5-axis CNC machining services are effectively reshaping the limits of premium manufacturing. The chase for excellence has led to the creation of complex, lightweight, and highly integrated metal parts as the new norm to succeed.

From molds with conformal cooling channels to integral blades in the aerospace industry, traditional machining methods are no longer sufficient.

This write, up will discuss how 5-axis CNC machining service is the solution for all your manufacturing requirements whereas it will also take you step by step from understanding the technology to receiving a quick quote to realizing your high-end designs.

Summary of Core Answers

| Guideline Highlights | Key Decision Factors | JS Precision Core Value |

| Understanding the Technology | Relation Principles, Operational Efficiency, and Accuracy Advantages | True 5 axis linkage technology enables the creation of complex geometries in a single operation. |

| Assessing Value | Capability to solve geometric, precision, and surface finish problems. | 5 axis high speed cnc machining makes the production of complex parts possible with improved efficiency and quality. |

| Choosing a Partner | Equipment Power, Technical Team, Quality System | We are fitted with best 5 axis CNC machine tools (e.g., DMG MORI) and engineering support is at a maximum level. |

| Meeting Requirements | From receiving a quick quotation through mass production, the whole process is completely supported. | Professional aluminum 5-axis CNC machining has made it possible for a product to be launched in the market from the prototype stage without any problems. |

Key Takeaways

- 5-axis CNC machining fundamentally depends on the 5 axis linkage which allows the tool to reach the workpiece from any location and thus is the only method for manufacturing complex parts.

- When deciding on a supplier, look at the brand of 5 axis milling machines, the precision (positioning accuracy 0.003mm), and the analytical capabilities of their technical team (DFM, etc.).

- The correctness of a quick quote CNC machining depends on how complete the details given are, while it's essential to have clear technical requirements for 3D models, materials, etc.

- 5 axis high speed cnc machining, with its programming and automation advantages, can be a single reliable solution from prototyping to mass production and even throughout the product lifecycle.

Why Choose JS Precision's 5-Axis CNC Machining Services?

Technical expertise of 5-axis CNC machining services in a complex parts manufacturing sector will directly determine whether a product becomes a hit or a failure. Indeed, JS Precision delivers a value proposition heavily hinged on the collective years of both their hard and soft powers.

The core of our manufacturing infrastructure, which comprises 15+ world, class 5 axis milling machines, is furnished with leading brand measuring tools such as DMG MORI and MAZAK.

Machine tools execute true 5-axis simultaneous motion, spindle and table positioning accuracy is up to 0.003mm and repeatability within 0.0015mm, therefore hardware reliability is assured a high, precision machining.

JS Precision technical team engineers on average have more than 8 years' experience in 5-axis CNC machining, they are also highly familiar with professional CAM programming software such as HyperMILL and Mastercam, and can provide clients with very detailed DFM analysis to optimize part structures from the design stage, therefore reducing machining difficulty and cost.

We are ISO 9001 quality certified and have all kinds of testing equipment including coordinate measuring machines and surface roughness testers, so we can provide the entire chain of precision control from machining to inspection.

Since 2024, JS Precision has delivered services to over 500 top-tier clients worldwide in various fields including aerospace, automotive, high, tech, and has completed more than 3000 complicated part machining projects, with a customer repurchase rate of 78%.

Most notably, with the help of the 5 axis high speed cnc machining technology, the machining cycle was shortened by 50% for a complicated titanium alloy structural component of an aerospace client, and the accuracy was maintained within 0.02mm, thus the client was highly satisfied.

Want to experience truly professional 5-axis CNC machining services? Contact JS Precision's engineering team now and tell them your part requirements to receive a free customized machining solution and DFM optimization suggestions. Let us use our expertise to safeguard your project.

What Is a True 5-Axis CNC Machining Service?

Understanding its core essence can help you accurately determine compatibility. The true 5-axis machining is not about stacking the number of axes, but about achieving efficient and precise manufacturing of complex parts through multi axis collaboration, which is the core difference between it and traditional machining.

Core Principle: The Freedom of 5-axis Linkage

The essence lies in the simultaneous linkage of the X, Y, and Z linear axes and two rotary axes, so that the tool is always cutting at the right angle and is able to circumvent the blind spots of the workpiece. This is the basic principle that enables us to deal with the complex parts.

Fundamental Differences from 3-Axis Machining

| Comparison Dimensions | 3-Axis Machining | 5-Axis Machining Service | Unit Cost (USD) |

| Number of Clamping Sessions | Multiple clamping sessions, requiring repositioning | Single clamping session for full machining | 50-200 |

| Machining Accuracy | Large cumulative error (±0.1mm+) | Minimized clamping error (within ±0.02mm) | 80-300 |

| Surface Quality | Tool marks present, requiring secondary processing | No tool marks (Ra≤0.4μm) | 150-800 |

Key Advantages: Accuracy, Efficiency, and Possibilities

- Lower clamping errors: Single clamping prevents the compound of errors, thus accuracy of the core is ensured.

- Greater rigidity of machining: The tools making shorter cuts return less vibration, thus the surface quality is being improved and the secondary processing is no longer necessary.

- Broadened limits of production: The combination of revised 3, axis machining and new accessories offers a wider and more economical range of features such as deep cavities and undercuts.

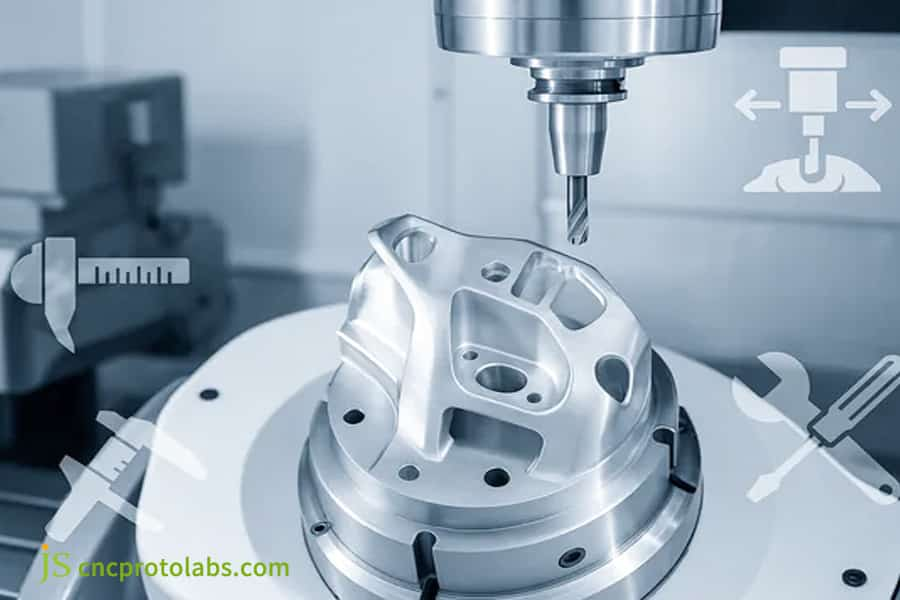

Figure 1 Five axis CNC machining is an advanced subtractive manufacturing technology that enables manufacturers to produce highly complex and high-precision parts in a single clamping process.

Figure 1 Five axis CNC machining is an advanced subtractive manufacturing technology that enables manufacturers to produce highly complex and high-precision parts in a single clamping process.

Why Is 5 Axis High Speed CNC Machining The Best Choice For Complex Component Manufacturing?

Traditional machining has become insufficient due to the geometric complexity, precision, and efficiency requirements in the manufacturing of complex parts. The best answer to complex part machining is high-speed 5-axis machining.

Powerful Tool for Conquering Complex Geometric Shapes

- Deep cavity structures: The system is capable of carrying out Deep cavities with a depth, to, diameter ratio of more than 5:1 by rearranging the tools to avoid interference and ensuring precision.

- Undercut features: The rotary axis changes the posture, so there is no need for disassembly design for back, side cutting.

- Continuous multi-curved surfaces: Linked cutting allows for the smooth machining of aerospace bladed disks and conformal flow channels.

A Double Leap in Precision and Efficiency

- Precision control: In a single clamping, errors are kept within 0.02mm, and with the help of advanced equipment, 0.003mm positioning accuracy is achieved, consequently fulfilling high-end requirements.

- Efficiency Improvement: Spindle speed 20, 000-30, 000 RPM, machining cycle time reduced by 30%-60%.

Surface Quality: Reduced Secondary Processing

By constantly keeping a good tool cutting condition and reducing thermal deformation, Ra up to 0.4m, with aluminum 5-axis CNC machining even more major benefits can be achieved, thus a lot of the polishing steps can be done away with.

Figure 2 Five axis CNC machining services perform excellently in manufacturing parts with composite angles, free-form surfaces, and deep cavities.

Figure 2 Five axis CNC machining services perform excellently in manufacturing parts with composite angles, free-form surfaces, and deep cavities.

How To Choose The Best 5 Axis CNC Machine Tools And Service Partners For Your Project?

Choosing a reliable service provider is the key to ensuring processing quality, efficiency, and controllable costs, and requires multidimensional evaluation and consideration of one's own needs.

Core Capabilities of a Technical Service Provider:

- Equipment Strength: Brands like DMG and MORI should be given priority, deciding on a real 5-axis linkage and positioning accuracy 0.003mm.

- Technical Soft Strength: Having the ability to do DFM analyses, being a user of CAM softwares like HyperMILL, and being able to re-program complex parts creatively.

- Quality System: Holding ISO 9001/IATF 16949 certifications and having coordinate measuring machines and other testing equipment.

Understand Your Project Needs:

Identify the essential information: the complexity of the part, what kind of material is used, how large is the production volume, and what the tolerances are (e.g., 0.025mm).

Beyond Price: Comprehensive Value Considerations:

Concentrate on technical optimization, openness of the production progress, and customer support, instead of just looking at the prices.

Want to quickly find the best 5 axis cnc service partner for your needs? Request JS Precision's "5-Axis Machining Service Provider Evaluation Checklist." Compare each item on the checklist to easily avoid selection risks and find a truly reliable manufacturing partner.

What Are The Unique Advantages And Application Scenarios Of Aluminum 5-Axis CNC Machining?

Aluminum alloy is one of the most commonly used materials in high-end manufacturing, which simply makes it a perfect match for 5-axis machining technology. Aluminum 5-axis CNC machining, through its distinct benefits, has found applications in various industries and thus, has become the golden standard of lightweight, complicated parts manufacturing.

Why are aluminum alloys and 5-axis machining a match made in heaven?

Aluminum alloy has excellent cutting performance, coupled with 5-axis equipment for high speed and high feed performance, which can achieve high material removal rate, avoid thermal deformation, and balance accuracy and smoothness.

Key Industry Application Panorama

| Industry Sector | Typical Application Parts | Machining Requirements | 5-Axis Machining Advantages | Material Type | Single Part Machining Cycle (hours) |

| Aerospace | Cabin Structures, UAV Frames, Satellite Supports | Lightweight, High Precision, Complex Structures | Single molding of complex features, weight reduction of 15%-30% | 6061-T6, 7075-T6 | 8-24 |

| Automotive & Transportation | Lightweight Chassis Components, Battery Trays, Integrated Body Parts | High Strength, High Consistency, Short Cycle Time | High-speed machining results in more efficient production and batch precision | 6082-T6, 5083- H112 | 4-12 |

| High Technology & Industry | Robot Articulated Arms, Optical Equipment Brackets, Thermal Management System Housings | High Precision, Low Noise, Excellent Surface Quality | Tool marks removal, no need for secondary polishing | 6063-T5, 7050-T7451 | 6-18 |

| Medical Equipment | Surgical Instrument Housings, Rehabilitation Equipment Parts | Biocompatibility, High Precision, Complex Curved Surfaces | Accurately controlled tolerance, saving materials | 6061-T651, 2024- T351 | 10-20 |

| Electronic Equipment | Mobile phone mid, frame, base station heat sink, precision connector. | Thin-walled, high, gloss finish, small tolerances. | High-speed cutting lowers deformation and enhances surface texture. | 6061-T6, 6005A- T6 | 2-8 |

Key Processes for Achieving Excellence

High-speed cutting strategy, specialized aluminum alloy tools, combined with oil mist cooling to control deformation and smooth chip removal, ensuring excellent machining results.

Do you need a reputable aluminum 5-axis CNC machining service? Send us your part drawings and technical requirements.JS Precision will offer you a free quote of machining costs and lead time, as well as material selection consultation, thus turning your aluminum alloy parts machining both efficient and economical.

Case Study: JS Precision Helps Electric Aircraft Lightweight Joint Arm Reduce Costs And Increase Efficiency

Electric aircraft manufacturing is a field where lightness of materials and precision of dimensions are essential requirements, and yet, the machining of complex structural parts often remains a major obstacle for the project progress.

JS Precision, a company for precision machining, has been able to help a challenging machining issue in a lightweight articulated arm for an eVTOL project by using 5 axis high speed cnc machining technology.

Challenge:

The core articulated arm of this project is made of 7075-T6 aluminum alloy material, with a complex component structure that includes multiple deep cavities and thin-walled features, with a thin-walled thickness of only 2mm. The customer required that the tolerances at only the most important locations be kept within 0.05 mm while also meeting the weight reduction targets.

The traditional multi process processing solutions not only took the product to full delivery for up to 15 days and had high costs (US$800 per piece), but also, due to multiple clamping operations, the part was deformed excessively causing its weight to no longer comply with the design requirements.

JS Precision Solutions

1.In-depth DFM Optimization:

JS Precision's engineers analyzed the original design thoroughly and proposed changing three assemblies into one single piece for the machining process, which allowed them to reduce the number of connectors and ultimately, attain a 15% weight reduction accompanied by even higher structural strength.

2. 5-axis high-speed Machining Strategy:

A German DMG MORI 5 axis high speed cnc machining center was utilized to develop a specially designed milling strategy. By combining high speeds (25, 000 RPM) and ideal cutting path selections, a material removal rate of more than 80% was attained while the deformation control at the thin, walled sections was kept to less than 0.1mm.

3. End-to-End Precision Control:

In order to check critical dimensions in real time and make compensations accordingly, an on, machine measurement system was employed during the machining process. For the full-dimensional verification after the process, a three- coordinate measuring machine (CMM) was used, thus assuring that each piece complied with the set tolerance requirements.

Results

By leveraging JS Precision's 5-axis CNC machining services, the articulated arm component yielded an almost perfect 99.5% first, pass yield rate, which resulted in a reduction of the total machining duration from 15 days to 9 days (a decrease of 40%).

The unit cost came down to $600, and the overall project cost dropped by 25%, hence, the weight reduction targets were surpassed and improved overall machine performance in a direct manner.

Have similar complex part machining needs? View JS Precision's complete case library to learn more about industry solutions, or contact us directly to let us customize a machining solution for your complex parts, achieving cost reduction and efficiency improvement.

Figure 3 Electric vertical takeoff and landing aircraft, with the cockpit supported by an eight rotor boom.

Figure 3 Electric vertical takeoff and landing aircraft, with the cockpit supported by an eight rotor boom.

How Do 5-Axis CNC Machining Services Support The Entire Process From Rapid Prototyping To Mass Production?

The advantage of 5-axis CNC machining services goes beyond a single machining phase, as it covers the whole lifespan of the product from rapid prototyping to large-scale production, thus facilitating coherent and efficient manufacturing support for projects at various stages.

Rapid Functional Prototype Development

Easily interpret 3D models to quickly deliver functional prototypes without the need for complex tooling, swiftly validate the design and assembly, and speed up the R&D circle.

Simplifying the Small, Batch Pilot Production Process

Prototypes and small, batch production utilize the same 5 axis milling machines and methods, thus eliminating the risks of process conversion and the need for secondary investments, resulting in "the prototype as the product."

Ensuring Stability and Efficiency in Large, Scale Production

Production at scale is based on automation and standardization:

- Automated Configuration: Pallet exchange and robotic loading/unloading allow non-stop 24/7 production.

- Standardized Procedures: The use of uniform CAM programming parameters ensures that the processes are repeatable(CpK > 1.67), which leads to a guaranteed consistency.

What Are The Key Factors Affecting The Pricing Of Precision Parts For Obtaining Fast CNC Quotations?

Accurate and rapid quotations are vital for the progress of projects, and the correctness of a quick quote CNC machining is dependent on a few main points. Knowing these points will facilitate you to give complete information, thus resulting in a more precise quote.

The Logic Behind Rapid Quotes

Expert service providers use automated software tools to perform an analysis of the models, and engineers check the Designed Cost Model (DFM), thus producing correct cost analyses within 24-48 hours, achieving a balance between precision and competitiveness.

Core Components of Part Cost Analysis

| Cost Composition | Influencing Factors | Percentage Range (%) | Calculation Method | Space Saving (%) |

| Machining Cost | Part complexity, programming difficulty, machining time | 40-60 | Machine tool hourly rate × machining time + programming fee | 15-30 |

| Material Cost | Material type, specifications, utilization rate | 15-30 | Material unit price × usage × (1 + loss rate) | 5-15 |

| Precision Cost | Tolerance requirements, inspection difficulty | 5-15 | Precision premium + inspection equipment usage cost | 3-10 |

| Surface Treatment Cost | Treatment method, surface requirements | 5-10 | Treatment unit price × part surface area | 2-8 |

| Management Cost | Order quantity, project complexity | 5-10 | Fixed management fees + variable service fees | 3-7 |

Materials and tolerances largely determine the cost. Titanium alloy is priced at a level 8-10 times higher than 6061 aluminum alloy. Strengthening tolerances to 0.025mm may lead to an increase in machining costs by 30%-50%.

How to get ready for quick and accurate price quotations?

Gather together your "Request for Quotation (RFQ) Package": 3D model, material specifications, 2D drawing with key tolerances, surface treatment requirements, and estimated production volume. The more detailed the information is, the more precise the quote will be.

Want to get accurate quick quote CNC machining? Upload your complete RRFQ Package to JS Precision. We will provide a detailed quote within 24 hours, highlighting cost optimization points to help you control your budget while ensuring quality.

FAQs

Q1: What level of precision can 5-axis CNC machining achieve?

JS Precision is able to achieve a positioning accuracy of 0.003mm by using high, level 5 axis milling machines and mature processes. Normally, workpiece tolerances can be stably kept within 0.025mm, and under special processes, even higher precision can be obtained.

Q2: What is the difference between 5-axis and 3+2-axis positioning machining?

5-axis linkage refers to the continuous cutting of complex surfaces by cutting tools during motion, capable of handling multiple continuous surfaces. The 3+2 axis is only processed in a 3-axis manner after positioning, and cannot handle complex surfaces, resulting in lower machining accuracy and efficiency.

Q3: What are the smallest/largest parts that can be machined?

The machining capacity is different from one machine to another. JS Precision can produce very small parts (such as 2mm precision mobile phone components) as well as large, complex parts of over 1 meter in size, thus being able to meet the size requirements of different industries.

Q4: Does the quotation include all costs?

JS Precision's quotation covers materials, machining, standard deburring, and basic inspection fees. Additional inspections, special packaging, or surface treatments, etc. would be negotiated and specified separately.

Q5: How long does it typically take from inquiry to receiving a sample?

JS Precision should be able to get the first sample out for aluminum alloy parts of standard complexity within 2-4 weeks after they have the full data and have confirmed the quotation. They do expedite rush orders.

Q6: How do you control deformation during machining?

We manage the machining deformation very well and guarantee the part accuracy by using multiple steps including optimized clamping schemes, scientifically planned cutting paths, setting reasonable cutting parameters, and stress release during the process.

Q7: Can you machine difficult-to-machine materials such as titanium alloys or stainless steel?

JS Precision was able to acquire specialized machine tools, cutting tools, and cooling processes for utilizing difficult, to, machine materials, thus now it can make precise machining of various high, temperature alloys, stainless steel, titanium alloys, and other materials.

Q8: Why is the unit cost higher for small-batch production than for large-batch production?

Because the fixed costs of programming, process preparation, and first piece debugging are allocated to fewer parts, the larger the batch size, the lower the fixed cost allocated to each individual piece, resulting in a lower overall cost per piece.

Summary

5-axis CNC machining services used to be an option only in elite manufacturing. Now they are a vital part of achieving accurate and efficient production for complex parts and developing new products.

With our ultramodern equipment, expert technology, and end-to-end solutions, JS Precision can take your most complex designs and turn them into top, notch physical parts by balancing accuracy, efficiency, and cost.

Your next revolutionary design deserves the best manufacturing processes. Just send your 3D model to JS Precision and discover our quick quote CNC machining capability and engineering suggestions based on thorough DFM analysis.

Let us use the best 5 axis CNC technology and full process project support to become your most reliable manufacturing partner for overcoming complex part processing challenges and winning market competition.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com