5 axis CNC machining services are not a preserve of modern manufacturing. Are you suffering when designing complicated gimbals for drones, precision components for the healthcare sector, or distinctively shaped structures for the aerospace sector because of things like late delivery, inferior precision, and high costs?

In fact, for most engineers, 5 axis CNC machining services are still clouded with a haze of "expensiveness" and "barriers to entry," when the fact is that because of the development of precision manufacturing in China, accomplished firms such as JS Precision have made this high-tech service highly accessible.

This article, in addition to unearthing the hidden realities behind the advantages of 5-axis machining vs. 3-axis machining, will also showcase how our intelligent online CNC machining service helps you to procure precision custom 5 axis parts at predictable prices.

Core Answers Table

| Customer's Core Concerns | Industry's Common Situation | JS Precision's China Intelligent Manufacturing Solution |

| Technological Capabilities & Precision | Most suppliers have limited capabilities, resulting in low machining yield and large precision fluctuations for 5-axis impellers such as impellers. | Multiple high-end 5-axis machining centers, specializing in customized complicated 5-axis machining, reliable precision of +/-0.02mm, Ra0.8μm surface finish. |

| Predictability of Cost & Lead Time | It takes a long time to quote, with high communication costs, making it a challenge to predict the lead times because the process is complex. | Online intelligent quoting CNC machining service platform with preliminary DFM analysis, providing a transparent quote within 60 seconds, with standard parts available within 7 business days. |

| Collaboration and Knowledge Threshold | The customers require a high level of 5-axis knowledge that leads to high design risks. | Providing free deep DFM collaboration, our engineers are an extension of your team, working together to optimize designs to maximize 5-axis machining efficiency. |

Key Takeaways

- 5-axis is not necessarily cost-prohibitive: Often, for a complicated component, 5-axis machining is less expensive than a multi-step 3-axis machining operation when multiple machining tasks are reduced to a single process.

- Precision is a result of systematic control: The China-based suppliers have hardware as well as databases that are on par with European and American suppliers, making it possible to provide precision components.

- Online services are critical to efficiency: Smarter quoting systems can instantly translate designs into manufacturable plans, which cuts the initial time significantly.

- Early collaboration on DFM is highly valuable: Early intervention on a quote can mitigate as much as 30% of potential costs.

- Make in China is a competitive advantage: Compared to other technological conditions, the China supply chain is unbeatable in speed, flexibility, and overall cost competitiveness.

JS Precision: 5 axis CNC machining services For Precise Customization Of Complex Parts

Having 15 years of experience within the realm of 5-axis CNC machining, the strengths of JS Precision lie in its accumulated experience as well as stringent quality control.

We have been handling more than 5,000 customers worldwide, pertaining to a host of high-end sectors such as the aerospace, healthcare, drone, and renewable energy sectors, besides handling more than 100,000 customized machining orders.

In the aerospace industry, the 5-axis impellers that we have processed for our customers have passed aerospace-grade performance verification, with more than 2,000 sets shipped. In the drone industry, our aluminum 5-axis CNC service has assisted more than a dozen customers in realizing a lightweight and strong structure for the critical components of drones.

We have more than 30 sets of high-tech machines with 5 axes, , all of which comply with ISO 23218-2 standards. We have also created a database of more than 500 types of materials, which helps us quickly find the best solution for machining different types of complicated components.

This e-book is a compilation of what we consider our most essential knowledge on how to address a variety of complicated machining requests. We have verified every assertion presented here with actual cases, and all recommendations offered have been proven in practice.

Do you have a need for customized complex parts? Submit your parts immediately, and our 5 axis CNC machining service will evaluate the feasibility for you free of charge. We can also send precision custom 5 axis parts samples for you to visually verify our international standard quality and practical strength.

How Does The Strategic Use Of 5 axis CNC machining service Optimize Lead Times?

Lead time is a matter of machining speed, but it is also a matter of the intelligence of the path of the process. The most essential reason why the 5 axis CNC machining service is capable of overcoming the problem of lead time in traditional machining is that it reconstructs the logic of the process, thus making the machining process of complicated parts smoother.

Moving from "Serial" to "Parallel": Reducing Multi-Process Waiting Time

In traditionnal 3-axis machining, there are several stages of clamping and machine-to-machine transfer, thereby involving a "serial" process with highly waiting times. In 5-axis CNC machining, all the machining of features is carried out in one clamping, with the steps progressing at the same time in "parallel" modes, devoid of waiting times.

Reduced Auxiliary Time: Extreme Simplification of Fixtures

The machining of complex components on a 3-axis machine mandates several sets of specialty fixtures, with the development time being 1 to 2 weeks. The 5-axis machine tool has a simple vise that is sufficient for complete clamping.

Our "Fast Track" Production Scheduling Logic

We have created a green channel with available capacity that is matched on a real-time basis by the intelligent production scheduling system that has been set up by JS Precision. We provide aluminum 5-axis CNC service with a turnaround for complicated pieces in 7 business days, which is 40% faster than average.

How To Get An Instant Online Quote CNC Machining Service For Complex Parts?

Our online quote CNC machining service simplifies taking an online quote for 5-axis impeller machining. The technology engine from JS Precision optimizes the complex quote process.

Three Steps to Get an Intelligent Quote: Upload, Configure, Confirm

The quote process is easy to use, with only three steps to follow:

- Upload the STEP/IGES 3D model, making sure the model captures all the details in the part.

- Choose the material (like aluminum alloy 7075, titanium alloy Ti6Al4V, etc.), the number of pieces to produce, and what additional processing is required (like anodizing, sandblasting).

- The system is capable of automatically determining the complexity level of the product based on geometric properties, along with preparing a quotation based on material prices, machining hours, and so on. The entire procedure takes not more than 10 minutes.

AI-Powered Preliminary Manufacturability Analysis

The quoting engine reviews the model in real-time, identifying potential machining difficulties such as deep cavities, negative angles, and thin-walled areas, making preliminary suggestions that form the basis for the following in-depth DFM analysis.

Transparent Cost Breakdown

We reject "black box" pricing. Our quote includes a breakdown of the price of the material, price of machine time, programming cost, fixture cost, and post-processing cost, giving you complete transparency on exactly how your money is being spent, giving you peace of mind.

Ready to get a quick quote on 5-axis impeller machining? Upload your 3D file now to take advantage of our online quote CNC machining service that provides a transparent quote in 10 minutes, along with a free preliminary manufacturability assessment.

What Tolerances And Finish Can You Expect From Top-Tier Aluminum 5-Axis CNC Service?

For precise custom aluminum 5-axis aluminum components, precision and surface finish are primary concerns. Aluminum 5-axis CNC service, with distinct advantages in the fabrication process, has far more precision in terms of accuracy and surface finish than regular machining, thereby meeting the stringent standards for high-quality products.

The Breakthrough in Geometric Tolerances: The Natural Advantage of Single Setup Machining

In 5-axis machining, all tasks are accomplished within a single set-up, with all dimensions relying on a common datum. The positioning error is within ±0.02mm, while the error in perpendicularity and concentricity is ≤±0.01mm. The precision offered by this machining technique is adequate for IT5 precision components, as specified in ISO 1101:2017, indicating a marked advantage in accuracy.

The Art of Surface Finish: Continuous Toolpaths and Cutting Angles

The 5-axis machining helps keep the ball-end mill at all times at the best cutting angle, ensuring smooth, continuous toolpaths. It is easy to produce a mirror finish with Ra 0.4-0.8μm on aluminum, which requires no polishing.

Overcoming the Limitations: Machining of Thin Walls and Micro-Features

We have machined 0.3mm thin-walled aluminum alloy components with a deformation of ±0.008mm, as well as high aspect ratio micro-holes with a ratio of 10:1 with a tolerance of ±0.01mm, continuously breaking through the processing limits of aluminum parts.

Would you like to know what accuracy your aluminum 5-axis CNC service is capable of? We can develop a tailored solution for your tolerance and surface finish needs, and send you a free precision custom 5 axis parts sample.

Figure 1:5-axis CNC machining of aluminum can achieve very strict tolerances and good surface smoothness.

Is Professional DFM Analysis Included In Your Online Quote CNC Machining Service?

In custom complex 5 axis machining, the most useful component of a quote is free DFM analysis, which is useful for optimizing designs with a cost-effectiveness goal.

Phase One: Automated Geometric Analysis by the Online System

In the quoting process, our cybersystem includes automatic geometric analysis of the part models. This corresponds to the "quick scan" step of the DFM process.

The system analyzes whether the minimum tool radius is adequate for part processing, notifies of potential difficulties during part processing with deep cavities, and notifies of potential instabilities during part processing with thin-walled cavities.

For instance, in case where the internal cavity of a part is not wide enough, the system will alert: "It is recommended to widen the inner cavity in order to take into account the minimum tool radius," which helps to identify potential problems even before designing.

Phase Two: In-depth Collaborative Review by Human Engineers

After that, a deep DFM analysis is carried out manually by the senior process engineers of JS Precision. Not only do we identify design problems, but we also come up with solutions for improvement.

For instance, in cases involving too complicated inner cavities, we will propose dividing the design or changing the structure, in cases involving insufficient strength, we shall recommend improved rib configurations for reinforcement, in cases involving difficulties in machineability, we will provide more.closest alternative designs.

Having arrived at the plan for optimization, we shall revise the final quotation in order to optimize the feasibility and economic efficiency of the solution.

Reducing Costs to Benefit from DFM

The customer changed the design of a complicated 5-axis component. Following the application of the DFM optimisation technique, the probability of equipment failure reduced by 15%, working hours reduced by 20%, cost per unit reduced by 18%, but the lead time reduced by 10 days.

| Project | Original Design Plan | DFM Optimized Plan | Optimization Range |

| Unit Machining Cost (in USD) | 650 | 533 | Reduce by 18% |

| Machining Scrap Rate | 12% | 1.8% | Reduce by 85% |

| Production Lead Time | 35 days | 25 days | Shorten by 10 days |

| Fixture Investment (in USD) | 3000 | 800 | Reduce by 73.3% |

| Total Investment (100 pieces, USD) | 71000 | 56100 | Reduce by 20.9% |

How Can The Benefits Of 5-Axis Vs 3-Axis Actually Lower Your Total Cost?

In fact, a common belief is that 5-axis machining is more costly than 3-axis machining, which is not true. The benefits of 5-axis vs 3-axis are evident in the increased efficiency, accuracy, and other cost savings, which are directly linked to TCO, thereby dismissing the belief that "5-axis is more costly."

Unit Cost Comparison: In cases when the degree of complexity surpasses a definite level

The cost differential is dependent on part complexity, 5-axis machining is more desirable for complex parts:

| Part Complexity | Manufacturing Technique | Unit Cost (USD) (10 pieces) | Unit Cost (USD) (100 pieces) | Total Cost (USD) (100 pieces) |

| Simple Parts (1 setup) | 3-axis | 250 | 200 | 20,000 |

| Simple Parts (1 setup) | 5-axis | 300 | 240 | 24,000 |

| Medium Complexity Parts (3 setups) | 3-axis | 480 | 400 | 40,000 |

| Medium Complexity Parts (3 setups) | 5-axis | 420 | 350 | 35,000 |

| High Complexity Parts (5+ setups) | 3-axis | 850 | 700 | 70,000 |

| High Complexity Parts (5+ setups) | 5-axis | 680 | 550 | 55,000 |

Costs of Quality: Reducing Scrap and Rework

Single setup 5-axis machining machines have less chance of error in setting datums, with a first-pass success rate that now reaches 98%+ compared with 85% for a 3-axis machine. 5-axis machines eliminate the cost of scrap and rework.

Time Costs: The Core Value of Accelerating Product Launch

The completion time for high-complexity components in 3-axis machining is 4 weeks, but for 5-axis, it takes only 10-15 days. This brings a drastic reduction in the entire product development life cycle, leading to a faster launch of the product in the market.

In the case of high-tech devices, a faster launch of 1-2 weeks will result in a 30%+ increase in sales, which is a huge margin over the cost differential in processing.

Want to quantify the cost benefits of 5-axis vs 3-axis? Kindly share your part details and production plan, and we can do a one-on-one cost comparison analysis to find, with numbers, which machining process is more cost-effective.

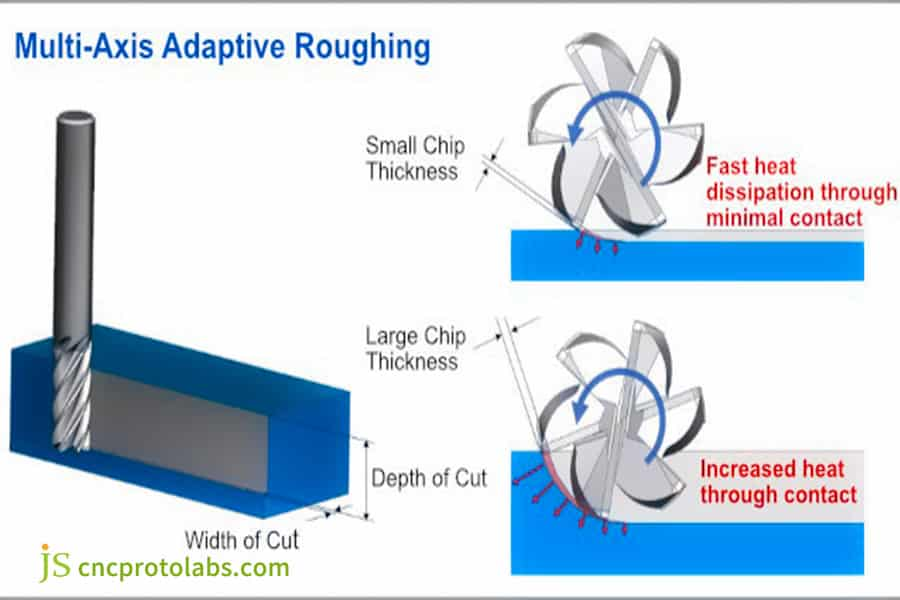

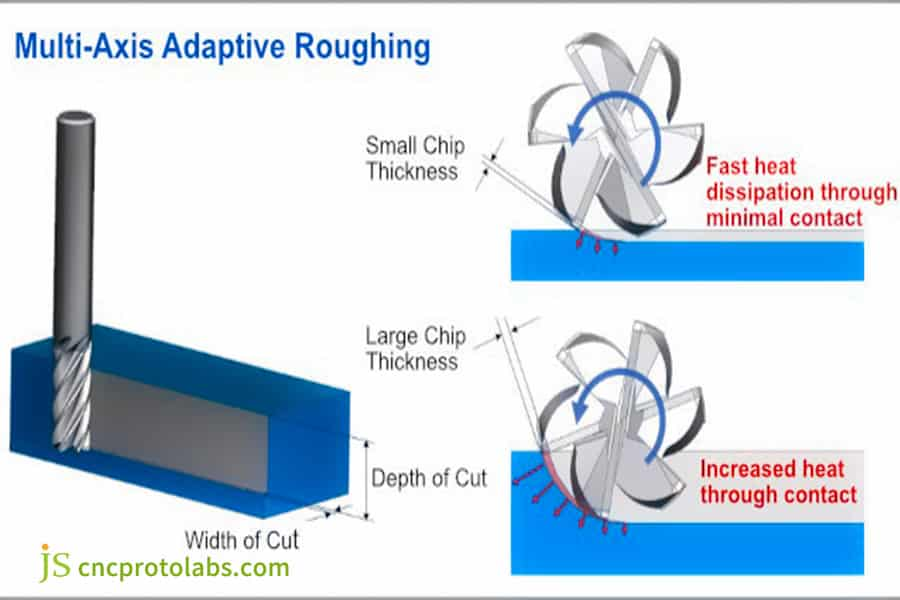

Figure 2:Multi axis adaptive rough machining adopts smaller step sizes and larger cutting depths, which can achieve faster feed rates and higher metal removal rates.

What Is The True Capability Scope Of custom complex 5 axis machining?

The essential meaning of custom complex 5 axis machining is to overcome the limitation of production. Multi-scenario complex machining problems can be solved with the help of JS Precision:

Materials Spectrum: Aerospace Aluminum & Titanium to High Performance Engineering Plastics

We are capable of handling difficult-to-cut materials such as aluminum alloys, titanium alloys, Inconel, as well as engineering plastics such as PEEK.

In the case of titanium alloys, we strictly follow the process specification that includes ASTM B348-13 and use low temperature cooling systems. In plastics, we optimize the design of the fixture to prevent deformation, including all the requirements of different plastics.

Geometry of Complexity: Impellers, Turbines, and Conform

The 5-axis impeller machining is our core competence that can tackle narrow flow channels, large-angle blades of closed impellers, integral blisk machining, and complicated medical surface machining, which can avoid tool interference problems by CAM programming.

Large Size & Micro-Precision: Covering Capability of Our Equipment Matrix

Our equipment can machine precision watch components with a diameter of Φ50mm, with a tolerance of ±0.005mm, and process big UAV aircraft body frames with sizes over 1200mm, with high precision.

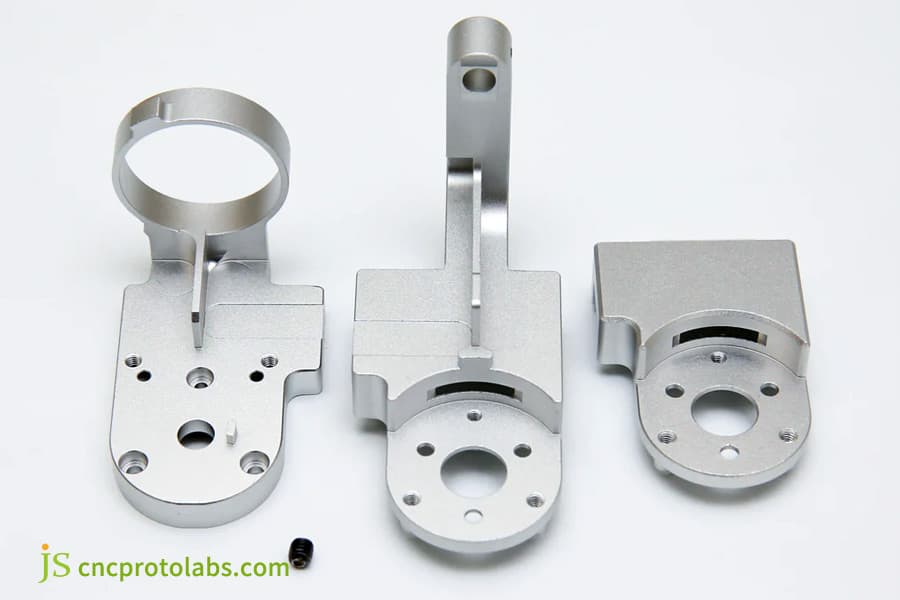

Figure 3:The flexibility of five axis machining supports a wide range of materials and geometric shapes, making it easy to process even precision parts with complex curves, shapes, and angles.

Case Study: From 4 Weeks To 9 Days: How 5-Axis Machining And Online Collaboration Redesigned a UAV Mount

5 axis CNC machining service has the potential to turn the entire product development and production process for complicated parts upside down, and a drone gimbal case is the best example.

Customer’s Original Plan and Bottlenecks

A company that produced UAVs came up with a design of a gimbal bracket made of 7075 aluminum alloy. The plan for the design was “3-axis milling of the body + welding multiple lugs," which involved teamwork with 3 third-party suppliers, taking a minimum of 4 weeks. Moreover, the joints of the welding section were brittle, with a high tendency of fracturing.

JS Precision's Intervention and Solution

The customer used our online quote CNC machining service to upload his design. The instant check result for him was as follows: "Multiple independent features can be combined into a single complex part for 5-axis machining.” On the basis of this result, our engineers contacted him directly and advised him to redo the design.

Our engineers returned in under 24 hours with a brand-new solution that accepted the original assembly of 7 pieces that were welded together and rebuilt it into a topological structure that could be optimally produced in one piece via aluminum 5-axis CNC machining.

The optimized design retained the mounting interfaces, as well as the necessary functionality, with unnecessary material subtracted in topological optimisation, thus increasing the strength of critical regions.

During machining, a large machining center with 5 axes has been used to complete all curved surfaces, irregular holes, as well as thin wall machining on the same setup, thereby dispensing with subsequent welding tasks.

Results

It cut the final delivery down to only 9 working days, which is a 77.5% reduction from the original plan, the cost of the total product was cut by 22%, the weight reduced by 18%, the strength problems at the welding point were corrected entirely, becoming one of the points of competitive advantage offered by the customer's end product to the market.

Would you also like to realize your short lead times and cost optimization on your complicated parts? Now, please upload your part model to our online quote CNC machining service, receiving our free DFM analysis with our overall machining solution, imitating the success of drone cases, releasing the core value of our 5 axis CNC machining service.

Figure 4:Aluminum alloy drone gimbal bracket

FAQs

Q1: I have only a concept sketchAvailable models are a rough model. Can I get a quote?

In that case, we recommend that you send us a complete 3D file so that we can give a precise quote. Alternatively, should your design only be a concept sketch or a rough 3D file, we are on hand with our concept consulting service.

Q2: What is the minimum / maximum workpiece size for the 5-axis machining?

The size of the workpiece depends on each machine tool. Our equipment is capable of processing from a small precision part of 50mm cube size to a large structural part of up to 1200mm in length. You can offer your approximate dimensions, and we will match you with a suitable machine tool.

Q3: Will the price change after the online quote?

The online quote that comes out based on the files you upload is quite accurate and reliable. If the design needs to be adjusted after we do DFM optimization, then we will provide the updated final quote. With an optimized solution, the price usually goes down, rather than up.

Q4: Is it possible to machine closed impellers for 5-axis machining?

Yes, the machining of closed impellers is one of our core capabilities when it comes to custom complex 5 axis machining. We can do the best job in the machining of narrow flow channels and large-angle blades, guaranteeing precision and quality in its surface.

Q5: Can small quantities, say 10 pieces, also accept online quotations and rapid delivery?

Of course, all our systems and flexible production lines are prepared for small batches and multi varieties of precision custom 5 axis parts. Small batch orders can also enjoy online quotations and fast delivery services.

Q6: How much more expensive is 5-axis machining compared to 3-axis machining?

Impossible to generalize. For simple parts, 3-axis machining is cheaper, for complex parts-more than 3 setups-5-axis machining can be less expensive because you save on multiple equipment and setup costs. You can consider our online tool for a comparison.

Q7: Is it possible that the parts will be damaging during transportation?

We use rigid fixed packaging and insure each item. In case of transportation damage, we will assist you in handling claims and prioritize remanufacturing to ensure that it does not affect your project progress.

Q8: What is the logistics time and cost from China to the US/Europe?

It takes about 3-7 days by air freight and about 20-35 days by sea freight. The logistics cost can be estimated on our official website by using an online quotation tool. We also offer a door-to-door service that includes shipping and insurance, thus saving you time and effort.

Summary

It is no longer proper to mention 5-axis CNC machining with high cost. The real value of 5-axis CNC machining lies in the freedom it gives the designers from manufacturing constraints and ultimately gives efficiency to the manufacturers.

JS Precision combines world-class 5 axis CNC machining services through intelligent online quoting, offering this freedom and efficiency to innovators worldwide predictably and at an affordable cost.

No longer compromise on manufacturability and high costs of complex parts.

Unlock your designs' full potential today! Go to the JS Precision website and upload your 3D model on our intelligent online quoting platform. Within 60 seconds, you won't just see a price but get a clear roadmap for the future of your part manufacturing. Let us create, together, from the most complex of ideas to the most exquisite realities.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com