Prototype CNC machining forms one of the main pillars on which rapid product development is hinged.

We've all seen such high-pressure scenarios where a startup rushes to fix a defective prototype 10 days before a trade show, where engineers spend weeks revising designs because the first batch of products doesn't meet tolerance requirements, or when a team goes over budget because of unforeseen machining complexities.

Rapid prototyping is no longer just about speed but a balance of precision, cost, and delivery deadlines to transform ideas into usable physical parts.

This guide will walk you through the whole process from online inquiry to finished product delivery, revealing how JS Precision can be your most trusted engineering partner from "inspiration" to "market launch."

Key Answers Summary

| Customer Core Questions | JS Precision's Solutions and Capabilities | Key Value For You |

| Quotation Process: Is it complex and transparent? | Streamlined online quotation process and transparent pricing factor analysis. Supports instant online estimates, with all key factors fully disclosed. | Clear and controllable budget, simplified procurement process, allowing you to focus on core design. |

| Capability Limitations: Size/Material? | Comprehensive rapid prototyping and custom parts machining capabilities. Covering parts from micro to large, supporting both metal and CNC plastic prototyping. | A one-stop solution for all prototyping needs, eliminating the need to find multiple suppliers for different parts and ensuring efficient collaboration. |

| Optimization and Confidentiality: How to save money?How to ensure design security? | Professional design-to-manufacturing (DFM) optimization advice and strict prototyping confidentiality agreements. Our engineering team is your extension. | Significantly reduce costs and protect intellectual property, achieving both cost-effectiveness and security. |

Key Takeaways:

- Easy Startup: Get a clear quote in 3 minutes by uploading 3D files through the CNC machining prototype service online platform, eliminating cumbersome communication and allowing projects to get off to a fast start.

- Effective Cost Reduction: Optimized design is key to controlling prototype CNC machining costs. Early DFM analysis with professional service providers like JS Precision can significantly reduce additional expenses.

- Security First: When choosing CNC machining prototype service manufacturers, it is crucial to confirm their physical, digital, and legal confidentiality mechanisms to protect core design assets.

- Take Immediate Action: Accurate quotations rely on specific drawings. Prepare design documents immediately to complete the initial quote, quickly verify feasibility, and plan the project timeline.

Choose JS Precision Prototype CNC Machining: Precise Control Of Budget And Delivery Time

Rapid prototyping requires a partner who understands technical details and can handle tight deadlines.

JS Precision's quality management system strictly follows the International Organization for Standardization (ISO) ISO 9001:2015 quality management system standard, which provides a framework for our process stability and continuous improvement, ensuring that every prototype project can be completed with high quality within the predetermined budget and time.

Over the past 12 years, I have provided CNC machining prototype services to over 5,000 clients in robotics, medical devices, aerospace, and consumer electronics.

The parts we've machined are incredibly diverse, ranging from 0.5mm high-precision components for wearable devices to 800mm large-scale structural parts for industrial robots. Even for rush orders, we maintain a 99.7% on-time delivery rate.

My team has undertaken complex projects, such as machining 5-axis aluminum alloy brackets with tolerances of ±0.01mm for drones, and creating FDA-compliant cnc plastic machining prototype for medical inhalers.

This guide is far from theoretical—it's a summary of our practical experience solving thousands of prototype machining challenges. You can completely trust every suggestion, data point, and recommendation, as they have all been tested in real-world production scenarios and have helped clients reduce costs by up to 30% and shorten delivery cycles by half.

Want to ensure your rapid prototyping project stays on budget and on time? Contact JS Precision engineers, share your project requirements, and we'll provide a free preliminary feasibility analysis, using our professional experience to mitigate potential risks.

From Drawings To Quotations: How Simple Is The Online Process Of Prototype CNC Machining?

Rapid prototyping eliminates cumbersome communication. JS Precision has streamlined the online prototype CNC machining process to the extreme, requiring only a few steps from drawings to a quote:

- Upload Files: Supports CAD formats (STEP, IGES, STL) and PDF drawings. The system automatically recognizes key dimensions, eliminating the need for manual annotation.

- Select Parameters: Fill in the material type, surface treatment requirements, quantity, and delivery date. Expedited service is available.

- Intelligent Quotation: The system combines real-time material prices and machining complexity to generate an instant prototype CNC machining quote, simultaneously providing preliminary DFM (Design for Manufacturing) suggestions.

- Order Confirmation: After online deposit payment, engineers will review drawings and discuss optimization opportunities within 2 hours.

The entire process requires no software downloads and can be operated online. Even those without machining experience can easily get started, ensuring a quick start for the CNC machining prototype service and not delaying the rapid prototyping schedule.

How big is your creativity? Exploring the Dimensional Boundaries of Rapid prototyping CNC Machining

Rapid prototyping CNC machining is not limited by size. JS Precision equipment can handle prototyping from micro-components to large structural parts, while solving the core challenges brought by different sizes.

Machine Tool Dimensions and Travel Capacity

| Type of Machine Tool | Maximum Machining Size (Length × Width × Height) | Applicable Scenarios |

| 3-Axis CNC Milling Machine | 800mm × 600mm × 500mm | Large sheet metal, simple structural parts, shell-type prototypes |

| 5-Axis CNC Machining Center | 500mm × 400mm × 300mm | Complex curved surfaces, polyhedral parts, small high-precision structural parts |

| CNC Lathe | Maximum diameter 100mm, length 300mm | Shafts, sleeves, rotationally symmetric parts |

Core Challenges and Large-Scale Solutions for Prototyping

- Material Deformation: Segmented machining + secondary finishing, combined with an air-cooling + water-cooling composite cooling system.

- Clamping Stability: Customized tooling fixtures, multi-point uniform force clamping, reducing local stress.

- Precision Control: Full-process online inspection, key dimensions verified at each stage using a coordinate measuring machine.

Whether machining tiny electronic components or large equipment frames, JS Precision's rapid prototyping CNC machining meets your needs with consistent precision.

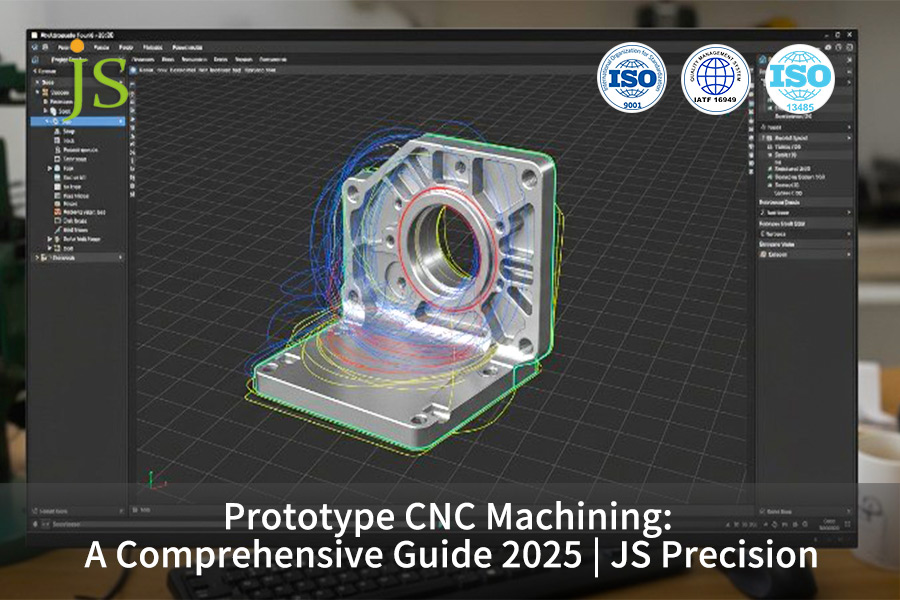

Figure 1: CNC machining is particularly suitable for rapid prototyping, enabling rapid iteration and testing of design solutions.

Smart Design, Significantly Reducing Costs: Optimization Tips For Custom Machined Parts

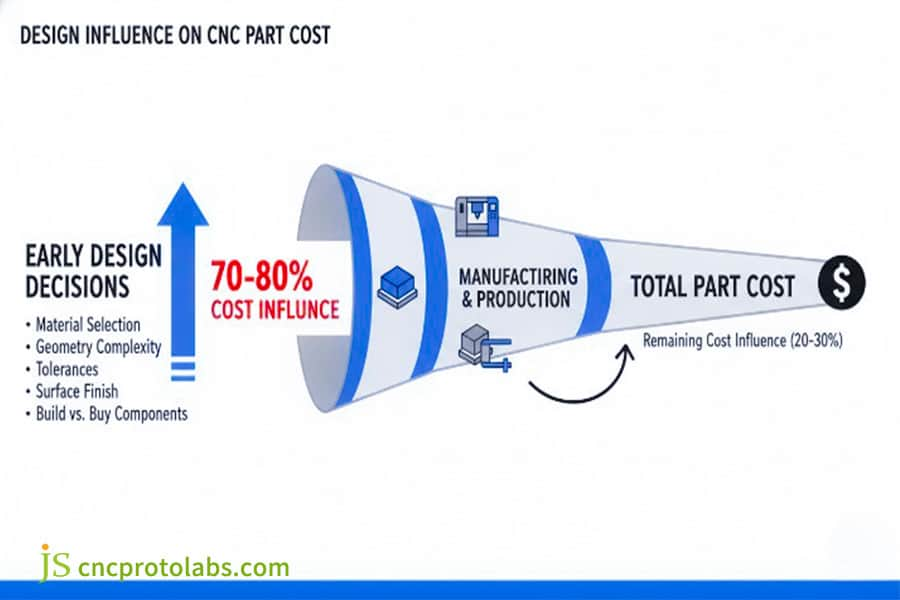

Design drives the cost and machining time of custom machined parts. Even the tiniest optimizations may save up to 20%-40% in their costs. Practical tips for metal and CNC plastic machining prototype are discussed below:

Simplify Geometry: The Art of Reducing Complexity

- Deep Holes: The depth should be about 3-4 times the diameter, to avoid specialized tools and much extra time.

- Avoid Tiny Features: Enlarge features smaller than 0.5mm to over 1mm unless necessary to reduce machining difficulty.

- Loosen non-critical tolerances: the non-core surface tolerance has been changed from ±0.01mm to ±0.05mm and saves 30% in machining time.

Synergistic Selection of Materials and Processes

| Material Type | Machinability | Cost (USD per kg) | Applicable Scenarios |

| Aluminum Alloy 6061 | Excellent | 3-5 | Structural parts, casings, brackets - lightweight and strong. |

| 304 Stainless Steel | Medium | 8-10 | Corrosion-resistant parts, medical and chemical equipment. |

| ABS Plastic | Good | 2-3 | Low cost appearance parts, non-load carrying structures. |

| POM Plastic | Good | 4-6 | Wear-resistant, low friction pieces/parts (gears, sliders). |

The scientificity of material selection directly affects the cost optimization effect. The material standard system of the American Society for Testing and Materials (ASTM), such as ASTM B209 for aluminum alloy sheets, provides an authoritative benchmark for the scientific evaluation of material properties and processability.

For CNC plastic machining prototype, ABS is preferred: low cost, short lead time. For rapid prototyping of metals, the preferred material is aluminum alloy due to excellent machinability and moderate cost.

Employ Standard Parts and Standard Features

- Use standard drill bit sizes (1mm, 1.5mm, etc.) and common threads (M3, M4, etc.) to avoid custom-made tools.

- Reuse common features in design, share tools and fixtures to save money.

Special Considerations for Machining Plastic Prototypes

- Thermal deformation: Employ high-speed and low-feed machining with effective cooling.

- Avoid sharp internal corners: Corner radius ≥1mm to prevent stress concentration.

- Wall thickness: Reasonable, in the range of 1-3mm to avoid warping by being too thin or shrink marks by being too thick.

Want to reduce the cost of custom machined parts and make it easier to machine? Send your 3D model to JS Precision, where engineers will provide a free DFM optimization report to address specific cost pain points.

Figure 2: The decisive impact of early design decisions on the cost of CNC parts accounts for 70-80%.

Security Is The Primary Productivity: How To Protect Your Ip In Prototype Manufacturing?

Prototype manufacturing needs to safeguard core design. JS Precision puts in place a multi-level protection system: physical, digital, and legal to comprehensively safeguard your intellectual property:

- Physical Security: 24-hour monitoring of the production workshop, access control with limits to authorized persons, and management of prototypes and documents by lock and lock.

- Digital Protection File transfer and storage are encrypted with AES-256, dedicated access rights of the employees; regular data backup; security audits.

- Legal Protection: A Non-Disclosure Agreement is signed prior to the start of a project in which all design and project information is kept confidential. This NDA is binding, both nationally and internationally, and any remaining files and prototypes can be destroyed upon request.

With JS Precision, you can confidently outsource sensitive prototype manufacturing projects, with full protection of your intellectual property.

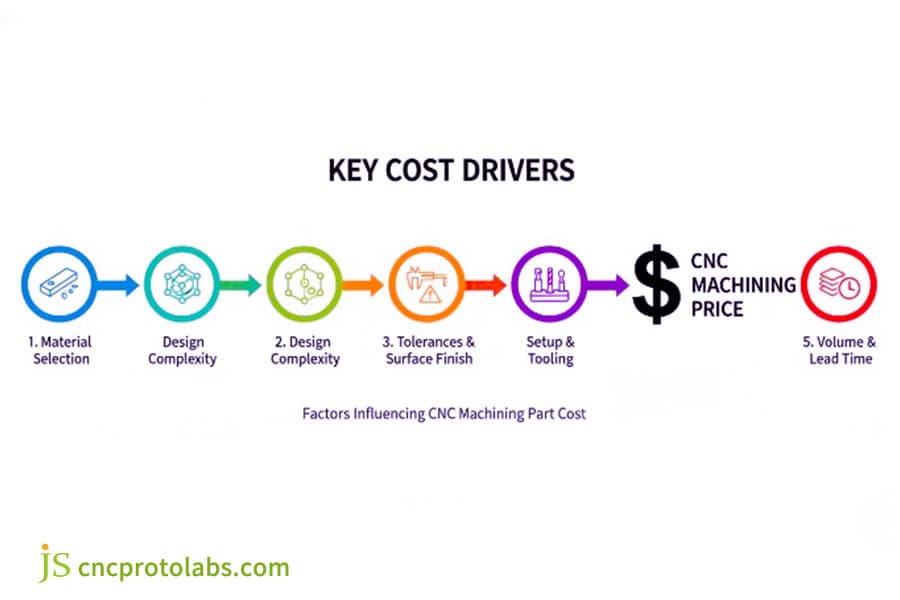

What Determines The Price? Deep Analysis Of 6 Factors Affecting Prototype CNC Machining Quote

Understanding the makeup of a prototype CNC machining quote empowers real cost control. JS Precision clearly breaks down major cost drivers:

Material Costs and Machinability

- Material Type: Titanium alloy ($30-40/kg) is more expensive than an aluminum alloy at $3-5/kg and ABS at $2-3/kg.

- Material Specification: Optimize the part dimension to suit the standard raw material, no excess, and no waste. There is considerable stock for common materials, while rare materials need extra time and cost to procure.

- Machinability: The difficult-to-machine materials such as stainless steel show rapid tool wear and slow cutting, increasing both labor and tool costs.

Programming and Machine Tool Time

- Geometrical Difficulty: Simple parts require 1-2 hours of programming and machining, while complex ones take 5-10 hours.

- Type of Machine Tool: 5-axis machining has a 30% higher hourly wage than 3-axis machining and is essential for complex parts.

- Toolpath Optimization: The toolpath will be further optimized by the engineers, but highly complex designs take more time.

Post-processing and Manual Intervention

- Deburring: $5-20/pc depending on complexity.

- Surface Treatment: Anodizing $10-30/PC, Painting $15-40/PC, Electroplating $20-50/PC.

- Quality Control: Advanced part CMM inspection $15-$30/pc

Other Factors

- Quantity: High cost for each piece, while small batches of 50-100 pieces can save the cost by 20%-40%.

- Tolerances Tolerances tighter than ±0.02mm require special tools that raise costs by more than 50%

- Expedited Service: 24-72 hour delivery, 30%-50% premium.

Prototype Manufacturing Cost Breakdown and Reference Price

| Cost Element | Part Ref. Price Low Complexity USD/unit | Part Ref. Price Medium Complexity USD/unit | Part Ref. Price High Complexity USD/unit |

| Material Cost | 5-20 | 20-50 | 50-150 |

| Programming + Machine Tool Machining | 30-80 | 80-200 | 200-500 |

| Post-processing (Deburring) | 5-15 | 15-30 | 15-30 |

| Surface Treatment | 10-30 (Anodizing) | 30-80 (Painting/Electroplating) | 80-200 (Precision Coating) |

| Quality Inspection | 10-20 (Routine Inspection) | 20-50 (Sampling CMM) | 50-120 (Full-size CMM) |

| Expedited Service Fee | 15-40 (24-48 hours) | 40-100 (72 hours) | 100-300 (4-5 days) |

Want to know the specific cost breakdown of a prototype? Upload part information to the JS Precision platform to obtain a detailed prototype CNC machining quote, itemized out, making every expense transparent and traceable.

Figure 3: Display the five key driving factors that affect the price of CNC machined parts, and present their logical relationships in the form of a linear flowchart.

Race Against Time: What Is The Typical Delivery Time For Your CNC Machining Prototype Service?

Rapid prototyping prioritizes speed and quality. JS Precision's CNC machining prototype service balances speed and quality, with clear lead times based on part complexity:

Typical Lead Time Range

| Part Complexity | Standard Lead Time | Expedited Lead Time |

| Simple Parts (Plate Brackets, Simple Holes) | 3-5 Working Days | 24-48 Hours |

| Medium Complexity Parts (Curved Shells, Multi-Feature Brackets) | 5-7 Working Days | 72 Hours |

| High Complexity Parts (5-Axis Machining Components, Tight Tolerance Parts) | 7-10 Working Days | 4-5 Working Days |

Key Factors Affecting Lead Time

- Material Preparation: Available are all common materials, and rare ones take 2-3 days to prepare.

- Programming Review: Standard orders 2-4 hours, expedited orders within 1 hour.

- Production Queuing: Expedited orders are prioritized for dedicated equipment in order to reduce waiting times.

- Postprocessing: Simple processes take 1-2 hours, complex surface treatments add 1-2 days.

Emergency projects (exhibitions, production line failures) can enjoy 24/7 urgent service, and the team produces 24/7 to ensure fast delivery.

Beyond Machining: Core Characteristics Of Top CNC Machining Prototype Service Manufacturers

Not all CNC machining prototype services manufacturers are the same. Great service providers know how to become partners with their clients. JS Precision defines the greatness of this industry in the following way:

- Strong Engineering Support: Offering DFM analysis before production to optimize design from cost, speed, and performance perspectives.

- Rigorous Quality Control: Provide three-step inspection, incoming materials, process, and finished product by using CMM and vision equipment to ensure accuracy.

- Stable Supply Chain: Inventory of more than 20 common materials, cooperating with trusted suppliers to ensure fast production.

- Clear Communication: Assigned project manager who provides regular progress updates; inquiry responses within 30 minutes during working hours.

- Flexible Adaptability: Supports modification in design, urgent order, and customized post-processing to offer alternative solutions.

These qualities make us much more than mere equipment operators but an invaluable partner in your journey of rapid prototyping.

Want to work with top CNC machining prototype service manufacturers? Book a virtual factory visit with JS Precision and directly understand our engineering team, quality control processes, and production capabilities-experience the difference in professional service.

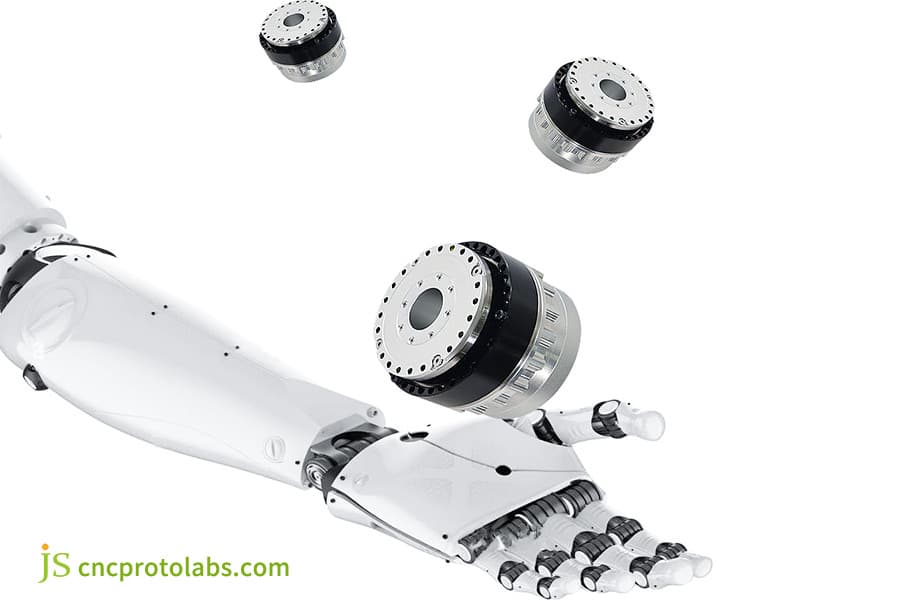

Case study: 72 Hour First Aid! The Rebirth Path Of A Robot Joint Prototype

Customer Challenge:

A robotics startup was in readiness to attend a significant exhibition event in the industry when, a week prior to this event, it found itself in some crisis, where its core aluminum alloy joint prototype suffered a structural fracture during load testing due to internal stress concentration.

This joint is a critical load-bearing component of the robot arm, its appearance and dimensions cannot be modified, and the original supplier clearly stated that it could not deliver a replacement within 10 days. Without a timely solution, the company would miss the exhibition opportunity and potential investment.

JS Precision Solution:

Upon receiving the client's 3D model and fault report, we immediately activated our emergency response mechanism. Within 2 hours, a DFM analysis was completed, revealing a lack of supporting structure in the original design's internal cavities. An expedited quote was immediately provided.

The engineers suggested the addition of three 2mm thick cross-shaped reinforcing ribs, without changing the external dimensions, 5-axis machining in one process to avoid strength problems due to assembly gaps.

By utilizing our onsite inventory of 6061-T6 aluminum alloy, we employed dedicated equipment manufacturing the parts 24/7 continuously while concurrently working on machining, deburring, and anodizing. The quality is checked by our quality people accordingly.

Final Result:

It delivered three improved prototypes in only 72 hours. The customer successfully demonstrated the robot in an exhibition and acquired $2 million in investment from three institutions. Third-party testing showed that the optimized joint strength increased by 40%, fully meeting usage requirements.

Later on, this design went directly into small batch trial production. Later still, the client entered a long-term partnership with us, outsourcing all prototype and small-batch production orders to JS Precision.

Have an urgent prototype failure or a trade show/production launch deadline? Please immediately contact JS Precision, noting "Emergency Project Assistance." We will conduct DFM analysis and provide expedited solutions within 2 hours using our CNC machining prototype service to make sure that the delivery is rapid and your project milestones and market opportunities are protected.

Figure 4: Prototype of Robot Aluminum Alloy Arm Joint

Take Immediate Action: How To Obtain Your Exclusive CNC Machining Quotation Online?

Getting a prototype CNC machining quote is simple. The JS Precision online system is intuitive and yields exacting results in minutes:

- Go to the online quotation page and upload your CAD drawings in STEP, IGES, STL, etc., or PDF format.

- Please specify the type of material, such as 6061 aluminum or ABS, surface treatment; quantity, from 1-100 pieces, due date.

- Please advise on any special requirements such as tight tolerances and customized packaging.

- Click "Generate Quote" to get a full quote including total cost, unit price, delivery date, and DFM recommendations in 3 minutes.

- Immediate deposit payment through online mode will confirm the order. Engineers' immediate review of the drawing and programming will start.

FAQs

Q1: What kind of materials are usually used in making prototypes through CNC Machining?

The metals generally used are aluminum alloy 6061 and 7075, stainless steel 304 and 316, ordinary steel, brass, and CNC plastic like ABS, nylon, POM, PC, and PP. You can use them flexibly according to your request for strength and corrosion resistance.

Q2: What tolerances are achievable with CNC machining?

The general machining tolerance is up to ±0.025mm. For precision features involving mating holes and locational grooves, it is up to ±0.0125mm. As narrower tolerances mean greater machining difficulty and more expense, discussion in advance and determination of feasibility are quite necessary.

Q3: What is the major difference in machining plastic and metal prototypes?

Plastic prototypes, in general, tend to deform under heat and require sharp tools with high speeds, besides effective cooling. Metal prototypes are concerned with material hardness, tool wear, and cutting forces, for which the machining speeds are more moderate and the relative cost is higher.

Q4: Is there a significant difference in unit price between single-piece prototypes and small-batch production, say 50-100 pieces?

The difference is great. The entire cost of clamping and programming has to be amortized for single-piece prototypes, whereas in small-batch production, it can be optimized and the unit cost lowered. In general, the price for small batches is 20-40% lower compared with single-piece production. The more substantial price advantage usually comes with bigger lots.

Q5: How can I ensure mating accuracy for my complicated multi-part assemblies?

The best method is to machine all of the mating parts consecutively on a single high-precision machine tool using the very same coordinate system. This reduces equipment errors and positioning deviations. We also perform assembly simulation verification prior to machining.

Q6: Outside of CNC, what other prototyping technologies do you offer, such as 3D printing? Why choose CNC?

We provide multi process prototyping services, including 3D printing. In this case, we chose CNC among other techniques because its prototypes are closer to mass-produced parts in material fidelity, mechanical properties, and isotropy, hence better suited for functional testing and appearance verification.

Q7: The prototype of mine is intended to meet some industry standards like medical or aerospace, can you meet that requirement?

Of course, yes! For this, let us know what particular standards would apply in advance; for example, ISO 13485 for the medical field, AS9100 for aerospace applications. We can select compliant materials, develop specific processes, and offer complete quality documentation.

Q8: How do I keep track of the production progress in my order?

You can view, in real-time, the status of every order through our customer portal at JS Precision. Updates on every step, from quotation confirmation to the preparation of materials, producing it, and quality inspection/shipping, will be updated. And you also can contact your responsible project manager for real-time feedback.

Summary

Prototype CNC machining is never just a simple material cut, it is an essential stage for ideas to be transformed into reliable and cost-effective custom machined parts.

With years of experience in the industry, JS Precision optimizes the entire process for you-from design optimization and cost control to rapid delivery-which truly liberates rapid prototyping from complicated processes and imminent deadlines.

Your next breakthrough product starts with a perfect prototype. Take a moment to visit the JS Precision quotation platform now, upload your 3D files, and start experiencing our fast, transparent, and professional prototyping services. Let's take the first step together in turning ideas into value within the next 48 hours.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com