Aerospace CNC turning plays a vital role in manufacturing the main rotating parts of aero engines. Such components can be engine turbine disks, landing gear shafts, etc., which, apart from having high strength, should be constructed to be very light.

Materials and manufacturing processes affect both safety and success in aerospace. Titanium alloys are chosen for their extraordinary strength-to-weight ratio and resistance to corrosion, however, their challenging-to-machine nature is a major problem.

The guide will review AS9100 approved aerospace CNC turning options and emphasize the turning of titanium alloys and the finishing of large-diameter components with high precision. Besides that, it is meant to assist in converting the latest technological designs into dependable parts and the selection of the best manufacturing partners.

Key Takeaways

| Your Core Challenges | JS Precision's Core Solutions | Core Value for You |

| Meeting the rigorous standards for the extreme performance and reliability of aerospace-grade parts. | Offering AS9100 certified aerospace CNC turning services with a focus on titanium alloys and large diameter turning. | Getting precision aerospace parts that are safe and compliant, thereby lowering the risks of project certification and supply chain. |

| Addressing the challenges in cost, efficiency, and quality that are inherent in working with difficult-to-machine materials such as titanium alloys. | Using high-precision CNC turning technologies and state-of-the-art equipment to achieve process stability. | Ensuring the integrity of the part, optimizing the use of resources and cost, and facilitating a smooth transition from prototype to mass production. |

| Discovering technically competent and trustworthy partners in the global supply chain. | Being a technology-driven supplier, offering a full range of pre-production support and establishing a strong relationship as the technology arm of the customer. | Developing reliable partnerships that ensure projects are delivered on time, to standards, and within budget. |

Key Takeaways

- AS9100 accreditation is basically the minimum standard an aerospace CNC machining supplier needs to get their foot in the door, and it's a systematic way to make sure that parts can always be traced and that they are safe and reliable.

- The key to machining titanium alloy well is precise cnc turning technology and process strategies that take into account the alloy's low thermal conductivity and high chemical reactivity.

- To be able to do large diameter cnc turning, the equipment's absolute rigidity, special tooling, and online compensation technology are what's needed to control the deflection of thin walled parts.

- It's a must to check a potential supplier's technical portfolio and list of machines (especially their best cnc turning center) very carefully since these aspects directly set the limits of their capability when picking a supplier.

- A DFM collaboration with suppliers who have aerospace experience is a great way to have the costs, performance, and project timeline pace optimized.

Why Trust This Guide? JS Precision's Aerospace Turning Solutions

Aerospace CNC turning is JS Precision's main proficiency. We have been in this business for a long time more than 15 years. We have an AS9100 Rev D certified quality system and a very extensive process database of over 1000 sets of materials, including not only titanium alloys but also other materials that are difficult to machine.

Our machines include multi DMG MORI NT series 5 axis milling and turning centers, which can perform single, set machining of precision parts in the size range of 10 to 1500mm with repeatability within 0.002mm and runout error 0.001mm, thus fulfilling the precision requirements of the aerospace industry.

To work with titanium alloys such as TC4 and Ti-6Al-4V in aerospace, we apply 70-100bar high pressure cooling and tailor the toolpath optimization so as to get more than a 30% increase in tool life, 25% machining efficiency, and almost 20% unit cost reduction.

Our customers include the world top 5 aero-engine manufacturers as well as major military aircraft landing gear manufacturers. The main parts that we have handled consist of turbine disks and load, bearing shafts. We have supplied over 100, 000 parts and all have gotten FAA airworthiness certification. They meet AS9100 Rev D standards and there have been no quality complaints.

Our team thoroughly recognizes the crucial role of aviation projects in ensuring flight safety and strictly following the requirements of AS9100 Rev D standard, we have set up a total lead tracking system from raw material to finished product.

This includes the traceability of raw materials (furnace number and material certificate), process testing, and product testing (coordinate measuring machine and non-destructive testing).

Every batch of components is accompanied by a full FAI report and a material certificate, which are always at hand for customer audits. We can be trusted as a partner for sharing the burden of the project and handling the technical challenges together.

Want to obtain JS Precision's AS9100 certification documents and titanium alloy machining case studies? Contact our engineers immediately, noting "aviation turning needs," to receive a free customized technical solution.

Why Is Aerospace CNC Turning The Cornerstone Of Manufacturing Lightweight Aerospace Structural Components?

Aerospace CNC turning is the core process for lightweight and high-precision aviation parts, and the lack of mature technology cannot translate the advantages of titanium alloy into part performance. This chapter will discuss the indelible nature of aerospace CNC turning through the lens of parts' demand-working environments, and quality assurance.

Uncompromising Airworthiness Requirements for Aerospace Components

Aerospace components performance require high input and tightly controlled core indicators of strength-to-weight ratio reduction of over 30%, fatigue life exceeding 10^7cycles, and dimensional tolerance of 0.025mm even for the most critical parts, which directly influence the flight safety.

The Role of CNC Turning Applications in Aerospace

CNC turning applications cover aviation core rotating components, with key precision CNC turning parts including engine spindles, turbine discs, etc. The machining accuracy directly determines the safety of the components.

Technology and Quality: A Must Win Combination

Mature precision CNC turning technology is the only way to the dimensional and surface quality standard, hence the performance of the components and compliance with airborne life require quality system such as AS9100 to guarantee batch consistency and product traceability, both are indispensable.

Want to understand how aerospace CNC turning achieves strength balance in lightweight parts? Download our "Aerospace Turning Lightweight Process White Paper," noting "lightweight requirements," to receive detailed technical parameters and case studies free of charge.

Figure 1: An assortment of seven precision-machined metallic components with polished finishes, including cylinders and hex shapes.

Figure 1: An assortment of seven precision-machined metallic components with polished finishes, including cylinders and hex shapes.

Why Is CNC Machining AS9100 Certified a Mandatory Requirement For Aerospace Projects?

CNC machining AS9100 certified is a strict prerequisite for aerospace projects suppliers. Here, the chapter dives deep into the major benefits of the standard and how it helps to guarantee the precision CNC turning parts.

The Heart of AS9100 Is More Than ISO9001

Aviation specific requirements are added to the existing ISO9001 by AS9100, which basically focuses on mandatory first article inspection (compliant with SAE AS9102), full process traceability, tightened upstream control, and early avoidance of processing quality risks.

How Certification Plays a Part in Quality Assurance of CNC Precision Turning Parts

Batch consistency of the product and performance predictability of precision CNC turning parts are ensured by AS9100 through thoroughly documented management. JS Precision sets standards and keeps inspection records for every step, with dimension measurement accuracy for critical parts reaching to 0.0005mm.

The Tactical Advantage of Working with a Certified Supplier

Choosing a CNC machining AS9100 certified supplier can meet customer audits and transfer project risks. With standardized processes and rich aviation experience, it can predict and solve machining problems in advance.

| Standard Comparison Items | AS9100 | ISO9001 |

| Industry Targeting | Aerospace-specific | Universally applicable |

| First Article Inspection Requirements | Mandatory | No explicit requirements |

| Traceability | Full-process traceability | Basic traceability requirements |

| Supplier Management | Strict auditing of upstream suppliers | General auditing requirements |

| Risk Prevention | Mandatory risk identification mechanism | No mandatory requirements |

| Airworthiness Certification Compatibility | Airworthiness Certification Compatibility | Cannot be met |

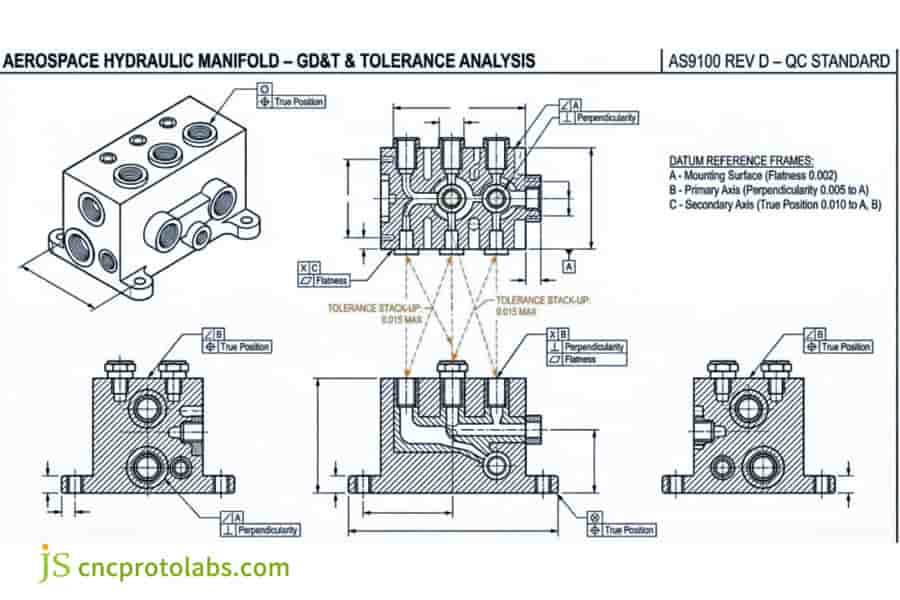

Figure 2: Technical drawing of an aerospace hydraulic manifold with GD&T annotations, tolerance analysis, and references to AS9100 standards.

Figure 2: Technical drawing of an aerospace hydraulic manifold with GD&T annotations, tolerance analysis, and references to AS9100 standards.

Which Precise CNC Turning Technologies Can Overcome Machining Difficulties For Titanium Alloys?

Titanium CNC machining service has always been considered a difficult aspect of aerospace machining. This article delves into the various challenges of machining and the effective precise CNC turning technology that can be used.

Typical challenges of Titanium CNC Machining Servic

Usually, when titanium aerospace alloys such as TC4 and Ti-6Al-4V are machined, it is expected there will be three hurdles: due to low thermal conductivity, tool wear is accelerated, high chemical affinity results in the formation of built-up edge, and low elastic modulus leads to machining deformation, thereby, loss of precision control.

Key Process Technologies and Strategies

JS Precision adopts three core precise CNC turning technologies to address the challenges of titanium alloy processing:

- High Pressure Cooling Technology: 70-100 bar high pressure coolant is directly injected into the cutting zone for rapid heat dissipation, chip breaking, and prevention of built-up edge.

- Specialized Tools: PVD (AlTiN) coated carbide tools with optimized geometry improve wear resistance and anti- adhesion properties.

- Toolpath Optimization: Combining constant surface velocity and cycloidal toolpaths controls thermal load and effectively reduces part deformation during machining.

The Value Brought by Specialized Services

Mature suppliers can optimize parameters through process databases, reduce tool costs by more than 20%, and ensure part fatigue strength. JS Precision can control the deformation of titanium alloy thin-walled parts within 0.05mm, with a pass rate of 98%.

Titanium Alloy Machining Process Parameter Table

| Parameter | Roughing | Semi-finishing | Finishing |

| Cutting Speed (m/min) | 30-40 | 40-50 | 50-60 |

| Feed Rate (mm/r) | 0.2-0.3 | 0.1-0.2 | 0.05-0.1 |

| Depth of Cut (mm) | 2-3 | 1-2 | 0.2-0.5 |

| Coolant Pressure (bar) | 70 | 80 | 100 |

| Tool Coating Type | AlTiN | AlTiN | AlTiN |

| Surface Roughness (Ra) | 6.3μm | 3.2μm | 1.6μm |

Want a customized titanium CNC machining service? Submit your part drawings, and JS Precision engineers will conduct a free DFM analysis and provide a detailed cost calculation.

How To Choose The Best CNC Turning Center For Aerospace Parts?

Given the high precision requirements of aerospace parts manufacturing, selecting the best CNC turning center becomes a matter of paramount importance. In this chapter, we examine key selection criteria and discuss some special equipment requirements that will help to make the right choice.

Core Performance Indicators

There are three main attributes that should be taken into account while choosing a best CNC turning center: spindle radial run out less than 0.003mm, linear axis positioning accuracy of 0.002mm/full stroke, as well as high static rigidity capable of withstanding the cutting forces of titanium alloy.

Special Requirements for Large Diameter CNC Turning

Large diameter CNC turning requires more advanced features of the equipment: a milling-turning center equipped with B-axis/Y-axis for error reduction, a spindle power >1000 Nm for the roughing process, and a thermally stable layout to avoid equipment distortion.

Equipment Investment Indicates the Supplier Commitment

A supplier's commitment to the high end market can be estimated by the extent to which it keeps investing in the best CNC turning center. We company renews our tools every year, thus its current milling-turning centers allow a maximum machining diameter of 1500mm and a length of 3000mm which is sufficient for large parts.

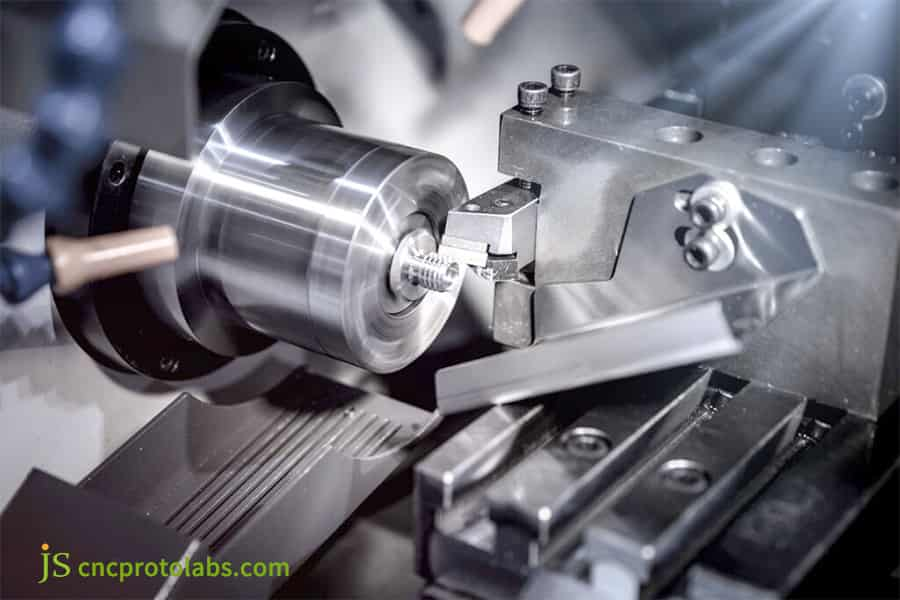

Figure 3: A CNC lathe precisely machines a rotating titanium workpiece, with the cutting tool engaged and fine metal shavings visible.

Figure 3: A CNC lathe precisely machines a rotating titanium workpiece, with the cutting tool engaged and fine metal shavings visible.

How To Control Deformation And Accuracy In Large Diameter CNC Turning For Large Aviation Components?

The primary difficulty in large diameter CNC turning is the distortion of thin walled parts. This chapter dives into the production problems faced when handling large parts and the specific solutions JS Precision comes up with.

Manufacturing Problems of Large Diameter Thin-Walled Parts

When machining casing, type parts with a diameter > 500mm and a wall thickness < 5mm, two major deformation issues arising from machining are: deformation resulting from the residual stress release in the blank and elliptic deformation of more than 0.1mm caused by the low rigidity of thin walled parts when subjected to cutting forces.

Specific Solutions and Closed-Loop Control

In dealing with the deformation of big thin walled parts, we utilize three closed-loop control methods:

- Contouring Layered Turning: Layered cutting is one way of balancing cutting forces and hence, no layer is excessively deep, which might have otherwise resulted in deformation.

- Online Probe Compensation: While finishing, the probe is utilized for real time dimension detection and tool defects are automatically compensated for so that the accuracy is within the standard.

- Dedicated Expansion Fixture: Based on stress finite element analysis, the fixture is designed to offer stable clamping without raising the stress level.

Experience Is an Irreplaceable Asset

The history of process data and experience gained by the iterative method are what successful large diameter CNC turning projects depend on. JS Precision has more than 50 case studies of handling large, thin-walled parts and thus, they know exactly how to come up with the solutions required in no time.

Case Study: Challenging The 0.05mm Deformation Limit, Machining a Thin-Walled Shell Of Titanium Alloy With a Diameter Of 220mm

Challenge

Machining a TC4 titanium alloy servo housing with the following dimensions: outer diameter 220mm, height 150mm, and a minimum wall thickness of 3mm. The overall roundness should be 0.05mm, the internal cavity includes complex irregular curved surfaces.

The supplier's previous machining of the same part resulted in deformation up to 0.15mm, which caused their assembly to be impossible and the project delayed by over two weeks. The client was in an emergency situation, requiring a supplier very quickly to fix the deformation problem and be capable of producing the parts at AS9100 quality standards level.

JS Precision Solution

JS Precision upon receipt of the file request immediately set up a multifunctional group and identified a three-step solution:

1. DFM and Process Simulation:

Introducing a stress, relief annealing step at 550-600℃ for 2-3 hours after the blank stage resulted in residual stress being reduced by more than 40%.

By applying cutting simulation software DEFORM-3D, the stress distribution obtained from the machining was also simulated, and the toolpath was adjusted to "outside first, then inside-symmetrical layering", cutting force variations were limited within 50N and machining stress was balanced.

2. Specialized Tooling and High Pressure Cooling:

The segmented vacuum adsorption fixture has an adsorption pressure of 0.08-0.1 MPa, and there is a clamping deformation of 0.005 mm, which means that clamping damage caused by insufficient rigidity has been avoided.

In combination with 70 Bar high pressure coolant that is directly injected into the cutting zone, the cutting temperature is lowered from over 600 to 380, thus reducing built-up edge and securing stable clamping.

3. Turning-Milling Composite and Online Compensation:

The DMG MORI NT five axis turning-milling composite center delivers multiple processes such as turning, milling, and drilling in a single setup, which has a clamping error of 0.002 mm. The RENISHAW online probe is employed to measure and compensate for 0.02 mm tool deformation in real, time, thus ensuring that roundness tolerances are standards-compliant.

Results

10 housings delivered with roundness 0.038 mm, thus complying with internal cavity surface accuracy standards, and passing air tightness and fatigue tests at the first attempt.

This has not only raised the parts qualification rate from 60% to 98% but also shortened the delivery cycle to 5 days, thus recovering the delays. The customer later delegated all orders for this series of parts to JS Precision.

Want to replicate this success? Submit your complex part drawings, and JS Precision will provide you with one-on-one DFM analysis and machining solutions. Note "Case Study Reference" and you can also enjoy a process optimization subsidy for your first order.

Figure 4: A single metallic CNC-turned aerospace component with a cylindrical shape and internal grooves, isolated on a white background.

Figure 4: A single metallic CNC-turned aerospace component with a cylindrical shape and internal grooves, isolated on a white background.

How To Screen And Evaluate Reliable CNC Turning Service Suppliers In The Global Supply Chain?

An Evaluation Checklist Beyond Price

CNC turning service suppliers cannot rely solely on price. It needs to be evaluated from four perspectives:

- The technical capability matching.

- The AS9100 certification and testing records.

- The production capacity resilience.

- The end-to-end DFM and mass production support capabilities.

Keys to Building Successful Partnerships

There are three key elements to the long-term partnerships:

- Early design participation, suppliers need to intervene in the product design phase and provide DFM suggestions to optimize processing technology.

- Clear technical communication and project management ensure synchronized information throughout the machining process.

- Long-term agreements and continuous improvement commitments based on project needs, work to optimize processes and cut costs.

Ideal cnc turning service suppliers should be more than a mere processor, rather they should be a technical partner capable of addressing manufacturing challenges, optimizing product performance, and ensuring supply chain security.

Want to obtain an evaluation list of CNC turning service suppliers? Contact JS Precision's supply chain specialist and note "evaluation needs" to receive a detailed evaluation form and selection guide free of charge.

FAQs

Q1: What is the biggest difference between AS9100 certification and ISO9001?

AS9100 requires the implementation of a comprehensive quality management system that includes risk management, product safety, traceability, and first, article inspection. AS9100 is a quality standard developed specifically for the aerospace industry, which has very high reliability requirements, whereas ISO9001 is a generic standard that can be used by any industry.

Q2: What type of cutting tools are most commonly used for machining titanium alloys?

These are mainly carbide cutting tools with PVD coatings (like AlTiN). A variety of flute and edge designs are used for roughing and finishing to enhance the wear resistance and anti, adhesion of the tools.

Q3: What is the maximum turning diameter and length you can process?

Our maximum turning diameter is 1500mm, and we can machine parts up to 3000mm in length. The exact machining capabilities will vary depending on the part structure and tolerance requirements. We will be able to provide a list of equipment for matching purposes.

Q4: What specific process measures are used to prevent deformation of thin walled parts?

The detailed measures are symmetrical machining, multi-pass progressive cutting, using hydraulic expansion fixtures, and integrating intermediate stress, relief operations to limit the amount of part deformation during machining.

Q5: Can you provide full material certification and heat treatment reports?

Yes. We are fully compliant with AS9100 and are supplying original manufacturer's quality certificates for each batch of materials. Besides, all heat treatment and machining process records are fully traceable and meeting the requirements of airworthiness certification.

Q6: What stages are typically included in the delivery time? How is it guaranteed?

Delivery time covers the process review, programming, production, testing, and the issuance of the report. Our transparent and reliable delivery times are a result of our standardized operations and project management processes, which allows real time tracking of the production progress.

Q7: How do you make sure that the surface integrity of parts is suitable for very high fatigue strength?

We ensure that the surface quality of parts remain at a high level, and can satisfy the requirement of high fatigue strength by adjusting the cutting parameters, utilizing high pressure cooling, and determining the surface enhancing final treatments (e.g. shot peening).

Q8: What do you do with the chips that result from machining?

We are strictly sorting and recycling the chips that come from precious materials such as titanium alloys, and we are also cooperating with the compliant channels for recycling. We are saving resources and supporting the sustainable development of the manufacturing industry.

Summary

Exceptional aerospace manufacturing is a very high precise CNC turning technology deeply integrated with an AS9100 quality system supported by top-tier suppliers, who have a sound knowledge of aerospace requirements.

When you choose JS Precision, you get the finest turning equipment, well-developed process solutions, and an entirely traceable quality assurance system, meeting the challenges of titanium alloys and large complex parts.

We not only manufacture parts, but also safeguard your flying dreams. Send us your drawings or technical requirements immediately, and you will receive a detailed plan containing preliminary process analysis and compliance commitments within 24 hours, taking the first step towards project success.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com