Rapid prototypes are the primary solution to the pressing problems posed by product development.

Following the determination of the ID of the smart bracelet or after completing the structural model of the medical device, before investing hundreds of thousands of dollars in mold tooling, are you concerned about hidden problems in assembly gaps or stress concentration? How can you rapidly and affordably check the validity of your design at critical decision points?

It is more about "rapid model building" and is also a solution for risk management and innovation, an integration between design in cyber space and physical product development.

This article analyzes the mainstream types of rapid prototyping, clarifies the rapid prototyping process, provides cost-effective decision-making guidelines, and provides clear guidance for you to choose functional rapid prototyping parts or high-precision prototype CNC machining services.

Core Answer Summary

| Core Issues | Key Takeaways | Value to You |

| Technology Outlook | It is mainly divided into two categories: additive manufacturing (3D printing) and subtractive manufacturing (CNC). SLA accuracy is ± 0.1mm, SLS is ± 0.3mm, and CNC can reach ± 0.025mm. The material covers resin, nylon, metal, etc. | Understand the limits of technology and avoid paying for incorrect technological paths. |

| Decision Core | Decisions involve five factors: budget, time, quantity, material performance needs (resistance to temperature, impact), and precision tolerance. | A scientific approach to decision-making incorporates short-term prototyping expenses and long-term project risk factors. |

| Outsourcing Advantage | Professional rapid prototyping services vendors have technology integration capabilities, support for equipment, and engineering expertise, which lead to overall cost of ownership that is 30% to 50% lower compared to in-house development. | Reduces the cost barrier for entry, acquires flexible and economic expertise, and speeds up project development. |

Key Takeaways:

1. Rapid prototypes serves as a means of validation-not the final product. Where the real value of the rapid prototype actually lies is in failing fast but cheaply to learn and avoid huge costs later on.

2. There's no best technology, only the most suitable: SLA for high-detail demonstrations, SLS for functional testing, CNC for high-precision, high-material prototyping.

3. Material selection is about the effectiveness of the prototype, and characteristics over the final product, such as temperature resistance above 100°C and impact resistance, are of paramount importance for functional testing.

4.The performance of service activities by professional service providers, such as JS Precision, may allow more technology options and engineering support at a lower cost overall.

Why Is This Guide Trustworthy? It Comes From The Experience Of JS Precision

This is a credible resource as JS Precision has 15 years of valuable experience in rapid prototyping. Since JS Precision is an ISO 9001:2015 certified company, they have more than 500 critical industrial customers globally and have supplied more than 100,000 pieces of rapid prototyping components with a repurchase percentage of 78%.

We own more than 20 precision machines, ranging across different scenarios, such as 0.1mm detailed exterior models to metal models with precision of ±0.025mm, through our extensive data collected from medical models of biocompatibility, as well as auto models with resistance capabilities up to 150°C.

For instance, we are able to supply 10 rapid prototypes of high-resistant gear with a tolerance of ±0.05mm to a Europe-based car manufacturer in two weeks, using prototype CNC machining to process aluminum alloy 7075. After 1000 hours of continuous operation testing, we helped them complete the validation 3 months ahead of schedule.

With an intimate understanding of rapid prototyping process, strong expertise in working with a range of rapid prototyping materials, and flexible integration of various types of rapid prototyping technologies, it is possible for us to offer clients a full-service solution from design optimization to delivery of prototypes.

If you are looking for a reliable partner, contact JS Precision's technical consultants for a free rapid prototyping solution evaluation tailored to your project, allowing their professional experience to safeguard your project.

What Is Rapid Prototyping? Why Is It The Key To Modern Product Development?

In the current product development time, rapid prototyping has moved from the category of 'optional' to 'essential.' Being aware of the definition of rapid prototyping helps in its better application.

Definition of Rapid Prototyping

Rapid prototypes are the rapid production of physical prototypes based on digital data, such as 3D CAD models, using automated machinery. The heartbeat of it is rapid iteration—rapidly creating physical things, learning from feedback, and iterating to make improvements.

Rapid prototyped models tend to be more precise, more consistent, more capable of dealing with complex structures than handmade models.As the heartbeat of rapid prototyping, it helps to bridge the gap that exists between physical and virtual designs by enabling design groups to convert ideas into physical objects quickly.

Four Key Business Values of Rapid Prototyping

- Faster time-to-market: Reduces the prototyping time period from weeks to days and allows for the launching of the product to be accomplished 3-6 months sooner.

- Reduced developmental risk: Technologies that identify problems prior to the production of molds could save tens of thousands of dollars in modification costs, resulting in over 60% less modification of the molds.

- Improved communication efficiency: A model created is easier to understand compared to drawings.

- Support for crowdfunding testing: Low-cost, high-fidelity prototypes can test market response, thus reducing business risk.

Want to know how rapid prototyping can shorten your product's cycle? Contact JS Precision and provide your product type and timeline to receive a customized rapid prototyping process solution and cost-saving calculations.

What Are The Mainstream Types Of Rapid Prototyping? How Should You Conduct The Initial Selection?

There are so many different rapid prototyping technologies that one has to choose the right type to ensure their project's success. The following analysis of the principles, characteristics, and applicable scenarios of mainstream types of rapid prototyping will help you quickly identify the right solution.

Resin Accuracy: Stereopolymer Lamination(SLA)

SLA uses an ultraviolet laser to cure the photosensitive resin layer by layer. The precision can be up to ±0.1mm and the surface roughness Ra 0.8-1.6μm. It has very excellent detail displays, appropriate for use in verifying appearance and medical models.

The cost of a single piece of mobile phone parts ranges from $150 to $300, with the highest cost-effectiveness for batches of 1-10 pieces.

Support-Free Functionality: Selective Laser Sintering (SLS)

SLS means the nylon powder is sintered by a laser, no support is needed. The precision is ±0.3mm, and surface Ra is 3.2-6.3μm.Mechanical properties are very similar to injection-molded parts, and thus SLS is suitable for functional testing and parts with complex internal cavity construction.

For a mobile phone-sized part, the cost is between $200-$400, with huge efficiency advantages if batches of 1-50 pieces are required.

Desktop Mainstream: Fused Deposition Modeling (FDM)

Fused Deposition Modeling, or FDM, is a process that uses thermoplastic filament and produces a composite material by extruding the filament. FDM provides the lowest cost, varying materials, a resolution of ±0.2-0.5mm, and a surface Ra of 6.3-12.5μm, which is suitable for PoC and inexpensive internal review.

The cost of a mobile phone-sized object is $50-$150 and is a very common form of self-built 3D print.

Powerful Tools for Small Series Reproduction: Vacuum Casting

Vacuum casting uses an SLA/CNC master to vacuum cast polyurethane to replicate soft plastics, transparent components, and more with a surface finish of Ra = 1.6-3.2μm, near production quality. This method is appropriate for small series reproduction of 10-50 components with an aesthetic or functional purpose. One set of molds will cost $500-$1500.

| Types of Rapid Prototyping | Accuracy Range | Surface Roughness | Unit Cost (Mobile Phone Size) | Applicable Batch Size | Core Advantages |

| SLA (Photopolymerization) | ±0.1mm | 0.8-1.6μm | $150-300 | 1-10 pieces | High detail, smooth surface |

| SLS (Sintered Laser) | ±0.3mm | 3.2-6.3μm | $200-400 | 1-50 pieces | Excellent functionality, no support required |

| FDM (Fused Deposition Modeling) | ±0.2-0.5mm | 6.3-12.5μm | $50-150 | 1-20 pieces | Low cost, diverse materials |

| Vacuum Molding | ±0.2mm | 1.6-3.2μm | $80-200 | 10-50 pieces | Small batch, near-mass production quality |

How To Plan An Efficient And Reliable Rapid Prototyping Process?

A scientific rapid prototyping process ensures that twice the result is achieved with half the effort, without any wastage of time and cost. Below is a list that splits the entire process from digital files to feedback for verification, including the key components of digital integration.

The Five-Step Closed Loop Process – The Standard Process from Digital Files to Verification Feedback

Rapid prototyping process five-step closed loop:

- 3D Data Preparation and Optimization: Must provide prepared STP/IGES or STL files. JS Precision performs Data Analysis for DFM Optimization for the designed structure.

- Technology & Process Selection: Select the technologies, such as SLA, SLS, CNC, etc. depending on the criteria.

- Prototype Post Processing: Full sanding, painting, and so forth.

- Quality Control: Calipers, CMM, etc., can be utilized for inspecting important dimensions.

- Testing and Iteration: Feedback is obtained to optimize the model, and a new iteration of the process begins.

Digital Integration: Making Rapid Prototyping Processes More Precise and Efficient

Integrating rapid prototyping with CAD and CAE toolchains can improve efficiency. CAE simulations can pre-analyze stress, flow fields, etc., which permits the early identification and optimization of weak points, reducing the number of iterations.

For example, the prototype heat sink casing of some electronic devices, through CAE simulation, revealed unreasonable layouts of heat dissipation holes. Optimization reduced it by two iterations, saving 10 days and 30% in cost. JS Precision provides support in CAD optimization and CAE simulation.

How Do Rapid Prototyping Materials Affect The Success Or Failure Of Prototypes? How Should You Choose?

The selection of rapid prototyping materials directly decides whether prototype verification is effective or not, incorrect selection may cause distortion in testing. The following analyzes the characteristics and selection logic of mainstream materials.

Photosensitive Resins: From General Purpose to Engineering Grade

Photosensitive resins for SLA are of four types:

- General purpose resin, which costs between $80 to $150/L and is suitable for appearance verification.

- High toughness resin from $180 to $250/L, suitable for load-bearing structural parts.

- High-temperature resistant resin, $250 to $350/L, 80 to 120°C, suitable for high-temperature testing.

- Biocompatible resin, from $350 to $500/L, complying with the ISO10993-1 standard, suitable for medical parts.

Core Selection: Performance priorities shall be made according to the testing scenario, and then select general purpose resins for an appearance check or functional testing high-toughness or high-temperature resistant resins.

Engineering Plastics and Metals: Cornerstone of Functional Testing

The core materials for functional testing are engineering plastics and metals, such as:

- SLS nylon (PA12/PA11, $150-200/kg, high strength, and fatigue resistance).

- FDM materials (ABS temperature resistance 70-90°C, PETG with high toughness).

- Metal materials (aluminum alloy 6061/stainless steel 316, etc., processed by SLM or prototype CNC machining, with mechanical properties consistent with mass production).

Commercial Considerations: Balancing Performance and Budget

Rapid prototyping materials account for 20%-50% of costs and require a balance between performance and budget: low-cost materials can be selected for appearance review, but performance-matched materials must be used for functional testing, otherwise, test results will be distorted.

| Material Type | Applicable Technology | Core Characteristics | Applicable Scenarios | Cost Range (per unit) |

| General Purpose Resin SLA | SLA | Easy to mold, smooth surface | Appearance verification, assembly testing | $80-150/liter |

| High Toughness Resin SLA | SLA | Impact resistant, not easily broken | Structural component functional testing | $180-250/liter |

| PA12 Nylon SLS | SLS | High strength, fatigue resistant | Gears, buckles, and other functional components | $150-200/kg |

| Aluminum Alloy 6061 | CNC/SLM | Lightweight, high strength | Metal structural components, heat dissipation components | $80-120/kg |

| Stainless Steel 316 | CNC/SLM | Corrosion resistant, high strength | Medical and industrial precision parts | $150-200/kg |

Want to accurately select rapid prototyping materials? Tell JS Precision your testing needs (e.g., temperature resistance, impact resistance, human contact), and we will recommend matching materials and provide free sample testing to ensure the prototype can effectively verify the design.

How To Design Rapid Prototyping Parts That Are Easy To Manufacture And Practical?

With proper design, the difficulty, cost, and time of manufacturing rapid prototyping parts can be lessened, increasing their usability. The following shows some design criteria for bridging additive manufacturing and mass production.

Design Principles Exclusively for Additive Manufacturing (DFAM)

Specific Design Principles for DFAM in 3D Printing:

- SLA wall thickness should be minimum 0.6mm, SLS should be minimum 1mm, and FDM should be minimum 1.2mm.

- The surfaces with an angle of 45° or greater can be self-supporting or need additional supports.

- Reduce weight by 30% -50% using lattice structure.

- Integrated design reduces assembly steps.

Design for Prototyping and Mass Production (DFM)

The design of rapid prototyping parts should consider the feasibility of mass production in advance:

- Avoid too deep and no outlet cavity.

- Reserve a draft angle of 1 ° -3 °.

- Unified wall thickness to prevent shrinkage marks.

- Improve strength by changing sharp corners to ≥ 0.5mm rounded corners.

When Should We Give Up 3D Printing And Choose Prototype CNC Machining?

3D printing, in general, is the main trend in rapid prototyping, but in certain conditions, prototype CNC machining is better. Below, its features and applications are discussed.

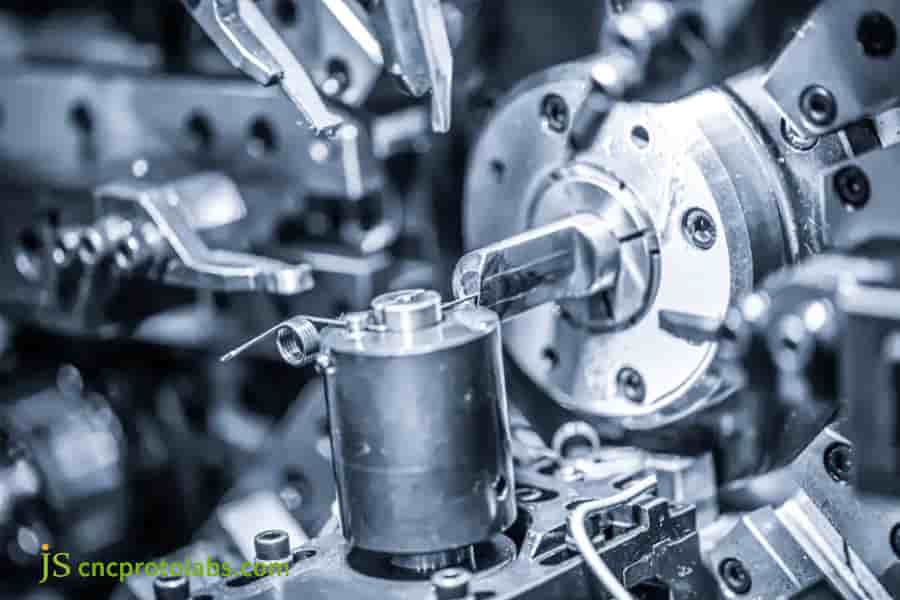

The Pinnacle of Subtractive Manufacturing Precision: In-Depth Explanation of Prototype CNC Machining

Prototype CNC machining is a subtractive manufacturing method which employs CNC machine tools to remove material to create parts from solid material.

- Technological Parameters: High precision, maximum ±0.025mm, surface roughness Ra is below 0.8μm, and materials used are final engineering materials (6061 Aluminum, 316 Stainless Steel, POM, PC, and so on).

- Material Properties: The material is isotropic, with mechanical properties being fully identical to mass-produced materials, no bonding problem between layers, and can accurately represent the state of use of the product.

- Processing range: It can handle various materials such as metals and engineering plastics, suitable for parts with simple to complex structures. The processing time for a single piece is usually 1-3 days.

When Should CNC Machining be Used?

Improved scenarios for prototype CNC machining:

- Testing of final material’s mechanical/thermal/chemical properties will be required.

- Tolerances tighter than ±0.1mm.

- Small to medium batches of 1-100 high-reliability prototypes.

- Simple structures suitable for machining (lower cost).

Case Study: How Smart Wearable Devices Can Use Hybrid Prototypes To Shorten Development Cycles By 60%

Challenge

The company is an consumer-electronics manufacturer that has four months to finish developing a smartwatch, ranging from designing an ID layout to handing in an engineering prototype for global crowdfunding.

The company faced several challenges: the complex curved shell, detailed metal frame, and rubber strap, and has to produce a total of 50 working prototypes.

JS Precision Solution

JS Precision follows a 'hybrid technology path + parallel process management' approach that blends different technology paths according to the requirements of different parts.

1.Shell and Buttons: It deals with the SLA photopolymerization technology, selects a photosensitive resin with high transparency, and succeeds in achieving a precision level of ±0.1mm. It was later subject to surface polishing and spraying, thereby regaining its texture with a high gloss and screening the assembly clearance.

2. Internal Component: Designed and made using SLS laser sintering, the high power and durability of this material, which is PA12 nylon, has made it survive over 1000 assemble tests without undergoing breakage/deformation.

3. Metal Frame and Connectors: For this part, the technology adopted is the prototype CNC machining technology that processes 6061 aluminum alloy material. Its purpose is to ensure the highest precision of ±0.025mm through the use of 5-axis CNC machines, and it is capable of surface anodizing for aesthetic features and wear resistance.

4. Silicone Wristband: Copy 50 sets of the wristband using the vacuum molding process with a master mold produced by SLA, and apply medical-grade silicone to replicate the touch and water-resistant functionalities of the final product.

5. Parallel Process: Start processing rapid prototyping parts created by other processes, design optimization, material procurement, manufacturing things simultaneously by verifying the quality after the post-processing step, trying to bring each iteration cycle to a period of 5 days.

Results

The project was completed with 50 working crowdfunding prototypes two weeks ahead of schedule and within budget requirements with successful crowdfunding of 150% of the target amount. The mass production mold successfully performed the trial run on the first attempt without major design changes, avoiding costs of modifying the mold designs by at least $80,000.

Client Feedback: "JS Precision's hybrid prototyping solution allowed us to obtain near-production-ready prototypes in a short time, thus validating the design feasibility to impress investors."

Having difficulties in prototype development for smart hardware, consumer electronics, or any other product series? Contact JS Precision to share your project difficulties with us. We'll arrange a customized hybrid rapid prototyping solution similar to this case, helping to rapidly move your project forward and grasp market opportunities.

Should We Build Our Own Production Capacity Or Outsource Rapid Prototyping Services? How To Calculate The Real Cost?

The enterprises using rapid prototyping face two choices: develop internally or go for outsourcing. Cost of ownership will be of assistance in making a choice.

Importance of Professional Service Providers

Experienced rapid prototyping services companies like JS Precision also offer one-stop services that include technological consultation to avoid mistakes in selection, DFM analysis for better manufacturability, the ability to match combinations of technologies according to demand, and analysis of post-processing quality, without installing the necessary infrastructure in the enterprises.

Total Cost of Ownership (TCO) Analysis: Unveiling Hidden Costs

| Cost Breakdown | Self-built Capacity | Outsourced Rapid Prototyping Services |

| Equipment Procurement | $50,000 - $500,000 (single high-precision device). | $0 |

| Maintenance Costs | 10%-15% of equipment price per year (consumables, repairs). | $0 |

| Personnel Costs | Operator and engineer salaries $80,000 - $150,000 per person. | $0 |

| Materials Inventory | Multiple materials stocking up, occupying funds. | Charged by piece, no inventory cost. |

| Site Costs | Equipment placement, material storage space. | $0 |

| Processing Costs | Material loss + equipment depreciation. | Payment per piece (including materials, processing, and post-processing). |

Ultimate Decision Guide: Match The Best Rapid Prototype Path For Your Project

When it comes to rapid prototyping technology, one does not have to think in terms of "best" only, but "most suitable" with respect to the choices. Some guidelines with respect to decision-making, as well as some tips in terms of cooperation, have been provided below.

Four-Dimensional Decision Making Guidelines

- Select prototype CNC machining for accuracy ± 0.025mm, SLA for ± 0.1mm, SLS for ± 0.3mm.

- Choose prototype CNC machining/SLM for metal/engineering plastics and SLA/SLS for resin/nylon based on their actual performance.

- Select SLA/CNC for 1-10 pieces and vacuum replica for 10-50 pieces.

- Delivery time is 24-48 hours for SLA/FDM, and 3-7 days for SLS/CNC.

Collaborate with your suppliers to develop a process

Successful rapid prototyping needs a good partnership with the service providers. We recommend that:

1. Transparent communication requirements: Clearly define project goals (such as verifying appearance, functional testing, crowdfunding display), timeline, budget, and accuracy requirements to JS Precision to avoid information bias.

2. Team Design Information: The article encompasses entire 3D design requirements along with specifications such as critical design dimensions, points of stress, and test requirements that ensure assistance through design optimization by design suppliers.

3. Participate in iteration feedback: Provide timely feedback on prototype testing results, work with service providers to adjust design or process, and ensure that each iteration can solve core problems.

JS Precision, as a professional rapid prototyping services provider, can tailor mixed technology solutions and phased rapid prototyping process based on your project needs, maximizing every investment you make.

FAQs

Q1: How much does it cost to make a rapid prototype of a simple part?

The cost depends on the type of technology, size, and materials. A SLA prototype for a mobile phone size would cost around $150-$300, for SLS $200-$400, for FDM $50-$150, whereas the cost of CNC metal parts may exceed $800.

Q2: Which has higher precision, 3D printing or CNC machining?

General prototype cnc machining is more precise, with a tolerance of ±0.025mm, and the material properties are close to that of the end product. High-resolution SLA models have a tolerance of ±0.1mm, and it is appropriate for aesthetic and disassembly verification checks.

Q3: Can I use 3D-printed prototypes for small-batch production?

It's possible, but not economical. Small batch production of 50-500 pieces, vacuum replication or rapid prototyping is a better choice. The cost per piece is 30% -50% lower than 3D printing, and the surface texture is closer to mass-produced products.

Q4: What 3D file format is best?

The files should be STEP or IGES format solids, as these files are more suited to capturing design detail, STL files are acceptable, provided they are "watertight" (not holey), with a precision of 0.05mm.

Q5: What types of testing can rapid prototyping be used for?

It can be used for cosmetic inspection, functional tests, ergonomic tests, airflow and heat dissipation tests, and other functional tests, as well as market exhibitions and crowdfunding. But life fatigue tests are normally conducted using final production material.

Q6: How can I ensure the confidentiality of my design data when outsourcing?

Hire trustworthy service providers, such as JS Precision, which have Non-Disclosure Agreements (NDAs). These service providers have tight data security management practices, which include encryption and secure storage of projects and files.

Q7: How long does it typically take from placing an order to receiving the prototype?

Small components can ship within 24-48 hours with SLA/FDM, SLS/CNC generally requires 3-7 days, vacuum molding for small batch production can ship within 5-10 business days.

Q8: What are JS Precision's unique advantages in rapid prototyping?

JS Precision offers a full “hybrid manufacturing" facility ranging from 3D printing to precision CNC machining. It is ISO 9001 certified, has 15 years of experience in the industry, and can deliver engineering support from design optimization to mass production transfer.

Summary

The basic risk in product development is the 'unknown' and one of the most important approaches to overcome this "unknown" phenomenon is rapid prototyping. This is because, by employing rapid prototyping, the "unknown" can be turned into the "known."

There isn’t a best prototyping technique, but rather a most appropriate one for a particular situation. Whether it’s high detail SLA, functional SLS, or precise prototype CNC machining, JS Precision will be there for you with professional assistance.

Take Action Now & Let Experts Fast Track Innovation.

If you are seeking a trusted partner that can help with complete rapid prototyping services and has knowledge in a variety of techniques, as well as being an extension of your R&D department, JS Precision is always ready to serve you. Contact our technical advisor for a free solution and quote tailored to your project, to take your next product from concept to market, one step ahead.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com