The 5-axis CNC machining supplier selection is a key prerequisite for machining complex surfaces of impellers and precision cavities of molds. However, there is a significant disparity in quotes from 5-axis CNC machining suppliers in the market, from "affordable" to "exorbitant," leaving consumers in a confused position while trying to determine reasonableness.

Such misunderstandings arose from the lack of understanding of 5-axis machining value.

It is not just about equipment hourly rates, but a reasonable 5-axis CNC machining quotation is a comprehensive reflection of process planning, precision stability, technical support, and quality assurance. Automatic, intelligent, sustainable-endowed with these elements, the cost and value drivers started to emerge in 2025.

This article will establish a clear assessment framework, dissect the driving factors around 5-axis CNC machining quotation, list an updated supplier selection for 2025, help understand the pricing, and select a high-value partner like JS Precision.

Key Summary

| Dimensions of Evaluation | Basic Proposition of Value | JS Precision Solution | Key Indicators/ Case Studies |

| Technical Competence | Five-axis simultaneous machining for complex surfaces with precision up to ±0.003mm. | With high-end equipment such as DMG MORI, all automated production lines with real-time accuracy compensation are adopted. | Drone mold case: surface accuracy ±0.025mm, yield increased to 98% |

| Pricing Transparency | Reasonable pricing includes the cost of equipment, process, and quality inspection. | Provides detailed price lists showing in clear percentages how the costs are structured: equipment 35-45%, process 25-35%, and quality inspection 15-20%. | Saves customers from potential rework costs through DFM optimization and path simulation. |

| Industry Adaptability | It meets the high requirements in aerospace, medicine, etc. | Having AS9100D certification and supporting the processing of special materials such as titanium alloys and composite materials. | Composite mold cooling channel accuracy control: ±0.02mm, helps customers reduce weight by 15%. |

| Long-Term Cooperation Value | Intelligent manufacturing decreases the TCO. | Combining AI process optimization and IoT monitoring, the capacity utilization of JS Precision reached 95% and its scrap rate was less than 0.5%. | Automated systems lower the cost of labor by 30%, enabling green and efficient production. |

About JS Precision: We Build Professionalism With Data And Experience

Being deeply rooted and with extensive involvement in the 5-axis CNC machining niche, JS Precision has completed over 600 custom metal processing projects to serve such demanding industries as aerospace, medical equipment, and robotics.

Material machining characteristics, like 6061-T6 aluminum and Ti-6Al-4V titanium alloy, are known to us, and it stipulates accurate cutting parameters. For instance, in the case of machining 304 stainless steel, the feed rate is about 0.03-0.05mm/tooth, which allows us to ensure a surface roughness of about Ra 1.2-2.0μm.

We have carried out 5-axis gear custom machining for automotive customers and ensured accuracy with a lead time of just 12 working days, while meeting assembly tolerance requirements for customers.

Within the framework of our equipment, there are high-class models like DMG Mori DMU 65 and Haas UMC-500, among others. The repeatability accuracy reaches up to ±0.002-0.005mm.

According to ISO 2768-1, an internationally accepted standard, the medium tolerance grade for precision mechanical parts has a threshold of ±0.2mm, and our routine machining accuracy far surpasses that figure.

The suggestions in this guide are based on real project experience, and everything has been tried and validated in practice. If you have a 5-axis CNC machining project needing support, contact us and let our professional team tailor a solution for you.

Why Has The Standard For Selecting Five Axis Machining Suppliers Changed In 2025?

With the deepening of Industry 4.0, a new transformation has appeared in the manufacturing industry, and the selection standard for 5-axis CNC machining has been upgraded correspondingly.

The time when only equipment brands could be compared has passed. Now, what's more crucial is the comprehensive solution capability of a 5-axis CNC machining supplier. Because in customers' eyes, it's no longer the mere "machining parts" that are required but "efficient, precise, and traceable one-stop service."

JS Precision keeps pace with the times, establishing a complete service system:

- Automated loading and unloading systems offer unmanned production for 24/7 and reduce errors caused by manual intervention.

- It monitors, with in-machine measurement technology, the machining accuracy in real time and makes timely compensation adjustments.

- The intelligent process library stores machining parameters for thousands of parts, drastically reducing programming time.

- Full-process data traceability system assures that raw materials are traceable at every working process down to the finished products.

- Energy management module that could optimize the production process, decreasing environmental impact while optimizing operating costs.

With such a number of upgrades, TCO decreases significantly for long-term partnerships, and cooperation stability improves greatly.

How To Break Down The Deep Structure Of a Five Axis CNC Machining Quotation?

When receiving a 5-axis CNC machining quotation, many people only pay attention to the total price and seldom think of the components behind the quotation. In fact, a reasonable CNC machining quote should transparently display all costs, and JS Precision's quotation does just that, making it clear where every penny is spent.

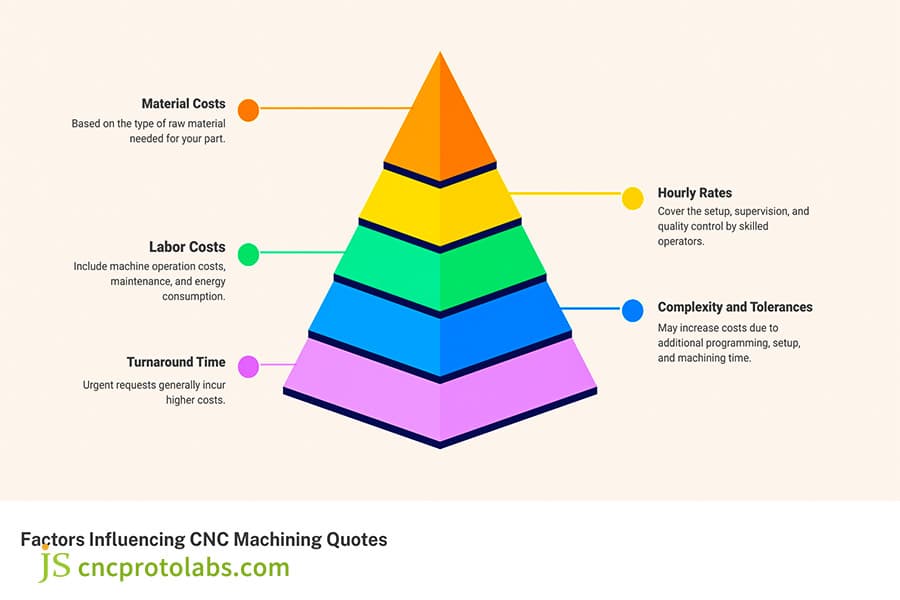

Core Elements of a Quotation:

1. Equipment and Technology Costs: including the kind of 5-axis machine tool-cradle type, swivel head type, etc., accuracy level, and the use cost of in-machine measurement system. High-end equipment usually means high processing costs but promises precision and efficiency.

2. Processing and Engineering Costs: Complexity of CAM programming, investment in toolpath optimization. Example: Using HyperMill 2025 for simultaneous 5-axis programming is costlier compared to basic programming.

3. Costs of Quality and Control: Expenses in laser scanning inspection, CMM, FAI, etc. These inspections are essential for ensuring part quality.

For instance, taking common parts, the breakdown of price would go as indicated on the table below:

| Part Type | Equipment Cost Percentage | Process Cost Percentage | Quality Control Cost Percentage | Other Cost Percentage |

| Simple Bracket | 45% | 25% | 15% | 15% |

| Complex Mold | 35% | 35% | 20% | 10% |

Figure 1 The five core factors that affect CNC machining quotations through pyramid analysis are materials, labor hours, manpower, complexity, and delivery time.

How Do Device Performance And Automation Directly Affect Your Component Costs?

In the 5-axis CNC cost analysis, the performance of the equipment and the degree of automation are the core factors. Different levels of 5-axis machine tools have great differences in accuracy, efficiency, and the ability to machine complex surfaces. It directly determines the cost of part machining and is also the core focus of 5-axis CNC cost analysis.

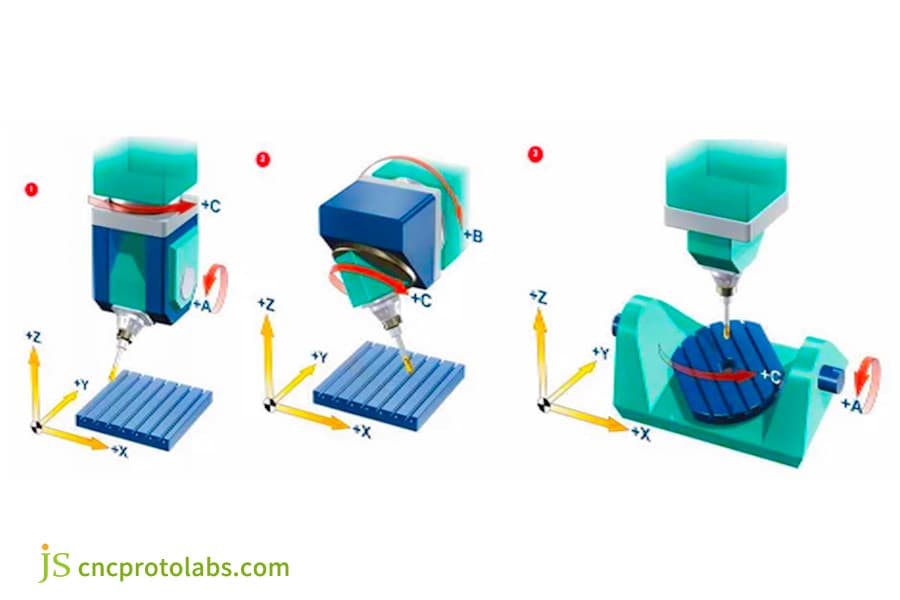

Comparison between Types of 5-Axis Machine Tools:

- Cradle-type 5-axis machine tool: Suitable for small to medium-sized complex parts, high machining accuracy. Repeatability up to ±0.003mm, suitable for small aerospace part machining.

- Swing type five axis machine tool: larger range of processing, suitable for large parts, with a load capacity up to 5 tons, it can be applied for mold processing as well as large structural component processing.

- Composite 5-axis machine tool: Integrates many functions, like milling and turning, reducing clamping time and hugely improving efficiency in processing.

The investment in an automated production line brings significant advantages to JS Precision, such as automation of loading and unloading that reduces the labor cost by 30%, unmanned operation for 24 hours raises equipment utilization to 95%, and an on-machine measurement system reduces scrap rates to below 0.5%.

Eventually, these advantages result in a reduction of part costs. We can offer more competitive prices without any damage to high-quality products.

Do you want to calculate the cost of your parts in automated production mode? Please provide us with the dimensions, materials, and production capacity of your parts. JS Precision will generate a customized 5-axis CNC cost analysis and cost optimization plan for you, using advanced equipment and automation technology to help you reduce costs and increase efficiency.

Figure 2 The core structural differences of three types of five axis CNC machine tools are achieved through multi-directional machining using the+A,+B, and+C axes, respectively.

What Are The Six Key Dimensions For Evaluating Five Axis Machining Suppliers In 2025?

When you choose CNC machining supplier, it is not enough to rely solely on a single indicator, a comprehensive evaluation is necessary. The most authoritative evaluation system in 2025 includes six dimensions, and JS Precision has set industry benchmarks in each dimension, making it a high-quality choice when you choose CNC machining supplier.

1.Technical Equipment and Advanced Technology: JS Precision mainly has high-end five-axis machine tools like DMG Mori and Haas equipped with 24,000 rpm high-speed spindles and can produce various kinds of parts with complicated shapes.

2. Engineering Team and Process Experience: Our engineers have an average of over 10 years of experience, familiar with the special requirements of industries such as aerospace and medical, and can provide professional DFM advice.

3. Quality Management Systems and Certification: ISO9001-and AS9100D-certified, JS Precision established a comprehensive quality inspection system from raw material inspection to finished product delivery.

4. Project Communication and Transparency: It offers real-time updates on production progress through project managers, plus comprehensive reports on processing and testing data.

5. Automation and Intelligence Level: 80% automation coverage of production lines, intelligent process planning systems significantly shorten the delivery cycles.

6. Sustainable Development Capacity: Material utilization rate is over 90%, energy consumption is more than 20% lower than the average for similar enterprises, and green production has been achieved.

Not sure how to rapidly assess suppliers? Request JS Precision's "Supplier Evaluation Checklist" and check against the six dimensions one by one for a more proper CNC machining supplier selection.

Successful Case -Aerospace Field: Five Axis Precision Machining Of Composite Material Molds For Drone Engines

In the field of aerospace, the precision and stability of five-axis CNC machining directly determine the performance of the product. We solved the problem of machining composite material engine molds for UAVs for an aerospace startup, one of our many successful precision 5-axis machining services cases.

Customer dilemma

The customer needs to manufacture large, lightweight molds with complex conformal cooling channels, with a surface accuracy requirement of ± 0.03mm. The cooling channels need to be tightly attached to the mold cavity to ensure uniform solidification of the composite parts.

The original supplier, due to insufficient rigidity of equipment and a limited capacity for programming, produced molds with surface deviations over 0.05mm, and cooling channels misaligned, which caused deformation of the cured composite material. The yield rate was just 70%, and the whole project was right at the verge of stalling.

JS Precision Solution

After taking over, JS Precision developed a multi-dimensional solution in detail as follows:

Equipment Selection and Parameter Optimization:

Adopt a large five-axis machining center with the travel over 2 meters, match it with a high rigidity spindle and special fixture to ensure stability in big mold processing from a hardware point of view, and avoid vibration distortion in cutting.

Process Planning and Path Optimization:

Using the software of HyperMill 2025 with a dynamic milling strategy, respectively controlling cutting force and speed, toolpaths are optimized to reduce idle travel and improve the efficiency of processing while reducing the damage of the mold surface.

Real-time Accuracy Control:

Real-time compensation of surface accuracy and flow channel position is performed during the whole process by monitoring the processing data through an in-machine measurement system, ensuring that the distance tolerance between cooling channels and cavities is strictly controlled within ±0.02mm. Special selection of dedicated composite material tools can effectively reduce surface burrs.

Results and Value

The accuracy achieved in the final mold surface was ±0.025mm, cooling efficiency enhanced by 30%, while the yield of composite parts rose to 98%. Our client was thus able to achieve a 15% weight reduction in their engine casing and a related 12% gain in thrust. To date, we have become their sole mold supplier.

Are your aerospace parts facing complex machining challenges? Please contact JS Precision, share your project pain points with us, and we will provide customized precision 5-axis machining services solutions.

Figure 3 Drone engine

What Indispensable Values May Be Hidden In Seemingly High Priced Quotations?

Most clients often feel that the quotes by JS Precision are on the high side, but when understood in-depth, you will realize that there are many indispensable hidden values within these quotes that help avoid additional costs later on.

- Advanced simulation software: Universal toolpath simulation before machining eliminates trial and error costs. Simulation has pinpointed interference issues and prevented tens of thousands of dollars in rework for the clients.

- Fine tools and consumables: Imported tools ensure surface integrity of parts and extend mold life.

- Complete quality data package: Provides thorough inspection reports, material certifications, and traceability records for compliance purposes.

- Professional DFM advice: Proposes optimization solutions during the design phase for less machining difficulty.

These investments are all to guarantee that the project is done correctly the first time, without delays or reworks because of quality. This is the key behind a reasonable CNC machining quote-not necessarily a low quote, but more towards the ultimate creation of "value-for-money."

How To Obtain The Most Accurate Quotation From Suppliers Through Effective Communication?

An accurate 5-axis CNC machining quotation relies on effective communication with suppliers and the provision of all details related to the project. Most clients face large quotation discrepancies and frequent subsequent changes due to incomplete information.

Core Information Required for Accurate Quote:

- Completed 3D model with associated 2D drawings, clearly showing tolerance requirements along with critical dimensions.

- Full detail of material information, which must be stated with its grade and heat treatment requirements.

- Surface treatment standards, such as anodizing and passivation requirements.

- Annual usage target and project stage: prototype, small-batch trial production, or mass production.

- Delivery cycle requirements and special packaging needs.

JS Precision recommends that prior to quotation, clients consult with the engineers. We will offer optimization suggestions to bring down the cost while performance is maintained.

Want a fast and accurate quotation? Please organize your project information as above and email to us - JS Precision Technology team, we will send over a detailed 2025 CNC machining pricing and process plan within 24 hours. 2025 CNC machining pricing depends on a variety of factors, professional analysis will help you avoid some pricing traps.

Why Is JS Precision The Ideal Partner For Five Axis Machining Needs In 2025?

Competition in the manufacturing industry is getting increasingly intense, and in 2025, the choice of an ideal 5-axis CNC machining supplier becomes critical. At JS Precision, our unique value proposition has led to us becoming the go-to choice for many customers, and we have set a very high bar for CNC machining supplier selection.

We have a state-of-the-art equipment cluster consisting of various types of high-end 5-axis machine tools with different sizes and precisions that can meet the machining requirements.

Years of accumulation have created a profound process database, which enables us to develop optimal solutions for parts from different industries and made of different materials as soon as possible. A comprehensive quality assurance system is our core advantage, every step undergoes rigorous testing to ensure 100% part quality.

Not only does it provide machining services, but we are committed to customer success by proactively offering suggestions for cost optimization and design improvement. Looking into the future, intelligent factories under construction have further enhanced efficiency and precision by optimizing toolpaths using AI and by monitoring production status using IoT.

Immediate Action: Get Your Exclusive Five Axis Machining Plan And Value Evaluation Report

By now, you fully understand how to select 5-axis CNC machining and understand the pricing and the costs. JS Precision provides more than a quote, we provide a customized "Technical and Value Assessment Report" to help our customers better complete CNC machining supplier selection.

The following report contains detailed process design proposals, cost optimization analysis, lead time estimations, and quality assurance plans that enable a clear understanding of the feasibility and value proposition of the project. Be it the R&D or mass production stage, this report amply supports your decisions.

Please provide your part information now-3D drawings, materials, and tolerance requirements, and we will deliver to you a custom report in 3 business days, complete with free process diagnostics. How JS Precision helps you to mitigate risk, reduce costs, and boost efficiency: Make 5-axis CNC machining your competitive advantage.

FAQs

Q1: What brand and model is your 5-axis machining equipment? What precision does it have?

The high-end 5-axis machining centers are mainly used in our workshop, including German DMG Mori DMU 65 and Japanese Haas UMC-500. The positioning accuracy can achieve ±0.003mm and repeatability ±0.0015mm.

Q2: Does the quotation include all inspection fees?

Yes, the FAI cost and mass production SPC cost are clearly included in our quotation for transparent pricing.

Q3: Can you handle large or ultra-heavy 5-axis machining parts?

Is yes, count with big 5-axis machines with more than 2 meters travel and with a load capacity up to 5 tons to meet all the machining needs for large moulds, base plates among other ultra-heavy pieces.

Q4: How do you guarantee the security of my design data and intellectual property?

We strictly sign NDA agreements with our clients while protecting data against encrypted servers and hierarchical accesses. Protection of intellectual property is our most important concern.

Q5: What's MOQ? Does your company support small batch trial production?

We support prototype production and small-batch trial production starting from 1 piece, with no strict minimum order quantity. We are committed to accompanying our clients from the R&D stage to mass production.

Q6: How long is the production cycle normally? Do you have expedited service?

The production cycle for common projects is 15-25 working days. We have an accelerated green channel which can highlight productions by customers' needs. Pls consult your PM for details.

Q7: Do you supply raw material certification documents and full-process traceability documentation?

Yes, we provide complete material certification (MTC) and full-process traceability records from raw material procurement, processing to finished product delivery.

Q8: What would be your after-sales policy if a part has a problem in its final use?

When the root problem is confirmed to lie in our process responsibility, we will promptly start a quality traceability mechanism, finalize reproduction or return top priority, and bear corresponding liability and loss.

Summary

Selecting a 5-axis CNC machining supplier in 2025 requires more than just price comparison, it needs consideration of comprehensive strength and long-term value. Eventually, whether or not CNC machining pricing is reasonable in 2025 will have to be justified by the overall ability of the supplier.

It is expected that with its forward-looking technological layout, transparent cost structure, and outstanding delivery capabilities proved by cases like [Aerospace: 5-axis precision machining of composite material molds for UAV engines], JS Precision can ultimately be your trusted strategic partner. Try JS Precision, and let our precision 5-axis machining services power your projects.

That's the wisest choice for your project. Click "Get Customized 5-Axis Machining Value Assessment Report," submit your part information, and JS Precision's expert team will provide you with a detailed process and pricing analysis within 24 hours!

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com