CNC machining quote mark the beginning of any manufacturing job, and many people face the issue of significant variations and comparability. This ambiguity not only hampers the progress of projects, and budgets can also exceed, resulting in the timeline of the actual final launch of products getting affected.

On the contrary, procuring the right quotes, as well as the supplier, is a process of finding the right mix of technical, cost, and supplier chain considerations. Whether you need "CNC services near me" or a custom precision machining solution, the insights in this resource will ensure you minimize errors.

Core Answer Summary

| Core Questions | Key Answers | Value for You |

| How to Get an Accurate Quote? | Accurate quotes are based on clear design documents, such as STEP/2D drawings, with well-defined tolerances, materials, and quantities. Poorly defined requirements inevitably lead to estimation errors. | Master standard inquiry methods to make sure that the received CNC machining quotes are based on the same standards and can be effectively compared. |

| How to Compare Different Suppliers? | Go beyond unit price and comprehensively evaluate the technical solution provided DF&M feedback, quality process provided FAI report, scope of services provided capability of CNC machining on demand, and total cost of ownership. | Develop a multi-dimensional evaluation framework to choose the custom precision machining partner that is able to offer better long-term value and reliability. |

| When to Do Volume Conversion? | When annual demand is stable, design is fully finalized, and fixed costs constitute a high percentage of the unit price for low volume CNC machining, shift to high-volume production for cost amortization. | Correctly master the inflection point of production scale to enable the best cost-effective transition from prototype to production and avoid unnecessary wastes of funds. |

Key Takeaways

Design documents are the backbone of quotations: When comprehensive 3D models, 2D engineering drawings, and critical tolerances are provided, there can be an improvement of over 70% in the accuracy of the quotation.

A supplier’s DFM expertise is really precious: Suppliers that take the initiative to provide suggestions on how to optimize can definitely reduce up to 30% cost of parts CNC machining in the supply chain itself.

"Nearby" is not the same thing as "best": While assessing CNC services near me, the priority must shift away from location, towards competency, logistical integration, and collaboration for maximum efficiency.

The core of volume conversion is demand stability: Hasty transition to high volume CNC machining before the design completion would increase the generation of scraps or modifications, thereby being counterproductive.

Why Trust This Guide? JS Precision CNC Machining Quotes Based On Experience

You surely want a capable and professional team for a partner, and the credibility of this guide comes from JS Precision's years of experience within the industry.

For the last 15 years, I ballpark that we have focused on the CNC machining process and have done over 100,000 quotes about CNC machining. Our service has involved high-end clients across many industries such as automotive, medical, and electrical. In fact, our coverage involves all categories of machining, from precision parts to structural componentss.

Our quotes are strictly in accordance with the ISO 9001:2015 quality management system standard. Every data point is based on real production experience instead of a theoretical estimate. Be it rapid prototyping for low volume CNC machining or high volume CNC machining, we can provide an accurate quote and deliver reliably.

In the past, a customer had to bear high CNC machining part costs because his design was unreasonable. The production cost of customers was reduced by 35% after optimization through DFM analysis. There are many such successful cases, all of which are the best proof of our professional capabilities.

Want to verify our capabilities? Submit your basic part information, and our engineers will provide you with a preliminary cost estimate and process feasibility analysis free of charge, allowing you to directly experience our professionalism.

What Factors Affect Your CNC Machining Quote Accuracy?

CNC machining quote precision directly affects the cost of projects, and the variance in the quote has affected many people. Instead, there are three reasons for inaccuracy in CNC machining quote, and understanding these will help save you the trouble.

Design and Document Clarity: Fuzzy Input and Fuzzy Output

- Incomplete Geometric Information: STL file alone or part views with no assembly relation will necessitate guessing from suppliers, leading to quotations including risk premiums.

- Missing Key Manufacturing Notes: 2D drawings, which do not have a detailed thread definition, deburring, etc., can breed extra costs.

rigor in Technical Requirements Definition

Tolerancing and materials are important factors in CNC machining quotes. Simply applying ±0.025mm tolerances throughout the system can increase system cost by more than 50% more when compared to applying system precision to critical surfaces. Using "aluminum" alone can provide a possible pricing basis conflict when "6061-T6" is not mentioned.

Quantity and Supply Chain Assumptions

When the order quantity is not known, the suppliers are unable to provide accurate quotations regarding the low volume models and the processing of the high volume models. Additionally, the costs that are not communicated, such as special packing, FAI reports, among others, can result in additional costs being incurred.

| Tolerance Grade | Typical Application Scenarios | Relative Cost Coefficient | Applicable Process |

| ±0.125mm | Non-mating structural parts | 1.0 | Ordinary milling/turning |

| ±0.05mm | Generally mating parts | 1.8 | Precision milling/turning |

| ±0.025mm | Critical mating surfaces | 2.5 | Precision CNC machining |

| ±0.01mm | High-precision transmission parts | 4.2 | Five-axis simultaneous machining |

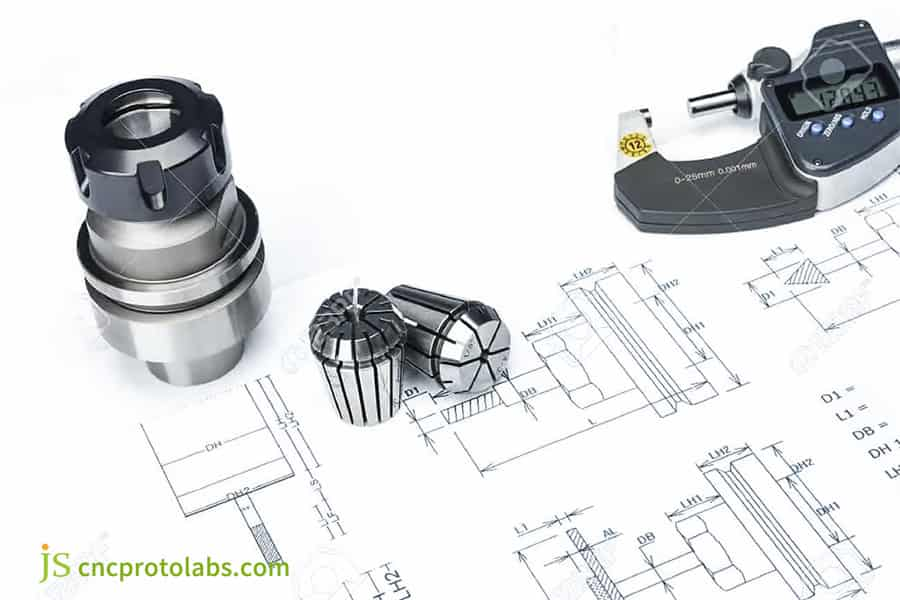

Figure 1 In order to obtain a CNC machining quotation as quickly and accurately as possible, you should prepare complete and detailed drawings.

Why Choose CNC Machining On Demand For Your Project?

When facing the challenge of market changes, an agile model of production will assist you in creating competitiveness, and CNC machining on demand is the best option. This is because it is highly beneficial in managing uncertainty and risk.

An Agile Shield Against Market Uncertainty

- Zero Inventory Pressure: The product does not require heavy capital expenditure for mass production, and a low number of units can be restocked according to demand.

- Rapid Iteration & Validation: Enables one-off or small-batch manufacturing with ease, with the facility for design change and functional validation.

Externalization of Professional Capabilities and Resources

You do not have to invest a lot of money in five-axis machine tools and other equipment for enhanced parts CNC machining services. At the same time, it is possible to delegate tasks like manufacturing, supply chain, and so on, and concentrate on your business alone.

| Material Type | Processing Difficulty Level | Processing Time per Piece (minutes/piece) | Surface Treatment Cost (USD/piece) | Applicable Production Mode | Tolerance Stability Rating (1-10) |

| 6061-T6 Aluminum Alloy | 1.2 | 8-15 | 3.5-8.0 | Low/High Volume Compatible | 8.5 |

| 7075-T6 Aluminum Alloy | 1.8 | 12-22 | 4.2-9.5 | Medium and Large Batch | 8.2 |

| 304 Stainless Steel | 2.5 | 18-30 | 5.0-12.0 | Full Batch Compatible | 9.0 |

| Titanium Alloy Ti-6Al-4V | 4.0 | 35-60 | 12.5-25.0 | Low Volume/Custom Production | 8.8 |

| POM Engineering Plastic | 1.0 | 6-12 | 2.0-5.5 | Small Batch Prototype | 7.3 |

Can Your Design Be Made? Exploring Complex Parts CNC Machining Capabilities

Of course, many people worry about the complexity associated with machining complex parts. However, due to technological advancements, it is not a challenge to machine complex parts using CNC. It is all about the technical expertise associated with the service provider.

Advanced Machining Technology Unlocks Complex Geometry

- 5 Axis Simultaneous Machining: This machine can move on any axis to the workpiece and perform the machining operation in a single setup to overcome the problems of multiple clamping.

- Mill-turn composite technology: Several operations are integrated within one machine to ensure the coaxiality of the rotating complex part.

Collaborative Boundaries Between Design and Manufacturing

Real power not only consists of having equipment but is based on DFM (Design for Manufacturing) as well. JS Precision engineers will analyze machining difficulties beforehand and provide optimization proposals to ensure manufacturability.

Following the ISO 13485 standard for complex parts machining requirements, we have successfully delivered thousands of complex parts. Want to know if your design can be efficiently machined? Submit a 3D model of your part, and our technical team will provide a free manufacturability analysis and optimization suggestions.

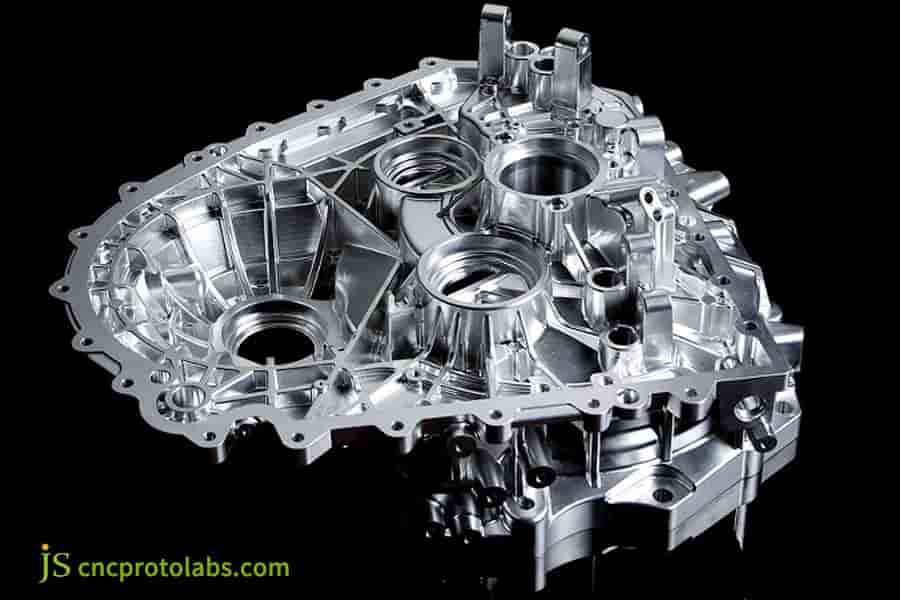

Figure 2 CNC machining, with its advanced features, performs excellently in manufacturing complex parts.

What Tolerances Are Realistic For Precision CNC Machining Parts?

A practical understanding of the true tolerance ability of CNC machining helps to optimize performance and cost in the design phase. Tolerance levels greatly differ based on the process and material used, and the relationship between cost and tolerance quality is non-linear.

Standard and Economic Tolerance Ranges

The standard tolerance for metal CNC machining part is ± 0.125mm, without additional cost. ± 0.025mm is a common threshold for precision CNC machining, beyond which the cost will significantly increase. Aperture tolerance H7 (such as Ø 10H7) is commonly used for precision fitting.

Key Factors Affecting the Costs of Tolerance

Material stability and feature size influence tolerance cost. It is easier to machine 7075 aluminum alloy with a tolerance of ± 0.02mm than to machine materials that are easily deformable, like POM. It is difficult and time-consuming to maintain tighter tolerances for small features and deep cavities.

How JS Precision Helped Electric Vehicle Companies Reduce Motor Housing Costs By 35%

Examples of projects can only be demonstrated with actual projects. Our electric vehicle motor housing project is a complete demonstration of our technical capability, cost optimization capability, or any capability.

Challenge: Expensive prototypes and unclear production cost feasibility

A complex aluminum alloy housing with cooling channels was designed by the client to encase a high-performance motor. The first 10 low volume CNC machining units were extremely costly, and the design was not suitable for mass production.

JS Solution: DFM-Driven Integrated Engineering

1.Production-Oriented DFM:

Our engineers re-designed the positioning of the strengthening ribs in thin-walled regions, optimalizing the width of the ribs from 2.2mm to 3.0mm. At the same time, six non-standard sealing grooves were unified to Φ8mm, conforming to common end mills to realize one-time molding.

The clamping method was optimalized to a dual station rapid positioning system, optimalizing three steps to clamp and keeping errors in ±0.015mm to prevent possible deformation when processing the thin-walled parts.

2.Process & Supply Chain Pre-simulation:

In the prototype development phase, we modeled a simulation of high volume CNC machining withoptimized cutting speeds and feeds of 8000rpm and 2500mm/min.

In addition, we obtained a dedicated material supply channel for 6061-T6 aluminum alloy, as well as a quarterly price-lock agreement to address the risk of material price variability. Not only did this optimize machining speed by 20% with a 12% cutback in energy costs, but it also reduced individual piece machining time by 15%, down to 38 minutes per piece from 45.

Results: Triple Victory in Cost, Time, and Quality

Based on mass production, the production cost per unit was lowered by 35% (from $280 to $182), the production cycle time was cut down by 30%, while the quality of the key mounting surface flatness was maintained within 0.05mm, meeting the requirements. Apart from the above, we provided the quality traceability system to the customer.

Have similar cost optimization needs? Contact our engineers, share your part design and production plan, and we will provide you with customized cost reduction solutions to replicate the success of our case studies.

Figure 3 Complex motor housing with integrated cooling channels

When Should You Switch From Low Volume To High Volume CNC Machining?

The transition from low volume CNC machining to high volume CNC machining should be done at appropriate times to avoid counterproductive outcomes. This should be done depending on the status of your designs and the level of demands.

Key Decision Signals

- Design Fully Frozen: The functional testing and compliance approval process is finalized, and major design changes are unlikely to occur in the ensuing 12-18 months.

- Stable and Continuous Demand Forecasts: A good sales forecast would denote a stable and continuous demand for parts rather than irregular orders.

Cost Structure Analysis: Finding the Break-Even Point

When fixed costs like programming, fixtures, etc. exceed 30% of the unit price for low volume CNC machining, a possible re-engagement in high volume machining could reduce unit prices substantially. However, simultaneously, an assessment needs to be made if the total production volume is sufficient to meet the initial investment in molds, fixtures, etc.

| Production Batch | Fixed Cost per Unit (USD) | Variable Cost per Unit (USD) | Total Cost per Unit (USD) | Applicable Scenarios |

| 1-50 units | 45-60 | 30-40 | 75-100 | Prototype Verification |

| 51-200 units | 20-35 | 25-32 | 45-67 | Small Batch Trial Production |

| 201-500 units | 10-18 | 20-28 | 30-46 | Medium Batch Production |

| 501 units and above | 5-10 | 18-25 | 23-35 | High Volume Production |

Figure 4 Mass CNC machining refers to the process of producing a large number of parts with high precision and consistency using CNC machine tools.

How To Truly Compare CNC Services Near Me And Beyond?

Most people want to have priority for "CNC services near me", but the geographical location is not the sole criterion in choosing a supplier. All-round strength is the guarantee of long-term cooperation.

Evaluation Dimensions Beyond Geographic Location

- Technical Response and Collaboration Depth: Suppliers that offer DFM feedback at the quotation stage are more capable of cost reduction and are more important than geographical proximity.

- Quality Assurance System Transparency: The custom precision machining services which present the first-article inspection reports and quality control that is documented are the ones upon which more reliance can be placed.

Digital Capabilities: The New Era of "Near-Me"

Digital platforms supporting online instant quoting and progress tracking could overcome the limitation of geographical distance, while integrated service providers may provide shorter lead times due to their supply chain network and controllable costs.

Looking for truly reliable CNC services near me or remote service providers? Schedule a one-on-one consultation with our engineers, share your project needs, and we'll prove why we're your best choice.

Your Comprehensive Manufacturing Partner: JS Precision’s Customized Service Approach

JS Precision will be able to assist in the one-stop custom precision machining process from quotation to delivery, including not only taking orders and making products but also acting as one-stop manufacturing partners.

End-to-End Process from Inquiry to Delivery

During the quotation stage, our engineering intervention will occur with the aim of providing DFM analysis and cost optimization solutions. Still, we support the seamless transfer from single-piece CNC machining on demand prototype manufacture to high-volume manufacture based on various stages' needs.

One-stop Guarantee of Technology, Quality & Supply Chain

We possess multi-axis CNC, mill turning, and CMM for the machining and inspecting capabilities of very complex components. Moreover, the entire process of quality control was also adopted, along with the management of the supply chain, for the assurance of smooth delivery.

FAQs

Q1: How long does it usually take to get a CNC quotation?

For simple CNC machining part, we can quote in 4-24 hours and also take around 1 to 2 business days to evaluate the process of complex features parts.

Q2: What is the Minimum Order Quantity (MOQ)?

As for CNC machining, actually, there is no fixed order quantity, even single parts CNC machining is possible. However, when there is only one part to be made, the unit price will be high, but when the order quantity increases for batch production, the unit cost will be drastically reduced.

Q3: Does the quote include all costs?

In a quotation for CNC machining, it is imperative to include the cost of material, machining cost, standard post-processing cost (e.g., deburring), and taxes. Special packaging, rush order, or additional report copies may be separately quoted.

Q4: How can I ensure the security of my intellectual property?

But nondisclosure agreements are upheld stringently at JS Precision. Our design files are sent via an encrypted server, and all our project staff members have agreements about keeping it confidential. Additionally, we remove design files if our customers ask us for this.

Q5: What surface treatment options are available?

Sand blasting, anodizing, which can be provided in a variety of colors, electro plating, passivation, painting, and screen printing are some other surface finishes. A suitable one will be recommended based on the functional need.

Q6: What if there are problems with the part?

JS Precision offers a 100% guarantee for quality. If there is a situation wherein the parts were produced improperly and are defective, JS Precision will replace them or give a complete refund and will focus on analyzing and improving the problem.

Q7: Do you offer assembly services?

We do assembly work. We, at JS Precision, also provide one-stop precision machining, cleaning, assembly, and functional testing (proving pressure tests, air tightness tests, or electrical tests, etc.) of plural parts in order to serve your entire requirement.

Q8: How can I track my order progress?

JS Precision offers real-time updates on your order status through a personal account manager, completed photos, and reports on main processes, which enables you to keep track of the manufacturing process.

Summary

Obtaining accurate CNC machining quote and selecting suitable suppliers is never a simple comparison, but a strategic decision based on clear communication and professional judgment. JS Precision, with years of experience, advanced technology, and customized services, can solve the entire process from prototype to mass production for you.

Whether you need CNC machining on demand services, parts CNC machining solutions, or anything in between, we can enhance your expectations.

The time to take action is now! Please transmit your files to JS Precision with the remark "Precise Quote." Within 24 hours, you will receive your cost quote, cost optimization strategy, and DFM recommendations for maximizing your ROI.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com