CNC machining services have emerged as a driving force in the manufacturing industry. It will continue to be so in the years leading up to 2025.

Suppose you are an engineer at an aerospace industry firm struggling to find a supplier with the ability to make precision turbine parts for timely delivery, or a purchasing manager at a medical device manufacturer fed up with ambiguous pricing terms and quality of components from a more conventional supplier.

Such situations have become quite prevalent in the current competitive manufacturing environment where organizations are under immense pressure to cut down costs and improve efficiencies with technological innovation.

This guide is designed to provide answers to these questions, digging out the latest CNC machining applications, as well as factors to consider in choosing a supplier, to help you turn technology hurdles into a competitive edge through collaboration.

Core Answer Summary

| Dimensions | Core Capabilities | Customer Value |

| Technical Strength | Five-axis CNC Machining, AI Predictive Maintenance, Digital Twin Simulation | 60% Improved Machining Efficiency, 40% Shorter Delivery Cycle |

| Quality System | ISO9001 Certification, 3D Coordinate Measuring Machine Full Inspection, Material Batch Traceability | 99.8% Product Qualification Rate, Full Process Traceability |

| Cost Optimization | Free DFM Analysis, Material Substitution Solutions, Process Integration | Average Reduction in Total Cost of Ownership by 18-25% |

| Service Features | 4-Hour Quick Quote, Dedicated Project Manager, Intellectual Property Protection | Seamless Integration from Prototype to Mass Production |

Why Is The JS Precision 2025 CNC Machining Guide Reliable?

JS Precision is very much engaged in precision CNC machining services for over 15 years, specializing in making various kinds of custom CNC parts.

We have satisfied over 2,000 clients in diversified sectors such as aerospace, medical, automobile, and electronics, and completed over 10,000 projects, right from producing prototypes to mass production of complex parts, following the globally acclaimed standard of the ISO 9001:2015 quality management system.

For instance, we completed the successful delivery of 5,000 pieces of high-precision structural parts in aluminum alloy for a top electric vehicle-maker, registering a pass rate of 99.8% and reducing the delivery cycle by 30% compared to the regular norm.

Furthermore, we have vast experience in machining special materials ranging from titanium alloy, Inconel, and even PEEK, which work well in high temperature, high pressure, and high corrosion applications.

This 2025 CNC machining guide is an accumulation of our know-how gained over the years of our practice. All recommendations, statistical data, and cases presented in this article have been taken from real project work. Whether it is CNC machining services you look for or simply an associate for long-term business, these articles prove their practicality and authenticity.

To test out our capabilities, simply send in your part drawings, and our team of engineers will give you a free DFM analysis in 4 hours or less.

Which CNC Machining Applications Are Redefining Manufacturing Competitiveness In 2025?

In 2025, multiple CNC machining applications are driving industry change, and JS Precision has fully grasped the essential technologies to offer customers a competitive edge. Of course, the intelligent upgrade of industrial CNC machining has become the mainstream trend, realizing the double leap in processing speed and quality.

1.AI-based predictive maintenance: We have AI algorithms embedded in CNC milling machines that predict possible failures 24 hours in advance, and it results in a 30% reduction in equipment downtime and smooth production flow.

2.Hybrid additive and subtractive manufacturing processes: This technology helps us to create custom CNC parts with complex architectures that cannot otherwise be manufactured. This process can decrease material waste by 40% and overall production cost.

3.Lightweight micro-hole processing: In the aerospace and automotive industries, we provide precision micro-hole processing with the minimum diameter of 0.1mm, which enables customers to reduce the weight of products by 15-20% without losing strength.

4.Five-axis Simultaneous Machining: Equipped with an advanced five-axis machining center that enables machining of complex parts in one setup, thus enhancing machining accuracy to ±0.005mm and reducing machining procedures by 50%.

5.Digital twin simulation technology: The entire CNC machining process is simulated through a digital twin prior to actual production to eliminate any possible problems prior to actual production, thereby enhancing the rate of project success by 25%.

6.Collaborative Robot Automatic Production Line: In this, we designed a collaborative robot automatic workshop, facilitating continuous production in 24 hours, thus improving efficiency by 60%, while ensuring part Quality.

These CNC machining applications are not limited to mere demonstrations, but are practical tools that provide real value to customers. The essence of the benefits that precision CNC machining provides is fully accomplished by these high-tech application softwares that give customers more precise and reliable products.

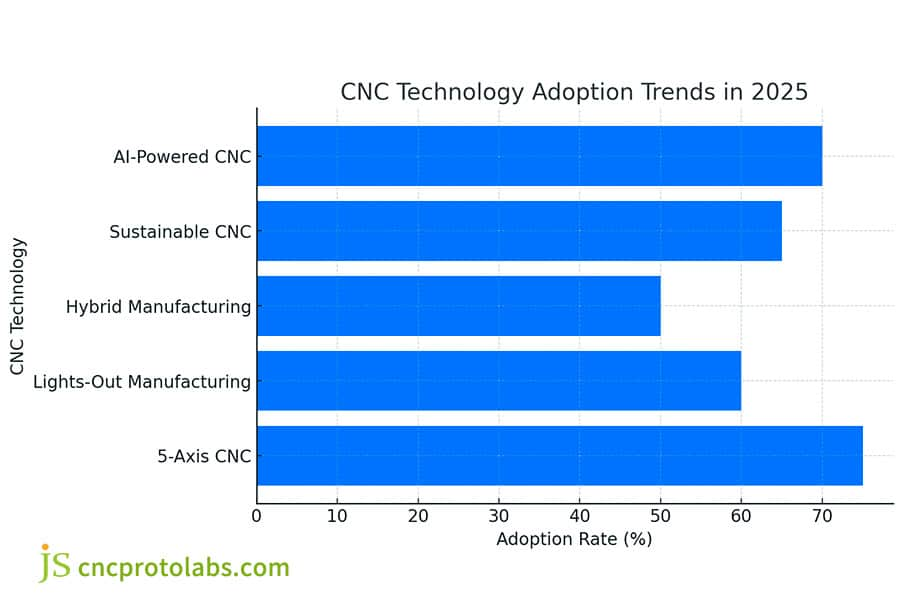

Figure 1 By 2025, automation, multi axis machining capabilities, hybrid technology, and sustainable development initiatives will completely transform the CNC machining industry.

How To Evaluate The True Strength Of a CNC Machining Supplier?

The selection of the CNC machining supplier plays an important role in the success of projects, however, in terms of CNC machining suppliers, they should not solely rely on costs and delivery time. JS Precision always maintains that in developing an assessment framework, there are four important angles, which are also the key basis for CNC machining supplier selection.

Technical Capabilities

- Does the supplier have five-axis machining facilities and the ability to machine complex curved surfaces?

- Does the supplier have experience in machining special materials like high-temperature alloys, titanium alloys, and engineering plastics?

- Does the supplier have expertise in highly advanced technologies in the field of industrial CNC machining, such as CNC milling, turning, and grinding, and can offer Integrated processing services? This is the core point of technical capability evaluation in CNC machining supplier selection.

Quality System Certification

- Does the supplier have global certifications like ISO 9001:2015 to ensure that the quality process in its production is standardized?

- Does the supplier have sophisticated testing equipment like coordinate measuring machines (CMMs) and optical measuring devices, in addition to having the entire quality inspection process?

Project Management and Communication Process

- Is there a project manager in place at the supplier to monitor the progress of projects in real time and attend to customer demands within 24 hours?

- Are there clear communication channels that enable customers to be supplied with real-time information regarding production and quality?

Technical Support Services

- Can customers take advantage of a DFM analysis offered by the company, without charge, as part of its services?

- Is technical consultation and after-sales service offered by the company to resolve issues arising from the usage of parts by its consumers?

JS Precision fully complies with this structure in our business. We currently have 12 five-axis machining centers, a professional testing staff, and an advanced project management system to guarantee that all orders are delivered as expected by our clients.

If you are doubtful about how to select a supplier in the CNC machining industry, you can give your contact information so that the complete CNC machining supplier selection checklist from JS Precision will be sent to you. The checklist has been developed in a manner that it includes the latest concepts about how a supplier should be evaluated as in the 2025 CNC machining guide.

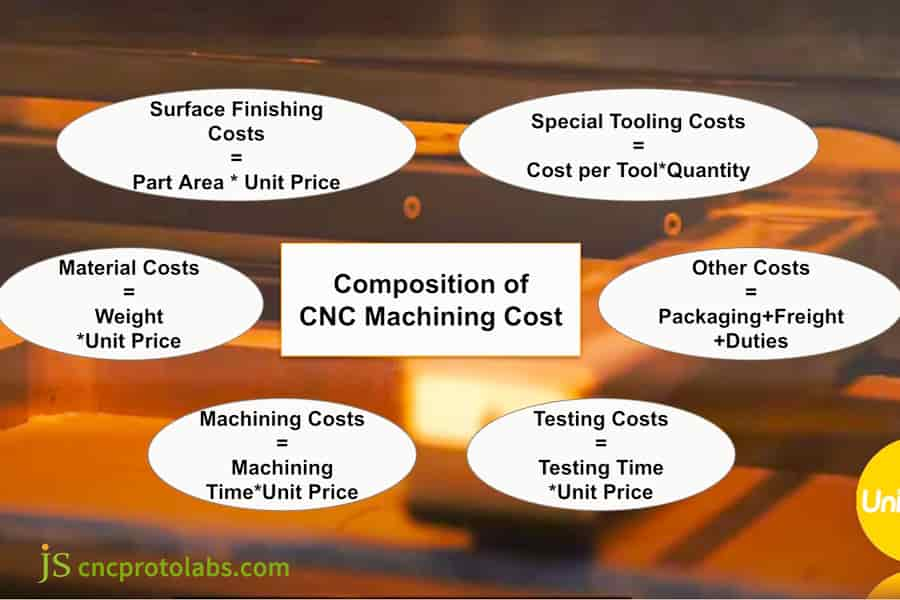

Why Is Transparent CNC Machining Quotation The First Step To Project Success?

An open and transparent CNC machining quote is an important aspect of avoiding conflict and managing project costs.

Many customers have found themselves trapped in what they considered a low-cost price—they initially asked a company to do the work and the company quoted them a low price only to bill them numerous fees that add up to way more money in the end. A quality CNC machining quote should include the following details:

| Cost Items | Detailed Explanation |

| Material Cost | Material Quality, Specification, and Price to be Clearly Stated |

| Labor Costs | Based on difficulty of machining and equipment usage. Also includes detalied labor hours. |

| Surface Treatment Cost | This includes spraying, anodizing, and electroplating operations. The costs are itemized with details of each process. |

| Packaging and Logistics Costs | Use appropriate packaging and logistics channels based on parts characteristics and ensure that packaging and logistics cost estimation is transparent. |

| Taxes and Fees | Ought to clearly state tax rates and fees based on national tax laws. |

JS Precision operates on the principle "detailed, transparent, no hidden charges" while quoting. JS Precision gives clients an in-depth quote breakdown, where each cost component is defined. Clients can easily see where every dollar is going, so there are no worries about surprise charges.

Figure 2 Understanding the constituent elements of processing quotations is crucial for interpreting their meanings and making informed decisions.

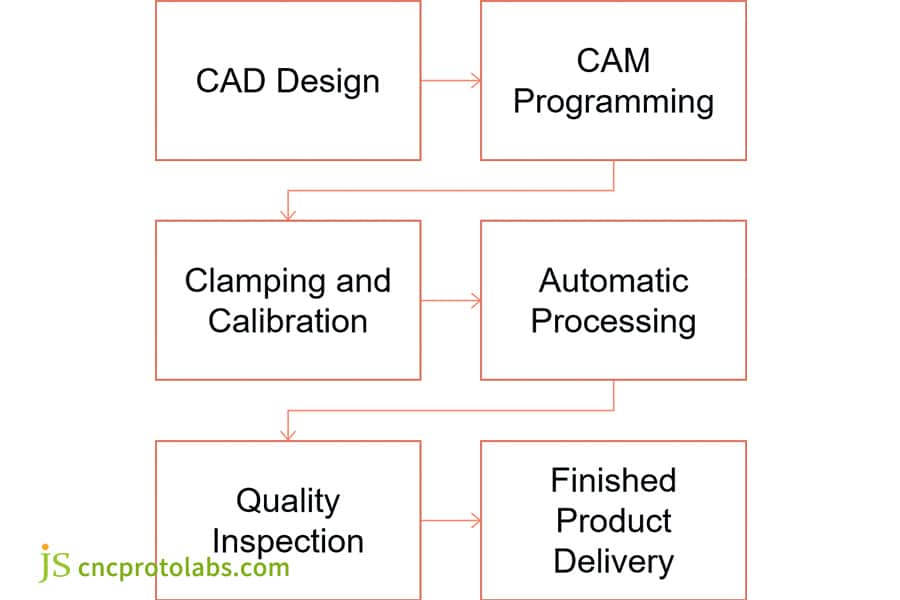

From Design To Finished Product: What Are The Differences In JS Precision's CNC Machining Process?

JS Precision boasts a special type of "customer-collaborative" CNC processing, in which all processing steps culminate in adding value for customers. We have made a comprehensive CNC machining process guide, systematically explaining all processing standards, as well as all value points of individual processing steps.

1. DFM Analysis: Analysis of the customer's product design by our engineers with recommendations from the perspective of manufacturability cost optimization, resulting in an average savings of 15% of production cost to our customers.

2. Programming and Simulation: Utilization of professional programming tools for programming the machining process, as well as using digital twin technology for simulating a machining process in a computer.

3. Precision Machining: Based on highly advanced machines like CNC milling machines and five-axis machines, precision parts are machined with good precision, with dimensional accuracy met according to design specifications.

4. Multiple Quality Inspections: The component quality is checked through first piece inspection, process inspection, and final inspection, and all inspection stages record the component quality to ensure that 99.8% of the parts qualify.

5. Protective Packaging: According to the materials and structures of the parts, anti-corrosion and shockproof packaging are employed to resist damage in transit.

6. Logistics Tracking: The logistics tracking system is implemented so that the customers can track the status of the transport of the components.

This process emphasizes close collaboration with customers, with timely communication at every stage, listening to their needs, and adjusting plans.

To see how this process may be implemented for your application, you need to get in contact with the JS Precision customer service team to request a CNC machining process guide and develop your customized production plan.

Figure 3 The flowchart clearly shows the complete six step process of CNC manufacturing, from design, programming to machining, inspection, and final delivery.

Processing Of Complex Structural Components In The Aerospace Industry: a Successful Case Of Ls Manufacturing

Client Challenges

LS Manufacturing, which has long-standing credibility in aerospace parts production, required a high-temperature alloy turbine housing meant for a new-generation aircraft engine.

This project entailed very complex custom CNC parts with features such as thin-walled parts, a tolerance of ±0.008mm, and extremely high surface finish requirements. The project met the ISO 2768 Precision Class (f) requirements, an ISO standard recognized worldwide, hence considered a very high difficulty project in the industrial CNC machining.

LS Manufacturing hunted around for CNC machining suppliers, but many were unable to meet technical specifications because they lack the required machining capacity. This resulted in protracted times and market pressure.

JS Precision Solution

As soon as JS Precision received the order, we set up a project team.

- In the first case, we carried out an analysis of part drawings and DFM optimization in order to enhance manufacturability for the thin-walled section.

- Later on, a high-rigidity five-axis gantry machining center with high precision and customized fixtures were chosen to handle the issue caused by deformation during thin-walled parts processing.

- During this period, simultaneously, we optimized cutting parameters, introduced high-speed cutting tools and cooling systems to improve machining efficiency and surface quality of machining high-temperature alloys.

- Real-time data monitoring technology was employed in the machining process to monitor the process status in real time by adjusting parameters in case of anomalies.

Results & Value

Through their hard work, JS Precision was able to accomplish the task of making a high temperature alloy turbine housing that met design specifications. The delivery time was cut down by 40% compared to what LS Manufacturing had initially expected.

On the other hand, the rate of part qualification reached 100%, which gave a major fillip in the success of the entire project of LS Manufacturing. LS Manufacturing realized the capabilities of JS Precision in technology, therefore, a lasting strategic partnership was formed.

If you also have the need to machine the parts that fall under the category of “complex,” in the areas of aviation and healthcare, you can share the problems of your project with JS Precision. We can offer you solutions from our technical experts to make your project a success.

Figure 4 High temperature alloy turbine housing for aircraft engines

How Can Precision CNC Machining Help You Control Costs And Increase ROI?

Precision CNC machining can help businesses control costs and improve return on investment (ROI) through multiple channels. In the industrial CNC machining scenario, this advantage is particularly prominent, as it can achieve cost reduction on a large scale through process optimization.

To begin with, while designing part materials, JS Precision engineers suggest the most economical materials depending on part operational environment and performance specifications. For example, for non-critical structural parts, we suggest the use of ordinary steel instead of alloy steel, thus reducing material cost by 20-30% without impairing performance.

Second, process optimization can minimize machining procedures and maximize manufacturing efficiency. For example, based on five-axis machining technology, multi-angle machining in one clamping can reduce clamping times and elevate machining efficiency by 50%.

Moreover, we also offer free DFM analysis for our customers to optimize designs, eliminate unnecessary machining operations, and minimize manufacturing costs.

Data illustrates the impact customers have experienced, averaging a reduction in total cost of ownership by 18-25% and an improvement in ROI by over 30% by implementing our process improvement and cost control techniques.

What Key Factors Are Most Easily Overlooked When Customizing CNC Parts?

While custom CNC parts, some of the customers' notable concerns include the accuracy of the parts and the required delivery time, but they don't pay heed to some key aspects, which also play an important part in the quality and longevity of the parts, especially when customized by precision CNC machining.

Material batch stability:

Suppliers may use different material sets. This causes disparity in part performance. JS Precision is very particular about material origin. We use material sets supplied by prominent brands, ensuring consistency in material performance across orders by ensuring that all orders of similar material parameters involve the use of the same material batch.

Deformation Control after Heat Treatment:

Heat treatment is a processing that plays a significant role in enhancing the performance characteristics of components. However, improper implementation can cause deformation to components.

We have rich experience in this field and, according to the composition and structure of components, control deformation during and after heat treatment to within an acceptable range.

Cleanliness standards:

The industries related to the aerospace and medical sectors have very strict standards regarding the cleanliness of the parts. JS Precision has an expert cleaning workshop where it uses ultrasonic cleaning to remove any oil and impurities from the surfaces of the parts.

Parts Traceability:

When there are quality concerns regarding parts, there should be traceability to the process in which parts are manufactured. We have implemented an end-to-end traceability process for parts from purchases to inspection to achieve traceability for all parts.

JS Precision maintains strict vigil over every detail in the production process, closely regulating such easily overlooked details in order to supply customers with high-quality, highly reliable custom CNC parts. This is, of course, another key benefit we have honed over the years in the industry of industrial CNC machining services.

What Will You Gain By Choosing JS Precision As Your CNC Machining Partner?

By picking JS Precision CNC machining services, you can expect the following benefits in addition to receiving quality parts:

Individual technical expert support: We have engineers with more than 8 years of technical expertise that provides professional technical consultation and solution services throughout the project process so that you can address different technical issues.

Traceable quality reports: With each order, a comprehensive quality report will be provided, containing test data, inspection results, and material certificates, so that you have a clear view of the quality status of your parts.

Guaranteed on-time delivery: We have an efficient production planning system and capacity, so there is a guaranteed on-time delivery for 99% of our ordered goods. To accommodate your project timeline, for urgent ordered goods, there is expedited delivery service.

Continuous technical upgrade services:We keep up with the latest trends in CNC machining applications, this helps us upgrade our technology as research progresses. This makes it possible for you to be competitive in the market.

FAQs

Q1: What is the minimum order quantity for CNC machining services offered by JS Precision?

Services range from single prototyping to mass production, and the MOQ will depend on the complexity of the design and the material used. We are determined to meet all your R&D and production requirements.

Q2: How long does it take from inquiry to obtaining quotation?

In general, after getting your drawings or 3D models, our engineers will give you a detailed quote within 4 business hours. We will respond quickly to your requests.

Q3: How does your firm protect intellectual property?

We enter into tight non-disclosure agreements (NDAs) with all of our clients and have an excellent data management system that ensures your design plans are under maximum security.

Q: Can you handle special materials that I provide?

Yes, we have ample experience with the machining of different metals (like titanium alloys and Inconels) and engineering plastics, and I can give you expert advice based on your requirements.

Q: What is your typical delivery cycle?

The average delivery time will vary from project to project. However, as the case study in LS Manufacturing illustrates, our optimized processes translate into an average delivery cycle that beats the industry standard. The exact average will be outlined with the quote.

Q: Are your design services, such as your DFM analysis, complimentary?

Absolutely. We also offer professional and free DFM analysis for every project that will help you optimize your design and minimize production costs.

Q: What quality control procedures do you have?

Our quality control process involves inspection of the first piece, in-process inspection, and final inspection using CMMs, optical instruments, etc., for checking the dimensions of the parts.

Q: How do I start my first CNC machining project?

All you have to do is upload your files via 'Get a Free Quote Now' and our team of experts will connect with you immediately in order to understand your requirements and work in an efficient and effective manner.

Conclusion

By the year 2025, competition in manufacturing will not only be based on product quality and pricing, but also based on the technical capabilities of the partners and the efficiency of partnerships. Selecting the appropriate provider of CNC machining services can play an important role in lowering costs and creating an edge over the competition.

With its rich experience, advanced technology, and customer-oriented service philosophy, JS Precision will be your best choice. Whether you need machines to machine complicated structural components, control cost, or look for a reliable and long-term cooperation partner, we can satisfy you.

Don't let technical challenges and supplier selection difficulties hinder your development.To receive a Free DFM analysis as well as a customized quote, get in touch with JS Precision today. We look forward to helping you turn your designs into high quality precision parts in order to build a better future together.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com