Precision CNC milling pursues ±0.01mm tolerance, which represents control at the ultimate microscopic scale. Such precision allows two fitted metal parts to be fitted perfectly without additional fitting, it allows the leakage rate of fluid valves to approach zero, and it allows high-tech equipment to possess a stable and reliable core.

However, high precision CNC milling is not an easy undertaking, it is a systems engineering project entailing knowledge of machine tools, cutting tools, materials, and processes.

This guide will walk you deep into the mysteries of reaching ±0.01mm, analyze the cost structure, and reveal how to find the optimal balance between precision, productivity, and cost in the complex choice between 3-axis vs 5-axis CNC milling.

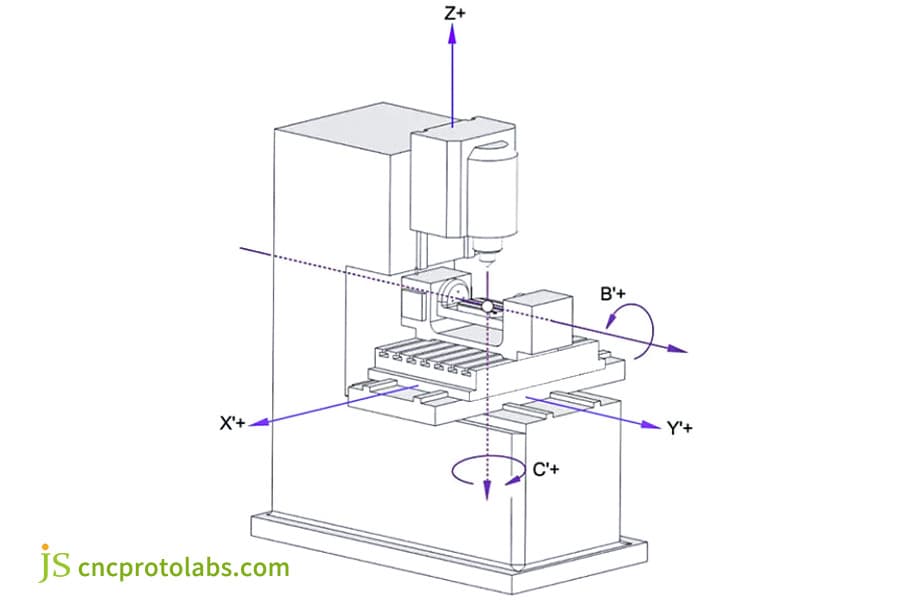

Figure 1:The figure shows the working principle of a CNC milling machine, where the workpiece is fixed on a vise and precision cut by a rotating tool.

Key Answer Summary

| Customer Goals | Technical Challenges & Solutions | JS Precision's Value-Added Services |

| Realize Ultra-High Precision (± 0.01mm) | Requires top-of-the-line equipment, temperature-controlled environments, precision cutting tools, and sophisticated processes. The main difficulties to overcome in this field include heat distortion, vibration, and tool wear. | We guarantee stable CNC milling accuracy and cost effectiveness through a fully closed-loop servo system, workshop temperature control, and end-to-end tool life management. |

| Handle Complex Parts | Complex parts CNC milling requires multi axis linkage, intelligent CAM programming, and extensive experience to avoid interference and deformation. | Our team of experts offering 5-axis CNC milling services is good at dealing with challenging structures like thin walls, deep cavities, and an irregular curved surface, and free DFM analysis is also offered. |

| Cost Control of Projects | The cost of high precision CNC milling depends upon materials, labor times, and yield. Optimizing design, process, and batch production are key. | We provide transparent quotations and support you in balancing CNC milling accuracy and cost with process optimization to avoid paying for unnecessary "over-precision." |

Precision CNC Milling: How JS Precision Achieves ±0.01mm Tolerance

The company where I work, JS Precision, has provided precision CNC milling services to over 500 clients across the medical, aerospace, automotive, and optics industries for the last 15 years.

We have machined engine blades for aerospace companies, controlling tolerances to ±0.008mm using 5-axis technology, and mass-produced Ti-6Al-4V implants for medical clients, with material specifications strictly following the ASTM F136 surgical implant titanium alloy standard published by ASTM International.

With these practical experiences, we have summarized a systematic approach: first, using THERMO-FIDELITY series high-stability machine tools to reduce temperature deformation, then, using Swiss STUDER cutting tools to control cutting errors, and finally, machining in a workshop with a constant temperature of 20±1℃.

We have also established a "5-step quality inspection process" from raw material inspection to finished product CMM measurement, with data recorded at each step.

This guide summarizes our technical know-how, and each suggestion has been verified by real project examples. For instance, how to choose cutting tools based on materials, and how to reduce vibration by programming, some experiences distilled from solving hundreds of precision problems, which you can fully trust.

Want to validate how practical this guide is? Send us your part tolerance requirements and JS Precision will send free, experience-based process advice that will help you avoid common pitfalls. You will also receive our "±0.01mm Tolerance Implementation Checklist."

What Is Precision CNC Milling? From Concept To Widespread Applications

After understanding JS Precision's practical experience, you might ask what exactly precision CNC milling is. How does it differ from ordinary CNC milling? Next, I'll clarify this for you, from concept to application.

Beyond "Cutting": The Core of Digital Subtractive Manufacturing

Precision CNC milling is a technology in which a computer-controlled rotating tool "carves" out parts from a block of material, using a digital model as a blueprint. It has a higher degree of digitalization, with CAM pre-set steps that avoid human error, and stronger consistency, batch error ≤ ±0.005mm, compared to ordinary CNC milling.

Precision CNC milling, for example, can achieve a position error of ≤±0.008mm for 100 parts when machining automotive prototype parts, but ordinary CNC machining might have an error of about ±0.05mm, which clearly cannot satisfy the high requirements for fitting such parts into high-performance engines.

Ubiquitous Applications:

Precision CNC milling covers several significant sectors:

- Medical Field: Surgical instrument teeth, titanium alloy implants, tolerance ≤±0.01mm.

- Aerospace Industry: Engine blade cooling holes, structural component connection holes, tolerance ≤±0.008mm.

- Automotive Industry: high-performance engine pistons, gear prototypes, tolerance ≤±0.015mm.

- Optics Industry: lens barrel threads, lens brackets, tolerance ≤±0.005mm.

Want to see if your parts are suitable for precision CNC milling? Upload your part's 3D drawings, and then JS Precision engineers will analyze application compatibility for free. You can also download a collection of case studies about CNC milling services for your industry and find solutions from similar projects.

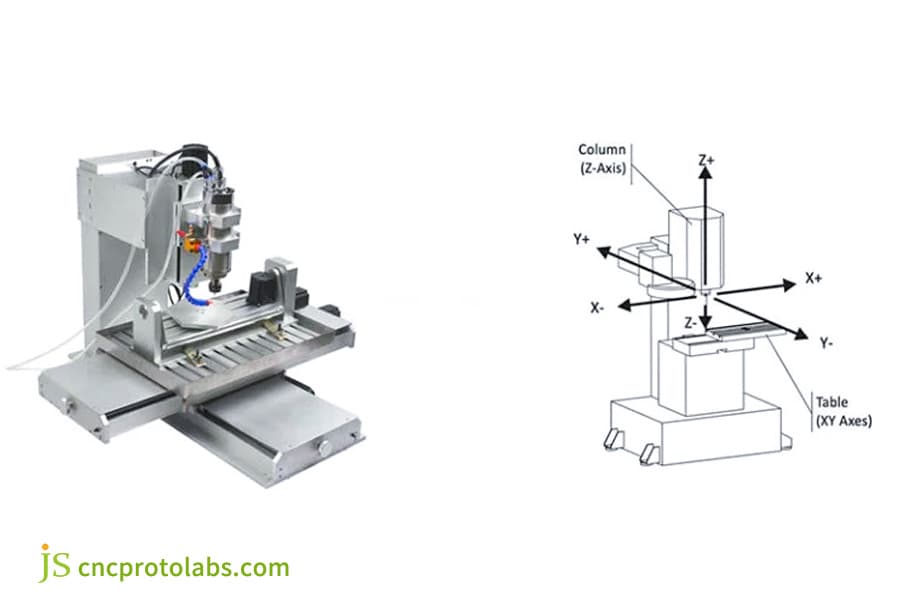

Figure 2: Numerical Control (CNC) milling utilizes rotating cutting tools that move along multiple axes to machine complex shapes from solid materials such as metals, plastics, and composite materials.

±0.01mm Tolerance CNC Milling: Does It Apply To All Types Of Materials?

After understanding the application fields of precision CNC milling, you are sure to ask: Can ±0.01mm tolerance CNC milling be realized for all materials? Let me give a detailed analysis.

Material Machinability and Ultimate Precision

As shown by the table below, large differences exist among different materials in the difficulty of achieving a ±0.01mm tolerance.

| Material Type | Machinability | Difficulty of Achieving ±0.01mm Tolerance | Typical Application Scenarios |

| Aluminum Alloy (6061) | Excellent | Low | Aerospace structural components, housings |

| 304 Stainless Steel | Good | Medium | Medical device and valve component |

| Titanium Alloy (Ti-6Al-4V) | Poor | High | Medical implants, aero-engine parts |

| Engineering Plastics (POM) | Good | Medium | Optical equipment brackets |

For example, aluminum alloy 6061 can achieve a ±0.008mm tolerance using ordinary precision machine tools, with titanium alloy, specialized hard milling tools and high-speed strategies would be required to achieve a ±0.01mm tolerance.

Beyond the Material: A System for Achieving Super-Tolerance

Achieving a tolerance of ±0.01mm requires a complete "ecosystem," which JS Precision builds from four aspects:

- High-stability machine tools: Choosing precision 5-axis machine tools with spindle runout ≤0.001mm.

- Temperature-controlled environment: Workshop temperature 20±1℃, humidity 50±5%, to avoid thermal expansion and contraction of materials.

- Precision cutting tools: Using micro-diameter carbide cutting tools with a cutting edge accuracy of ±0.002mm.

- Senior engineers: With over 8 years of average experience, depending on the material characteristics, such as titanium alloys, the feed is reduced by adjusting the cutting parameters.

Decoding The Cost Structure Of High Precision CNC Milling

After understanding the impact of materials on tolerances, you might wonder: what constitutes the cost of high precision CNC milling? Why do different parts have such different prices even with the same ±0.01mm tolerance? Let me break it down.

Time is Money: Machine Tool Runtime and Setup

Time-related costs constitute the highest percentage of the unit cost of high precision CNC milling, as shown in the table below.

| Cost Components | Percentage (%) | Influencing Factors |

| Programming and Preparation Time | 15-20 | Part geometric complexity, tolerance requirements. |

| Machine Tool Runtime | 30-40 | Material hardness, cutting parameters, number of features. |

| Post-processing | 10-15 | Surface treatment requirements, deburring difficulty. |

| Quality Inspection | 10-20 | Tolerance accuracy, number of inspection items. |

Programming of a simple aluminum alloy sheet takes 1 hour, while operating the machine tool takes 2 hours. For example, for a part in titanium alloy with 10 micro-holes, programming takes 3 hours and operating the machine tool takes 8 hours, doubling the cost.

Hidden Cost Drivers: Geometric Complexity and Tolerances

Geometric complexity and the associated tolerance requirements of the parts may result in "hidden costs":

- Deep cavity features: Deep holes require extended cutting tools, which are prone to vibration, speed reduction, increased time, and tool wear.

- Thin-walled features: Thinner walls less than 0.5mm tend to deform and need many cooling cycles with special fixtures, therefore increasing the cost.

- Narrow tolerances: Requiring tighter tolerances from ±0.05mm to ±0.01mm, significantly increase quality inspection time, and require rework, thus increasing the cost by 50%.

Want to optimize the cost of ±0.01mm tolerance CNC milling? Upload your part drawings, and JS Precision engineers will help you analyze process optimization points (including simplifying non-critical features and adjusting tolerances) to reduce machining time, tool wear, and also provide a "Cost Optimization Checklist".

Figure 3: CNC milling can produce complex shapes and designs that would be difficult or impossible to create with traditional manufacturing methods.

Complex Part CNC Milling: What Are The Challenges? How Does JS Precision Solve Them?

The next part will elaborate on the problems in the machining of complex parts, which can be found from understanding the cost structure: multiple clamping errors, thin-walled deformation, and deep-hole vibration. Following is a discussion on the challenge of complex parts CNC milling and the solution provided by JS Precision.

The Magic of Multi-Axis Machining: When to Upgrade to 5-Axis?

The main differences between 3-axis vs 5-axis CNC milling determine their ability to handle complex parts. A detailed comparison is shown below:

| Comparison Dimensions | 3-Axis CNC Milling | 5-Axis CNC Milling |

| Applicable Part Types | Plate-like, 2D contour parts. | Complex curved surfaces, multi-angle feature parts. |

| Number of Clampings | Multiple | One |

| Tolerance Control Capability | Medium, prone to tool marks. | High, more stable overall accuracy. |

| Unit Cost (Simple Parts) | Low | High |

| Unit Cost (Complex Parts) | High (Multiple Clampings) | Low (Efficiency Improvement) |

For example, machining an engine bracket with tilted holes requires 3 clampings on 3-axis (error may exceed ±0.03mm), while 5-axis requires only one clamping (error ≤ ±0.01mm).

Conquering Complexity: How We Do It

JS Precision provides three main solutions for any complicated issues arising during the process of CNC milling.

- Advanced CAM Software Optimisation: Simulated machining to avoid collisions, automatic toolpath adjustment for deep cavities.

- Customized Tooling Strategies: Thin-walled "layered cutting" ≤0.1mm per cut, reducing the force, micro-hole "spiral cutting" to avoid chipping.

- In-Machine Measurement Technology: Real-time dimensional measurement during machining using in-machine probes, such as every 10 minutes for thin-walled parts, timely adjustment for deformation.

Encountering complex parts CNC milling challenges? Schedule a consultation with a JS Precision engineer to get free part structure diagnosis, advice on 3-axis vs 5-axis CNC milling selection, and access to the "Complex Parts CNC Milling Guide" for reference on solutions for similar projects.

3-Axis Vs. 5-Axis CNC Milling: Choosing The Best Technology Path For Your Project

After understanding solutions for complex parts, you might struggle with the question: Should I choose 3-axis or 5-axis milling for my project? Choosing the right one saves money, while choosing the wrong one will bring accuracy issues. Next, I'll help clear up your selection logic.

The Power of Simplicity: Cost-Effectiveness of 3-Axis Milling

The following high-cost-performance scenarios are suitable for 3-axis CNC milling:

- Parts: Plates/blocks without complex curved surfaces, such as square housings.

- Tolerance requirements: ±0.05mm - ±0.02mm (common automotive parts, casing of electronic devices).

- Batch production: Large-volume production of simple parts. For example, the production of 1000+ gaskets in one month.

For example, a simple aluminum alloy plate with 4 holes will cost only $20 per piece in 3-axis machining, but in 5-axis machining, it would cost $35, which is completely unnecessary.

5-Axis CNC Milling: More Than Just Complexity, It's About Precision and Efficiency

The following scenarios are suitable for 5-axis CNC milling, which shows the advantages in precision and efficiency:

- Parts: Complex curved surfaces, multi-angle holes (e.g., aerospace blades, medical implants).

- Tolerance requirements: ≤±0.02mm, for example, optical lens barrels and precision molds.

- Clamping difficulty: The part is of an irregular shape. Multiple clamping operations are error-prone. Examples include irregular bone implants.

For instance, the 3-axis takes 8 hours with an error that may exceed ±0.02mm for the machining of a three-15°-inclined-hole titanium alloy part, whereas a 5-axis takes 3 hours with an error of ≤±0.01mm, for a 10% lower total cost.

Struggling with 3-axis vs 5-axis CNC milling? Send in your project requirements, and JS Precision engineers will recommend the most cost-effective technology path considering part complexity and precision requirements for a given batch size and present this in a cost comparison table to intuitively help you make a decision.

Figure 4: Five axis CNC milling machines can shorten setup time, improve accuracy, and produce high-quality components that meet the strictest tolerance requirements.

Case Study: Conquering ±0.008mm! 5-Axis Milling Empowers Next-Generation Medical Implants

After all that theory, let's take a look at a real-world case. This case will give you a clearer understanding of how high precision CNC milling solves real-world challenges, especially in achieving ultimate precision for complex parts CNC milling.

Customer Pain Points

A medical technology company needs to fabricate porous bone implants of medical-grade titanium alloy (Ti-6Al-4V). This part entails several difficulties:

- The structure is complicated, with 20 thin walls of 0.3mm and 50 micropores of 0.5mm in diameter, with only 0.2mm between the walls.

- The tolerances are rigorous, with the overall tolerance controlled within ±0.01mm and the micropore diameter error not exceeding ±0.005mm.

- The surface finish must be high, and no burrs or stress concentration points can be allowed lest inflammation may occur after implantation.

The client previously contacted two other manufacturers, but their respective productions failed in thin-wall deformation and precision issues in micro-holes. It was at this point that they approached JS Precision before the project got delayed.

JS Precision Solution

Our team, after analyzing the situation for 3 days, came up with a complete 5-axis machining solution:

Process Selection:

We applied 5-axis simultaneous precision CNC milling because there are several tilted micro-holes in this part, and all features can be machined in one setup to avoid the positioning error brought by several setups. We also customized a dedicated vacuum fixture to firmly secure the parts and reduce machining vibration.

Tooling and Programming:

0.2mm diameter micro-diameter carbide tools of Japanese OSG brand were used, with the precision of the cutting edge given as ±0.002mm.

In programming, "high-speed shallow cut" strategy was adopted: 15000rpm of spindle speed, feed rate 50mm/min, and depth of cut of 0.05mm per pass to minimize the cutting force and thermal deformation. A "helical cutting" method for the micro-hole was adopted to avoid tool breakages.

Quality Control:

The machining was monitored online with the use of a laser displacement sensor, with dimensions measured every 5 micro-holes machined, and immediate compensation for tool wear made.

Full-dimensional verification after machining was done with a Zeiss CONTURA G2 coordinate measuring machine, with an accuracy of ±0.001mm, by inspecting each thin-walled section and micro-hole.

Our Final Success

The critical dimension control in our final delivered implant was within ±0.008mm, much better than the requirement of our customer, which was ±0.01mm. Excellent performance, thin walls without any deformation, the maximum error of the diameter of micropores is only ±0.003mm, the surface roughness Ra0.8μm without burrs.

Our client's product successfully reached clinical trials and we became their core supplier, subsequently taking up three more similar projects with them.

Figure 5: CNC Titanium Medical Implants

How To Get A CNC Milling Service Quote For Your Prototype?

If you've read those case studies, when you need to get a quotation for CNC milling services, you probably don't know what documents you need to prepare. You may also worry about the inaccuracy of the quotation or complicated procedures. I'll be teaching you how to efficiently obtain a quote.

The "Golden Three Elements" of a valid quote

The following three inputs are needed:

- Complete 2D/3D drawings: specify such things as tolerances ±0.01mm and material type 6061.

- Quantity and delivery time: for example, "5 prototypes, delivered within 10 days" or "Small batch of 50 pieces, delivered within 30 days"

- Requirements on surface: such as "Alloy anodizing," "Stainless steel passivation," "Ra0.4μm

If the above information is not available, this quotation will be subject to more than a 20% error margin or cannot be quoted at all. For example, if only "machining aluminum alloy parts" is provided without drawings or tolerances, a rough range can only be estimated, which has no reference value.

JS Precision Quoting: How It All Works from Document to Quote

The quote process here at JS Precision is quite straightforward and transparent:

- Document Transfer: Transfer the 3D/2D drawings, fill in the quantity, delivery date, and surface treatment requirements.

- DFM Analysis: Manufacturability analysis is done by engineers in 8 hours, feasibility of tolerance is checked, and features are optimized.

- Quotation Generation: A detailed quotation including process specification, itemized cost, delivery time, and terms of payment will be issued within 24 hours.

- Q&A and Adjustments: Quotation questions will be answered and the process adjusted where budget allows to relax any non-critical tolerances if that reduces costs.

Practical Strategies To Balance CNC Milling Accuracy And Cost Effectively

How can one ensure accuracy with low cost after getting the quotation? Of course, there are ways to balance CNC milling accuracy and cost. I will be sharing two practical approaches with you.

"Assignment as Needed": The Art of Loosening Tolerances for Non-Critical Features

Many customers specify an overall tolerance that represents the entire part, such as ±0.01mm for the entire part. This level of precision is really not needed for features that are non-critical.

For example, for aluminum alloy shells, a tolerance of ± 0.01mm is only required for fitting holes, and non fitting features such as side and top surfaces can be relaxed to ± 0.05mm without affecting use.

This reduces costs: the machining time for non-critical features is reduced by 30%, tool wear by 20%, with an even greater saving in batch production.

Early Collaboration with Engineers: How to Maximize the Value of DFM

Involvement by JS Precision engineers at the design stage enables DFM optimisation, balancing cost and accuracy right from the start.

- Optimize fillets: Change the 0.1mm fillet to 0.3mm in order to avoid special tools and decrease machining time.

- Avoid deep cavities: Minimize cavity depth when possible and meet requirements by flattening or shortening the tool. Vibration is to be avoided.

- Standardization of hole diameters: Reduce the variety in hole diameters to decrease the frequency of tool changes, thereby improving efficiency.

FAQs

Q1: What is the minimum size of a feature that can be machined to obtain a ±0.01mm tolerance?

That depends on the feature type and material. Generally speaking, the minimum diameter of a milling hole can be as small as 0.5mm, but for tolerance purposes it is advisable to design above 1mm. If you are not sure, please consult with a JS Precision engineer.

Q2: Which among the three-aluminum, steel, or titanium-is the most expensive for precision?

Among all, the price of titanium alloys is the highest. Due to their high strength combined with poor thermal conductivity, tool wear during machining happens rapidly, this requires longer times and more stable machine tools, which raises the price of high precision CNC milling.

Q3: Is 5-axis milling always more expensive than 3-axis milling?

Not necessarily. Although it is more expensive to make simple parts by 5-axis machining, it may save setups and fixture costs on complex parts and will also improve accuracy, possibly lowering the overall cost of complex parts CNC milling.

Q4: Does my prototype need additional surface treatment?

It depends on the functional needs. If anodizing is applied to aluminum alloys, it can increase wear and corrosion resistance, similarly, the passivation of stainless steel will enhance rust resistance. The recommendations according to application scenarios are made by the JS Precision engineers themselves.

Q5: Is it possible to machine hardened steel with a hardness over HRC 50?

Yes, JS Precision has high-speed hard milling technology that can directly mill mold steel with hardness up to HRC 60, avoiding electrode machining and EDM processes, thus increasing efficiency.

Q6: What file formats do you support?

JS Precision recommends 3D formats with complete geometric information, such as STEP, IGES, and X_T, besides 2D engineering drawings in PDF or DWG format. These formats have the capability to present completeness of information.

Q7: How long does it normally take from inquiry to prototype delivery?

JS Precision can provide the first batch of prototypes for standard materials and non-extremely complex parts within 3-5 business days after confirmation of the order. For rush orders, they can expedite according to customers' requirements.

Q8: How will you control unit cost for the small batch (<10 pieces)?

Optimize the part layout to reduce material usage, use standard tools and standardized processes as much as possible. JS Precision engineers can also provide suggestions for cost optimization in small batches in order to lower the unit cost.

Summary

To achieve a precision tolerance of ± 0.01mm, it relies not on a single technology, but on a complete solution from material selection, equipment selection to process optimization.

The experience of JS Precision in precision CNC milling proves that high precision and reasonable cost can be entirely achieved just by finding the right approach. We understand that behind every ±0.01mm is your ultimate pursuit of product performance and market success.

Turn your design into reality now! Please upload your 3D files to JS Precision's instant quote platform to experience professional and fast CNC milling services.

Our engineering team is happy to provide free tolerance assessments and process solutions for you within 24 hours. You can also obtain the "High Precision CNC Milling Cost Optimization Handbook" to explore the best path to balance the accuracy and cost of CNC milling together.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com

Resource