A CEO of an American startup company is worried about quoting for a small batch, high-precision part: Local vendors were quoting high prices and long lead times, while Pacific vendors in China were quoting half the price with guaranteed faster delivery. He was racked with uncertainty: "With prices this low, is quality guaranteed? What is hidden behind this?"

It's not an isolated occurrence, it's one of the "China cost effect" the overall manufacturing industry is experiencing right now.

This article, an expert advice by JS Precision, will take the surface price tag at face value and make a close-up study of cost structure, international comparison, and true value of CNC milling China services in 2025, and how "Made in China" today equals "superior value for money."

Key Answer Summary

| Comparative Dimensions | Chinese CNC milling | Traditional European and American Suppliers |

| Hourly Rates | Extremely low, typically 40%-60% of European and U.S. rates. | High, constrained by labor and operating costs. |

| Material Costs | Foreign procurement, economies of scale lower costs. | Relatively rigid supply chains, more costly. |

| Technology Penetration | Widespread use of advanced 5-axis and multi-tasking machine tools, developed technology. | High equipment upgrade costs, a high percentage of which are legacy equipment. |

| Supply Chain Efficiency | Single "one-stop" facility with complete integration from machining to surface treatment. | Communication and time costs increase as more is outsourced. |

| Implicit Value | High engineering support and flexibility in batches. | Fixed processes with no allowance for small-batch customizing. |

JS Precision Global Data Analysis: How Significant Is China's CNC Milling Cost Advantage

JS Precision has over 15 years of experience in CNC milling, having served over 20 industries including aerospace, medical device, automotive, and consumer electronics, and having shipped over 100,000 precision parts.

For example, we've manufactured light-weighted structural components for commercial spaceflight with ±0.005mm tolerance. Mass production of metal enclosures with a daily capacity of 500 pieces for smart wearable products is also offered.

Our CNC machining factory has over 50 precise machines, of which 20 are 5-axis machining centers, and ISO 9001 and AS9100 certificated.

The examination is backed by 15 years of project background, experience in machining 100,000 pieces, and foreign customer complaint feedback. All the conclusions and data sets have been field tested. You can depend absolutely on this professional evaluation of the cost advantage of CNC milling China.

JS Precision with excellent experience in CNC milling and specialty tools can quote you cost-competitive services. Upload a 3D file to receive a transparent quote and Design for Everything (DFM) remarks and initiate a successful machining process.

Behind The "Cheap": Decoding The Cost Code Of CNC Milling In China

Now that you understand the advantages of JS Precision, you may be asking yourself why China possesses CNC milling cost advantages. The reason is that much more than just labor, it is due to a series of benefits, each with strong relationships to successful CNC milling operations.

Scale and Cluster Advantages

China's manufacturing base is gigantic, with CNC machining clusters now appearing in metropolitans like Shenzhen and Suzhou. JS Precision's industrial belt can quickly integrate resources, dilute equipment depreciation, site leasing and other costs.

In manufacturing a batch order of 1,000 units, the cost in the cluster is 15%-20% lower than a scattered operation, placing CNC Milling China squarely in the lead position for large orders.

Mature Supply Chain Network

From steel and aluminum to tools and fixtures, we acquire raw materials locally without the middleman markups. To illustrate, when we buy 7075-T6 aluminum alloy, local suppliers quote us a price roughly 25% less than that of overseas suppliers. This also decreases material lead time and increases CNC machining factory efficiency.

Technological Dividends and Automation

JS Precision's CNC machining factory achieves high automation, with multiple milling machines CNC linked through MES system to reduce manual intervention. This results in 30% greater machining efficiency compared to traditional factories, and labor cost reduction to less than 10%, reducing costs as well as CNC milling precision variance.

Successful Operations and Logistics

Well-integrated domestic logistics enables raw materials to arrive at the factory within 24 hours. Internationally, with partner ports, components are shipped to Europe and the U.S. within 7-10 days. Transit time and warehousing costs are 12% lower than industry standard, in addition to cost advantage of our China CNC milling service.

JS Precision leverages China's advanced supply chain and automation technology to reduce your CNC milling China service price. Upload a 3D file and experience our efficient machining and logistics services and receive your parts in haste.

Beyond Price: Why Choosing A Chinese CNC Machining Manufacturer Is The Cost Choice

Considering this, you can be worried about "cheap goods don't guarantee quality." However, when we choose a CNC machining manufacturer in China, we not only care about price but the entire lifecycle value as well. JS Precision always provides services with value at its core.

1.Advice on Quality Assurance System

JS Precision is internationally ISO 9001 and AS9100 certified and has rigorous quality checks at every stage of the process. Dimensional inspection is carried out using CMM measuring machines after machining, keeping the percentage of defects below 0.5%, so that you don't have to worry about the quality of CNC milling.

2.Engineering Support - Hidden Value Creation

Our custom CNC machining service includes skilled Design for Manufacturing (DFM) evaluation. We have already reduced deep groove design costs for our customers by 15% without sacrificing function. This is cost reduction from the source, which a simply low-priced service cannot provide.

3.Total Cost of Ownership Perspective

Based on the calculation of procurement total cost, quality risks, and delay in delivery, JS Precision saves 35%-45% on average by availing the services locally in Europe and the United States. We can avoid market losses through rework costs and delay in delivery, adding further to the overall advantages of our China CNC milling service.

4.Speed is Value

Our 50% shorter average delivery time compared to Europe and America sets us apart. Taking an example of a small order of 500 parts, while the delivery takes eight weeks in Europe and America, we deliver it in four weeks. This enables you to seize the market quickly, and the value of the saved time exceeds by far the machining fee difference, which adds even greater value to our CNC milling service.

JS Precision's custom CNC machining service excels at whole life-cycle value, with expert Design and Function (DFM) support and rigorous quality inspection. Upload your 3D file and we will help you control your total cost of ownership as well as deliver good-quality parts in a short period of time.

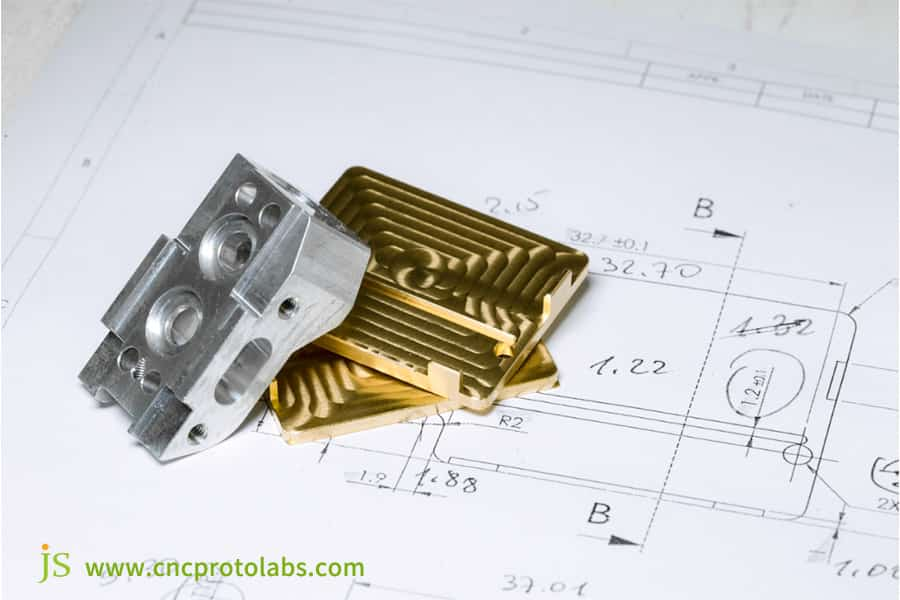

Figure 1: CNC machining factory

2025 Global Comparison: China's CNC Milling Service To Other Regions

To give you a better overall impression of the advantages, we compared China's CNC milling service to other regions in accordance with the latest statistics from 2025. The precise differences are as follows:

| Comparison Indicators | China (JS Precision) | Western Europe | North America | Southeast Asia |

| Hourly Price (USD) | 25-45 | 80-120 | 75-110 | 30-50 |

| Small-Batch Prototype Cost (Aluminum Alloy Pieces, 10 pcs) | $300-500 | $800-1200 | $750-1100 | $400-600 |

| Medium-Batch Production Cost (Aluminum Alloy Pieces, 500 pcs) | $12,000-15,000 | $30,000-35,000 | $28,000-32,000 | $16,000-19,000 |

| Hidden Costs (Communication + Project Management) | Low (Chinese and English teams, project tracking system). | High (time zone differences, poor communication). | High (time zone differences, high management). | High (language barriers, unstructured processes). |

The graph shows that Chinese hourly costs are only a third to half of Western Europe's, and mid-volume pricing is around 20% lower than in Southeast Asia.

When it comes to concealed costs, JS Precision has a professional team in both Chinese and English and project tracking system, resulting in 40% lower project management charges than in Europe and America, and its CNC milling China services are even more competitive.

JS Precision China CNC milling service has significant price and underlying cost benefits. Upload 3D files to obtain transparent quotes consistent with the table, and experience cost-effective processing.

Figure 2: China CNC milling service

Dynamic Pricing: Four Core Variables Affecting Custom CNC Milling Prices In China

Notice that custom CNC milling costs aren't fixed and rely on some key variables. Being aware of the variables, you are able to control the costs better, and JS Precision will accommodate accordingly. The following table visually displays the cost differences of different variable combinations (market data up to 2025):

| Part Type | Material | Order Quantity (Pieces) | Processing Difficulty (Complexity) | Unit Cost (USD) | Total Order Cost (USD) | Delivery Time (Days) |

| Standard Bracket | 6061 Aluminum Alloy | 50 | Low (No Complex Structure) | 28-32 | 1400-1600 | 7-10 |

| Standard Bracket | 6061 Aluminum Alloy | 500 | Low (No Complex Structure) | 15-18 | 7500-9000 | 15-20 |

| Precision Gear | 304 Stainless Steel | 100 | Medium (With Tooth Structure) | 65-70 | 6500-7000 | 12-15 |

| Surgical Instrument Component | TC4 Titanium Alloy | 200 | High (Thin Wall + Deep Hole) | 180-200 | 36000-40000 | 25-30 |

| Smart Wear Housing | 7075-T6 Aluminum Alloy | 1000 | Medium (Curved Surface + Holes) | 35-40 | 35,000-40,000 | 20-25 |

Part Complexity and Design

Parts with deep holes (depth > 5 x diameter) or walls which are thin (wall thickness < 1mm) are more difficult to program and machine, and are 30%-50% more expensive than simple parts. JS Precision minimizes complexity through the use of Design for Factorization (DFM) analysis in an effort to decrease complexity and decrease the cost of CNC milling.

Material Selection

6061 aluminum will run you a typical rate of about $2.50 per pound, and medical-grade titanium alloy will run you over $30 per pound, or over 10 times the range. We recommend the appropriate material on your needs, by trading cost versus performance, to have a lower-cost custom CNC milling quote.

Order Quantity

Small lots (1-100 pieces) have high per-unit expenses, while large lots (above 1,000 pieces) can be utilized to drive costs below $20 per unit. Intermediate lots (100-500 pieces) require process enhancement to keep costs under control. JS Precision is capable of making production plans flexible based on order size in an effort to maximize CNC machining factory throughput.

Post-Processing and Quality Requirements

Anodizing adds another $5-10 per unit, and Teflon coating adds $15-20 per unit. Increasing tolerance from ±0.05mm to ±0.01mm adds 20% on the machining time and 15%-25% on cost. We'll compute the variation in the cost of the process and help you budget your overall custom CNC milling expense.

Figure 3: custom CNC milling mass production

Ultimate Efficiency: How The Best China CNC Milling Service Works

Internal operations should be efficient enough to realize the optimal cost and efficiency balance. JS Precision, as a leading CNC machining manufacturer in China, has a mature operational system to ensure the efficiency of China CNC milling services.

Intelligent Scheduling and Machine Tool Interaction

We integrate all milling machine CNC production plans using MES system and automatically assign equipment based on part demand to avoid idle time. This results in equipment usage greater than 90%, 20% higher than the industry standard, making the CNC milling more effective.

Tool Management and Optimization

We create a professional tool database to capture tool life and machining parameters. We implement advanced carbide tools for aluminum alloys and enhance tool life by 30%. We optimize machining paths, maximizing machining time by 15%, reducing tool change frequency, and reducing custom CNC milling cost.

Digital Quality Control

We use online measuring machines to perform in-process dimension check and complete inspection by CMMs subsequent to the machine. We are able to quickly identify defective parts and have less than 0.3% scrap rate, eliminating material and time wastage and reducing CNC machining factory costs from another dimension.

"Single-Stop" Solution

Incorporates turning, milling, grinding, and surface finishing. For example, if the customers need threaded parts machined and anodized, we are able to process all the steps in-house. It saves the customers over 60% of managerial expense, ensures uniformity of process, and makes China CNC milling service even less stressful.

JS Precision speeds up milling machine CNC efficiency with smart scheduling and single-stop assistance. Upload 3D files to take advantage of our smooth operating system and get fully integrated high-precision parts on schedule.

Case Study: Silicon Valley To Shenzhen – A Cost Reduction And Efficiency Enhancement Experience For A Core Smart Home Component

Client Background

A Smart Home R&D engineer An IoT firm in Silicon Valley needed to produce a critical transmission component of an intelligent door lock. The component, responsible for triggering the door lock, needs to have precision (tolerance ±0.015mm). Material is 7075-T6 aluminum alloy, and the number ordered is 500 pieces.

The client contacted three US-based local manufacturers, and they all quoted anywhere from $25,000 to $28,000, 50% over the budgetary price of $20,000, with an eight-week lead time that would put them behind their target launch dates.

Core Challenge

The component had a 15mm deep by 2mm wide deep groove. The US company claimed that it was difficult to machine and warped, requiring additional processing processes, which further increased cost and lead time. The customer ultimately contacted JS Precision with the expectation of rectifying the issue through CNC milling China services.

JS Precision's Solution

1. With an extensive Design for Manufacturing (DFM) report: The engineers concluded that the groove width could be reduced to 2.2mm (with no compromise on actuation), reducing vibration of the tool and facilitating easier machining. This would save machine time and cost by around 15%, and streamline the CNC milling process.

2. Running a 5-axis machining center: In the case of parts with complex curved surfaces, the 5-axis machining center performs all surface machining in one fixture without precision error and works 40% more efficiently than with 3-axis machines and ensures timely delivery.

3. Anodizing integrated: The customer requested black hard anodizing, which we accomplished in-house, which assisted in developing a consistent appearance and cut the process cycle by 5 days, improving efficiency for our custom CNC milling service.

4. Complete tracking of progress: There is a particular account that is established for the customer where there is real-time access to production progress and updates at each step, without constant communication, such as working with a project in a local CNC machining factory.

End Outputs

After the customer approved the DFM proposals, 500 pieces were machined and anodized in 4 weeks, which was 50% less than US delivery time. Settlement cost was $14,500, down 42% from estimate.

Customer quality inspection of the components showed them to be perfect and uniformly coated anodizing. The customer successfully launched the product, with sales exceeding 10000 units in the first month and an additional 1000 orders to follow.

Figure 4: CNC machining smart door lock parts

Driving Innovation: Why China's CNC Milling Is The Silent Engine Of Global Industry

Not only does China's CNC milling enable companies to reduce their costs and increase efficiency, but it also plays a central support in world industrial innovation and becomes an intangible driving power for many industries. JS Precision also applies CNC milling technology to support development in multiple industries.

Aerospace

We manufacture light drone frames for drone manufacturers with aircraft-grade aluminum alloys and CNC milling for integrated processing of complex structures. This reduces weight by 20% and increases strength by 15%, meeting flying conditions. The tolerance of satellite components is ± 0.008mm, which meets space standards and reflects the technical strength of CNC machining manufacturer in China.

Medical Devices

We manufacture extremely precise surgery instruments (such as laparoscopic forceps) out of medical-grade stainless steel and give them a post-machining passivation process to ensure biocompatibility. We also provide prototype machining for implants such as artificial joint, enabling medical companies to confirm designs and enhance medical innovation with custom CNC machining services.

Automotive Industry

We manufacture battery box components for new energy vehicles with CNC milling to achieve close fit and leak prevention. We also manufacture engine intake manifolds for racing vehicles with high performance, and we design flow paths for maximum intake efficiency and power output, as a demonstration of the advantage of China CNC milling services to the auto sector.

Consumer Electronics

We machine smartwatch cases with metal using 316L stainless steel to precise milling for smooth surface and uniform thickness (weight < 20g). We also machine wireless earbuds' internal brackets to realize precise fit inside components, making CNC milling services viable to facilitate thinner and lighter consumer electronics trend.

Get Started Now: Your Best CNC Milled Parts with JS Precision

After understanding the advantages of CNC milling in China and JS Precision's services, good-quality CNC milled parts are only three steps away:

Step 1: Transmit your 3D file (STEP, IGES, X_T, etc.) to JS Precision instant quote website. No software download required, just upload via the web, and IP rights are protected with file encryption.

Step 2: Smart Quote and Expert Review. With the integration of AI with engineer expertise, the system provides you with a step-by-step accurate quote and Design for Everything (DFM) review within 24 hours, enabling you to iterate your design and design a better custom CNC milling solution.

Step 3: Quotation Confirmation and Production. Once the quote is confirmed, order with just a single click. Production begins on payment of deposit. You can see your progress through the project tracking system. We arrange logistics after production and make it convenient for you to pick up your CNC milling products.

JS Precision boasts a hassle-free and simple ordering process, which supports various 3D file formats. Upload your 3D file today and receive a clear quote and design for manufacturing (DFM) response, and have your CNC milled parts manufactured in no time.

FAQs

Q1: How can my design drawings and IP be protected in China?

JS Precision has a strict requirement for customers to sign very tight confidentiality agreements, which detail the extent and term of confidentiality over design drawings. Furthermore, we employ an encrypted file transfer system as well as isolated management in the production process, limiting access to design files by designated staff.

Q2: Will tariffs and logistics override cost advantages of Chinese sourcing?

For small and medium-sized orders, even with international logistics and tariffs included, JS Precision's overall cost is still 30% -40% lower than in Europe and America.We offer DDP services such as customs clearance, tariff fees, and logistics planning. We will quote to you the complete door-to-door price in advance, giving transparent clarity of price without fear of additional costs undermining the value of our China CNC milling service.

Q3: What should I do if I notice defects upon receiving the parts?

JS Precision provides a full quality report, including dimension inspection data and appearance photos. If you find there are quality defects when receiving the part, please notify us within 7 days. We then arrange a re-inspection right away. After verifying the fault, we will rework or re-manufacture it for free.

Summary

Choose CNC milling services in China no longer an "inexpensive price" race but a wise option for "greater value." It takes advantage of world-class manufacturing capacity, supply chain mastery, and pervasive engineering expertise. In the intense market conditions of 2025, this might be the key to success of your product.

Being a CNC machining manufacturer in China, JS Precision has proved in cases that its CNC milling China service might be your cost-saver, efficiency-promoter, and innovation-leader.

Act now and experience the efficiency and worth of China's intelligent manufacturing! Visit the JS Precision platform, upload your CAD, and get a precise instant quote in 60 seconds with DFM analysis. We can demonstrate to you that you can have higher quality at lower prices.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com