Prototype manufacturing is a bridge that connects virtual design with physical products. It can verify the feasibility of the design, reduce research and development risks, and accelerate market launch.

How to balance cost, speed, and quality in the face of the choice between plastic and metal prototype manufacturing, as well as the technological differences between CNC and additive manufacturing?

This manual dissects prototyping to the very essence, thus revealing how JS Precision, through its one, stop service, can assist you in effectively crossing the divide from "idea" to "physical object." At the same time, its rapid prototyping technology is there to help the whole innovation iteration process.

Key Answer Summary

| Your Core Concerns | JS Precision's Solutions | Core Value for Projects |

| Importance of Prototypes and Material Selection | Features a library of materials from plastics to metals and professional advice on the selection of materials to meet different requirements. | A prognosis in line with testing objectives having the functions, appearance, and cost aspects, which also offers a proper basis for decision-making. |

| Cost and Speed Optimization | Presents the cost structure of prototype machining and also provides a range of delivery times from days to weeks to suit different needs. | Achieve cost effective iteration speed, thus, shortening the R&D cycle. |

| Technical Reliability and Collaboration Launch | Provides the assurance of quality prototype machined parts and also enables a smooth launch process. | Attain top-notch prototypes that will turn manufacturing into the main source of innovation. |

Key Takeaways

- Prototyping's main principle is to lower risks and gain deeper understanding quicker, rather than just producing a model.

- The choice of material (plastic versus metal) should be a well thought out decision considering the prototype's functional testing aspects, mechanical performance requirements, and the available budget.

- CNC machining rapid prototyping has very good advantages in precision, strength, and small-batch economy, which is especially great for functional metal prototypes.

- Additive manufacturing rapid prototyping is unique where there are complicated shapes, fast iteration, and lower assembly costs.

- Working with manufacturing specialists on Design for Manufacturability (DFM) at the very beginning, can save up to 30% of later extra costs and time.

- If you choose a partner like JS Precision, who has both CNC and additive manufacturing skills, you will get genuinely independent and best technical path recommendations.

Why Trust This Guide? JS Precision's Extensive Experience In Prototype Manufacturing

Prototype manufacturing is a tough niche requiring both technical know, how and experience. JS Precision has been in this line of work for more than 10 years now, delivering services to over 1000 clients from different industries, such as aerospace, medical devices, and consumer electronics, with a record of over 1 million prototype machined parts.

We have the full complement of CNC machining equipment ranging from 3-axis to 5-axis, and we are also equipped with additive manufacturing rapid prototyping production line using FDM and SLA, thus we are able to satisfy diverse client requirements in a single visit.

Speaking of quality control, JS Precision is ISO 9001:2015 certified and has set up a thorough quality control system from design analysis to finished product inspection. Each and every batch of prototype machined parts is checked with the help of precision instruments like CMM coordinate measuring machines to guarantee dimensional accuracy.

Our engineering team members have each spent on average over 8 years in the industry, which means they can quite quickly come up with the best process solutions for various kinds of prototype requirements.

In plastic prototype manufacturing, for instance, they guide the choice of proper engineering plastics while in metal prototype manufacturing, they pick up the most cost-effective metal materials for the job.

Moreover, JS Precision has gathered an extensive record of successful rapid prototyping projects, hence a repertoire of proven and mature solutions is at disposal for reproducing anything from a basic concept model to a highly intricate functional prototype.

As a matter of example, we tailored 200 sets of PEEK plastic functional prototypes for a medical device client. The client requested a precision of 0.05mm and a lead time of 10 days.

Through process optimization of CNC machining, we managed to deliver in 8 days with a yield of 100%, thus, the client's initial budget went down by 18% and the client was able to complete functional testing two weeks before the schedule.

Want to know how JS Precision can tailor a prototype manufacturing solution for your project? Submit your requirements now to receive a free, customized technical assessment report and have professional engineers answer your questions.

What Is Prototype Manufacturing And Why Is It Critical For Your Project Success?

Prototype manufacturing refers to the creation of physical models which are verified-tested, and demonstrated based on the product design. Rapid prototyping technology is the essence of work efficiency, which directly impacts design viability and hence the cost and time for mass production.

Functional Definition of Prototypes

There are 3 different types of prototype manufacturing prototype which are adjusted to different stages of the project:

- Concept Prototype: is usually plastic or foam and is used to reveal external features and the shape visually at a very low cost, thus it's perfect for early-stage idea sharing.

- Functional Prototype: a multi material process that imitates the mass production process produces a fully functional prototype, which can help you test the product's performance and gather user feedback. It is the main application of both plastic and metal prototype manufacturing.

- Pre-production Prototype: is made according to the specifications of mass production and used for confirming production processes and evaluating the supply chain. It is the final check before the product launch.

Why is one prototype worth a thousand meetings?

The value of prototype manufacturing extends far beyond model demonstrations, with three core aspects:

- Early defects identification is one of the great benefits of physical prototypes. They allow checking physical assembly and strength, thus making it possible to find more errors in CAD models. Then you can make the amendments at a time when the cost of changes is 10 times less than after the product is manufactured.

- Market feedback verification is one of the advantages of functional prototypes. Small-scale testing using them can provide genuine consumer feedback, thus avoiding a lukewarm response post-launch.

- Investor pitching is a great reason to develop a high quality prototype. They are far more persuasive than PowerPoint presentations, showing product value visually and thus, increasing the probability of obtaining the investment.

Plastic Vs. Metal Prototype Manufacturing: How Do You Choose The Right Material?

Plastic prototype manufacturing and metal prototype manufacturing are two major areas, which have significant differences in material properties and application scenarios, so the selection should be made according to the project requirements.

Plastic Prototype Manufacturing

The advantages of plastic prototype manufacturing are low cost, fast processing, and light weight. Commonly used materials and their properties are shown in the table below:

| Material Type | Tensile Strength (MPa) | Temperature Range (°C) | Typical Applications |

| ABS | 40-50 | -20~80 | Electronic product housings, snap-fit structures |

| PC | 60-70 | -40~120 | Transparent parts, impact-resistant structures |

| Nylon | 50-80 | -30~100 | Wear-resistant gears, sliding parts |

| PEEK | 90-100 | -60~250 | High-temperature, corrosion-resistant precision parts |

All the material properties are in line with ASTM D638 standards. Plastic prototype manufacturing is a good option for appearance verification, lightweight testing, and early iterations, the processing costs being only 30%-50% of those for metal prototypes of the same specifications.

Metal Prototype Manufacturing

The advantages of metal prototype manufacturing are high strength, high precision, and near-mass production readiness. Commonly used materials and their properties are shown in the table below:

| Material Type | Tensile Strength (MPa) | Density (g/cm³) | Typical Applications |

| Aluminum Alloy 6061 | 276 | 2.7 | Lightweight structural components, heat dissipation components |

| Aluminum Alloy 7075 | 572 | 2.8 | High-strength load-bearing structures, drone components |

| Stainless Steel 304 | 550 | 7.9 | Corrosion-resistant components, medical equipment |

| Titanium Alloy | 860 | 4.5 | Aerospace components, high-end medical implants |

Metal prototype manufacturing is a good option for functional, high temperature and high pressure testing, and strength verification, and is a main application area of CNC machining rapid prototyping.

Unsure whether to choose plastic or metal prototypes for your project? Inform JS Precision of your testing needs to receive a free material selection recommendation, reducing the trial-and-error costs of prototype manufacturing.

Figure 1: A diverse collection of prototype parts in various shapes, colors (silver, black, red, white), and materials, neatly arranged on a white surface.

Figure 1: A diverse collection of prototype parts in various shapes, colors (silver, black, red, white), and materials, neatly arranged on a white surface.

CNC Machining Rapid Prototyping: How Fast Can You Really Get a Functional Prototype?

CNC machining rapid prototyping is a most precise and highly utilized method in prototype machining to directly transform 3D models into high strength prototype machined parts.

The Highway from Digital Models to Physical Objects

CNC machining rapid prototyping is a very fast way of production, which efficiency is mainly derived from the next the core steps:

- Programming Stage: The CAD model is imported into CAM software, generating toolpaths and machining parameters, and engineers optimize the process.

- Clamping Stage: The raw material is fixed on the machine tool table, and specialized fixtures ensure stable machining.

- Machining Stage: The machine tool cuts according to the program, completing roughing and finishing.

- Post, processing Stage: Deburring, polishing, and anodizing of the parts can be carried out for better appearance and performance.

Their delivery time is very flexible, and the delivery of simple parts can be done within 3-5 days, while complex parts within 7-10 days, which is better than traditional machining.

Two Core Advantages of CNC Machining Rapid Prototyping

- Ultra high accuracy: Normal accuracy is 0.1mm, and high accuracy can reach 0.01mm, which is more than enough for functional prototype testing.

- Material fidelity: By using a sheet or bar stock of mass, production grade, the mechanical properties of the prototype will be almost the same as the final product, and the test results can be trusted.

Need high-precision prototype machined parts urgently? Contact JS Precision now, submit your 3D model, and you can get a CNC-machined prototype that meets your requirements in as little as 3 days.

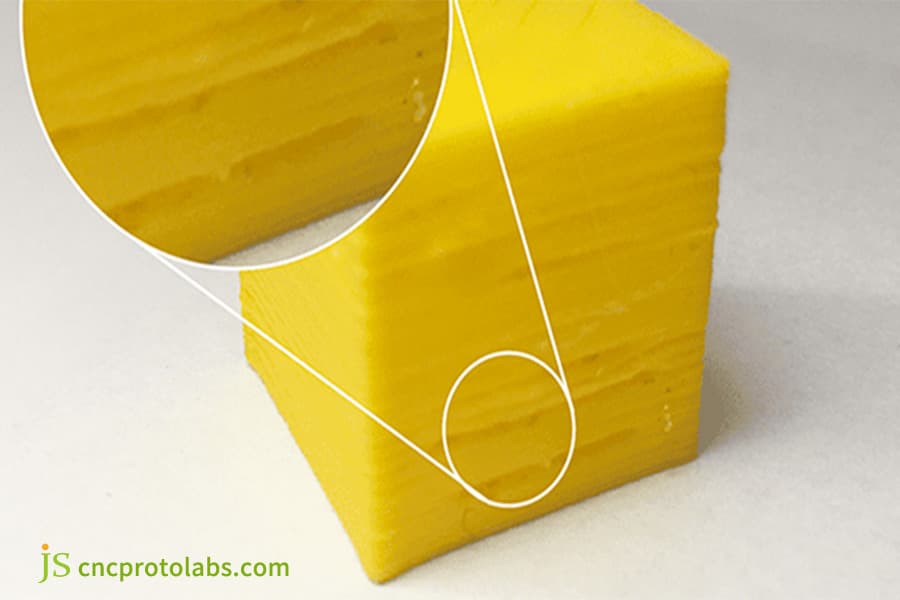

How To Ensure Layer Adhesion In Additive Manufacturing Rapid Prototyping?

Additive manufacturing rapid prototyping is a process to create prototypes by layering materials one on top of another. The strength of the part is mainly determined by the interlayer adhesion, if there is poor adhesion, it can cause the part to crack and deform.

Understanding Layer Adhesion: The Main Factor Affecting the Strength of the Printed Part

Interlayer bonding in FDM and SLS methods is material melting and cooling based. If the adhesion is not enough between the layers, then the part will become anisotropic, and vertical strength might be even less than 50% of the horizontal strength, thus it may not be able to pass the functional testing.

Key Process Parameter Control

To get the best interlayer adhesion, the control of the four core process parameters:

- Printing Temperature: The nozzle temperature should be sufficiently high to melt the material. A nozzle temperature in the range of 195-220℃ and a heated bed temperature of 50-60℃ are recommended when using PLA material.

- Layer Thickness Selection: The smaller the layer thickness is, the stronger the adhesion will be. It is a good idea to set the thickness to 0.1-0.2mm when creating functional prototypes.

- Printing Speed: If the speed is very high, there will not be complete melting, at the same time, if it is very slow, the part will get deformed. 50-80mm/s is the range where the speed is good.

- Material Dryness: Materials that take up moisture will result in getting the air bubbles. Before using the material, dry it in a drying oven for 4-6 hours.

Want to solve the layer adhesion problem in additive manufacturing rapid prototyping? Download JS Precision's "Additive Manufacturing Process Parameter Optimization White Paper" for free professional debugging solutions.

Figure 2: A yellow block made through additive manufacturing, showing distinct horizontal layers on its surface with a magnified inset view, on a white background.

What Are The Cost Drivers For Prototype Machined Parts?

Many factors contribute to the cost of prototype machined parts. By learning about these factors one can use prototype manufacturing budget more efficiently.

Design Complexity: How Machining Time is Decided

Design complexity is the main factor that determines price. The following features increase the cost:

- Deep cavity structure: cutting tools are longer thus resulting in more tool wear and longer machining time.

- Thin walled structure: Since it can be easily deformed, it requires several clamping and adjustment which will increase the time consumption.

- Small internal fillets: small-diameter cutting tools are used which reduces the machining efficiency.

- Strict tolerances: For each increase of one tolerance grade, machining costs rise by 20%-30%.

Materials and Processes: Core Factors Affecting Cost

Materials and processes have a significant impact on cost. Specific data is shown in the table below:

| Material Type | Unit Material Cost (USD/kg) | Processing Time (hours/piece) | Accuracy Grade (mm) | Accuracy Grade (mm) | Total Cost for 10 Pieces (USD) |

| ABS (Plastic) | 8.5 | 1.2 | ±0.10 | 32.6 | 298.5 |

| PEEK (Plastic) | 158.2 | 2.8 | ±0.05 | 289.7 | 2712.3 |

| Aluminum Alloy 6061 | 12.8 | 1.8 | ±0.08 | 68.4 | 632.5 |

| Stainless Steel 304 | 28.6 | 2.5 | ±0.06 | 115.8 | 1086.2 |

| Titanium Alloy | 135.4 | 4.2 | ±0.03 | 398.6 | 3724.8 |

Small batch prototype machining is priced based on "labor + materials + consumables," with tiered discounts available for bulk orders.

How Do I Start Customizing My Prototype Machined Parts?

It's easy to tailor prototype machined parts, JS Precision has a nifty 3 steps startup plan.

Step 1: Prepare your design files

Initially, you need to prepare your design files according to the following:

- 3D model: STEP or IGES format is recommended, making sure there are no broken surfaces or overlapping.

- 2D drawings: PDF or DWG format, highlighting key dimensions, tolerances, and surface treatment requirements.

- Requirements description: Clearly define the prototype's purpose, standards for testing, and delivery time, so engineers can understand easily.

Step 2: Get professional DFM analysis and instant quotation

The platform instantly gives you a rough estimate, and DFM experts will give you optimization tips and cost breakdown soon after. You can also get your consultation and personable assistance on DFM improvements.

- Simplify complex structures and reduce machining costs.

- Change materials according to the tests.

- Tweak process parameters to shorten the delivery time.

Step 3: Confirmation and Production, Enjoy a Transparent Process

After confirming the order in Step 3, you have a chance to trace the progress via the platform. You will be informed at particular stages about the continuing compliance with the design specs.

- Along with the first piece, you will be given the inspection report and high resolution pictures.

- If there are any problems during production, the engineers will contact you instantly.

- Before final delivery, a comprehensive inspection will be conducted to ensure compliance with design requirements.

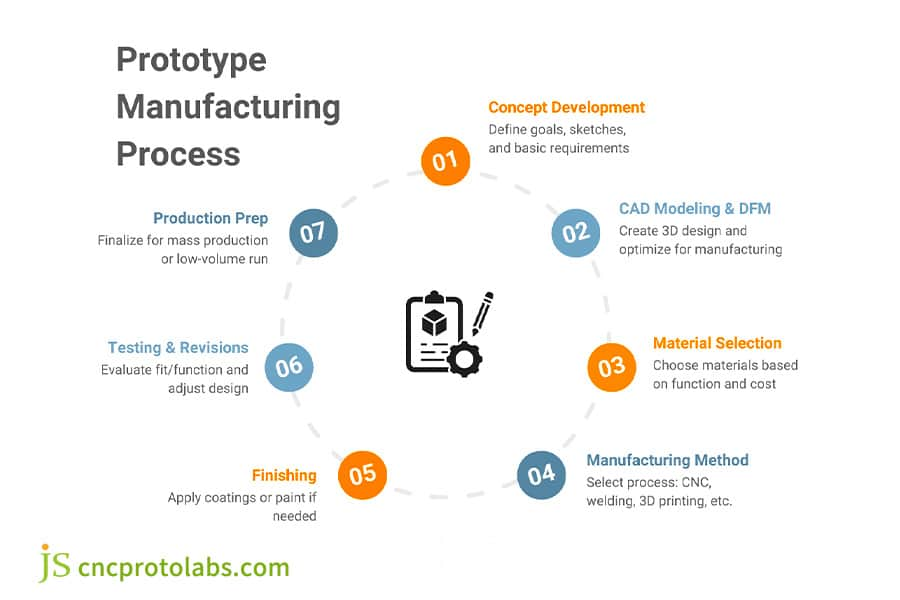

Figure 3: A circular diagram illustrating the seven-step prototype manufacturing process, from concept development to production preparation, with numbered stages and icons.

Figure 3: A circular diagram illustrating the seven-step prototype manufacturing process, from concept development to production preparation, with numbered stages and icons.

Case Analysis: Metal Structural Components Of Unmanned Aerial Vehicle Aerial Gimbals, From Design To Functional Verification, Only 7 Days

Challenge: The Ultimate Balance Between Strength and Lightweight

A client wanted a main frame for an aerial photography gimbal in high, end drones, with the 7075 aluminum alloy being a requirement. The structure is complicated and has multiple irregular curved surfaces along with weight, reduction cavities.

The customer wanted parts weighing less than 120g but capable of withstanding 15G impacts. Local suppliers' 3D printed parts were not strong enough, and traditional CNC machining had a two, week lead time, so the customer's urgent testing needs were not met.

JS Precision Solution: Five, Axis CNC High, Speed Precision Machining

Agile DFM Response: Designers at JS Precision, within four hours of receiving the model, suggested changing some sharp internal angles to rounded transitions. This change was maintained strength while also improving tool life and machining efficiency which resulted in a 30% reduction of machining time.

Five, Axis Linkage One, Step Molding: A German imported five axis CNC machining center was used, and through optimized toolpaths and specialized fixtures, complex curved surfaces were finished in a single setup, which gave the overall accuracy of 0.05mm and at the same time no errors of the secondary clamping were made.

Parallel Post Processing: Sandblasting and hard anodizing were done right after machining. The process was performed in parallel with the inspection process and the overall delivery time was not impacted.

Results

- JS Precision produced 10 sets of prototype parts that satisfied the design requirements completely within 7 days, and the actual weight was only 115g.

- After the 15G impact test, the part is capable of performing to the standards without any doubt and the cost is 20% below the customer's initial budget.

- Such a quick success allowed the customer to use the solution directly for the small, batch production stage, thus the product launch cycle was shortened considerably.

Do you also have similar urgent prototyping needs? Contact JS Precision, we can provide you with CNC machining rapid prototyping services with delivery as fast as 3 days, helping your project accelerate its implementation.

Figure 4: A robust metal structural component for a UAV aerial gimbal, featuring cylindrical and angular sections for stabilization, isolated on a white background.

FAQs

Q1: Which is better for my prototype: CNC machining or 3D printing?

If you want a functional prototype that is strong, precise, and has a beautiful surface, then CNC machining is the way to go. On the other hand, 3D printing can be used for verification models when you want to work very fast, have complex internal flow channels, or integrated structures. JS Precision can give you an unbiased opinion.

Q2: How strong can plastic prototypes be?

The key factor that determines this is the type of material. For instance, CNC, machined PEEK plastic can reach a strength level comparable to certain metals, whereas ABS prototypes of have good impact resistance and toughness, thus can be used for plastic prototype manufacturing scenarios like shell testing.

Q3: What surface treatments are metal prototypes usually given?

Aluminum alloys are mostly anodized to improve wear and corrosion resistance as well as to make coloring possible. The stainless steel is mostly passivated or electropolished. These types of finishing works are the ones most commonly used in metal prototype manufacturing.

Q4: How fast can I get my plastic prototype after placing the order?

If we're talking about single, simple ABS or nylon CNC machined parts then the whole process can be done and the goods dispatched within 3-5 working days. More complicated components or products that require special post, treatment will obviously take more time.

Q5: How can I ensure the security and confidentiality of my design files?

JS Precision signs strict NDA agreements, transfers, and stores files in an encrypted manner, and additionally, implements an employee confidentiality system to guarantee the 100% security of your intellectual property.

Q6: Can I order multiple parts with different designs at the same time?

It is possible at all! JS Precision is a one-stop service provider which means that you can place one order which includes multiple prototype machined parts of different materials and designs, thus, management and logistics costs will be optimized.

Q7: What is the process if modifications are needed after prototype testing?

Just send us your new design files, and JS Precision in no time will re-quote and arrange production as per our previous cooperation so you can benefit from the iteration efficiency advantages.

Q8: Do you provide assembly services?

Certainly, JS Precision will machine the parts and also provide you with professional assembly services, complete- functional assemblies will be delivered to you, saving your time and ensuring assembly quality.

Summary

Prototyping is not merely "making models, " but rather an essential strategic lever for product innovation. Selecting the appropriate materials, utilizing the right methods, and identifying the suitable collaborators can convert your design concepts into tangible products at the fastest pace and lowest cost.

JS Precision, as a specialist in prototype manufacturing, is capable of recognizing both the high accuracy and speed of CNC machining rapid prototyping and the versatility and creative potential of additive manufacturing rapid prototyping, and deciding on the most suitable solution for you.

Don't let your concepts stay confined to the paper, commence your efficient prototype manufacturing process now:

Submit your 3D files to the JS Precision platform, and within 24 hours, you will get a comprehensive quote and production plan along with professional DFM advice. Let's make your brilliant idea come to life quickly and accurately by working together.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com