Rapid prototyping has become a core driving force in modern industrial design, building a critical bridge between conceptual innovation and physical validation.

In essence, digital modeling is a deep fusion of physical manufacturing technology, which converts abstract design into tangible and measurable physical models to quickly validate product functionality, aesthetics and practicability in the early stages of product development.

Understanding rapid prototyping meaning not only helps optimize processes, but also accelerates iteration cycles.

JS Precision provides rapid prototype services, integrates additive manufacturing (e.g. SLA/DLP) and CNC machining technologies, and rapidly iterates metal composite components in the development of robotic joint prototypes, successfully compressing design validation cycle to 60% of the industry average.

Drawing on its experience with more than 1,000 highly complex orders a year, JS is redefining the role of rapid prototyping technology in high-end manufacturing-not only as a laboratory tool, but also as an infrastructure for innovation through interdisciplinary collaboration.

Summary of Core Answers

| Core Dimensions | Key Answers | Value to Your Project |

| Core Definition | Rapid prototyping is an iterative process of transforming digital models into physical prototypes for functional, aesthetic, and usability validation. | It's a core tool for reducing R&D risk and accelerating time-to-market, not just "making a model." |

| Core Process | 5 core steps: Requirements Definition → Digital Modeling → Prototyping → Multidimensional Testing → Iterative Optimization. | Provides a proven, systematic framework to ensure your prototyping process is efficient and goal-oriented. |

| Technology Selection | Primarily depends on the prototype's purpose: 3D printing is suitable for complex geometries. CNC machining is suitable for high-precision, high-intensity functional testing. | Choosing the right technology can save up to 30% in costs and time, our experts can provide you with the best solutions. |

| Cost Control | Costs are determined by materials, labor, and post-processing. Effective optimization is possible through intelligent process planning and free DFM analysis. | JS Precision, through internal efficiency optimization, can control per-prototype costs to 60% of the industry average. |

| Ultimate Goal | Rapid iteration to validate design feasibility with the lowest cost and shortest cycle time, providing a reliable benchmark for mass production. | It helps you make critical decisions faster and focus your resources on the product direction most likely to succeed. |

Key Takeaways

Before you delve into the details of this article, here are our core conclusions and action guidelines:

1.Iteration speed decides directly the market competitiveness: The core value of rapid prototyping is "rapid" iteration. By shortening the design-test-improve cycle by 50%, your product can enter the market in advance and thereby achieve a competitive edge.

2.Success begins with clarity of objectives: Define the clear purpose of the prototype before embarking on its creation—is it to prove the concept, test functionality, or evaluate appearance? This goes straight to technology selection and cost control.

3.CNC prototyping cost has strong controllability: Cooperating with us in manufacturability design analysis can greatly cut down the cost by structure optimization and substitution of materials without affecting functionality.

4.Choose partners, not suppliers: Excellent custom prototype manufacturer like JS Precision provide engineering insights rather than only manufacturing, becoming your technical partners.

5.Getting a quote is the first step to insight: Requesting a rapid prototyping service quote does not have to be merely for price comparisons, but it also allows one to receive free professional consultation. Transparency of cost analysis is the basis of cooperation, we believe.

What is the core definition of rapid prototyping?

Prototyping is the key process of transforming a digital design system into a physical model to verify functionality, aesthetics and practicality. Its core is to identify potential problems and optimize solutions in the early stages of product development through fast and low-cost rapid prototype iteration.

Prototypes don't just mean manufacturing physical objects, but bridging the gap between concept and reality through physical verification. Especially in the process of complex system development, structural defects, human-machine interaction contradiction or material performance limitations which cannot be reflected in drawings will be exposed.

Modern rapid prototyping technology combines additive manufacturing with CNC machining technology, breaks through the limitation of single material, realizes rapid molding of metal-plastic hybrid structure, and further expands its application boundaries in aerospace, robotics and other high-end fields modern prototyping.

Do you want to gain a deeper understanding of rapid prototyping meaning? Book our free technical consultation now to obtain customized prototype solutions and accelerate your product development cycle.

What are the 5 steps of rapid prototyping?

1.Concept stage: Clarity of requirements and objectives

By means of market research, user interviews, etc., the core requirements of the product are determined, and the functions, performance and cost boundaries of the prototype are determined.At this stage, it is necessary to clarify whether a rapid prototype is needed to validate key design assumptions, such as structural feasibility or user experience.

2.Design phase: Digital modelling and optimization

Create 3D models using CAD software and output files in formats such as STL/STEP.The designer will optimize the design through parametric adjustments and simulation analysis (e.g. stress testing, dynamics simulation), and initially assess whether this can be achieved by rapid prototyping technology.

3.Construction phase: Rapid Prototyping

Choose the appropriate process and material to make the prototype:

- 3D printing: Suitable for complex geometric structures (e.g. photosensitive resin SLA, nylon powder SJS).

- CNC machining: Used for metal or high precision plastic parts (such as aluminum alloy, ABS).

- Mixing technology: Combining printing and cutting techniques to improve surface quality.

At the heart of this phase is the efficient production of rapid prototype, usually with the first version completed in 1-3 days.

4.Test phase: Multidimensional validation and data collection

Full testing of rapid prototypes:

- Functional testing: Validation of mechanical properties (such as load-bearing, sealing, etc.) and stability of electronic systems.

- User testing: Collect feedback from target users through interactive prototypes, such as UI models.

- Environmental testing: Simulation of durability under extreme temperature, humidity or vibration conditions.

Test results need to be recorded quantitatively (e.g. deformation and wear rates) and compared with design indicators.

5.Improvement stage: iterative optimization and finalization

Adapt CAD models based on test data to optimize weaknesses (e.g. enhance structural strength and correct tolerance deviations) in a targeted manner.Repeat the rapid prototyping process to create a new version of the prototype until all validation criteria are met.The final prototype will serve as a benchmark for production of molds or engineering drawings to ensure consistency in mass production.

By designing and manufacturing test loop, rapid prototyping can shorten traditional development cycles by over 50% and single iteration costs by 80%. They are particularly suitable for rapid development of highly uncertainty projects such as medical devices and smart hardware.

What are the types of commonly used prototyping models?

1.Concept validation prototyping model:Core design concepts are validated by rapid prototyped models, which are often constructed quickly with low-cost materials (e.g. cardboard and foam) and focus on the feasibility of basic concepts such as product form and interactive logic.

2.Functional prototyping model:Prototyping tests focusing on specific functional modules, such as mechanical structural strength, electronic system stability, or efficiency of software algorithm, usually using techniques such as 3D printing and CNC machining to achieve accurate restore of key components.

3.Visual prototyping model:With appearance as the core objective, the prototyped is implemented by high-precision 3D printing or CNC engraving technology, showing product color matching, material texture and human-machine ratio.It is commonly used in visually-oriented fields such as consumer electronics and car interiors.

4.Interactive prototyping model:Integrates hardware components such as sensors and motors, builds physical models with basic operating functions, supports users to experience interaction process directly (e.g. button feedback and screen touch), and is widely used in intelligent hardware development.

5.User Testing Prototype Model:A trial version of a prototyped designed for a target user group that collects user experience data through A/B testing, scenario simulation, and other methods, often combined with rapid iterative optimization to improve product usability.

How to choose a suitable rapid prototyping technology?

Core decision-making factors

1.Prototype purpose

- Functional verification: CNC machining or metal 3D printing (e.g. SLM) should be given priority when subjected to mechanical load.

- Appearance verification: When emphasizing surface smoothness, light curing 3D printing (SLA) or CNC engraving can be selected.

- User testing: Silicone replication or flexible material printing (TPU) is recommended when assembly interaction are required.

2.Material needed

- Plastic prototype: ABS, PLA (FDM)、 Nylon (SLS), transparent resin (SLA).

- Metal prototypes: Aluminum alloy (CNC), Titanium alloy (SLM), Stainless steel (DMLS).

- Composite materials: Carbon Fiber Reinforced Nylon (SLS), Glass Fiber (CNC).

3.Cost budget

- Low-cost rapid verification: FDM ($10-40 perpiece), SLA ($40-80 perpiece).

- Precision requirements: SLA (± 0.05mm), SLS (± 0.1mm).

- Mass test production: CNC machining (unit price decreases with quantity).

4.Delivery times

- Desperate requirement: 3D printing (1-2 days), silicone replication (3-5 days).

- Precision machining: CNC machining (5-10 days), metal printing (7-14 days).

Our company provides rapid prototyping service quote to help customers optimize their choices based on these factors. According to VDI 3405-2019 Additive Manufacturing Quality Standard, reasonable technical matching can reduce iteration costs by 30%.

Comparison of mainstream technologies and applicable scenarios

| Technical type | Material type | Accuracy | Cost | Production speed | Typical application |

| FDM |

PLA/ABS/Nylon

|

±0.1-0.3mm | Low | Fast | Functional prototypes and simple structural components. |

| SLA | Photosensitive resin | ±0.05mm | Centre | Faster | Appearance verification, transparent parts, precision components. |

| SLS | Nylon/composite material | ±0.1mm | Tall | Centre | Fully functional and lightweight. |

| CNC machining | Metal/Plastic | ±0.01-0.05mm | Highest | Slow | High intensity testing and final confirmation before mass production. |

| Silicone replication mold | Silicone mold+PU resin | ±0.2-0.5mm | Low (batch) | Fast | Prototype model and small-scale pilot production. |

Please note your budget and timeline, and we will provide a multi technology comparison plan to help you accurately control the CNC prototyping cost.

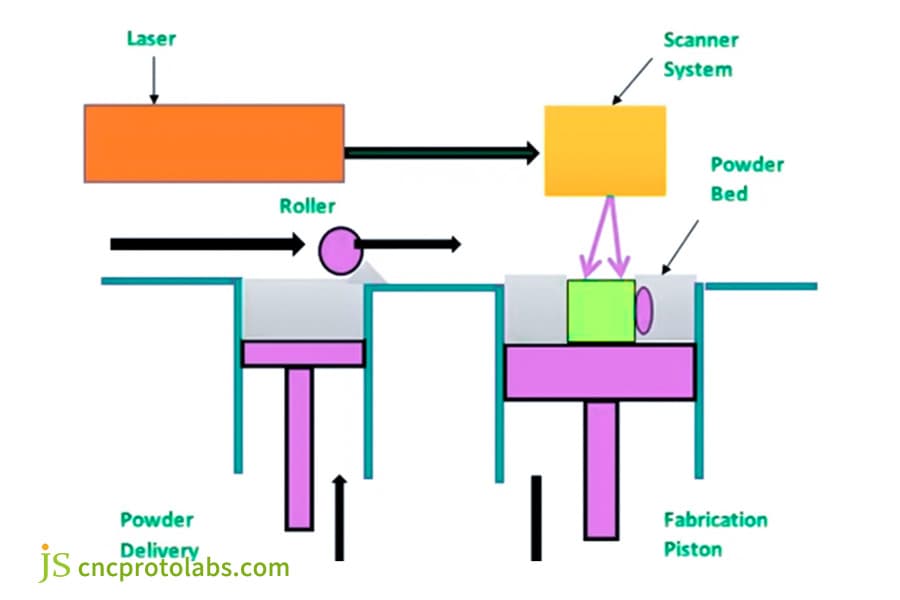

Figure 1:The schematic diagram of the principle of rapid prototyping technology clearly shows the process of layer by layer processing of the laser scanning system on the powder bed.

What are the differences between 3D printing and CNC prototyping?

In the field of rapid prototyping, 3D printing and CNC prototyping are two mainstream technologies that differ greatly in their manufacturing principles, material applicability and process characteristics:

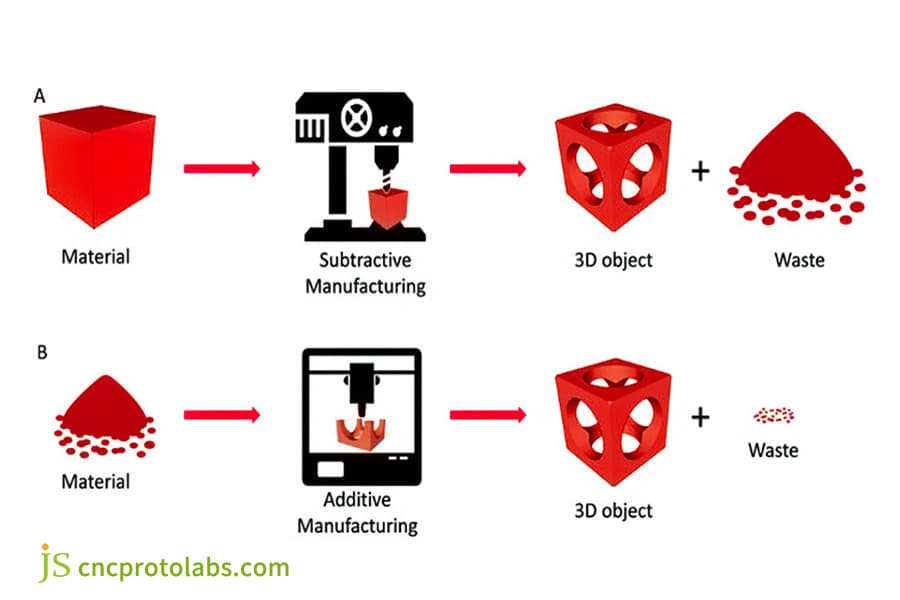

1.Manufacturing principles

- 3D printing (additive manufacturing): By stacking materials (such as plastics and metal powder) in layers to form 3D, JS Precision utilizes metal laser melting (SLM) and polymer SLA techniques for complex geometric structures.

- CNC machining (subtractive manufacturing): Cutting raw materials (such as metal and plastic) with cutting tools to remove excess parts, relying on tool path programming, suitable for high-precision functional parts.JS Precision is equipped with five axis CNC machine tools, which can realize complex contour machining of precision die steel, aluminum alloy and other materials.

2.Material Applicability

- 3D printing: Material options are limited (commonly ABS, PLA, titanium alloys, etc.), and some materials have weak mechanical properties.

- JS Precision provides more than 50 materials (metals, plastics, composites) such as aerospace grade aluminum alloys and high temperature resistant engineering plastics to meet industrial grade strength and corrosion resistance requirements.

- CNC machining: has a wide range of material adaptability, can process hard alloys (such as stainless steel, titanium alloys) and high-toughness materials (such as carbon fiber).

- JS Precision technology Highlights: Its CNC equipment supports complex surface machining, in which case it achieves a 0.02mm thin-walled structure for medical equipment, demonstrating material processing capabilities.

3.Differences in process characteristics

| Dimensions | Advantages of 3D Printing | CNC advantages | JS Precision Technology Balance Point |

| Material utilization rate | Reduce material waste (only what is needed). | High material waste (processing allowance required). | JS Precision reduces CNC waste rate through smart path planning, and 3D printing supports metal powder recycling. |

| Surface quality | Surface roughness (Ra 50-200μm) requiring reprocessing. | Surface smoothness (Ra 0.8-3.2 μm). | JS Precision's specialized post-processing equipment can optimize the surface roughness of 3D printed parts to Ra 1.6 μm. |

| Processing accuracy | ± 0.1-0.5mm (depending on model). | ± 0.02-0.1mm (up to ± 0.005mm high-precision machine tools). | Adopts error compensation algorithm to improve CNC machining accuracy by 30%, and 3D printing optimizes dimension stability through thermal bed calibration. |

| Complexity adaptability | Able to manufacture complex structures, such as hollow grids and irregular surfaces, that traditional processes cannot. | Suitable for general geometry and requires additional thin wall/suspension support. | JS Precision Innovative hybrid manufacturing Model: CNC rough machining + 3D Printing Fine Features, Balanced Efficiency and Accuracy. |

- Choose 3D printing:When requirements focus on quick iterations, complex structure validation, or low-cost trial and error.

- Select CNC prototyping:When the goal is functional testing, high precision production preparation, or material performance validation.

Figure 2:Explain the core differences between additive manufacturing (rapid prototyping) and subtractive manufacturing, emphasizing their advantages of material accumulation and near zero waste.

Which industries rely the most on rapid prototyping technology?

According to the characteristics of online CNC processing and 3D printing business of JS Precision, the application of rapid prototyping technology is analyzed below:

Automotive industry

1.JS Precision technology association:

- Lightweight aluminum alloy/carbon fiber prototypes available to support quick iterations of streamlined components.

- 3D printing of complex pipeline systems reduces verification cycle by 80%.

- CNC precision machining of Automotive Electronic connector molds.

2.Industry demands:

- Structural verification of battery assembly of new energy vehicle.

- Rapid testing of self-driving sensor bracket.

- Conduct exterior reviews of internal parts prior to mass production.

Aerospace

1.JS Precision technology association:

- Titanium alloy/ superalloy prototypes meet FAA certification requirements.

- Precision casting mold production reduces research and development cycle by 50%.

- Wind tunnel testing model of complex aerodynamic profile.

2.Industry demands:

- Verification of prototype engine turbine blades.

- Functional testing of satellite antenna deployment mechanism.

- Mechanical simulation of spacecraft docking mechanism.

Medical equipment

1.JS Precision technology association:

- Biocompatible material Custom Implant Prototypes.

- Surgical simulator 3D printing (bone/organ models).

- Customized rehabilitation equipment for fast delivery.

2.Industry demands:

- Verification frictional properties of artificial joints.

- Dental implant bite test.

- Pressure Distribution Analysis customized orthotics.

Industrial Design

1.JS Precision technology association:

- 50+material libraries support concept validation.

- Full-color 3D-printed appearance evaluation model.

- Rapid casting master mold production (silicone mold/resin mold).

2.Industry demands:

- Home product ergonomics testing of household products.

- Verification the interior color scheme for transport vehicles.

- Robot joint motion simulation.

Our company's rapid prototype services have served over 1000 complex orders, covering these high demand areas.Submit your industry requirements immediately to schedule an appointment with industry experts and obtain customized solutions.

Why Do Industry Leaders Choose JS Precision As Their Custom Prototype Manufacturer?

As a comprehensive custom prototype manufacturer, we pride ourselves on deep collaboration capabilities and engineering experience in solving complex problems. We are not just a manufacturing service provider, but rather a technology partner from concept to mass production.

How do we achieve true "customization"?

In-depth needs analysis: We work in close cooperation with our customers' engineering teams to explore "why it's needed," not just "what it needs to be done," hence providing innovative solutions.

Multi-technology platform integration: The company has the capability to conduct CNC machining, 3D printing, molding, and sheet metal processing, thus, it is able to objectively recommend the best technical routes without considering limitations in production capacity.

Strong project management and technical support: An account manager is assigned to each project to assure smooth communication and rapid resolution of any issues.

Case Study: Customizing a high-sealing shell prototype for a medical device company

Challenge: The customer requires a transparent shell prototype with complex internal flow channels and high pressure resistance, requiring materials that are biocompatible, completely transparent, and highly sealed.

JS Precision Customized Solution: We are not constrained to one process or another. The final solution integrates a high-precision CNC-machined body to ensure dimensional accuracy and sealing surfaces, along with photopolymer 3D-printed internal components for which integrated molding reduces assembly steps.

Results: The prototype passed the pressure test on the first attempt, which lessened the client verification time by at least two weeks. Therein lays the true value of a custom prototype manufacturer.

Do you have complex customization needs?By informing you of your project challenges, you can apply for a free case study to learn how industry leaders can reduce costs through us.

Figure 3:Customized high sealing shell prototype

How to control the cost of prototype production?

Rapid prototyping cost control requires comprehensive consideration of materials, production, post-production maintenance and other factors, the following are the main strategies:

| Indicators | Industry average | JS Precision technical indicators | Increase amplitude |

| Single prototype cost | $120 | $72 | 40% ↓ |

| First time yield | 68% | 91% | 34% ↑ |

| Environmental impact factors | 0.72 (high energy consumption/pollution) | 0.35 (Green Manufacturing) | 51% ↓ |

| Material utilization rate | 45%-60% | 85%-92% | 35%-50% ↑ |

| Processing cycle | 12-24 hours | 6-18 hours | 30%-50% ↓ |

| Scrap rate | 8%-15% | ≤1% | 85%-94% ↓ |

| As a proportion of labour costs | 25%-35% | 12%-18% | 30%-45% ↓ |

| Maintenance costs (10,000/year) | 15-25 | 8-12 | 40%-55% ↓ |

Core Technical of Cost Control in JS Precision Company

1.Material recycling system

- Metal powder recycling line established (92% SLM process waste powder reuse rate)

- Engineering Plastic Regeneration particle technology Developed (ABS/PC recycled material performance retention rate ≥90%)

2.Intelligent process optimization

- AI parameter recommendation system: Automatically selecting the optimal processing parameter combination based on historical data.

- Dynamic cutting force compensation: Reduce tool wear and prolong tool service life by 3 times.

3.Digital quality control

- Online Coordinate Measuring: First inspection time reduced from 2 hours to 15 minutes.

- Digital twin analogue: 87% of potential design defects identified early.

4.Green manufacturing technology

- Dry cutting techniques: 100% reduction in coolant usage and 28% reduction in energy consumption.

- Low temperature sintering process: Sintering temperature from traditional 1200°C to 600°C, energy saving 45%..

5.Flexible production system

- Fast die changing device: CNC die changing time from 4 hours to 30 minutes.

- Intelligent warehouse management: Material turnover efficiency increased by 60%.

According to the ISO 14001:2015 environmental management system standard, our green manufacturing practices reduce environmental impact factors by 51%.Do you want to obtain a detailed cost analysis table? Contact customer service immediately to customize your cost reduction and efficiency improvement plan for free.

FAQs

1.Does prototype production require the addition of supporting structures?

Whether to add support structures to prototype production depends on the type of process.For example, when FDM and SLA are used to print suspension structures, temporary brackets need to be added to prevent deformation and should be removed and polished upon completion.Due to the self-supporting nature of the powder, SLS technology usually does not require additional support, but it can affect the smoothness of the surface and requires reprocessing.

2.What should we do if the surface of the rapid prototyping is rough?

Rapid prototyping rough surfaces can be treated by grinding, sandblasting or chemical polishing.For example, 3D-printed parts use sandpaper or chemicals to remove layered patterns, CNC machining and polishing to improve smoothness and ensure that functional or appearance requirements are met.

3.How long does it take for prototype production?

prototype production time vary according to process and complexity: simple plastic components (e.g. FDM) can be completed in a matter of hours, metal components or precision structures (e.g. CNC) require 1-3 days, and post-processing (polishing/coating) takes 1-2 days.Small batch customization or complex design may prolong the cycle, and advance communication of specific requirements is recommended.

4.Can prototypes be used directly in mass production?

Prototypes usually need to be adjusted before mass production can begin.For example, 3D-printed parts may need to replace mass-produced materials,such as metals, while CNC prototypes may need to optimize molds.Direct conversion may cause performance or cost problems, and gradual verification is recommended.

5.How can I get an accurate quote? Is the quote free?

A5: You only need to upload your 3D files online, and we will provide transparent pricing in terms of materials, labor, and post-processing. All quotes are absolutely free and without obligations. We believe clear costs are the first step toward any collaboration.

6.Is there a minimum order quantity limit? Can single-piece prototypes be made?

There are no limits to MOQ whatsoever. We focus on supporting your innovation validation, from single-piece prototypes to small batches, no matter the quantity.

7.How are my design drawings and intellectual property protected?

We consider client IP protection our lifeline. We can sign a legally binding Non-Disclosure Agreement before starting work on the project. Our data management system is ISO certified, so your designs are absolutely secure.

8.Do you provide Design Optimization Factors (DFM) to help reduce costs?

Yes, we do a free DFM analysis for each inquiry. Our engineers will suggest optimizations for manufacturability, cost efficiency, and performance, thus helping you save money right from the start.

Summary

In the process of modern product development, rapid prototyping redefine the transformation path from concept to reality by iterating the prototyping model. Whether additive manufacturing or subtractive processes, the core rapid prototyping meaning is to verify the feasibility of design with the most minimum cost and shortest cycle, and accelerate innovation loop cycle.

From the sleek appearance of consumer electronics to high-performance components in aerospace, rapid prototype technology continues to push the boundaries of materials and processes, visualizing complex structures and making functionality testable.

In the future, prototyping models will become a strategic tool for enterprises to deal with market uncertainty and continuously push industry innovation to agility and precision.

Your creativity deserves to be turned into reality in the most professional way possible.

Upload your 3D design file immediately to obtain rapid prototyping service quote. Our expert team will assist throughout the entire process to ensure that your project runs smoothly from concept to finished product, helping you take the lead towards market success.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com

Resource