What is rapid prototyping?This is a key solution to address high-risk dilemmas in the product development process, and is not an optional convenience option.

In the product development arena, speed is of the essence. By the time your team is still trying to decide how to validate a complex design, your competitors might well be finishing their third iteration of design verification through rapid prototyping.

But do you understand what rapid prototyping is all about? How does it serve as an innovation catalyst? With the massive number of rapid prototyping services that currently exist, how do you separate the good ones from the bad and identify an efficient partner for your project that could ensure quality with efficient cost control?

This article gives a detailed analysis of the basic logic of rapid prototyping, decomposing the overall process from the concept stage to the physical model, as well as a partner evaluation checklist to enable the exploitation of market opportunities.

Core Answer Table

| Decision-Making Core | Common Misconceptions | JS Precision Solutions |

| Process Understanding | Believe that rapid prototyping is just "fast 3D printing" and ignore the complete chain from requirement analysis to post-processing. | Provide an end-to-end structured rapid prototyping process, covering design review, process matching, and functional testing to ensure that the prototype truly reflects the design intent. |

| Cost Control | Only compare the initial quotation, ignoring the repeated modifications and time costs caused by poor communication and immature design. | Through in-depth design and manufacturability analysis, hidden dangers are eliminated in the front-end of the rapid prototyping process, providing a transparent and cost free turnkey solution to achieve real cost reduction. |

| Supplier Selection | Select suppliers solely based on equipment lists or unit prices, ignoring their engineering support capabilities and project management experience. | Showcasing a cross industry successful case library and an engineer led collaborative process proves that we are not only a processing party, but also a strategic partner that can reduce your overall development risks. |

Key Takeaways:

- The core value of rapid prototyping is "rapid validation" rather than "rapid production", and the meaning of rapid prototyping is to reduce the risk and cost of large-scale modifications in the later stage.

- Cost optimization is made possible by front-end collaboration. Design reviews with suppliers and cost estimates work better in terms of overall development costs than just price comparison.

- While making a service provider contract, the word "quality" must be given priority to "speed." Evaluation of their engineering support, material, and quality process matters the most compared to the number of equipment they have.

- JS Precision is just one of the top Chinese suppliers that have global competitiveness in terms of having the latest technology and cost advantages that make them suitable partners globally.

JS Precision: The Key To Successful Rapid Prototyping

The success of rapid prototyping depends to a great extent on the involvement of professional and dependable strategic partners.

JS Precision has been nurturing this area for several years and has meticulously followed the ISO 9001:2015 standard for the quality management system in the service processes. This consistency has brought credibility from clients across the globe and has assisted over 2000 clients to reduce their development time by an average of 60% while ensuring project progress with a delivery rate of 98%.

As compared to other rapid prototyping firms, the prime benefit that JS Precision uniquely offers is in the area of "problem-solving" as opposed to the "production of prototypes." Our team of engineers, numbering over 50, holds collective industry experience, thereby enabling them to rapidly point out design errors, suggest material enhancements, or process enhancements.

For instance, an automotive company approached them for cooperation regarding a complicated interior part that had thrice failed to be prototyped by other suppliers. Our engineers conducted detailed Design for Manufacturing (DFM) analysis and optimized the design to improve manufacturability.

Through a combination of CNC machining and vacuum molding, they delivered a functional prototype that met durability requirements within 5 days, successfully resolving the client's challenges.

We always emphasize technological innovation. Our workshop is equipped with more than 100 machines, such as SLA, SLS, FDM 3D printers, as well as high-precision CNC milling machines. Nonetheless, we have more to boast about.

We have set up an efficient quality control process, such as 3D scanning examination and traceability of materials, to make sure that all prototypes have strict tolerance standards (critical parts have an accuracy of ±0.05mm).

Whether it’s the production of a conceptual mold or the production of 50 functional prototypes for pre-production testing, JS Precision has the relevant professional skills and resources.

Ready to feel the leverage of having a trusted rapid prototyping service provider as a tool in your hands? Submit your 3D design model now to get a complimentary DFM analysis report with your immediate quote. Let us help you with optimizing your design together, identifying the most suitable process for you, and achieving a perfect alignment of your prototype with your product objective.

What Is Rapid Prototyping And Its True Strategic Value?

To fully leverage the value of rapid prototyping, it is first necessary to go beyond the basic rapid prototyping definition and understand its deep strategic significance in product development.

Many teams mistakenly see rapid prototyping as a tool for "quickly making models," but its true power lies in supporting data-driven decision-making, thereby reducing risks and driving innovation.

From "Physical Validation" to "Risk Management": Redefining the Value of Prototypes

The meaning of rapid prototyping are much more extensive when it comes to physical object creation. Rapid prototyping is an essential tool for low-cost and rapid testing of the feasibility of a design or the user experience.

Rapid prototyping has functions of risk management as well. According to ASME Y14.46-2009 rules concerning annotation of a 3D working model, problems related to part assembly could be avoided if detected early, preventing the nightmarish process of rework when produced on a large scale.

Literature suggests that if problems at the prototyping phase were addressed, it would require 1/10th of the cost if addressed during large productions. Even more so when handled at a post-production stage, at 1/100th of its current price.

Speed is Everything: How Iteration Cycles Determine Product Success or Failure

The ability to iterate rapidly in today’s fast-paced marketplace is where leaders go forward and laggards fall behind. The 8-12 week cycle of traditional mold development and validation contrasts vastly with Rapid Prototyping, which can turn around the process within 3-7 days. Here are some specific examples of this disparity:

| Validation Method | Cycle Duration | Average Cost | Revision Flexibility |

| Traditional Mold-Making and Validation | 8-12 weeks | $10,000-$50,000 | Low (High cost of re-molding) |

| Rapid Prototyping (3D Printing/CNC) | 3-7 days | $50-$2,000 | High (Can make changes in a matter of hours) |

This gives corporations a very short time advantage in which they are able to perform multiple tests in the time that an opponent would take to complete a single test. This gives a company the capacity to develop and market their new product very fast.

Figure 1 The significant advantages of rapid prototyping include speed, cost reduction, etc.

Beyond Speed: A Deep Dive Into The Rapid Prototyping Process

An effective and reliable rapid prototyping process can therefore serve as a clean bridge between designing virtually and succeeding as a product. At the heart of rapid prototyping, as opposed to working as "rapid production," is the focus on the processes of quality and consistency.

As JS Precision, we always improve processes to eliminate unnecessary steps and errors to make sure that the required prototype reaches the customer accurately.

First Phase: Requirements Clarification and Process Matching (From 'What Do We Want?' to 'How Do We Do It?")

The initial requirement for the success of rapid prototyping activities is to ensure that the aim of the prototype is clear.

The most fundamental question to ask: Will the prototype to be created for the purposes of appearance check, assembly check, or functional check?On this premise, match the optimal process with the following: 3D printing (SLA/SLS/FDM) – Rapid and economical concept models, CNC machining – Precise metal/plastic parts, and Vacuum casting – Small series production of 5-50 prototypes.

This matching avoids paying for unnecessary precision or using a process which does not live up to the requirements. For example, a concept model used for market demonstration doesn't need to meet the ±0.1mm tolerance standard of a functional test prototype.

Second Phase: Seamless Integration of Design and Manufacturing (Core Role of DFM)

A crucial area that influences cost efficiency and cuts down costs is called Design for Manufacturability (DFM). This area is integral in terms of optimizing designs in such a manner that complexity in manufacturing is avoided, suggestions are made regarding the use of cost-effective materials.

Third Phase: Post-processing and Delivery (From Rough Prototype to Usable Prototype)

The need for post-processing is paramount in ensuring that the prototype becomes very close to the final product. The key services that are part of the core services include removal of support, sanding/painting, screen printing, and easy assembly.

The prototypes can be directly applied for user testing and marketing photography. This increases the effectiveness for gathering feedback in advance.

Do you want to know how our rapid prototyping process can be adapted to your project? Simply upload your 3D file and receive JS Precision’s recommendations for free. Our expert team would discuss the entire process in detail and make you understand the benefits and drawbacks of different processes involved so that you receive your prototype just the way you wanted.

How To Optimize Your Budget In Rapid Prototyping Services?

It is important to note that when searching for rapid prototyping services, it is possible to get a return on investment far beyond what you might expect. Many of these teams blow budgets because processes, materials, or volumes are simply wrong.

Cost Driver Breakdown: Materials, Labor, and Complexity

The price of rapid prototyping services relies on three main components: special materials, complex post-processing time, and complicated design structures. This explains the accuracy in controlling costs.

Understanding all these aspects will enable an economical decision to be made. For instance, using common materials may be economical if they are not required to be tested functionally.

“Just the Right” Precision: Selecting an Appropriate Process for Each Stage

By correlating processes with stages of a project, it is possible to control the costs tightly. The decision can be taken to opt for FDM/SLA for POC (Proof of Concept) development, SLS/CNC for functionality testing, or vacuum Try to avoid spending out too much on high precision in the initial stages.

Tolerances of ±0.5mm are sufficient for conceptual prototypes, and ±0.1mm is not necessary in most cases in conceptual prototypes. This helps in lessening costs by 30 to 50% through proper matching of processes with different stages.

Economics of Mass Prototyping: When 3D Printing Meets Vacuum Molding

For small batches from 5 to 50 prototypes, a combination of "3D printed master mold + vacuum molding" is suggested, which will be both faster and more economical. The result will be a finished product with a quality close to that achieved by injection molding at a low cost.

The Industry Lens: Where Do Rapid Prototyping Services Shine?

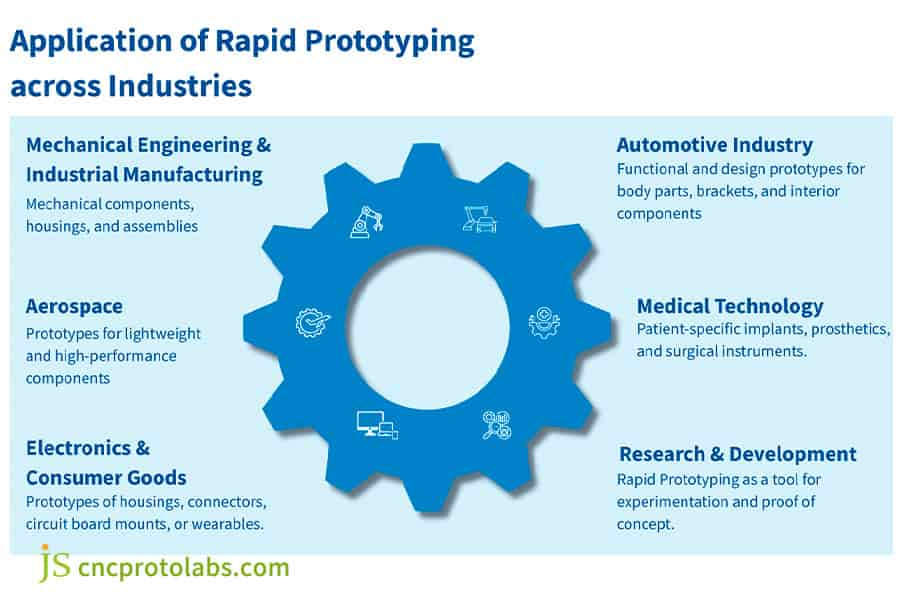

Rapid prototyping services have permeated all innovation-driven industries and become a standard feature of product development. From consumer electronics to aerospace, different industries make use of rapid prototyping to solve unique challenges or accelerate development processes in distinctive ways.

Consumer Electronics & Medical Devices: Balancing Iteration Speed and Compliance

Rapid prototyping is necessary in the consumer electronics and medical device industries to conduct tests for compliance verification: the former tests human-computer interaction and functionality to ensure rapid iteration, the latter verifies biocompatibility to accelerate compliant market launch.

Automotive & Aerospace: Rigorous Testing from Interior Components to Functional Prototypes

The performance requirements of the prototype are stringent in the automotive and aerospace industries: the former has wind tunnel tests and crash tests, the latter uses lightweight metal parts manufactured by 3D printing, both required to tolerate extremely bad working conditions.

Industrial Equipment & Smart Hardware: Visual Verification of Complex Internal Structures

The industrial equipment and intelligent hardware industries are in need of complex inner structure verifications, among which the former is used for the visualization of flow channels with transparent resin while the latter is for testing of circuitries and structural stresses with CNC machining.

Are you looking for rapid prototyping services in your industry? Rich experience at JS Precision involves consumer electronics, medical devices, automotive, and more. Let us know about your industry and project needs, and we'll be able to tailor a solution that addresses the needs of your particular industry.

Figure 2 Rapid prototyping is a key factor for innovation in various industries. In fields that require speed, precision, and flexibility, rapid prototyping can give you an advantage in the development process.

Case Study: From 30 Days To 3 Days,How Rapid Prototyping Saved a Smart Wearable Launch

Product development teams have always dreaded last-minute crises. But in this case, a rapid prototyping process and services have converted the crisis into an opportunity. This case study shows how JS Precision, through its fast and efficient prototyping services, enabled the client to avoid time-to-market delays at significant costs.

The Client's Crisis

It was time for a leading consumer electronics company about to launch a new smart bracelet, and it suddenly uncovered, one week from the start of trial production, a millimeter-level interference problem between the casing and internal PCB.

The traditional solution was modifying the mold, which took at least 30 days, which means the product would not make it on time for its planned launch window. This may translate to losing millions of dollars due to lost sales and damage its reputation within the highly competitive wearable device market.

JS Precision Solution

- Urgent Analysis: Our engineers diagnosed the problem within 2 hours of the receipt of the client's design files. Given that the fit of the part onto the PCB had to have tolerances at ±0.1mm, we would recommend the remaking of a new casing prototype through high-precision SLA 3D printing.

- Parallel Process: We set up a rapid response channel so that design adjustment, 3D printing, and post-process (sanding and painting) can be done at the same time.

- Functional Testing: Within the first 24 hours from the time the design change was received, we were able to deliver the first 5 sets of functional prototypes at the configuration level. The client proceeded to use the prototypes to undertake the functional and waterproof tests, and this was fundamental to ensure that the functional effectiveness of the design change worked properly.

Results:

The entire process from the point of problem identification to the return of testable revised prototypes took a record time of only 3 days. The test results substantiated the perfect fit of the revised casing to the PCB board, and the client modified the mold without any delay.

The final product was delayed by only 5 days, avoiding huge losses in the market as well as downtime costs. The case illustrates the emergency need for an effective rapid prototyping process and rapid prototyping services as shown above.

Facing tight deadlines or unexpected design problems? Let JS Precision help you resolve crises. Contact our emergency response team now, and we will collaborate with you to find fast, effective solutions to ensure your project progresses smoothly.

Figure 3 3D printed smart wristband

The Partner Checklist: How To Vet The Right Rapid Prototyping Companies?

Selecting suitable partners from numerous rapid prototyping companies is a crucial step in the success of the project.Numerous options make the situation confusing, and keeping the essential criteria in mind might assist in finding the right partner.

Assessments of Technical Capability – Equipment Breadth and Process Depth

Capability evaluation needs to be done in-depth in terms of experience in integrating additive and subtractive processes, special project handling, and case analysis in the same industry: rather than measuring purely in terms of the number of machines.

At JS Precision, we concentrate not only on investing in equipment capabilities, but in process knowledge as well. Our staff undergoes regular training, in addition to being updated on the latest processes, and has worked on projects varying right from micro-medical to automotive components.

Quality and Communication Processes: Standardization and Transparency

Service providers offering high-quality services should have standardized processes when it comes to quality services and communication. Factors that should be evaluated during this step include document preprocessing processes, quality inspection systems, and communication processes.

JS Precision has implemented a standardized process throughout the entire process, including the specifics of each step from the reception and review of the documents to the delivery of the prototype. Your project will have a designated point of contact to keep you abreast of the status and to provide a speedy response to any questions.

Seamless Integration from Prototype to Mass Production (Key Bonus)

The ease of integration from the prototyping state to mass production brings a big advantage as the designs will not require changes at a later date.

JS Precision offers complete services throughout the whole supply chain, from quick prototyping to batch production and mold making. Our engineers will take into consideration your needs for mass production during the prototyping phase.

Would you like an efficient way to shortlist suitable rapid prototyping companies? Simply ask JS Precision for the "Excellent Prototyping Supplier Evaluation Checklist." This checklist encompasses basic parameters of assessment, such as technology, quality, and communication, so that suitable vendors are shortlisted effectively. Just write "Evaluation Checklist" and we'll dispatch it immediately.

FAQs

Q1: Accuracy is measured at +/-0.001 inch, depending on the system used.

Accuracy of ±0.1mm and even higher is common when using rapid prototyping of industrial grade photopolymer 3D printing and/or CNC machining. This depends on the chosen technology and the material and size of the object being created.

Q2: Is rapid prototyping suitable for small-batch production?

Yes. For small series production quantities between 50 and 500 units, vacuum casting or direct metal 3D printing can be considered economical. In this context, the need for complex molds is eliminated, facilitating fast and economical delivery of the compliant product.

Q3: What kinds of file formats do you support?

We fully support numerous common 3D design file formats, such as STEP, IGES, STL, and X_T. To achieve the greatest precision during data processing, we kindly recommend transmitting the original file with your design done in STEP or IGES.

Q4: How long does it take from the time I submit the files until I get the prototype?

It depends on the size of the piece and the post-processing. For simple pieces, this will require 24 to 48 hours, while for complex ones, this will take 3 to 7 business days.

Q5: How do you protect the prototype when moving it?

We utilize layer protection packaging techniques such as specialized shock-resistant linings, bubble wrap packaging, and robust boxes. Delicate components are carefully secured to resist vibrations or shock as the prototype is transported.

Q6: Can you sign a confidentiality agreement?

Yes. The top priority is protecting intellectual property. A binding contract of confidentiality can be drawn up prior to project execution to guarantee total client intellectual property.

Q7: What is the average cost associated with rapid prototyping?

Pricing varies from tens to thousands of US dollars, depending upon the size of the parts, the method of their production, and their material. This information is provided in the form of drawings/file for an instant online quote.

Q8: Why not buy from JS Precision in China instead?

We integrate the best quality from Europe and America and combine it with the competitive advantage offered by Chinese production services, ensuring that we offer extreme cost-effectiveness, quick response to supply chain, and 24/7 Engineering Support Services.

Summary

Rapid prototyping is far from being a simple procedure described by "quickly producing parts," since its role in product innovation, management of development risks, and market competitiveness is quite complex.

In today’s global landscape of collaborative innovation, having a partner that offers complete technology, responsive behavior, effective communication, and cost competitiveness will play an important part in launching your product into the market successfully.

Don’t allow your ideas to stay at the screen.

Upload your 3D design files to our JS prototyping platform today to experience the one-stop rapid prototyping solution we provide. You will get a clear breakdown of your project cost estimate in hours, including processing options, cost, and delivery time, along with your initial design manufacturability assessment for free by our team of experts.

Click to get started to move your innovations from ideas to life.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com