5 axis CNC machining services are at the heart of manufacturing solutions that allow the industry to go beyond the limitations of traditional three axis machining.

In the world of manufacturing today, where the utmost precision and intricate geometries are being sought after, the conventional three axis machining has already hit the ceiling of what it can do. It has to be acknowledged that whether it's aerospace or medical implants, manufacturing technology breakthrough that is disruptive is what's needed.

This article aims to systematically answer the core questions about 5 axis CNC machining services, analyze how it becomes the ultimate answer to precision tooling and customized grinding solutions through unparalleled degrees of freedom and precision, and help you make the wisest and most cost-effective choice for your next difficult project.

Summary of Core Answers

| Your Core Challenges | JS Precision's 5-Axis Solution | Core Value For You |

| Machining Ultra-Complex Geometry | We've installed a 5 axis machining center with high-dynamic performance to allow machining of five faces and full curved surfaces in a single setup. | Thus, multi-process errors are eliminated, design freedom and accuracy are enhanced, and the manufacturing chain is shortened. |

| Ensuring Micron-Level Accuracy and Superior Surface Quality | By using a 5 axis vertical machining center with high-rigidity and a precision rotary table, and advanced processes, quality is guaranteed. | Producing high-finish parts that are suitable for functional testing or small, batch production, thus, lowering costs and risks. |

| Controlling Costs and Cycles for Complex Parts | We can help you from custom 5-axis machining design optimization up to efficient programming, with transparent pricing. | Thus, manufacturing risks are minimized from the very beginning of the project, total cost of ownership is optimized, and delivery times are kept competitive. |

Key Takeaways:

- The fundamental advantage of 5 axis CNC is that it can do the hardest geometrical machining in one time, thus perfectly solving the problem of cumulative errors caused by multiple settings, which is the source of precision.

- It is more important for a 5 axis machining center to have a good positioning accuracy (for example, 0.002mm), a good repeatability, and a powerful machine rigidity than having more axes.

- For complex parts 5-axis machining, collaborating with the manufacturer on manufacturability design in the early stages can save up to 30% of costs and time.

- In addition to being one of the most ingenious tools for prototyping, 5 axis milling services also provide a cost, effective solution for small-to medium-batch production of complex parts.

How To Achieve Precision Machining? JS Precision's 5 Axis CNC Machining Solution

5 axis CNC machining is essential for ultra high precision machining, and JS Precision has developed a complete technical system around this fundamental technology. Our 5 axis machining center can achieve tolerance accuracy down to 0.001mm, which is significantly better than the 0.005mm of traditional three axis machining.

This degree of accuracy is well within the ASME Y14.5-2009 dimensional tolerance standard. We run a very strict quality control process by which our coordinate measuring machines (CMMs) and optical scanners are used for multi-stage inspection, thus, we are consistently able to maintain a process capability index (CpK) level of above 1.33.

For complex components that would require five or more setups in three axis machining, our 5 axis CNC machining services can carry out the machining process in one or two setups, thereby saving 50% to 70% of the setup time. Besides lowering the possibility of human error, this also results in a 20%-30% reduction in overall production costs.

In real, world scenarios, our solutions have enabled aerospace clients to bring down their scrap rates from 8% to 2%, and medical device customers have been able to manufacture ultra high precision parts with tolerances as low as 0.0005mm.

Moreover, we have gathered numerous success stories of machining hard-to-machine materials such as titanium alloys and nickel alloys, thus, proving our expertise and professionalism.

Want to achieve complex parts 5-axis machining with micrometer level accuracy? Contact JS Precision engineers immediately, submit your part drawings, and receive a free customized precision optimization solution to reduce machining risks.

What Exactly Are 5 Axis CNC Machining Services?

5 axis CNC machining is an all-round manufacturing service which combines very accurate, very free, and very efficient features.

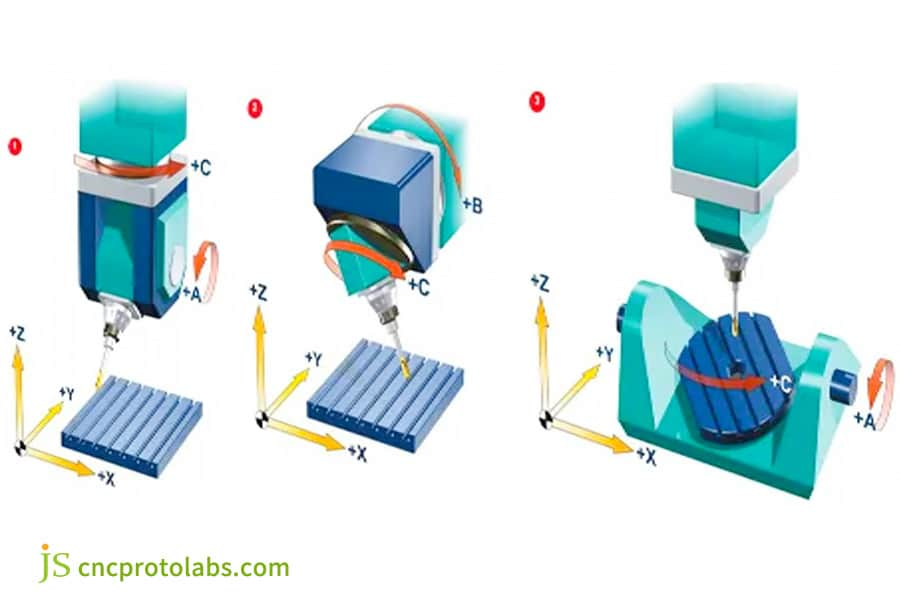

In contrast to three axis machining, which restricts movement to the X, Y, and Z linear axes only, this 5 axis CNC machining exploits the addition of two rotary axes (usually the A and C axes) to the three linear axes. Thus, the tool can be positioned at an almost unlimited number of angles to the workpiece.

Its two main uses are very specific:

- Precision tooling, e.g. injection mold cores and die-casting mold inserts, which entail complex surfaces and require high precision.

- The manufacture of very complicated parts, e.g. impellers, medical skeletons, and optical components, that are hard to be processed in traditional ways.

5 axis machining service is more than a mere machining technique, it is a full package solution that covers design optimization, programming, machining, and inspection.

Want to know if 5 axis CNC machining services can solve your precision tooling or complex part machining needs? Tell us your part material and precision requirements to receive a free feasibility analysis report.

How Does a 5 Axis Machining Center Work?

Coordination of Motion Axes: The Dance of X, Y, Z, A, C

A 5 axis machining center consists of three linear axes (X, Y, Z) and two rotary axes (A, C). A, axis is a rotation around the X-axis, and C- axis is a rotation around the Z-axis. The coordinated movement of these axes enables the tool to have any position and angle on the workpiece.

Normally, three axis machining needs the workpiece to be repositioned several times, but 5 axis machining can do the machining of multiple surfaces of a part with just one setting. This is the main benefit of 5 axis CNC machining.

Core Brain: High, End CNC Control Systems

High-end CNC control systems like Siemens SINUMERIK ONE and Heidenhain TNC 640 are the core of 5 axis machining centers. These control systems use sophisticated five axis linkage interpolation algorithms to convert the CAD model into a smooth, precise tool path. They also carry out real, time collision detection to avoid tool and machine damage during machining.

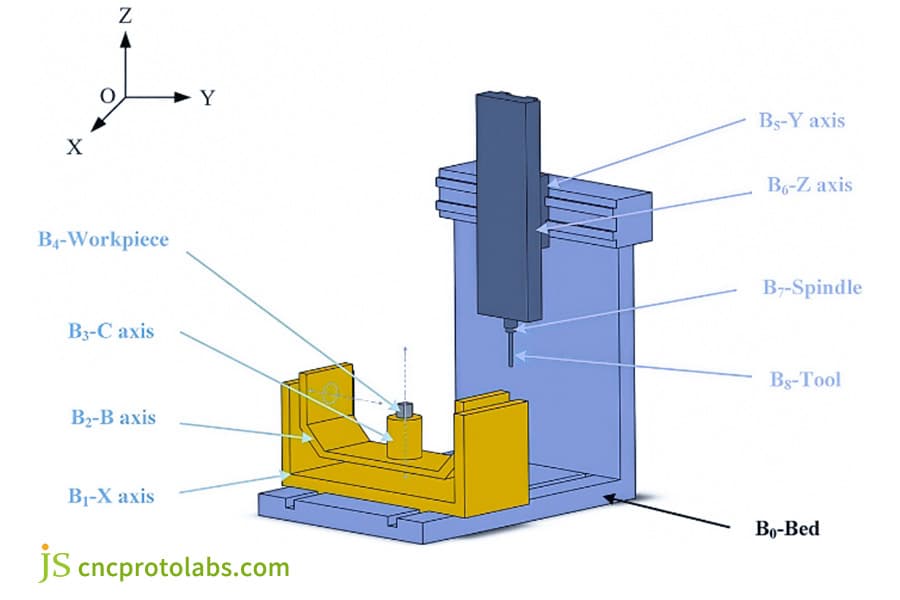

Structural Forms: Dual Rotary Table vs. Rotary Table with Swiveling Head

5 axis vertical machining center is usually of two main structural types:

- Dual Rotary Table: The two rotary axes are on the worktable side. This is a right choice for small many-sided parts. The workspace is less, but the machining accuracy is higher.

- Rotary Table with Swiveling Head: One rotary axis is on the worktable, and the other is on the spindle head. It is a good solution for big deep-cavity parts. The machining range is larger, however, more spindle rigidity is required.

Figure 1: An animated diagram showing the linear and rotational movement of a tool around a workpiece, illustrating the principle of multi-axis machining.

How To Choose a High-Performance 5 Axis Vertical Machining Center?

Precision Foundation: Positioning Accuracy and Repeatability

Two main criteria used to evaluate the accuracy of a 5 axis vertical machining center are:

- Positioning accuracy: It measures how far the tool's actual location is from its theoretical one. Top-tier machine tools can usually attain 0.003mm.

- Repeatability: It refers to the error when the tool is placed in the same spot multiple times. Usually 0.0015mm.

These two performance parameters lead to the dimensional accuracy and surface finishing of the products.

Stability Guarantee: Machine Tool Rigidity, Thermal Stability, and Dynamic Performance

- Machine Tool Rigidity: The mineral casting bed efficiently dampens the vibration, thus improving the stability during the machining process.

- Thermal Stability: Spindle thermal expansion compensation technology helps maintain machining accuracy by reducing the effect of temperature variations.

- Dynamic Performance: With the help of linear motors and roller guides, high-speed motion is achieved, thus, the maximum spindle speeds can be 30, 000 rpm, which is a perfect cutting speed for aluminum alloys.

High-Efficiency Production Support: Tooling and Tool Magazine System

- Tool Magazine Capacity: A tool magazine with over 60 tools can fulfill the needs of manufacturing complex components and thus significantly decrease the time required for tool change.

- Tool Change Speed: Automatic Tool Changer (ATC) time is less than 2 seconds, hence the production efficiency is increased.

- Specialized Tools: Long, neck tools designed especially for 5 axis machining and dynamic balancing technology are used for deep cavity machining so that tool interference can be avoided.

5-Axis Machining Center Accuracy Comparison Table:

| Model | Positioning Accuracy (mm) | Repeatability (mm) | Applicable Industries |

| Entry Level Model | ±0.005 | ±0.002 | General Machinery |

| Mid End Model | ±0.003 | ±0.0015 | Automotive Parts |

| Premium Model | ±0.001 | ±0.0005 | Aerospace, Medical |

Looking for a high-performance, cost-effective 5 axis vertical machining center? Contact JS Precision to get a free machine tool selection comparison list and avoid procurement risks.

Figure 2: A compact industrial 5-axis vertical machining center with a blue and grey enclosure and a control pendant on the side.

Which Problems Can 5 Axis Milling Services Solve That 3-Axis Cannot?

Problem 1: High Surface Smoothness Machining of Complex Surfaces

If you look at a turbine blade and propeller, 5 axis milling services can hold the tool precisely perpendicular to the surface throughout the entire machining process, thus, it is not the "step effect" in 3 axis machining, and it got a high surface finish (Ra 0.2, 0.8 m). The complex parts 5-axis machining of this type of component can only be efficiently achieved through 5-axis linkage.

Problem 2: Deep Cavities, Undercuts, and Inaccessible Features

In the case of molds with angled ejectors and medical implants with undercut structures, three axis machining is not able to reach the machining areas due to the limited accessibility. 5 axis milling services can change the tool angle through the rotary axis to machine the sidewalls, bottoms, and negative angle areas, thus, the design freedom of parts is greatly expanded.

Problem 3: Single, Set "Complete Machining" of Polyhedral Parts

For example, engine cylinder heads have features in five different directions. In this case, three axis machining needs five setups, which will take several hours. 5 axis milling services can finish all the machining in a single setup, thus, the setup time is reduced to a few minutes and the errors caused by multiple setups are eliminated.

| Machining Part Type | 5-Axis Milling Services Machining Error (mm) | 3-Axis Machining Error (mm) | Single-Piece Machining Time (min) | Daily Capacity (pieces) | Single-Piece Machining Cost (USD) |

| Turbine Blade | ±0.002 | ±0.015 | 45 | 12 | 185 |

| Engine Cylinder Head | ±0.003 | ±0.020 | 80 | 8 | 290 |

| Medical Implant | ±0.001 | ±0.010 | 35 | 15 | 220 |

| Optical Component Support | ±0.0008 | ±0.008 | 30 | 18 | 160 |

| Mold Angled Ejector | ±0.0025 | ±0.012 | 50 | 10 | 145 |

Figure 3: A cross-section technical diagram labeling all axes (X, Y, Z, B, C) and components of a 5-axis machining center.

How To Get a Quote For Custom 5-Axis Machining Services?

Step 1: Provide Clear and Complete Technical Documentation

Delivering a thorough technical documentation package is essential in setting the stage for a precise custom 5-axis machining quote. The clients are expected to supply a detailed 3D model (preferably in STEP format) along with 2D drawings that highlight the key dimensions, tolerances, and surface finish specifications.

Step 2: Obtain a Smart Quote Including DFM Feedback

Once the documents are uploaded to JS Precision, the system will automatically come up with a preliminary quote based on materials, time, and processes. Within 4 hours, a design for manufacturability (DFM) specialist will provide a detailed report pointing out potential optimization points that may additionally reduce costs.

Step 3: Confirmation and Transparent Project Tracking

Upon confirming the order, clients are able to monitor the production progress in real-time via a dedicated portal. At critical milestones such as first article inspection, inspection reports and photos will be handed over, making the entire process manageable and traceable.

Want a transparent custom 5 axis machining quote? Submit your technical documents and receive a detailed quote including DFM feedback within 4 hours.

How To Optimize Design For Cost-Effective Complex Parts 5-Axis Machining?

Design Golden Rules: Avoiding Tool Interference and Limiting Parameters

- The radius of the inner corner must be at least 1/3 of the tool diameter, the use of ultra small tools should be avoided.

- The depth-to-width ratio should not be greater than 8:1 to minimize tool vibration and deflection.

- Features that necessitate excessively long or thin tools to access should be avoided, this results in shorter machining time, less tool wear, and compliance with ASME B5.54-2011 standards.

Material and Process Synergy: From Titanium Alloys to PEEK

| Material Type | Cutting Speed (RPM) | Tool Wear Rate | Cooling Requirements | Applicable Scenarios |

| Applicable Scenarios | 30000 | Low | Air Cooling | Aerospace Structural Components |

| Stainless Steel 316L | 15000 | Medium | Emulsion Cooling | Medical Devices |

| Titanium Alloy Ti6Al4V | 12000 | High | High Pressure Cooling | Engine Parts |

| PEEK | 10000 | Medium | Air Cooling | Medical Implants |

Different materials have different cutting characteristics. Selecting appropriate process parameters can improve machining efficiency and reduce costs.

The Value of Pre-Simulation: Avoiding Real, World Mistakes through Virtual Machining

In the CAM programming stage, it is necessary to use software such as VERICUT for comprehensive tool path simulation and collision detection, which can prevent machine tool collision losses worth tens of thousands of dollars and optimize machining time. For complex parts 5-axis machining, simulation can reduce the trial cutting time by more than 50%.

Case Study: Aerospace Titanium Alloy Engine Bracket, Reduced From 18 Hours To 5 Hours, Reducing Weight By 35%

Challenge: Manufacturing Dilemmas of Topology-Optimized Components

A customer had designed a topology, derived titanium alloy (Ti6Al4V) engine mount. The shape was very complex, like organic mesh topology with curved surface and uneven wall thickness (the thinnest part is only 1.2mm).

Multi-part welding of traditional way had been heavy and weak in strength, and three axis machining had been unable to machine complex curved surfaces. 5 axis CNC machining was the only method that could work.

JS Precision Solution

1.DFM Collaborative Optimization:

After combining the features of complex parts 5-axis machining, the engineers proposed raising some very sharp internal angles from R2 to R3. They checked using tolerance analysis software to make the tolerance zones in non-critical areas equal. This allowed them to machine more easily, risk of tool interference was lowered, product performance was maintained at the same time.

2.Dedicated Tooling and High-Speed Strategy:

To suit the cutting characteristics of Ti6Al4V titanium alloy, a dedicated vacuum fixture was designed. Vacuum pressure was accurately adjusted at 0.08MPa in order to maintain the rigidity of the thin-walled part.

A high-speed (12000 rpm), shallow depth-of-cut, and fast-feed cycloidal milling approach was used for the working time being significantly reduced and the thermal deformation being kept within 0.005mm.

3. Five Axis Continuous Finishing:

A 6mm coated carbide ball end mill was applied. To finish all curved surfaces, a five axis continuous interpolation algorithm was utilized, which also allowed the surface quality to be consistent and thus the contour accuracy to be achieved. Manual polishing afterward was unnecessary, which largely cut down the labor costs and the risk of secondary damage.

Results

The component was milled out of a single titanium blank, thus the first functional prototype, which complied with all the design requirements, was successfully produced.

The single-piece machining time was brought down from the estimated 18 hours to 5 hours, thus the costs were reduced by 45%. The part survived a 150% load fatigue test and was 35% lighter than the original welding solution, which led the customer to make a small, batch order.

Want to significantly improve the efficiency of your complex parts machining? Contact JS Precision, share your project challenges, and receive a free customized 5 axis CNC machining services solution.

Figure 4: A lightweight, intricate aerospace bracket made of titanium alloy with a lattice structure, showcasing precision multi-axis milling capabilities.

FAQs

Q1: How much more expensive is 5 axis CNC machining than 3 axis?

Normally it is 30%-100% more expensive. However, for complicated parts, it can combine several processes, decrease tooling and fixture time, and thus, eventually lowers costs. Therefore, it actually saves money and increase efficiency.

Q2: What is the highest achievable accuracy?

In a controlled environment, a top, class 5 axis machining center can reliably deliver a contour accuracy of 0.01mm and a positioning accuracy of 0.002mm. This precision is suitable for high, end manufacturing.

Q3: What is the largest part that can be machined?

It is determined by the machine tool travel. Generally, JS Precision's 5 axis vertical machining center is made to work within an XYZ range of 800x600x500mm and has a rotary table diameter of 500mm, which is capable of handling a vast majority of machining requirements.

Q4: What is the typical lead time from quotation to delivery?

It normally takes about 5-10 business days from document confirmation to shipment for aluminum parts of standard complexity, for steel parts or more complicated components, it takes 10-15 business days, which is actually faster than average in the industry.

Q5: How do you ensure consistency in large batches of parts?

We achieve consistency by performing a first, piece inspection fully dimensionally, conducting SPC sampling of critical dimensions during production, and regularly precision calibrating machine tools. In this way, we are confident that every batch of parts will be in compliance with the set quality standards.

Q6: Is it suitable for small-batch production?

Certainly. Our 5 axis machining service offers both agility and effectiveness, thus it fits perfectly small to medium batch production of complex parts. This keeps you always ready to meet the market demands.

Q7: Is there a minimum order quantity (MOQ) requirement?

In the case of custom 5-axis machining, we are able to run small, batch productions starting with a single, piece prototype up to hundreds of pieces. There is no fixed MOQ requirement, thus allowing us to respond to different customers' needs suitably.

Q8: How is my design intellectual property protected?

JS Precision adopts multiple measures such as signing NDAs with customers, encrypting file transfers throughout the process, and implementing confidentiality management in the production area to guarantee 100% safety of your designs, so you no longer have to worry.

Summary

5-axis CNC machining has evolved from cutting-edge technology to a fundamental strategic resource driving product innovation.

It is not just about processing parts, but also the core means of transforming complex design concepts into reliable physical reality with the highest efficiency and optimal cost. By mastering its technological boundaries and business logic, one can grasp the competitive key of high-end manufacturing.

Go ahead and make complexity work for you!

Share your complex part drawings with the JS Precision expert team, and we will get back to you within 24 hours with a custom 5 axis machining solution, in-depth DFM analysis, and a competitive quote, thus enabling you to take the first step towards turning blueprints into precision objects.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com