CNC milling parts are essential core components in modern manufacturing. From tiny pieces inside medical devices to structural pieces in aerospace, their precision is essential.

Both are the precision scalpel for cutting-edge innovation and the reliable industrial engine driving mass production. Whether you need to iterate rapid product prototypes or mass-produce components with high tolerance requirements, CNC milling technology always solves the problem with efficiency and precision.

This guide goes in-depth into the world of CNC milling parts, showing how to master this technology, find the perfect balance between precision, cost, and efficiency, and ultimately bring designs to life.

Answer Key Summary

| Dimensions | Capacity & Process | Cost & Procurement | Partnership & Assurance |

| Key Questions | What accuracy is possible? How to prepare surfaces? How does the machine work? | How to reduce the cost of custom parts? How do I get a rapid quote? | How to reduce the cost of custom parts? How do I get a rapid quote? |

| Key Answers | Achieve precision of ±0.005mm or even higher, control surface through tooling, path, and parameter control, achieve precision motion through the collaborative operation of core machine tool components. | Optimize design (e.g., reduce deep cavities), select appropriate materials, and utilize online platforms for intelligent layout and real-time quotations. | Examine the advantages of integrated services from technical equipment, quality control systems, engineering support capabilities, supply chain, and JS Precision. |

| Action Points | Be aware of your process limits, define the technical specification. | Proactively participate in the DFM using digital tools. | Beyond price comparison, establish a partnership based on capability and trust. |

Key Takeaways

1. Precision and Cost Controllable:

CNC milling parts are able to reach micron-level precision, but top-level precision significantly increases costs. By optimizing design, such as avoiding extreme aspect ratios and selecting appropriate materials, the cost of custom CNC milling components can be effectively controlled with their functional requirements met.

2. Choosing the Right Manufacturer is Key:

When evaluating a CNC milling parts manufacturer, focus on their equipment capabilities (e.g., five-axis applications), quality control processes (e.g., full SPC), and engineering support team, this is more important than simply comparing unit prices.

3. Digitalized Processes Improve Efficiency:

Utilizing a professional online CNC parts quotation platform, simply upload 3D files to receive instant, transparent quotations and manufacturability analysis, significantly shortening the prototype-to-production cycle.

4. The Integrated Advantages of JS Precision:

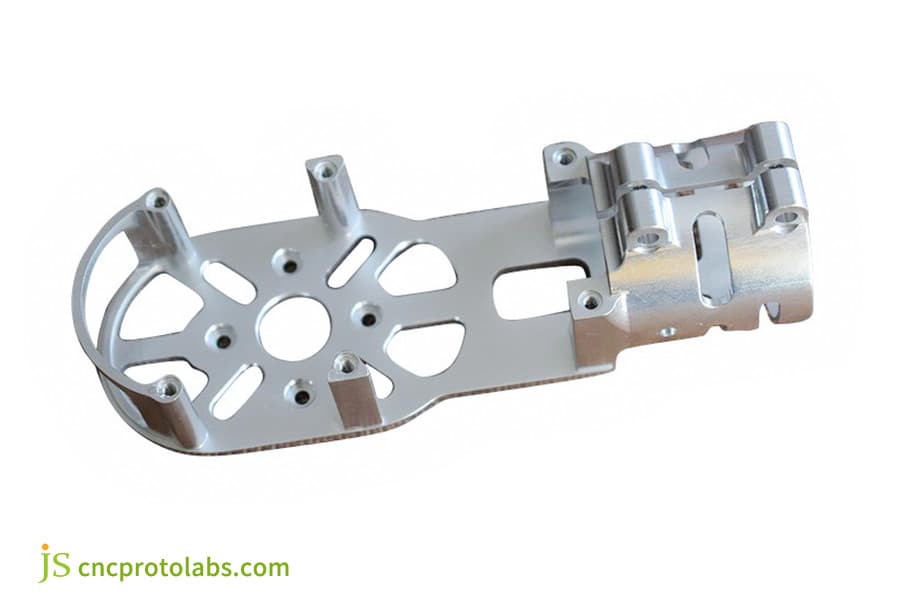

As a one-stop solution provider, JS utilises advanced knowledge in the cnc vertical milling machine parts and functions, along with robust quality control and supply chain management, to ensure customers receive dependable and effective services in manufacturing everything from complicated CNC milled parts to simpler ones.

Why Choose JS Precision? Precise CNC Milling Solutions For Parts

JS Precision has over 15 years of deep experience in the CNC milling industry.

Our quality management system strictly follows the International Organization for Standardization (ISO) ISO 9001:2015 quality management system standard, which provides a framework for our process stability and continuous improvement, ensuring that every CNC milling parts project can be completed with high quality.

We cater to clients in more than 30 countries all over the world, including those from the aerospace, medical devices, automotive manufacturing, and consumer electronics industries, successfully delivering over 50,000 custom CNC milling parts annually.

From high-precision medical components with tolerances of ±0.005mm, to mass-produced automotive structural parts, even urgent prototype parts, we can accomplish everything with our expertise.

Our engineering team has gathered an average relevant experience of more than 8 years, hence faster response towards complex needs with provision of end-to-end support, right from design optimization to production delivery.

This guide is the culmination of our experience from tens of thousands of successful projects. Every point has been tried and tested in practice, so you can refer to it with complete confidence.

Want a CNC milling parts solution designed for your project? Contact us today at JS Precision. We have free design assessments and process advice from our engineers to help ensure your project is off to a good start.

What Is CNC Milling? Why Is It Considered The Cornerstone Of Modern Manufacturing?

But have you ever wondered how those oddly shaped hard-material parts are manufactured to high precision? In this section, the mystery of CNC milling is demystified and its core principles explained as digital subtractive manufacturing.

CNC milling uses computer programs to control machine tools, driving cutting tools to cut and process workpieces, ultimately producing CNC milled parts with the required shape and precision.

The core advantage is "digital control," which changes sophisticated drawings into precise machining instructions and automate the machining of CNC milling components from simple planes to complex surfaces.

Compared to traditional machining, CNC milling significantly improves efficiency, ensures consistency in batches of CNC milling parts, and reduces human error. It allows for rapid prototyping without molds and enables large-scale mass production through process optimization. This combination of flexibility and precision makes it a cornerstone of modern manufacturing.

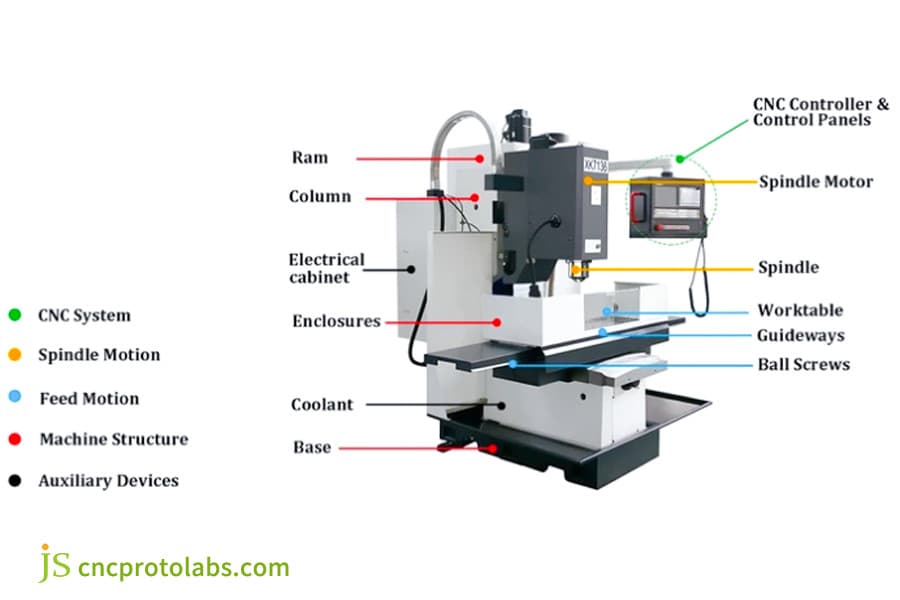

Figure 1:Numerical control milling machines operate through a combination of software, motors, and cutting tools to accurately remove material from workpieces, thereby obtaining the desired shape or design.

In depth Analysis of the Core CNC Vertical Milling Machine Parts And Functions Inside The Machine Tool

The machining capacity of a CNC milling machine is directly determined by its CNC vertical milling machine parts and functions. Familiarity with CNC milling machine parts and their function helps you communicate machining requirements more accurately.

The performance verification of these core components can refer to the specifications for performance evaluation of CNC machine tools in the American Society of Mechanical Engineers (ASME) ASME B5.57-2012 standard.

Motion Core: Guide Rails, Ball Screws, and Servo Motors

These three constituents form the very core of CNC vertical milling machine parts and functions that work in concert to translate digital commands into nanometer-level precision motion:

- Guide Rail: Make sure the tool movement is straight and rigidly fixed, first of all to guarantee the precision of CNC milling parts.

- Ball Screws: These transmute the rotary motion to linear, controlling the tool travel distance with much precision.

- Servo Motors: Quick responses, precision in positioning, and following controller instructions to the letter.

Power and Tool Systems: Spindle and Tool Magazine

Performance of the spindle and tool magazine is central to the roles of CNC milling machine parts and their function:

- Spindle: supplies the cutting power, and power and speed determine types of material to be machined and cutting efficiency.

- Tool Magazine: Stores and automatically changes tools. The greater the capacity, the faster complex processes can be done.

Want to know which machine tool parts your part machining requires? You can send your part drawings to JS Precision, and our technical team will analyze the corresponding CNC vertical milling machine parts and functions according to the requirements of the parts and ensure the precision and efficiency of the machining.

Figure 2:Each CNC milling machine includes some basic components to ensure its normal operation.

From Rough To Mirror Finish-How To Precisely Control The Surface Finish Of CNC Milled Parts?

The surface finish directly influences the service life of CNC milled parts and their performance during the assembly process. It could be precisely controlled in three aspects:

Tool Selection

- Number of Flute: Multi-flute tools can be utilized for finishing to reduce surface texture.

- Material: Use matched material, such as diamond tools for machining carbide, to avoid tool wear roughening.

Optimizing Cutting Parameters

- Cutting Speed: Use according to the material and the tool for perfection, neither overheating or with low efficiency.

- Feed Rate: Small feed rates reduce cutting marks and balance efficiency and cost.

- Depth of Cut: Use a small depth of cut for finishing in order to avoid burrs and scratches.

Programming Strategies

- Contour milling: embraces complicated surfaces, making the surface smooth.

- Helical milling: Smooth cutting, with reduced vibration.

- Climb milling priority: Reduces cutting forces, thus improving surface finish.

Figure 3:High speed end face milling can achieve machining with good surface smoothness and controllable roughness.

The Micron Debate: What Level Of Precision Can Your CNC Milling Parts Achieve?

Precision is the core competitiveness of CNC milling parts. Different precisions correspond to different application scenarios:

| Precision Grade | Tolerance Range | Conditions of Realization | Applicable Situations |

| General Machining | ±0.025mm | Ordinary CNC machine tool, ordinary temperature control, ordinary measurement. | General machinery / Non-critical assemblies |

| Precision Machining | ±0.01mm | High-precision machine tools, strict temperature control, professional measurement. | Automotive critical components / Electronic core components |

| High-precision Machining | Within ±0.005mm | Advanced multi-axis machining centers, climate-controlled shop with CMM inspection and error compensation. | Aerospace/Medical precision parts |

To achieve high-precision CNC milling parts, advanced equipment, constant temperature environment, and comprehensive quality inspection are required. Equipped with high-end multi-axis milling centers and temperature-controlled workshops, JS Precision is capable of stably delivering high-precision parts.

Cost-Effective Planning: How To Optimize Design To Reduce The Cost Of Custom CNC Milling Parts?

Design directly influences the cost of machining custom CNC milling parts. The following practical tips can reduce costs without sacrificing functionality:

Key DFM Optimization Techniques

- Loosen the tolerances for non-critical dimensions.

- Avoid deep cavities and narrow slits in order to reduce the difficulty of machining.

- The use of standard tool sizes avoids the creation of special tools.

- Use standardized hole and slot features.

- Trim extra and unnecessary complicated surfaces.

Material and Process Selection Based on Cost-Effectiveness

- The preference is for the use of aluminum instead of stainless steel, because it is easier to machine and less expensive, special high-cost materials are not needed except in special applications.

- Utilize alternate materials-e.g., engineering plastics to replace some metals.

- Select surface treatments if required (anodizing for normal environments, avoiding expensive electroplating).

A Wise Choice: 5 Key Dimensions For Evaluating A CNC Milling Parts Manufacturer Beyond Price

When selecting a CNC milling parts manufacturer, keep in mind the following key dimensions-not just price:

- Equipment and Technology: Does the manufacturer have advanced multi-axis machine tools and complex/high-precision machining capability?

- Quality Control and Certification: Is the manufacturer ISO certified? Does it have professional testing equipment, such as CMM?

- Engineering Support: Is DFM optimization possible by the manufacturer? What is the communication and response speed?

- Supply Chain: Is the supply of raw materials stable to avoid delays in delivery?

- Past Case Studies: Does the manufacturer have successful projects in similar industries?

As a professional CNC milling parts manufacturer, JS Precision owns a cluster of multi-axis milling centers, an ISO quality control system, and a full set of testing equipment to support projects end-to-end. If you would like to learn more about our experience in similar projects, please contact us for detailed case studies.

One-Click Start: How To Get Instant And Accurate Quotes For Online CNC Parts?

The quote shouldn't have to take very long in the digital age. An effective quoting methodology will help you move quickly forward with project decisions for online CNC parts. Here is an introduction to how modern manufacturing platforms work, enabling you to get accurate quotes in a straightforward manner.

Quotation on this modern manufacturing platform is very simple: you only need to upload a 3D model in STEP or IGES format, select materials and processes, post-processing requirements, and the system can provide transparent quotations and manufacturability analysis in minutes thanks to intelligent algorithms.

It involves no manual operation in the whole process, is highly efficient and quick, and allows understanding of production costs with regards to online CNC parts in short order.

Decoding the Logic Behind Instant Quotes:

The working principle of the quotation engine mainly comprises the following steps:

1. Geometric Feature Analysis: Analyzes the geometric features like shape, size, and complexity of a part automatically to determine the difficulty of machining.

2. Machining Time Estimation: Based on the geometric features of a part and selected process, in conjunction with tool parameters, cutting speed, and other data, it gives an estimate of the machining time required.

3. Material Usage Calculation: Based on the volume and material density of the parts, calculate the required amount of raw materials and combine it with the material unit price to determine the material cost.

4. Cost Integration: Add up the costs of the processing time, materials cost, post-processing, management, and other costs to give a quote.

Want a fast and accurate quotation for your online CNC parts? Log in to the JS Precision online quotation platform, upload your 3D model, select the relevant requirements, and within minutes, get a transparent quotation and manufacturability analysis report that clearly outlines the cost structure.

Case Study: How To Deliver Aerospace Aluminum Alloy Structural Parts With A Tolerance Of ±0.01mm Within 7 Days?

The Challenges Faced by the Client

A drone startup in Europe, in urgent need of a critical load-bearing bracket for its prototype, required delivery in 7 days, lightweight aerospace aluminum, and a critical assembly surface tolerance of ±0.01mm. Traditional machining methods struggle to find a balance between these often-competing elements of speed, weight, and precision.

Solution by JS Precision

Faced with the challenge, JS Precision team immediately launched a dedicated service by applying its technological strengths to develop targeted solutions.

1. Engineering Optimization:

The in-depth analysis by the engineering team on the 3D model revealed redundancy within the internal reinforcing ribs of the initial design. Their thickness was optimized to 0.8mm, while maximum weight reduction was ensured to maintain rigidity, improvements were achieved by enhancing milling accessibility and reducing machining dead zones.

2. Efficient Process:

Select 7050 aviation aluminum according to the American Society for Testing and Materials (ASTM) ASTM B209 standard. This material is high in strength and lightweight, meeting the lightweight requirements of the customers.

In addition, all the complex surface and high-precision holes were machined in a single setup on the five-axis CNC vertical milling machine, which avoided secondary clamping errors and guaranteed the accuracy during machining.

3. Overall Quality Control:

Applied online detection technology to track real-time dimensional accuracy throughout the machining process, timely correction of any deviation was performed. After processing completion, a Coordinate Measuring Machine was employed for comprehensive inspection, ensuring that all the critical dimensions were within the drawing requirements.

The Final Successful Result

JS Precision successfully delivered a complete set of lightweight bracket CNC milling components within 7 days. The final weight of the part was 15% lighter than the initial design, which fully met the customer requirements for range while all critical dimensions and tolerances were 100% verified by CMM inspection reports to ensure sensor installation accuracy.

All of that allowed the customer to smoothly continue with prototype assembly and flight testing, which considerably shortened the project cycle and laid a necessary foundation for further financing and product launching.

Later, the customer entered into a long-term partnership with JS Precision, and we've been in charge of producing several batches of custom CNC milling parts.

Urgent, High-Precision custom CNC milling parts Needed? Please upload your 3D models to JS Precision. Remember to note "urgent delivery date + precision requirements." We provide free DFM optimization and full-process quality control. Compliant parts will be delivered in as little as 7 days to meet your urgent needs.

Figure 4:Precision Aerospace CNC Aluminum Prototyping UAV Components

Why Do Global Customers Choose JS Precision As Their CNC Milling Partner?

In such a competitive market, we gain this trust from customers all over the world through the provision of unique value. Whether your needs are related to intricate CNC milling parts or any other precision CNC milling components, we can address all requirements based on the professional capability of our company.

- Multi-axis Milling Center Cluster: advanced equipment to machine complex custom CNC milling parts.

- Strict Quality Control: ISO system throughout the whole process ensures stability in the quality of CNC milling components.

- Professional Support: The engineering team of this company provides complete process DFM optimization, cost reduction, and efficiency improvement.

- One stop service: integrating raw material procurement, processing, and post-processing to save communication costs.

FAQs

Q1: What materials can the CNC mill?

CNC milling covers almost all kinds of engineering materials, including common metals like aluminum alloys, steel, stainless steel, titanium alloys, copper, and plastics such as POM, nylon, and ABS, and even some composite material blocks, in order to satisfy the needs of parts in different scenarios.

Q2: What is the smallest achievable detail dimension?

The minimum detail dimension achievable is firstly depending on the machined material. The common minimum diameter for a hole is 0.5 mm, and for a sharp edge or thin wall is 0.3 - 0.5 mm. In case even smaller dimensions of the detail are desired, special machining processes are applied.

Q3: What is the general range of tolerance?

The general tolerance range for CNC milling encompasses ±0.025mm considering different levels of machining accuracy: for general machining, it could be up to ±0.025mm, for precision machining, it is up to ±0.01mm, and for high-precision machining, it is within ±0.005mm. Dimensions not important to the part's functionality should be marked explicitly to save cost.

Q4: Is small lot single-piece production possible?

Absolutely. Compared to the traditional method, CNC milling requires no moulds and has flexible programming, making it ideal for single piece or small batch production. It can meet customer demands for fast customization and help customers shorten their product development cycle and reduce the cost of trial production.

Q5: Which are the most relevant factors that influence part pricing?

The basic determinants of how much one can price the CNC milling parts will be the material cost, time of machining, quantity, post-processing, and the tolerance level selected. Unit prices among different materials vary significantly. In addition, the more complex the part is, the longer the machining time.

Q6: What is the typical lead time from quotation to delivery?

Regarding lead time from quotation to delivery, it depends on part complexity and quantity ordered. Simple parts take 3 to 7 days. More complex components require 1 to 4 weeks for mass production. It is determined by the current production schedule.

Q7: How can I protect my design intellectual property?

JS Precision attaches great importance to customers' design intellectual property rights and will sign confidentiality agreements (NDAs) with customers. At the same time, it has established a secure IT system to protect customer data. Relevant design files can be deleted after completion according to the agreement by customers.

Q8: How do I communicate and resolve machining issues?

For any machining problems, please feel free to contact your account manager or engineering support directly, we will get in touch with you by email, phone, or video conference as soon as possible after getting a full understanding of the problem.

Summary

From principles down to practice, design to delivery, the world of CNC milling parts is all about the allure of precision and efficiency at each step, holding a key to improve project success rates.

This guide was prepared with rich practical experience that JS Precision has garnered over the years to enable you to break through the cognitive barriers in finding the optimal solution.

Let JS Precision be your reliable manufacturing extension. Come visit our online platform today, upload your 3D design files, and get instant quotations through intelligent analytics supported by professional manufacturability feedback. Let us turn your precise ideas into a tangible and reliable competitive advantage.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com