Rapid electronic prototyping helps you solve many urgent product development challenges.

Imagine yourself as the product manager of a smart home startup with only 5 days left to an industry trade show, and it is clear that the core prototype will not arrive in time because of insufficient delivery capabilities of your supplier, which may ruin the show presentation.

I face this situation on a daily basis at JS Precision.

This guide is a "pitfall avoidance manual" compiled by my team and me based on more than 10 years of practical experience. It helps you efficiently advance prototype development, avoiding common problems in fast rapid prototyping such as design errors, process bottlenecks, and cost overruns, allowing your prototype project to avoid detours.

Core Answer Summary

| Core Challenges | Ideal Solutions | Value of JS Precision |

| Technology Selection Confusion | Thoroughly analyze RP techniques with regard to functionality, budget, and time. | Professional consulting will be provided in order to match you with the best combination of technologies and optimize the prototype manufacturing path. |

| Cycle and Cost Control Issues | Transparent rapid prototyping cost structure and predictable rapid prototyping cycle. | Standardized processes and instant online quotes ensure on-time and budget delivery of rapid electronic prototyping projects. |

| Inefficient Quality and Collaboration | High-quality rapid prototyping parts with responsive communication mechanisms. | One-stop service, engineering support, and rigorous quality control guarantee seamless prototyping development and superior part quality. |

JS Precision Experience: How To Enable Efficient, Reliable Rapid Electronic Prototyping

For 12 consecutive years, JS Precision has been deeply involved in the field of rapid electronic prototyping, serving more than 20 industries such as smart home, medical devices, and industrial electronics, completing over 6,000 prototype development projects every year.

For instance, a medical device company needed to deliver a prototype of a high-precision blood glucose sensor housing in 3 days last year. We scheduled 4 CNC machines for 24-hour operation, along with optimization of the machining path, and eventually delivered half a day in advance with an accuracy error controlled within ±0.02mm.

Its processing accuracy and timeliness meet the testing requirements for housing structural accuracy in the International Electrotechnical Commission (IEC) IEC 60601-1 Medical Electrical Equipment Safety Standard.

The complex controller bracket was one that had fairly difficult parameters to achieve by traditional means for an industrial electronics customer. We used SLS 3D printing technology to create it in one piece and solve the geometric complexity problem. Over the years, we've helped clients avoid over 300 reworks due to design flaws, saving them an average of over $2,000 per project.

Every suggestion in this guide comes from retrospectives of these real-world projects, so you can confidently say it can help you achieve efficient and reliable rapid electronic prototyping.

Looking to access complete case studies on similar projects undertaken in the past? Send your industry and needs to JS Precision, and get a free case study manual that will help you avoid pitfalls in prototype development.

What Is Rapid Electronic Prototyping?

Perhaps, after learning about JS Precision's experience, one may ask: what is rapid electronic prototyping?

It is the technique of transforming electronic product designs rapidly into physical prototypes. That is its core value, allowing one to verify the feasibility of your designs in advance of mass production, and this prototype development is the entire process of implementing that technique.

In today's modern product development, it is like a "litmus test", without it, many design problems will only surface during mass production, increasing modification costs by more than tenfold times.

From Virtual to Physical: A Bridge Across the Creative Gap

Many designers create a model on the computer in CAD and think it is perfect, only to find out when they build a physical prototype that there are assembly conflicts or operational inconveniences. Rapid Electronic Prototyping bridges this gap.

It accurately converts the CAD model into a physical prototype, which you can use for three key tasks:

- Design verification, checking if parts can be assembled smoothly.

- Functional testing, such as button sensitivity and circuit continuity.

- Market research, distributing the prototype to potential users to collect feedback.

Why Is It an Essential Path to Success for Modern Products?

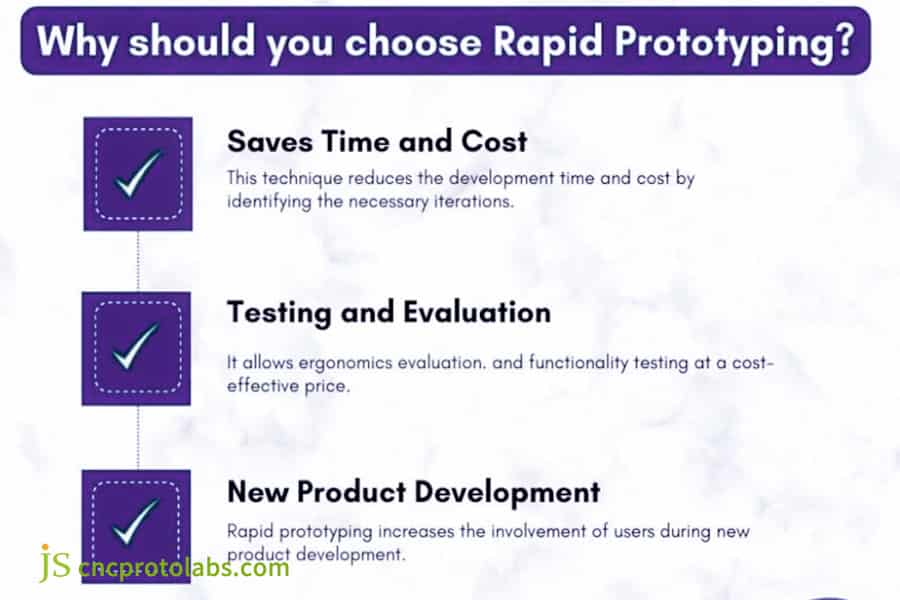

With increasingly rapid product iterations, rapid electronic prototyping helps you understand three basic concepts:

- It reduces time to market by 30%-50% compared to conventional methods.

- It reduces your development risk by finding design issues early and avoiding mass production failures.

- Attract investment-demonstrate to investors with a physical prototype, which is more convincing than a simple PowerPoint presentation.

Figure 1: Significance of Rapid Prototyping in Manufacturing. Innovation in technology and faster product development is vital which is why rapid prototyping is crucial to new product development.

How To Choose The Best Rapid Prototyping Methods For Your Project?

In fact, the efficiency in prototype manufacturing can easily be doubled just by choosing the proper rapid prototyping methods. Different technologies have different advantages and disadvantages. I have compiled a comparison of mainstream technologies to help you choose according to your needs.

CNC Machining vs 3D Printing: A Trade-off Between Precision, Strength, and Speed

| Technology Type | Precision | Material Range | Core Advantages | Applicable Scenarios |

| CNC Machining | ±0.01~0.05mm | Metal-aluminum and steel, plastic-ABS, PC | High strength, good surface finish. | Metal casings, high-precision electronic parts. |

| 3D Printing | ±0.1-0.3mm | Resin, nylon, metal powder | Rapid prototyping of complicated geometries. | Complex brackets, appearance prototypes. |

In other words, when it comes to the manufacturing of parts in metals or high-accuracy components, go for CNC, while for complex structure parts and quick prototyping, 3D printing will be more suitable.

Beyond the Ordinary: Specific Applications of Sheet Metal Manufacturing and Vacuum Molding

Apart from the above, CNC and 3D printing during sheet metal manufacturing and vacuum molding cannot be replaced.

Sheet metal manufacturing applies to the production of casings and brackets, among others, with advantages such as low cost and easy transition into mass production, including metal casings for electronic devices.

Vacuum molding applies to the production of small-batch appearance parts, such as plastic panels that need to mimic the texture of mass production and have the capacity to turn out 20-100 prototypes in 3-5 days.

Having trouble choosing the right rapid prototyping methods? Just tell JS Precision about project requirements such as material, precision, and quantity for free customized recommendations so detours in prototype manufacturing can be avoided.

Figure 2: Types of rapid prototyping. The world of rapid prototyping is diverse, with various methods and techniques tailored to different needs.

The Rapid Prototyping Cost Demystified: Where Is Your Money Going?

Many customers will ask why quotations of the same prototype have such a big difference. Actually, the cost of rapid prototyping mainly comes from three parts. I'll break them down for you and then give you optimization strategies.

Cost Driver Analysis: The Triangular Relationship Between Materials, Labor, and Post-processing

| Cost Drivers | Key Influencing Points | Percentage (approx.) |

| Material Costs | Type of Material (Metal is 3-5 times more expensive than Plastic), Quantity. | 30%-40% |

| Labor Costs | Programming Time, Machine Tool Running Time (Complex parts take twice as long). | 25%-35% |

| Post-processing Costs | Kind of Surface Treatment: Anodizing is 20%-30% more expensive than Sandblasting. | 15%-25% |

For example, for the CNC casing made of aluminum alloy, the cost breakdown is material cost = 40%, labor cost = 35%, post-processing cost = 25%. Once you know these factors, you might identify areas to optimize the cost.

Five Immediately Actionable Rapid Prototyping Cost Optimization Strategies

- Simplify Design: Get rid of unnecessary intricacies, for example, by converting deep cavity structures into modular designs where possible, to save time.

- Use Economical Material: Using ABS instead of PC for non-critical parts can reduce the cost by 30%.

- Consolidate Parts: Combine several small parts into one in order to help reduce assembly time.

- Take Advantage of Batch Discounts: It's 15%-20% cheaper to make 10 at a time than to make 1 at a time.

- Early DFM Analysis: The most cost-effective step is to have engineers review the design in advance to avoid rework.

Want to control the rapid prototyping cost? Upload the drawing of your part to JS Precision, and then engineers will analyze the optimization points for free, achieve fast rapid prototyping, and save 15%-20% of the budget.

How To Optimize Your Prototype Development Process For Ultra-Fast Delivery?

Most often, slow prototype delivery is due to process flow problems and not a lack of production capacity. Let me walk you through JS Precision's effective workflow and show you how to speed up your projects.

Step One: Provide Perfect Design Documents – Laying the Foundation for Efficient Collaboration

The design documents are the beginning of the entire workflow. The more standardized the documents are, the more smooth the subsequent process will be. You should pay attention to the following three key points:

- Select the best format. STEP format has the best compatibility, suitable for CNC, STL format is for 3D printing.

- Annotate the key information, including material requirements, tolerance range-for example, ±0.05mm-and surface treatment requirements.

- Avoid common missteps, such as a lack of dimensions or incomplete surface closure, which needs rework.

From Inquiry to Delivery: Unveiling JS Precision's Seamless Prototyping Process

Our process ensures fast rapid prototyping:

- Instant Quotation/DFM Analysis: Quotation and DFM report highlighting design issues will be provided within 4 hours of receipt of documents.

- Confirmation of Order: Production will be scheduled immediately upon your confirmation.

- Production Scheduling: Urgent projects are prioritized, such as starting CNC or 3D printing within 24 hours.

- Quality Inspection: Three inspections during processing, after processing, and after assembly guarantee accuracy.

- Packaging and Shipping: Use collision-resistant packing to avoid damage during shipment, and synchronize the logistics information.

Exceeding Standards: Choosing The Best Surface Treatment For Your Rapid Prototyping Parts

A good surface treatment can double the texture of rapid prototyping parts and enhance their functions. I'll introduce two commonly used, practical processes for you.

Aesthetics and Protection: How does anodizing enhance the texture of aluminium alloy prototypes?

If your prototype is made of aluminum alloy, anodizing is preferred. It has three advantages:

- Wear resistance is improved, the surface hardness is 5 times higher than the untreated surface.

- Corrosion resistance is enhanced, passing a 48-hour salt spray test.

- Rich colors including silver, black, and red are available to meet different aesthetic needs, such as the usually used silver casings in smart home devices.

Functional Surfaces: Achieving Conductivity, Shielding, and Special Textures

If there are special requirements of function for prototypes, the following treatments are necessary:

Electroplating-which enhances conductivity, such as copper, nickel plating, suitable for electronic contacts, sandblasting can evenly produce a matte texture, which avoids glare from affecting the operability, screen printing can print logos and button markings clear and wear-resistant, such as screen printing buttons in remote control prototypes.

Want to refine your rapid prototyping parts? Specify your surface treatment requirements-color or function-to JS Precision for free sample references and to help you choose the most suitable process.

Figure 3: Finished Prototype Parts.The issue where prototypes tend to fail lies in surface treatment. Make sure they can do back sanding, anodizing, painting, or finishes of a certain texture you need.

How To Evaluate The True Response Speed Of A Fast Rapid Prototyping Supplier?

Many suppliers say they are "fast", but true fast rapid prototyping is not just about quick quotes, collaborative efficiency and problem-solving capability are also very important. I'll teach you two evaluation dimensions.

More Than Just Fast Quotes: Communication Channels and Proactive Engineering Support are Key

Automatic quote replies are not "fast." True speed is reflected in the following two aspects:

- Communication channels-does the supplier have a dedicated project manager who can respond to messages within 2 hours?

- Proactively support engineering-for example, after receiving design documents, can they proactively point out problematic areas?

For example, once the hole spacing of the controller housing of our customer was too small, our engineers proposed an optimization solution within 3 hours and avoided 2 days of rework.

Case Study: How We Resolved a Client's Design Conflict Within 24 Hours

Within the last year, one of the customers in the industrial electronics needed to deliver a prototype of a sensor within 24 hours. There were some assembly conflicts between the circuit board and the housing in its design.

Upon reception of the documents, our engineers held an online meeting right away, pointing directly to the conflict and offering their solution to adjust the depth of the housing recess. The customer confirmed in one hour and began CNC machining at the same time. Eventually, the prototype was delivered within 22 hours and helped the customer meet the internal test schedule.

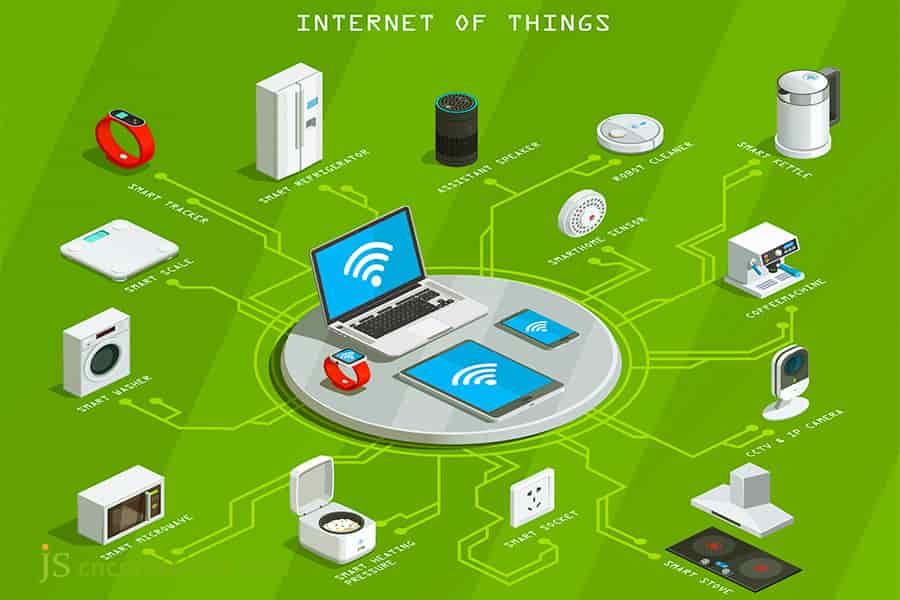

Case Analysis: Smart Home Hub Project, Delivering 50 High-Precision Assemblies In 5 Days

This smart home startup had approached two suppliers in the past, who eventually gave up on this project, unable to meet its requirement of delivering 50 units within 5 days. The product is a smart hub that integrates gateway, voice assistant, and camera.

Its challenges mainly come from the all-aluminum alloy CNC-machined casing with high accuracy requirements of ±0.03mm, the internal 3D-printed nylon bracket, and PCBA integration while guaranteeing direct use for trade show demonstrations.

Main Challenge: An Extreme Task Running Out of Time

The structure of the product is complex, including three processes: CNC, 3D printing, and assembly. Besides, the quantity requirement is huge, 50 units, to be manufactured in this short period.

Moreover, without optimization, the original design of casing heat dissipation vents would interfere with the PCBA installation, even if it is made, it cannot be used, and time does not allow for rework.

Our Solution: Parallel Multi-Technology and Precise Processes

- First, we completed the DFM analysis in 4 hours and came up with an optimization suggestion to move the heat dissipation vent position 1mm to the right, which was approved by the client in 1 hour.

- Then parallel production was kicked off: the CNC machining was scheduled on 8 machines running 24 hours per day, while the optimized paths reduced the processing time per piece from 45 to 38 minutes. 3D printing used SLS technology, 150 nylon brackets were printed at once-3 per set.

- Finally, a dedicated assembly line was set up, and 10 workers assembled and conducted power-on tests to make sure that each set could start up normally.

Results: Deliver Value above Expectations

Not only did we achieve 100% on-time delivery, but we also saved our client up to 18% in project costs. The client took the prototype to a product exhibition, where 3 investment institutions expressed interest, the client eventually placed all mass production orders in our company.

The client said, "The quality has reached the standard of mass-produced machines. So, JS Precision is our strategic partner."

Need urgent prototypes? Please submit your project details to JS Precision. We will customize an fast rapid prototyping solution for you, help you overcome time constraints, and deliver with ease, just like in this case.

Figure 4: smart home gateways

Ready To Actually Start Prototyping Efficiently?

By the end of this guide, you should have gained a clear understanding of what rapid electronic prototyping is. Now, starting your prototype project is very simple, just three steps to get professional services from JS Precision.

Get Your Customized Quote and Manufacturing Solution in Three Steps

- Upload CAD Files: STEP, STL, and more formats are supported-just upload them directly onto our platform.

- Customize: You fill in your requirements on the website, including material, quantity, surface treatment, and delivery time, and then get an instant quotation.

- Confirm Order: Right after paying the deposit, we will start the production straight away and continually update you on the production process.

Why JS Precision is Your Trustworthy Rapid Prototyping Partner

Core advantages help save your time and effort for high efficiency:

Comprehensive technologies including CNC, 3D printing, sheet metal, and vacuum casting avoid sourcing from multiple suppliers, a team of senior engineers who can proactively avoid design problems, with an average of 8 years of experience, transparent pricing without hidden fees, quality assurance, free remake for defective parts, and 24/7 response time, support immediately upon urgent needs.

FAQs

Q1: What is the main difference between rapid prototyping and mass production?

Rapid prototyping focuses on speed and flexibility while it is used for design validation without using any expensive molds. Mass production will save costs with its use of dedicated lines of production and molds, which are critical for mass production.

Q2: How long does it usually take from placing the order until receipt of the rapid prototype parts?

Simple parts, for example, a single plastic part takes about 1-3 days, while for complex assemblies, several parts combined, take about 5-10 business days. Urgent orders can be expedited using the faster service.

Q3: What 3D printing materials do you support?

Resin for appearance parts, nylon for structure parts, ABS-like resin for simulating the properties of ABS, and metal materials including stainless steel, titanium alloy, and aluminum alloy are supported to meet a wide range of testing needs.

Q4: How to prepare the optimal design files for CNC machining?

Please provide the full 3D CAD, best in STEP format. Attach also 2D engineering drawings that show main dimensions and tolerances to avoid omissions in precision machining.

Q5: What are the requirements for my design files before I can start quoting?

The design file has to contain full geometric information, such as STEP or IGES formats. Overly complicated notes are not necessary, the more standard the files, the more accurate and quick the quotation will be.

Q6: Can you support design optimization to improve Design for Manufacturability?

Yes, your quote will include a free DFM report from our engineers detailing issues such as assembly conflicts and also optimizations that will save you money and time.

Q7: Do you provide material certification reports?

Yes, we can provide the relevant certification documents, including material certificates based on your needs, and can ensure that all materials used are traceable, meeting the project requirements.

Q8: What is the procedure if the received parts are defective?

We ensure 100% quality assurance. If some of the parts happen to be defective, please contact your dedicated project manager immediately, we will find out the reason ASAP and take responsibility for free remaking or refunding.

Overview

In today's fast-moving world of product innovation, rapid electronic prototyping is no longer an option but a major distinguishing factor separating success and failure in the product world. It's also no longer just a design validation tool but a strategic weapon accelerating idea realization, decreasing prototype development risks, and as such conquering the market.

JS Precision is committed to becoming your most dependable partner on your product innovation journey. With our complete rapid prototyping methos, open and transparent rapid prototyping costs, effective prototyping process, and rigid quality control of rapid prototyping parts, we ensure every idea you have gets translated into reality by the best route.

Now, take action and speed up your ideas!

Upload your CAD files now for our industry-leading online instant quote system. Our professional team will offer you DFM analysis and a customized manufacturing solution. Let us work together to bring your ideas to market faster, more accurately, and more easily!

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com