Bronze, the alloy used for several millennia by mankind, still cannot be replaced in modern industry. From corrosion-resistant ship hardware to self-lubricating bearing bushings and electrical connectors demanding high conductivity, bronze has always performed exceptionally.

But finding the right manufacturing partner can make all the difference when transforming a bronze blank into a precision part to meet demanding operating conditions.

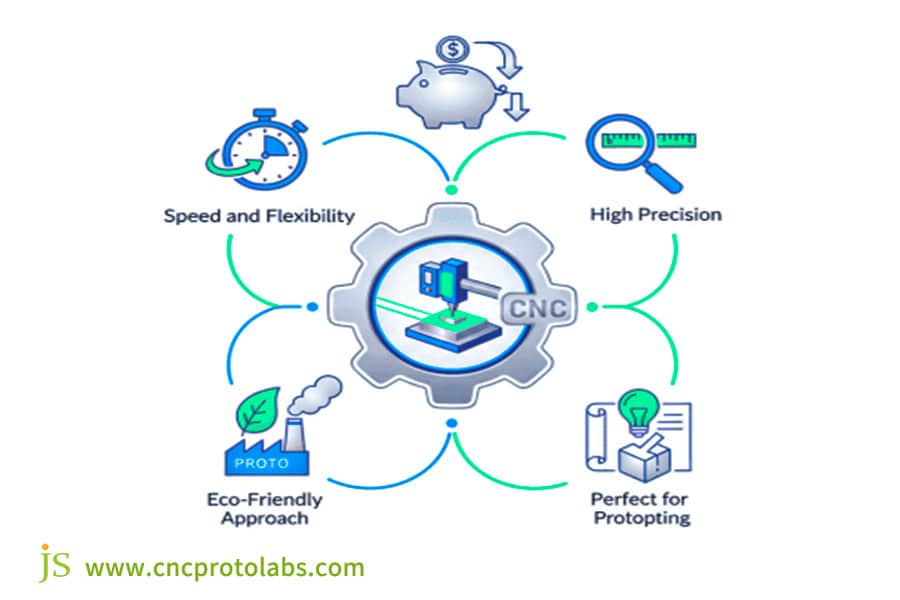

As an engineer at JS Precision, the following guide gives an in-depth cost, process, and value analysis of CNC machining bronze. It shows ways in which JS Precision helps you get high-quality bronze CNC parts with optimized project costs through its professional CNC precision machining services.

Core Answer Summary

| Comparison Dimensions | Conventional Suppliers | JS Precision's CNC Machining Bronze Service |

| Cost Transparency | Murky pricing, hidden costs. | Itemized pricing, cost breakdown is transparent, no hidden costs. |

| Material Knowledge | General parameters, could result in excessive tool wear. | Specific bronze machining parameter library, ensuring optimization of tool life and surface quality. |

| Process Efficiency | Standard processes, fixed machining cycles. | Process optimization, shortening cycles by means of high-speed cutting and intelligent toolpaths. |

| Quality Control | Final sampling inspection. | Full process monitoring, including critical dimension inspection reports. |

| Value Overall | A lower upfront price may be attainable. | A lower upfront price may be attainable. |

Why Trust This Guide? JS Precision's Complete Guide To CNC Machining Bronze

To earn your trust in the guide, let me first discuss where the strength of JS Precision lies: we have been deeply involved in CNC Machining for 15 years, serving over 200 clients in CNC machining bronze, covering hydraulic, aerospace, and medical industries.

We have completed more than 1,200 orders of CNC machining bronze parts within these three years, in which 80% are small batch and high precision requirements. For example, there are the bronze bearing sleeves we did for an aerospace client whose tolerances keep within ±0.005mm.

Our facility is well equipped with 30 top-of-the-line CNC precision machining machines, including 5-axis milling and turning centers. We are capable of processing 25 bronze grades, including C93200 tin bronze and C95400 aluminum bronze.

This book is not a collection of theories, but rather a collection of practical information that has been distilled from over 15 years and more than 1,200 orders. Every suggestion in this guide has been tested on projects.

If you're in need of dependable CNC machining bronze services, then JS Precision can definitely help in delivering quality parts with many years of experience in handling an array of grades with high precision equipment. Just send your drawings and needs, we'll review them in a prompt manner and give you a clear quotation thereafter. We'd love to work with you!

What Are The Major Cost Components In The CNC Machining Bronze Parts?

It is important to understand the cost of CNC machining bronze parts to control your budget and avoid waste. The core cost components are broken down in the following, while tables supplement relevant transaction data to make the information more complete.

Cost Breakdown

1. Material Cost: The basic cost comes from bronze bars/plates. Their price varies a lot depending on different grades. For example, the C93200 tin bronze is around $5.5-6.0 /lb, and the C95400 aluminum bronze is about $7.2-7.8/lb, also depending on volume and detailed specifications.

2. Machining Time Costs: A core variable determined by machine tool uptime, affected by the complexity of the parts. Simpler parts cost around $20-30/hour, like making gaskets, while complex parts, such as valve cores, need $50-80/hour.

3. Tool Wear Costs: Bronze is easy to machine, but the right tool selection must be made. Dedicated carbide tools wear out at $1-3 a piece. Proper selection extends tool life and controls costs.

4. Post-processing and surface treatment: Deburring $5-10/pc, polishing (Ra 0.8μm) $10-15/pc, Sn plating $15-20/pc will depend on structuring and surface requirement of the parts.

5. Management and Profit: This comprises project management, quality control, taking up 10%-15% of the total cost as a necessary investment in the progress of the project.

Bronze Processing Cost and Transaction Data Reference Table

| Cost Category | Specific Description | Reference Price (USD) | Influencing Factors | Delivery Cycle |

| Material Cost | C93200 Tin Bronze Bar | 5.5-6.0 / lb | Grade, Quantity, Specification | 7-10 days |

| Material Cost | C95400 Aluminum Bronze Bar | 7.2-7.8 / lb | Grade, Quantity, Specification | 7-10 days |

| Processing Time Cost | Simple Parts (e.g., Gaskets) | 20-30 / hour | Part Complexity, Machine Tool Type | 3-5 days |

| Processing Time Cost | Complex parts (for example, valve cores). | 50-80/hr | Part difficulty, type of machine tool | 5-8 days |

| Tool Wear Cost | Special Carbide Tools | 1-3 /piece | Tool Type, Part Material | - |

| Post-Processing Cost | Deburring | 5-10 / piece | Part Structure | +1 day |

| Post-Processing Cost | Polishing (Ra 0.8μm) | 10-15 / piece | Surface Finish Requirement | +2 days |

| Post-Processing Cost | Tin plating | 15-20/piece | Plating thickness | + 3 days |

| Management and Profit | project management + quality control + reasonable profit. | 10%-15% of total cost | Depending on the size of the order and the quality requirements. | - |

JS Precision provides transparent quotations, which clearly detail the cost breakdown so that you know where every penny is going.

Figure 1:The material cost is the basic cost of CNC machining bronze parts, with significant price differences among different grades.

What Are The Differences In Cost And Process Between Machining Brass And Bronze?

Many customers ask me how to choose between machining brass and bronze. Actually, you need to compare both material properties and costs in order to find the right solution for you.

Material Property Comparison

- CNC Machining Bronze (C93200): Tough, wear-resistant, and resistant to seawater corrosion, slightly higher cutting resistance, suitable for parts requiring strength and wear resistance.

- CNC Machine Brass (C36000): Good machinability, high machining speeds, minimal tool wear, recommended for parts with simple structures.

Cost Impact Analysis

- Machining Efficiency: The machining speed for brass on a CNC Machine is 10%-20% faster when compared to similar bronze parts, this reduces the time it takes, hence decreasing the cost of machining.

- Tool Life: Machining brass demands far less tool wear, the tools are able to function for 50%-80% longer than when machining bronze, thus reducing tool replacement frequency and cost.

- Material Cost: Brass is cheaper, for example, the price of C36000 brass is about $4.0-4.5/lb, which is relatively lower than the $5.5-6.0/lb for C93200 bronze.

Comparison Table of Brass and Bronze Machining

| Comparison Dimensions | CNC Machining Bronze (C93200 as an example) | CNC Machine Brass (C36000 as an example) |

| Properties | Tough, wear-resistant, resistant to seawater corrosion, with a slightly higher resistance to cutting. | Easy to cut, higher machining speed with lower tool wear. |

| Material Price (USD/lb) | 5.5-6.0 | 4.0-4.5 |

| Machining Efficiency | Base speed (100%) | 110%-120% |

| Tool Life | Base life (100%) | 150%-180% |

| Applicable Scenarios | Bearings, valve cores, corrosion-resistant parts. | Connectors, decorative parts, low-load parts. |

JS Precision engineers will advise on the most economical material for your application, which considers factors such as wear resistance and load that the part is subjected to.

Whether you need CNC machining bronze or CNC machine brass services, JS Precision engineers will recommend the most cost-effective materials based on your application scenario, ensuring part performance meets standards while costs remain controllable. Feel free to contact us.

Casting Of Bronze Parts Vs. CNC Machining Parts: Which Is More Cost-Effective?

Whenever you need bronze parts, you might hesitate between casting and CNC machining. Both have their advantages and disadvantages, the key is to consider your needs.

Advantages and Limitations of Casting

- Advantages: Suitable for complex internal cavity structures and very large parts, low unit cost for batches of 1000 or more.

- Limitations: Needs mold making, expensive, 1-2 month lead time, low surface quality and dimensional accuracy, defects such as shrinkage cavities and sand holes.

Advantages and Limitations of CNC Machining

- Advantages: No mold required, fast response time, lead time from design to finished product is measured in days, high dimensional accuracy, good surface quality, dense part material.

- Limitations: material utilization lower compared to casting, unit cost may not be advantageous for batches of over 5000 pieces.

Key Decision Points

In small to medium batches-ranging from tens to hundreds of pieces-and for applications that require high precision and high reliability, CNC machining bronze is faster, more reliable, and has a lower overall cost.

Why is CNC The Absolute Domain In Small-Batch Bronze Parts Machining?

Many customers who produce small-batch bronze parts ultimately choose CNC. Why is CNC the absolute domain for small-batch bronze parts machining? It can be seen from three aspects:

- Zero mold cost: In small-batch casting, the costs of molds are usually higher than that of parts. CNC machining does not require molds, so funds can be directly invested in the production of parts, greatly reducing waste.

- Rapid Turnaround: The cycle from CAD model to finished product is in days. For example, small-batch bronze sensor housings can be delivered in as little as 3 days, shortening time to market.

- Design Flexibility: Since the designs would only have to be iterated in the program, there is no extra cost or loss related to modifying molds.

We provide perfect solutions for our customers' small-batch and multi-variety high-precision needs, allowing you to enjoy top-tier CNC precision machining services at a reasonable price.

JS Precision specializes in small batch CNC machining bronze parts processing, which can help you save mold costs and quickly achieve design implementation. After you submit your requirements, we will quickly arrange production so that you can receive your parts as soon as possible.

Figure 2:Small batch production can provide a solution that is responsive, high-performance, and easy to scale.

How Does The CNC Machine Price Relate To The Price Of The Final Part?

You may wonder what's the connection between the CNC machine price and the final part price. Actually, the quality of the machine tool directly impacts processing efficiency and cost. Let me elaborate on this.

High-end machine tools: CNC machines are more expensive, such as a 5-axis milling and turning center costing over $500,000. However, they offer superior precision, stability, and efficiency, this reduces scrap rates and ensures consistent quality. Potentially, it may also reduce machining time and therefore lower overall costs in the long run.

Older machine tools: The initial depreciation is low, only tens of thousands of dollars, but they have poor precision, high failure rates, and low efficiency, easily leading to scrap and delays, which drive up overall costs.

JS Precision firmly believes that investing in top-of-the-line CNC precision machining equipment is the cornerstone of our ability to provide customers with stable, high-quality, and cost-effective services in the long term. We bear the high cost of the equipment, and you only pay for high-quality parts.

JS Precision invests in top-of-the-line CNC precision machining equipment. Although the CNC machine prices are high, they provide stable and high-quality parts, which reduces the cost. You only pay for quality parts. Try it now!

Figure 3:A multifunctional CNC machine tool that uses an automatic tool changer to complete multiple machining operations.

How Does JS Precision Reduce The Cost And Increase The Efficiency Of Bronze Machining With CNC Precision Machining?

After discussing so much about costs, perhaps you might be interested in how JS Precision brings down the cost and raises efficiency in bronze machining through its CNC precision machining. Well, we have two main focuses of interest: improving efficiencies and enhancing quality because ultimately, both lead to cost reduction.

Efficiency Improvement Equals Cost Reduction

1. High-Speed Cutting Technology: Optimization of the parameters of HSM for various bronze grades. For example, revisions in the cutting parameters of spindle speed and feed rate when machining C95400 aluminum bronze improve material removal rate and shorten machining cycle time by 20%-30%.

2. Intelligent Toolpath Planning: Effective CAM programming strategies, such as cycloidal milling, reduce tool idle time and better protect the tools to improve efficiency.

3. Multi-workpiece parallel machining: The optimization of clamping schemes, designing of multiple clamping positions for a single workpiece, and machining of several parts in one clamping maximizes the utilization of machine tools.

Quality Improvement Equals Cost Reduction

1. Full-process quality control: Dimensional monitoring by on-machine measuring equipment in real time, simultaneous process monitoring, to reduce the scrap rate to near zero, avoiding rework with material waste.

2. Optimized Tool Management: The professional team selects the tool based on the characteristics of bronze, tracks the tool life, and replaces it after expiration to maximize the value of the tool while guaranteeing the quality.

Working with us, you will not only get bronze CNC parts but also get an optimized manufacturing solution, which eventually means more competitive pricing and faster delivery.

Real-World Case Study: 45% Reduced Cost! JS Precision Re-engineers Valve Core Manufacturing Process

That cannot be achieved by theory alone, let me illustrate how we helped our client reconstruct the manufacturing process of a bronze valve core and effectively reduce costs with a practical case study.

Customer Challenge

Our client was a well-known hydraulic equipment manufacturer. Their traditional bronze valve cores were cast and then precision-machined through multiple processes including turning, milling, and drilling. This process had a production cycle of up to four weeks, and the defect rate of the castings was as high as 15%.

At the time, their cost per valve core was approximately $120, and with a monthly production of 500 units, the losses from defective products alone amounted to $9,000, resulting in persistently high overall costs.

JS Precision's Solution

First of all, we analyzed the customer's process and found that the casting stage was the key factor affecting high cost and long cycle time. Thus, we recommended giving up casting and applying the CNC machining bronze process for directly machining the high-strength C95400 aluminum bronze rod.

We used a five-axis milling and turning center in conjunction with a special fixture on the machining equipment to accomplish all the turning, milling, and drilling in one clamping. This not only reduced the number of clamping operations but ensured very high geometric tolerances because errors due to multiple clamping operations were avoided.

Meanwhile, we have optimized high-speed cutting parameters for the characteristics of C95400 aluminum bronze, which has reduced the single-piece machining time from 4 hours to 2.8 hours and greatly improved the machining efficiency.

Results and Value

The results were amazing: the customer reduced the general manufacturing cost of every valve core by 45%, the unit cost having decreased from $120 to $66, hence saving the customer US$27,000 every month. It shortened the production cycle from 4 weeks down to 5 days and reached a 100% yield rate.

The CNC precision machining capability of JS Precision brought disruptive value enhancement for the customer.

Figure 4:CNC Machining Bronze Valve Core

How To Start Your CNC Machining Bronze Project And Get An Accurate Quote?

Having learned so much about bronze CNC, starting a project of your own really isn't that difficult, you can get an accurate quote in just a few steps.

First you should prepare three things:

1. Provide clear drawings: The drawing should include the material grade of the parts, such as C93200 or C95400, and indicate all dimensional tolerances, geometric tolerances, and technical requirements so that we can accurately understand the specifications of the parts.

2. Clearly define the quantity and demand: Please let us know your estimated annual demand and quantity of your first order, such as the annual demand is 500 pieces and the first order is 100 pieces. That will affect our quotation and production schedule.

3. Notify post-processing: Indicate if post-processing is needed for the part and what treatment should be done on the surface, such as deburring, polishing, or tin plating. Different post-processing methods will make a difference to the final cost.

The process is quite simple at JS Precision:

Customers upload their prepared files, and then our engineers will review them in 6 hours and make optimization suggestions according to the structure of the CNC machining parts before giving you a transparent, itemized quotation. After confirmation of your quotation and order, we arrange production right away to make sure on-time delivery.

It's easy to start a CNC Machining Bronze project: just provide clear drawings and requirements to JS Precision, we will review them with a quotation in complete transparency. Production is started right after confirmation, which means you will get high-quality CNC machining parts easily.

FAQs

Q1: What are the common machinable bronze grades?

The two most commercially available grades of bronze that can be machined include SAE 660, more commonly referred to as C93200 tin bronze, and C95400 aluminum bronze. We can recommend the appropriate grade based on your needs for wear resistance, strength, or corrosion resistance.

Q2: What surface finish is possible with bronze CNC machining?

The standard surface finish of bronze CNC machining is up to Ra 0.8μm after professional finishing. For further optimizations, the processes will need to meet higher requirements in this respect.

Q3: Does bronze require cutting fluid when it is being machined?

The use of cutting fluid is recommended in general for the machining of bronze. It would help in chip removal, temperature control of the machining area, reduction in surface imperfections, and thus better surface quality.

Q4: My project requires very tight tolerances in dimensions. Can that be handled with bronze machining?

Of course, we can reach a dimensional tolerance of ±0.01mm with CNC precision machining at JS Precision to meet the strict requirements of your project.

Q5: What are the specific advantages that JS Precision has concerning bronze machining?

JS Precision can satisfy different kinds of requirements in bronze machining because we have different bronze grades of dedicated cutting parameter libraries, top-of-the-line carbide tools, and vast experiences in thin-walled and deep-hole machining.

Q6: How to reduce material waste in bronze machining?

Intelligent nesting software optimizes the layout of the billets, and billets of the size nearest to the finished product are chosen. Both of these methods can optimize material usage and minimize waste in bronze machining.

Q7: Which of the two, bronze or brass, is best for making bearings?

Bronze is more suitable for the manufacture of bearings, particularly tin bronze containing phosphorus, because it has better wear resistance and a higher load-carrying capacity to meet performance requirements for bearings in service.

Q8: How to get a quote for CNC machining bronze from JS Precision?

You just need to upload your part file and machining requirements according to our process. Our engineers will review and respond to your request within 6 hours to provide you with an accurate CNC machining quote for bronze.

Summary

By choosing CNC Machining Bronze, one chooses a way of manufacturing that can balance superior performance, rapid response, and controllable costs. Choosing JS Precision as your partner means assigning a complex manufacturing challenge to an expert team that best solves the problem.

We guarantee precision and efficiency in either CNC machining bronze parts or any other kind of CNC machining parts, and we are transparent about pricing so that you will understand every expense.

No more headaches trying to balance cost and quality. Upload your bronze part design now, and let the professional team of JS Precision provide you with clear process analysis and a highly competitive quote. Contact us now and experience how professional-grade CNC precision machining can add real value to your projects.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com