Rapid prototyping cost is a core focus indicator for product development. CNC rapid prototyping is an important way to transform ideas, verify designs, and seize market opportunities.

The cost structure of CNC rapid prototyping is an iceberg structure. Besides the obvious cost, like design complexity, the cost beneath the ocean needs to be considered, and precise cost control is the key to the project.

The following article will analyze various aspects that affect rapid prototyping cost, break down service quotes for rapid prototyping, and provide actionable cost optimization strategies.

Whether you're looking for the best option to compare rapid cnc prototyping costs or in search of the best prototyping and CNC machining solution, this guide will let you make accurate decisions-balancing quality and performance for budget value.

Core Answer Summary

| Core Question | Key Answer | Value for You |

| What is included in the cost? | Cost components include materials, labor costs, programming and debugging, post-processing, and management costs. For small production volumes, programming costs, and other fixed costs, form the basic unit costs. | A holistic chain cost perspective should be adopted and costs should not be overstimated. |

| Why and how to optimize DFM and cost? | Optimization is achieved through DFM process and material matching, and then unlocking economies of scale through batch and delivery planning. | A systematic way to lower costs and strike the right balance between cost and performance. |

| How to obtain the best value price? | Provide standard documentation, choose suppliers capable of giving feedback on DFM, and compare technology and pricing. | Ensure transparency in the pricing offered, taking decisions based on total cost. |

Key Takeaways:

- The design procedure accounts for 80% of the cost baseline: Difficult geometries and too tight tolerancing are mainly responsible for the skyrocketing costs, optimization at the beginning can avoid costs by 30%.

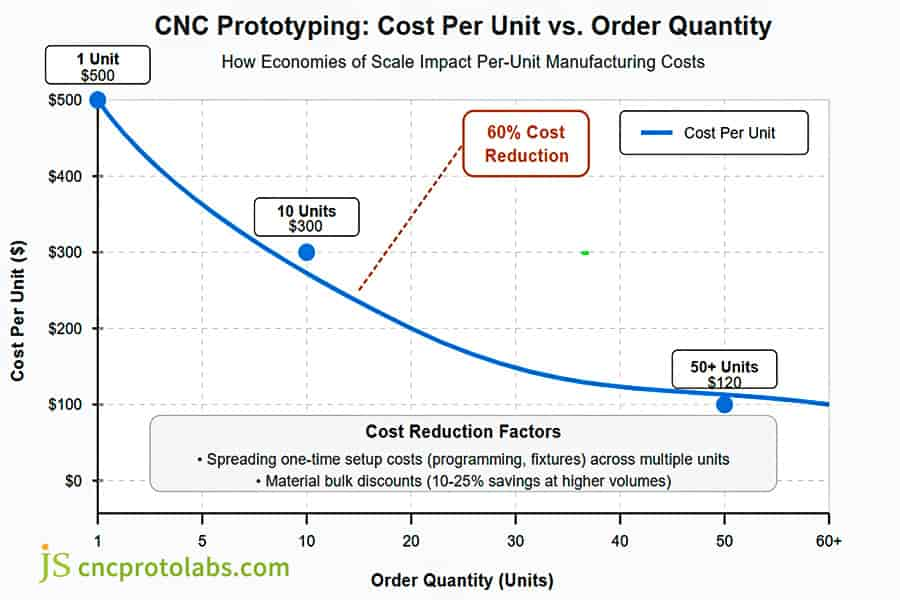

- For instance, batch production is a tool for minimizing unit costs: One should make use of the advantages of CNC machining and combine orders for one-off production.

- Delivery time is closely linked to cost: The standard delivery time is optimal, while the 24-72 hour rush delivery costs 50%-100% more.

- Selecting a complete service sourcing is better than disintegrated outsourcing: It is better to select a complete service sourcing partner such as JS Precision, who provides free analysis for DFM, rather than disintegrated outsourcing for the manufacture of the parts for the CNC machining rapid prototyping process.

Why Are There Such Large Cost Differences In CNC Rapid Prototyping? JS Precision's Cost Analysis

The difference in rapid prototyping service quote for the same CNC prototype can reach several times. This difference reflects many things in itself, which include a wide array of information about the technological barrier of the supplier, process maturity, quality control system, and supply chain capability.

With more than 15 years of experience in serving high-precision fields like medical and aerospace, Jiaxing Super Precision knows that low prices often mean hidden costs in rework and delays, further increasing overall costs.

We adhere to the ISO 9001:2015 standard, adopt five-axis machine tools, and use CAM algorithm, thus we can realize one-time prototyping with a tolerance of ±0.02mm. Trial cutting cost reduced by 40%, scrap rate less than 1%.

The customized cutting parameters and high-pressure cooling solutions for 316L stainless steel increase tool life by 2.5 times, which greatly reduces consumable consumption.

Initially, a medical startup in Silicon Valley was quoted a price of over $2,000 per unit for their TC4 titanium alloy fixture prototype by their supplier, with a lead time of 8 weeks and specifications that were not up to standard.

Through DFM optimization and supply chain integration, we have reduced the unit price to $1360 and shortened the delivery time to 2 weeks, helping customers complete clinical validation 3 months ahead of schedule and saving over $6400 per batch.

Want to quickly understand your project's cost range? Submit your 3D model, and JS Precision engineers will provide a free cost assessment and DFM optimization suggestions within 24 hours, helping you avoid high-cost pitfalls and understand the cost structure of CNC machining rapid prototyping.

What Really Makes Up Your Rapid Prototyping Cost?

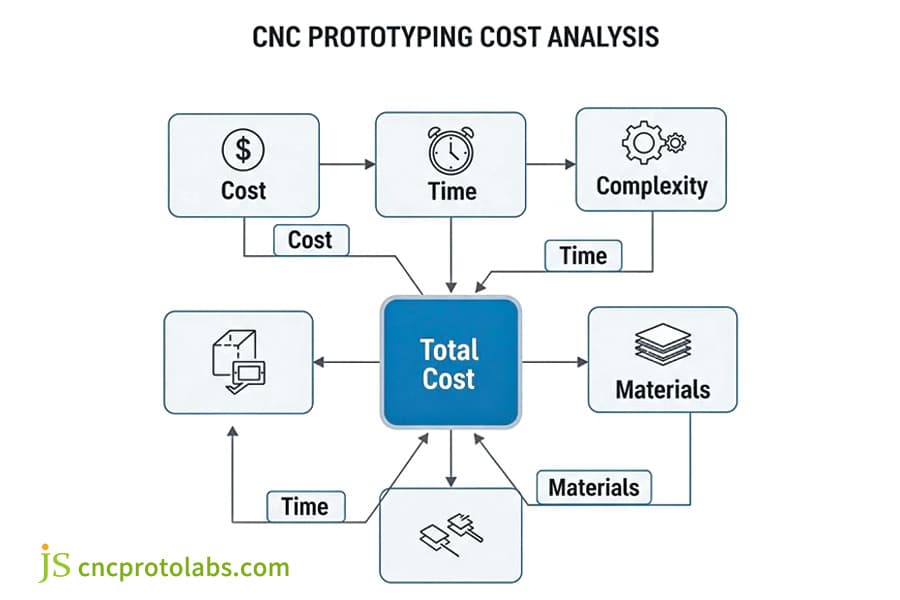

To accurately control rapid prototyping cost, it is necessary to first clarify its composition. The cost of CNC machining rapid prototyping is directly affected by the following five key factors, which determine the final cost:

1. Material Cost: Machability affects in proportion to the cost of materials. For instance, the lifespan of machined tools in 6061 aluminum alloys is thrice that of 304 stainless steel. This saves on cost.

2. Machine Labor Rates: This includes machine tool depreciation rates, energy rates, and labor rates. Five-axis machine tool rates are 30%-50% higher than the three-axis rates, but are appropriate for complex models.

3.Programming and Debugging: A fixed cost, which is the main reason for high unit costs of small batch prototypes.

4. Post-processing Cost: Deburring, oxidation, and polishing, etc., differ considerably in cost, the price of mirror finish is 3-5 times higher than the basic process.

5.Quality Control and Management: Includes hidden costs such as FAI inspection and sampling, a necessary investment to ensure quality and delivery time.

| Cost Type | Specific Composition | Relationship with Production Volume | Impact on Unit Price (10-piece Batch) | Percentage (Small Batch) |

| Fixed Costs | CAM programming, fixture design, first-piece debugging. | Unchanged. | 10% per piece, saving 90% of costs. | 30%-40% |

| Variable Costs | Materials, processing time, post-processing consumables. | Linear growth. | Fixed percentage, larger batches result in lower auxiliary costs. | 60%-70% |

| Hidden Costs | Quality inspection, coordination, logistics losses. | Slight fluctuations. | Larger batches result in lower unit costs. | 5%-10% |

| Rush Costs | Overtime hours, equipment priority occupancy fees. | Linked to delivery urgency. | 24-hour rush orders incur an additional 50%-100% charge. | 0%-100% |

Properly planning batch sizes can save fixed costs, producing 5 prototypes at once saves 40% compared to batch production.

What Factors Most Impact Your CNC Rapid Prototyping Quote?

The difference in rapid prototyping service quote depends not only on the basic cost, but also on three key parameters: design characteristics, material selection, and accuracy requirements, which help to accurately compare rapid CNC prototyping costs.

Design and Geometric Complexity: Time is the Biggest Cost

Complex shapes are difficult and time-consuming: deep pockets with depth-to-diameter ratio >5 must use special tools, walls under 1mm are not robust and are likely to deform, raising radius of internal fillet curves from 0.5mm to 1mm increases efficiency by 20-30%, and curved surfaces demand five-axis machining, raising the cost of CNC rapid prototyping.

Material Selection: The Art of Balancing Performance and Cost

Material processing difficulty and price directly impact rapid prototyping cost. Different materials are suitable for different scenarios:

| Material Type | Representative Grade | Processing Difficulty | Relative Cost Coefficient (6061 = 1) | Applicable Scenarios |

| Aluminum Alloy | 6061/7075 | Low | 1.0/1.2 | Conventional structural prototypes, non-load-bearing components. |

| Stainless Steel | 304/316 | Medium-High | 2.5/3.0 | Corrosion resistance, high strength requirements. |

| Titanium Alloy | TC4 | High | 4.0-5.0 | Medical, aerospace high-precision prototypes. |

| Engineering Plastics | POM/Nylon | Medium | 1.2-1.5 | Wear-resistant, insulating prototypes. |

| Specialty Plastics | PEEK | High | 6.0-8.0 | High-temperature, high-strength special scenarios. |

Precision and surface requirements: Cost increases exponentially with each grade improvement

Tolerances and surface finish drive complexity of the process: tolerance of ±0.1mm is sufficient, with ±0.025mm, it is precision machining, and it will be expensive by 30-50%, surface finish from milling (Ra value of 3.2µm), cost is lowest, and mirror-polished surface (Ra of 0.8µm).

How Can You Control Various Cost Factors In CNC Rapid Prototyping?

Being able to execute effective cost control methods helps optimize or maximize the value of rapid prototyping cost despite spending for quality.

Strategy 1: Implement Design for Manufacturing (DFM)

DFM is the core cost reduction method of prototyping CNC machining: simplifying geometric shapes, unifying fillet radii to reduce tool changes, only marking critical surfaces with strict tolerances, and cutting complex structures separately can save more than 40% of costs.

Strategy 2: Optimise Production & Procurement Decisions

Implement integrated multi-part orders for cost distribution, the standard lead time of 7-10 days is 30-50% less than the 48-hour rush order, select JS Precision for a seamless service for the elimination of logistics expense in outsourcing.

Strategy 3: Precise Matching of Materials and Processes

Choose the materials based on the scenario. Low-cost aluminum alloys can be used to begin with, followed by material testing using high-performance materials to avoid over-designing.

How Can Design Choices Drastically Cut Your Prototyping Costs?

The design phase determines 80% of rapid prototyping costs, even small design optimizations can significantly reduce costs. The following case studies vividly demonstrate the value of DFM.

Case Comparison: Cost Difference Before and After Optimization

| Design Dimensions | Original Design | DFM Optimized Design | Cost Impact | Optimized Time (hours) |

| Inner Corner Radius | Multiple R0.5mm deep inner corners | Unified to R1mm | Machining efficiency increased by 25%, tool wear reduced by 30% | 2.8 |

| Deep Cavity Structure | 3 deep cavities with a depth-to-diameter ratio > 8 | Changed to insert or split design | Reduced deep cavity milling time by 80% | 1.5 |

| Tolerance Requirements | All dimensions required ±0.05mm | Only critical mating surfaces ±0.05mm, others ±0.1mm | Reduced finishing step, cost reduced by 20% | 3.2 |

| Surface Treatment | Overall anodizing + local polishing | Anodizing only the outer surface, deburring non-outer surfaces | Post-processing cost reduced by 40% | 1.0 |

| Total | - | - | Total cost reduced by 25%-40% | 8.5 |

The cost for prototyping CNC machining was reduced 25-40% after optimization while retaining functionality, thus achieving a balance of manufacturing feasibility and cost.

The Value of Early Collaboration with Manufacturers

Most teams only quote after the design is finalised, which means that the cost of modifications becomes very high. With optimisation according to ASME Y14.5-2009, you have free-of-cost DFM analysis before finalization and thereby helps you avoid pitfalls.

The JS Precision engineers provide recommendations on structural and process optimization, which have greatly reduced the cost of rapid prototyping without affecting the functionality.

Want your design to have a cost advantage from the start? Upload your design files to JS Precision now, and our DFM engineers will provide a detailed optimization report within 24 hours, along with a precise rapid prototype services quote, giving you control over costs during the design phase.

CNC Machining Vs. 3D Printing: Which Is Right For Your Prototype Budget?

When choosing prototyping and CNC machining solutions, CNC and 3D printing have their own advantages and disadvantages, with significant cost differences, and need to be adapted according to the scene.

Benefits of CNC Machining for Rapid Prototyping

For functional testing of metals/engineering plastic, load-carrying parts, precision beyond ±0.05mm, or surface qualities, CNC machining provides cost and/or technological advantages for small series pre-production with 10 to 500 pieces.

Cost Advantage of 3D Printing

In the case of complex internal geometries, single concept parts, and demonstration parts, which only demand size verifications, the cost and time advantages of 3D printing shine through in cost savings and competitive turnaround times.

Hybrid Strategy: The Best Combined Approach for Cost and Speed

A complex project can be undertaken using a hybrid approach involving early resin 3D printing for verification, metal printing in the middle process for verification, and completion with CNC machining.

Unsure which process is best for your project? JS Precision engineers will provide professional process selection advice based on your prototype's purpose, quantity, and accuracy requirements, while comparing the rapid prototyping costs of two processes to help you choose the optimal prototyping and CNC machining solution.

Case Study: How JS Precision Helps Silicon Valley Medical Startup Complete Device Prototype Iteration

Cost and lead time of CNC rapid prototyping have been directly affecting the R&D process in the medical devices industry. A Silicon Valley-based surgical robot startup was assisted by JS Precision in overcoming the difficulties associated with high cost and long lead time for titanium alloy fixture prototyping, thus reaching a balance between cost and efficiency.

Customers' Challenges

A customer’s prototype fixture contained TC4 alloy with deep cavities and matching surfaces. It took over $2000 for one unit with an 8-week lead time from the original US supplier which slowed down R&D. This prototype had to be biocompatible, high in strength, and had tolerance of ±0.02mm which made machining tough.

JS Precision Solution

1. DeePCollaboration for DFM:

Analysis of the model led JS Precision engineers to realize that a non-load-bearing hollow structure was complex to machine. Recommendations included redesigning this structure from wire cutting to weld components to directly reduce the time for deep cavity milling by 80% and make sure this did not compromise structural integrity.

2. Process Optimization:

In order to overcome the problem of high hardness and low thermal conductivity of titanium alloys, a five-axis precision machine tool with high stability, dedicated titanium alloy cutting tools, and a high-pressure cooling system were used to improve the cutting process, which resulted in a reduction of 25% in single piece machining time and a scrap rate of less than 1%.

3. Integration of Supply Chains:

In utilizing localized supply chain advantages, we quickly sources raw material of biocompatible titanium alloys without having to wait long as would be required in sourcing imported material. The machining, heat treatment, and precision polishing operations are also incorporated in our own factory.

Quantitative Results:

As a result of optimization, the cost of doing one prototype went down by 32% ($2000+ to $1360), giving them over $6400 in cost savings with each set of 10 units, while the delivery time now was only 2 weeks, leading them to complete 3 iterations in time for clinical validation, 3 months before schedule, with the prototype fully satisfying the criteria.

Facing similar challenging prototype requirements? Contact JS Precision. We combine cross-industry experience to customize a CNC machining rapid prototyping solution, strictly controlling costs, ensuring delivery time, and guaranteeing quality.

How Can You Reduce Your Final CNC Rapid Prototyping Production Costs?

In addition to design optimization, process optimization, optimizing project management, order management, or supply chain optimization can also lower costs in CNC machining rapid prototyping.

Maximize Batch Effects and Spread Fixed Costs

- Order Consolidation: Centralizing the production of different parts allows for one-time amortization of fixed costs, reducing unit costs by 15%-20%.

- Phase Production: Before mass production, testing prototypes saves unnecessary cost in setting up.

Planning and Communication Create Value

- Reasonable Delivery Time Control: 5-10 working days for standard lead time, no rush charges (+30% to 100% for non-urgent requirements).

- Clearly define priorities: Communicate clear priorities to suppliers in order to assist in the provision of economical solutions that will prevent over-processing.

Select a Full Service Carrier to Minimize Hidden Charges

JS Precision, or one-stop solution provider, helps avoid the costs involved in outsourcing. Full supply chain integration can provide a saving of 10-15%, which is a major criterion in managing total cost.

Want to unlock your exclusive advanced cost reduction strategies? Tell JS Precision your project quantity, delivery date, and core requirements, and we'll plan the optimal order solution for you, while providing a transparent rapid prototyping service quote to further reduce total costs.

How To Get And Evaluate a Transparent Rapid Prototyping Service Quote?

A necessary step in managing the cost of rapid prototyping is having a clear, accurate rapid prototyping service quote. This demands skills in standardized processes and assessment techniques.

Offering Standard Inquiry Packages for Accurate Quotes

Give 3D STEP/IGES Models, detailed 2D Drawings, material names with their respective quality, amount, and delivery dates. The more detailed the data, the less the analysis error, and it is possible to tighten the range of the resulting quotations within ±5%.

Decoding a Professional Quote

A professional quote should thus involve elements of materials, man hours, post-processing, and taxes. It is advisable to be careful when offered quotes solely based on the overall cost to avoid extra costs.

Choosing a Supplier: Multi-Dimensional Evaluation, Not Just Price

Evaluation core: whether DFM advice is provided, whether there is multi axis machining equipment, whether there is FAI quality control plan, response efficiency, and NDA confidentiality ability.

FAQs

Q1: How much does it cost to make a simple aluminum alloy prototype?

The price for a fist-sized prototype made of a simple 6061 aluminum alloy can vary from $150 to $400, depending on the precision level, among other finishing techniques.

Q2: Why are CNC prototypes more expensive than 3D printed prototypes?

The major cost components in CNC are the cost of material, machine time, and programming, hence largely fixed costs. 3D printing is material-intensive and does not need any sophisticated programming, hence ideal for complex, low-strength objects.

Q3: How quickly can I receive my CNC rapid prototype?

For simple components, the shipping time can be 24 to 48 hours. However, for expedited shipping, they charge an expedited shipping fee. Standard shipping will take around 5 to 10 business days and will offer good value for money.

Q4: What prototyping materials do you (JS Precision) support?

JS Precision offers support for different materials, such as metals such as aluminum alloys, stainless steel, titanium alloys, and brass, in addition to different engineering plastic materials, such as POM, nylon, and PEEK.

Q5: How can I ensure the confidentiality of my design drawings?

JS Precision has strict adherence to non-disclosure agreements. Customer data is treated in an encrypted system, while project personnel are under confidentiality clauses comprehensively drawing security.

Q6: What is the smallest prototype part that can be machined?

JS Precision's CNC equipment can reliably machine features down to 0.5mm for high-precision prototyping needs for micro-medical devices or electronic components.

Q7: Do you provide assembly and functional testing services?

Yes, JS Precision can provide a complete range of rapid prototype services from multi-part machining to precision assembly and basic functional testing like airtightness to fulfill all your needs in one stop.

Q8: What is the process for re-quoting if the prototype needs modification?

Please provide the model files with modifications. JS Precision can usually evaluate, based on the changes, the cost and delivery time impact in one business day, update the quotation and provide explanation for the modifications.

Summary

Control in CNC rapid prototyping essentially means striking an optimal balance among design, process, and supply chain, not simply the slashing of costs in one area. With professional DFM capability, end-to-end service, and rich experience, JS Precision will help you precisely control the rapid prototyping cost.

Send your design files to JS Precision now, and we will give a detailed quotation with suggestions on optimization within 24 hours. Save time with controllable cost and delivery time in getting your innovative ideas to market with quick turns.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com