The forms of today's products have become increasingly complex in the modern engineering quest for ultimate performance: from turbine blades with a perfectly aerodynamic surface, to irregularly shaped aerospace skeletons developed for weight reduction, and to medical implants that merge with the human skeleton.

Manufacturing of these parts has come to pose near-obsessive challenges to traditional machining techniques. 5 axis CNC machining is the ultimate answer to this challenge.

It's not just a machine tool that can move in five directions but a philosophy towards the attainment of "perfect shaping in a single setup" through complex CNC machining thinking.

This guide will help you to understand fully the definition, process, and types of 5 axis CNC machining so that you can use the technology without further confusion about whether it's suitable for your project. It also shares some practical experiences of JS Precision in this area to give you a reliable reference for your manufacturing needs.

Core Answers Summary

| Comparison Dimensions | 3-axis CNC Machining | 5 axis CNC machining |

| Machining Degrees of Freedom | 3 linear axes (X, Y, Z) | 5 axes (X, Y, Z, A, B/C), tool can approach the workpiece from any direction. |

| Clamping Frequency | Several times, to machine different surfaces. | One clamping, to finish machining of five surfaces and complex curved surface. |

| Accuracy and Error | Cumulative error due to repeated clamping exists. | Extremely high, eliminates repeated positioning errors, accuracy can reach ±0.01mm or even higher. |

| Complex Surface Capability | Limited, many adjustments are needed. | Excellent, can complete the machining of continuous complex curved surfaces, such as impellers or reliefs, in one go. |

| Setup and Programming | Relatively simple. | Highly complex, relies on professional engineers and advanced CAM software. |

| Applicable Scenarios | Sheet metal parts, bases, simple contours. | Core complex components in aerospace, medical, automotive, energy, and other fields. |

JS Precision Engineer's Guide: Comprehensive Explanation Of 5 Axis Machining Technology

The 5 axis CNC machining at JS Precision has been deeply involved in this industry for 12 years, and it has played a decisive role, not only through.

Our company holds the ISO 9001 quality management system certification, AS9100 aerospace industry certification, and ISO 13485 medical device quality management system certification. We also have 30 high-end 5-axis CNC machines from brands such as DMG MORI and Mazak.

We have processed more than 100,000 complex parts for over 800 clients in the aerospace, medical, and drone industries, including a leading aerospace manufacturer and a leading medical device company.

For example, the structural parts of the engine combustion chamber made for an aerospace client were processed with Ti6Al4V titanium alloy and reached a tolerance of ±0.005mm.

We have finished the monthly mass production of 5,000 medical-grade PEEK spinal implant parts for medical clients and maintained a pass rate over 99.8%. And we accomplished an annual production capacity of 20,000 integrated frames for a drone manufacturer, ensuring a defect rate below 0.1%.

This is not a theoretical guide, it is a condensation of our practical experience over the years. Every point is verified in actual production, and you can completely trust its professionalism and practicality.

If you need reliable 5 axis CNC machining services, JS Precision has vast industry experience and authoritative certifications and can provide high-end equipment to give you a precise machining solution. Kindly submit your part requirements, and we'll get back to you in no time. Just reach out and let's get started!

What Is A 5 Axis CNC Machine? A Manufacturing Revolution Beyond Three Dimensions

After understanding JS Precision's expertise in 5 axis CNC machining, perhaps you would ask: what exactly is a CNC machine 5 axis? Why is it considered a manufacturing revolution beyond three dimensions?

Basic Definition

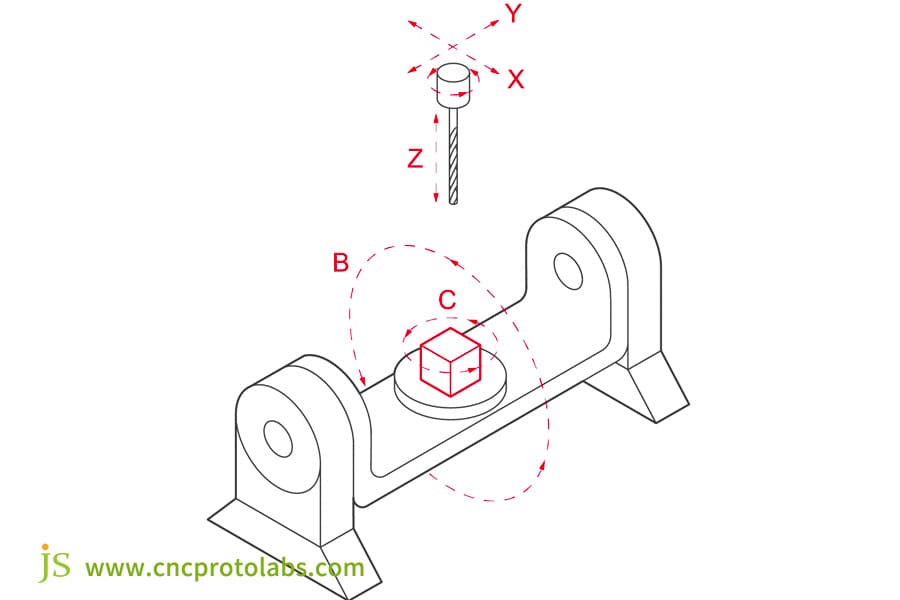

A 5-axis CNC machine tool is an advanced device that adds two rotary axes to the traditional three linear axes: X, Y, and Z axes control the forward and backward, left and right, up and down movements of the machine, respectively.

This enables the cutting tool to approach the workpiece from multiple angles, realizing five-sided machining and continuous spatial surface machining that could not be done by a 3-axis machine tool.

Core Type Analysis

| Type | Working Mode | Applicable Scenarios |

| 3+2 Axis Positioning Machining | After fixing the inclination angle of the workpiece, use 3-axis milling. | Rough cutting and simple precision machining of multi slope parts. |

| 5 Axis Linkage Machining | Five axes move simultaneously under the control of a computer, while the tool and workpiece are positioned in real time. | Complex machining includes such parts as engine blades and mold cavities. |

The core value that a CNC machine 5 axis can provide is "one setup, all done." Compared with 3-axis machining, it increases efficiency by over 50%, eliminates positioning errors, and can process complex geometries, which is the key to its revolutionary influence on manufacturing.

Figure 1:The additional two axes on a five-axis machine dictate how the A and B axes rotate around X, Y, and Z.

How Does The 5 Axis CNC Machining Achieve An Astonishing Accuracy Of ±0.01mm?

Following an introduction to the basics of 5-axis CNC machine tools, one may ask themselves, how is this even possible, to get such an astonishing accuracy as ±0.01mm? This accuracy is much smaller than the diameter of a single human hair, which is about 0.05 mm.

1. Error Elimination:

One-time setup is the fundamental way to eliminate errors. Conventional 3-axis CNC machining needs a lot of clamping processes, and the accumulation of datum conversion errors will affect the accuracy. In contrast, 5 axis CNC machining completes all machining operations in one setup without the accumulation of errors.

2. Advantages of Shorter Tools:

Because the workpiece angle can be adjusted by two rotary axes, the cutting tool is always entering at an excellent angle relative to the machined surface. The shorter the tool, the less it vibrates when speeds are high. It also exhibits less "tool deflection" and improves surface quality and dimensional stability.

3. Dynamic Precision Compensation:

High-end 5 axis CNC machines adopt multiple methods for accuracy compensation, among which some models can provide real-time deviation correction in a closed-loop feedback system using a linear encoder, temperature-adjusted parameters for thermal deformation compensation, and backlash compensation for backlash error elimination to ensure high precision during high-speed cutting.

Precision up to ±0.01mm is achieved by high-end machine tools, temperature-controlled workshops, and regular calibration.

Which Materials Perform Best On A CNC Machine 5 Axis?

Besides precision, some of the intrinsic benefits of 5 axis CNC machining include its wide adaptability to materials, thereby making it an "all-rounder." Which materials work best on a 5 axis CNC machine?

| Material Type | Representative Material | Application Area | Machining Advantages |

| Aerospace Grade Alloys | Titanium Alloy (Ti6Al4V), Inconel. | Engine and space craft structural components. | Controls cutting heat and work hardening, prevents material deformation. |

| Medical Grade Materials | Pure Titanium, Cobalt-Chromium Alloy, Medical Grade PEEK. | Artificial Joints, Surgical Instruments. | Meets biocompatibility requirements, achieves ultimate surface finish. |

| Mold Steel and Aluminum Alloy | 718H Mold Steel, 7075 Aluminum Alloy. | Injecting molds of various parts, lightweight structure parts for UAVs. | Efficiently processes complex cavities and surfaces, suitable for complex CNC machining. |

5 axis CNC machining has the capability to deal with almost all machinable materials, especially the ones of value or difficult to machine. JS Precision boasts a database of experience in machining hundreds of materials and offers special tools for preventing the hardening of titanium alloys, ensuring biocompatibility with medical-grade PEEK in strict environmental control.

3-axis Vs 5-axis CNC: What Is Your ROI?

When it comes to material adaptability, people often focus their attention on costs. What's the difference in 3-axis vs 5-axis CNC ROI? It needs to be considered both from a cost-saving and a value-enhancing perspective.

Apparent Cost Savings

| Cost Type | 3-Axis CNC Machining | 5 axis CNC machining |

| Jig Cost | Many specialized jigs are needed at $500-$2000 per set. | Fixture cost reduced by more than 60%, result is 30%-50% cost reduction. |

| Labor & Time | Clamping, debugging, inspection over 8 hours/piece. | Total time within 3 hours/piece, reduce labor cost 40%. |

| Scrap Rate | Positioning errors create a scrap rate of about 5%-8%. | Scrap rate decreases to nearly 0% because of one-time clamping. |

Increasing Hidden Value

| Value Dimension | 3-Axis CNC Machining | 5 axis CNC machining |

| Design Freedom | Complicated, difficult-to-machine complex surfaces necessitate design-for-manufacturability accommodation. | Unlocks difficult-to-manufacture designs, such as integrated structures. |

| Product Performance | Multi-part assembly contributes to structural instability and loosening. | Overall machining assures structural integrity, increasing reliability by 30%+. |

| Speed to Market | Prototype cycle of 2-3 weeks impacts iteration. | Prototype cycle reduced to 5-7 days accelerates time to market. Most companies invest. |

Most companies invest in 5 axis equipment with high costs and high risks. Choosing professional 5 axis CNC machining services can provide top-level capabilities, avoid risks, and reduce costs.

If you are considering between 3-axis vs 5 axis CNC machining, JS Precision offers value-for-money 5 axis CNC machining services. Please feel free to submit part drawings and technical requirements to get a detailed solution, saving your time from investment in equipment.

Figure 2: What is the difference in investment return between 3-axis vs 5-axis CNC?

How To Develop A 5 Axis Machining Process For Complex CNC Machining Parts?

Once you opt for 5-axis machining, how do you go about developing a process plan for a complex CNC machining part? Below is our process planning method in four steps:

1. DFM (Design for Manufacturing): Customers should, in the early design stage of the parts, work closely with the JS Precision engineers to perform design for manufacturing analysis. Based on the characteristics of 5 axis machining, the part structure will be optimized: adjust the position of holes, simplify surfaces, enhance manufacturability, reduce costs, and shorten the cycle time.

2. Strategy Selection: Adopt the strategy that combines "3+2" fixed-axis machining with 5-axis simultaneous machining. "3+2" is suitable for roughing and multi-angle machining, offering high efficiency, while 5-axis simultaneous machining is suitable for surface finishing to ensure accuracy and surface quality.

3. Toolpath Optimization: Apply helical milling and contour machining, among other techniques, to reduce shock, stabilize cutting forces, avoid overcuts from vibration, and protect the tool while improving quality.

4. Fixture Design: Actually, these custom fixtures are the basis for performing successful complex CNC machining. They need to ensure rigidity, not allowing wobbling of workpieces, while maintaining the range of rotation axes to avoid interferences.

We machine parts and also offer end-to-end process solutions, from design through mass production.

For complex CNC machining parts requiring process design, JS Precision provides 5 axis CNC machining services that will give full-process support from DFM analysis to fixture design. We follow through on the whole process in order to make sure your project is produced efficiently. Contact us to get this collaboration started.

What Are The Golden Parameters For 5 Axis High Speed CNC Machining?

5 axis high speed CNC machining can further improve efficiency. However, it is a matter not of increasing speed but of mastering the golden parameters. Well, what are these parameters?

Concept of High-Speed Machining

The principle underlying 5 axis high speed CNC machining is "high speed, high feed, small depth of cut, small step distance," meaning high tool speed, high travel, small depth of cut, and small step distance. This can be translated into more material removal per unit time and decreased cutting force for improved surface quality.

The Art of Parameter Coordination

1. Spindle Speed and Feed Rate Match: Calculated by tool diameter, number of flutes, and material. For instance, during the machining of aluminum alloy with a 10mm 4-flute carbide tool, the spindle speed should be set at 10000rpm and the feed rate at 1500mm/min to maintain the chip thickness for optimal conditions and to prevent tool wear.

2. Applications of Trochoidal Milling: The application area of the trochoidal toolpaths is for deep cavities/narrow grooves, without full-width cutting, less tool stress, thus protecting the tool, and providing efficiency especially in applications involving hard-to-machine materials.

3. Acceleration and Anticipation Function: High machine tool acceleration can make the tools quickly reach speed, cutting down non-cutting time. The foresight function analyzes events ahead of time in a toolpath, including necessary parameters to prevent deceleration or surface deformation.

We have a library of thousands of vetted parameters, balanced between efficiency and quality.

If you need 5 axis high speed CNC machining services, JS Precision has professional parameter libraries and high-end machine tools. It can efficiently machine the parts for customers. No matter whether it is deep cavities or complex surfaces, we are confident of making them easily. You just need to tell the requirement of the parts, and we will match the optimal parameters.

Case Study: How JS Precision Reshapes A Drone's Main Frame Using 5 Axis High Speed Machining

Client Challenge

A manufacturer of industrial-grade drones needed to manufacture a one-piece 7075 aluminum alloy main frame. Traditionally, the company used a 3-axis machine tool that needed the frame to be machined into 5 pieces, then assembled in more than 12 hours.

The precision error of the assembled frame was as high as up to ±0.1mm, which does not meet the requirements of flight stability. There were many connectors, weighing as much as 1.2kg, impacting flight range, and posing risks in respect to structural strength, some loose connectors were observed during testing.

JS Precision's Solution

1.Design Integration:

We integrated designs based on requirements first, designing the original 5 pieces into a single integrated structure. This design completely eliminated all connectors and solved assembly error and weight issues from their roots.

2.5 Axis High Speed Machining:

The 5 axis high speed machining center adopted was the DMG MORI DMC 850 Vec. First, it rapidly removed 70% of the extra material by using the "3+2" fixed-axis mode, and then switched to 5-axis simultaneous machining mode for finishing, which included some of the complex structures like the irregular curved surface and internal flow channel on the frame without secondary clamping throughout the whole process.

3.Optimized Parameters:

For 7075 aluminum alloy, the value for spindle speed was determined to be 18,000 rpm, feed rate as 8,000 mm/min, and depth of cut as 0.2 mm. Besides, a trochoidal milling strategy was used to avoid tool overload in machining narrow internal grooves. Smooth movement during surface machining was guaranteed by the 100-segment look-ahead function of the CNC system.

Achievements and value of our company

Eventually, we shortened the overall machining time from 12 to 4 hours, while increasing efficiency by 300%. This decreases frame weight by 15% to 1.02kg, with a 10% increase in range, overall rigidity increased by 40% makes it resist strong impacts.

Single-clamp machining provides part tolerances of ±0.008mm, which meets flight stability requirements and achieves perfect sealing without letting rainwater into internal circuitry.

With this frame, customers reached a better payload and range compared to their competitors, therefore gaining a great competitive advantage in the market.

Figure 3:7075 aluminum alloy integrated unmanned aerial vehicle main frame

How To Identify And Partner With A Reliable 5 Axis CNC Machining Services Provider?

In light of the above-mentioned benefits of 5 axis machining, you might look for a suitable service provider. How then would you identify and partner with a reliable 5 axis CNC machining services provider? I have summarized five key evaluation criteria.

1. Technical Equipment: Check the brand of machine tool, precision, milling, and turning capability. For instance, check if they have a 5-axis machine tool such as DMG MORI or MAZAK, and if the positioning accuracy reaches ±0.005mm.

2. Engineering Team: Provide an overview of their work experience in CAM programming and process engineering of parts. Must be familiar with UG and Mastercam software, be able to define processes, and provide solutions based on part-specific needs.

3. Quality System: See if they have full-size inspection equipment such as coordinate measuring machines and laser scanners. It's very hard to ensure the accuracy of parts without inspection capabilities.

4. Industry Expertise: Assess their successful case studies related to your industry. For example, aerospace requires experience with high-temperature resistant materials, medical applications require experience in biocompatibility.

5. Communication and Transparency: Observe if they are able to make clear process plans, progress feedback, and inspection reports. Transparency in communication provides more peace of mind.

The five standards of JS Precision include 30 high-end 5 axis machine tools, 10 of which are mill-turn centers, engineers with an average of 8+ years' experience, fully implemented testing equipment, numerous case studies across many fields, and transparent project progress.

We will constantly work to become a reliable "external R&D and manufacturing department" for clients in the complex CNC machining field.

Figure 4:Evaluate the reliability of 5 axis CNC machining service providers by examining their technical equipment.

FAQs

Q1: What is the general minimum tolerance usually reachable in 5-axis machining?

The precision can be up to ±0.01mm with high-quality equipment and rigid control at JS Precision, even for some features reaching ±0.005mm, thus satisfying the demands of high-precision parts.

Q2: Is 5-axis programming very time-consuming and difficult?

Programming for 5 axis machines is more complicated compared to 3-axis machines. Programming such machines requires advanced CAM software and great experience. At JS Precision, however, we negate this challenge for you with our professional programming teams with efficient workflows.

Q3: What is the difference between "3+2" machining and 5-axis simultaneous machining?

"3+2" is fixed-axis machining, where the angle of the workpiece is kept in the same condition as that before 3-axis milling and is suitable for multi-angle features. In 5-axis simultaneous machining, all 5 axes move simultaneously, suitable for complex curved surface machining. The above two kinds of methods can be completed at the same machine tool.

Q4: What are the special requirements for machining titanium alloys on a 5-axis machine tool?

Highly rigid machine tools, special cutting tools, high-pressure internal cooling, proper parameters, and avoidance of work hardening are needed to cut titanium alloys, which are put under control to avoid generating too much heat during cutting. That is exactly what JS Precision masters.

Q5: Is it possible to perform turning operations on a 5-axis machine tool?

Yes, a Mill-Turn Center combines 5-axis milling and turning capability, enabling true "one-stop, all-inclusive" machining. JS Precision has this kind of equipment, too.

Q6: What size 5-axis parts can JS Precision handle?

JS Precision 5-axis machining is very powerful and can process parts from the millimeter to the meter level. Please specify the size you need, and it will be matched with the appropriate resources.

Q7: How to get a mirror finish while doing 5-axis machining of aluminum parts?

With the application of diamond tools, optimized high-speed finishing parameters, and a stable cutting environment, JS Precision can finish aluminum parts with Ra less than 0.2μm.

Q8: What is the lead time of a 5-axis machining project from order placement to delivery?

The project lead time depends on the complexity of the part. For simple prototypes, 3-5 days will be enough, but for complicated parts, it may take as long as 2-3 weeks. JS Precision will provide a delivery date based on your project.

Q9: Do you provide post-processing surface treatment after 5-axis machining?

Yes, here at JS Precision, we provide a one-stop surface treatment service including anodizing, sandblasting, painting, passivation, and electroplating, hence assuring complete part delivery with no need to source other service providers.

Q10: How do I get a quote for 5 axis CNC machining from JS Precision?

Just send your 3D drawings and technical requirements to JS Precision, our professional team will help you with a detailed, transparent quote within the shortest time.

Conclusion

5 axis CNC machining is much more than just two extra axes of machinery, it is the basis for a manufacturing revolution which has enabled ±0.01mm accuracy and the ability to machine parts of higher complexity. It helps you save money, increase product performance, and speed time to market. This matters a lot to aerospace, medical, and drone industries.

As a professional 5 axis CNC machining service provider, it is the mission of JS Precision to convert this technological advantage into real value for you by making complex manufacturing simple.

Don't let the limitations of traditional machining become a bottleneck for your product innovation. Send your CAD file to JS Precision's expert team now, and experience the precision, efficiency, and value of top-tier 5 axis CNC machining services. You'll get an initial process feasibility analysis and competitive quote in your hands in under 6 hours.

Let's bring your next big idea to life together!

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com