control solution.

What Is The Specific Process Of Collaborating With JS Precision? How To Start?

Working with JS Precision, a very easy and efficient operation with explicit processes for transparency and controllable abilities, can be carried out as follows:

1. Communication of Requirements and Drawing Provision: You can reach us by telephone, email, or online consultation to explain your requirements about the material of the part, tolerances, surface finish, quantity of production, etc., and provide 2D or 3D drawings.

2. Free DFM Analysis & Quotation: Our engineers will conduct free DFM analysis of your part within 24 hours and provide detailed quotation according to the result and your requirements.

3. Confirmation of Orders and Scheduling of Production: We will arrange production right away after confirmation of quotation and the signing of contracts, and inform the customer of the production schedule.

4. First Article Inspection and Report: The client shall produce the first article, conduct comprehensive testing, and issue an FAI Report. On confirmation of its conformity, production shall start.

5. Mass Production & Progress Updates: During the production process, a project manager will be in contact to update you periodically on the production progress through your preferred means for complete information.

6. Shipment of Finished Product: After production is completed, we perform a final inspection of all products and ship the qualified product to you by designated logistics, providing a complete set of quality documentation.

FAQs

Q1: What is your minimum tolerance? What is the optimal surface finish for your CNC milling service?

Our precision CNC milling service standard has a precision tolerance of ± 0.01mm, and the best surface finish is Ra 0.4μm. For a specific value, it would depend on the material and structural complexity of the part.

Q2: Do you do small-batch prototyping, and high-volume CNC milling services?

Of course, we support it. We can fully satisfy both small-batch prototyping and mass production with our flexible capacity to meet the requirements of your project's various phases.

Q3: Does it include all costs in the quotation for the CNC milling service? Isn't there any hidden cost?

Our quote for the CNC milling service is based on your drawing and is straightforward, clear, and transparent. The quotation includes all costs of machining, material, and standard testing, there are no hidden costs. Additional requirements are preconfirmed with you.

Q4: How do I ensure the security of my product design and intellectual property when using your CNC milling service?

We maintain confidentiality under a non-disclosure agreement with clients in general. All electronic data regarding the design of the product is stored and processed in encrypted form, which fully ensures your intellectual property safety.

Q5: Can you give any progress updates throughout the production of a CNC milling project?

Yes, we will assign a dedicated project manager to your CNC milling project. The project manager will keep you regularly posted about the progress of production via emails or other means preferred.

Q6: What is the typical production cycle for CNC milling services? Do you offer expedited service?

The standard production cycle for the CNC milling project is 7-14 working days. We are also capable of providing expedited services to meet your urgent needs, so please consult details and lead times with our team.

Q7: What quality documentation is provided for the CNC milled parts?

A complete set of quality documentation will be provided with the shipment, including but not limited to FAI, Material Testing Report-MTC, and Final Inspection Report for the CNC milled parts.

Q8: What if quality issues are found after the parts' arrival?

If the quality problem is confirmed to be caused by us, we will immediately launch our quick response mechanism. Reproduction or return would be prioritized, and corresponding responsibility will be taken to safeguard your rights to the maximum extent.

Summary

A technically sound, closely managed, and co-coordinated CNC milling supplier can assure the quality of the product and thus guarantee the success of a project. JS Precision, with our professional technology, complete processes, high-quality equipment, and rich experience, has become your reliable partner in the field of precision CNC milling.

Whether it be design optimization for cost reduction and efficiency enhancement or finding a suitable, stable CNC milling supplier, we can offer you tailored solutions.

Your project deserves the most reliable manufacturing assurance. Just click "Get My Free DFM Analysis and Quote" now, upload your drawings, and expert JS Precision will provide you with professional process analysis within 24 hours, along with a highly competitive detailed quote!

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com