Speed is everything in today's winner-takes-all market. On Monday, a liquid-cooled heatsink for a next-generation electric vehicle was just a CAD concept. By Friday, a fully functional, test-ready aluminum prototype was in your hands, its internal flow channels optimized for 20% improved heat dissipation.

This is not science fiction, it is the day-to-day reality of contemporary metal rapid prototyping.

We at JS Precision understand that rapid prototyping is much more than "making something look like it quickly." It's a strategic race to convert ideas into verifiable assets with the fastest speed, lowest risk, and highest quality.

This guide, drawing on the numerous practical experiences of JS Precision, helps you in clearly addressing all aspects of the metal rapid prototyping process: technology selection, cost control, and even supplier evaluation are included, which enable your prototyping projects to move on efficiently.

Core Answer Summary

| Technical Path | Core Advantages | Typical Applications | Key Value |

| CNC Rapid Prototyping | Realistic material properties, high precision ±0.005mm, good surface quality. | High-load structural parts, verification parts of assembly, functional test parts. | Prototype performance consistent with mass-production parts to transition smoothly into production. |

| 3D Metal Printing | Extremely high degree of design freedom-Enabling geometrically complex lightweight structures, material usage >95%. | Topology-optimized scaffolds, personalized implants, internal flow channel parts. | Breakthrough traditional manufacturing limitations, achieve "impossible" geometries. |

| JS Precision Service | Provides hybrid manufacturing solutions with CNC and 3D printing, 15 years of experience, and over 30 machines. | Urgent high-precision prototyping needs in aerospace, medical, automotive, and other industries. | Offers the best technical path according to DFM analysis, including taking the right balance between speed, cost, and performance into consideration. |

| Cost and Efficiency | Quick quotations on the web: 5-10 minutes, standard delivery cycle: 3-15 days. | Small batches of prototyping to medium-sized batch trial production. | Transparent pricing avoids hidden costs, accelerating product development cycles. |

Why Trust The JS Guide?: Key Success Factors In JS Precision's Metal Additive Manufacturing

For 15 years, JS Precision has fostered in-depth expertise in the realm of rapid prototyping, not only as a technology practitioner but as a provider of industrial solutions as well. Especially in CNC machining rapid prototyping and metal 3D printing rapid prototyping, we have solid and verifiable experience.

For instance, in the making of a custom metal bracket prototype for a satellite attitude control system for an aerospace client, we shortened the original development cycle from 45 days down to 18 days, while achieving a stable dimensional accuracy of ±0.01mm and a 100% yield rate.

Our minimally invasive surgical instrument prototype for a medical client reached dual AS9100 and ISO 13485 certifications and successfully passed the preliminary review at the FDA.

On the hardware side, we have 30 five-axis CNC machining centers and 8 metal 3D printers covering SLM and EBM technologies, processing over 2,000 prototype orders annually, with an 82% customer repurchase rate.

More importantly, our engineering team has more than 8 years of average experience in prototyping, with over 1200 DFM optimization suggestions provided to help customers reduce the cost of metal prototyping by an average of 18%.

This guide is an in-depth review of over 1000 successful cases, ranging from practical subjects about technology selection, cost control, and risk avoidance to help avoid common pitfalls in developing a prototype.

With JS Precision's CNC machining rapid prototyping service, all you need to do is upload your CAD files. Our intelligent system will finish the manufacturability analysis and preliminary quotation within 5-10 minutes and will have prototype machined parts efficiently delivered to meet your needs. Repeat customers will enjoy a 10% cost discount.

Reconceptualization Of Metal Rapid Prototyping In 2025

In ensuring the reliability of this guide, the core connotation of metal rapid prototyping has to be demarcated to avoid any kind of cognitive biases that will affect the selection of technologies.

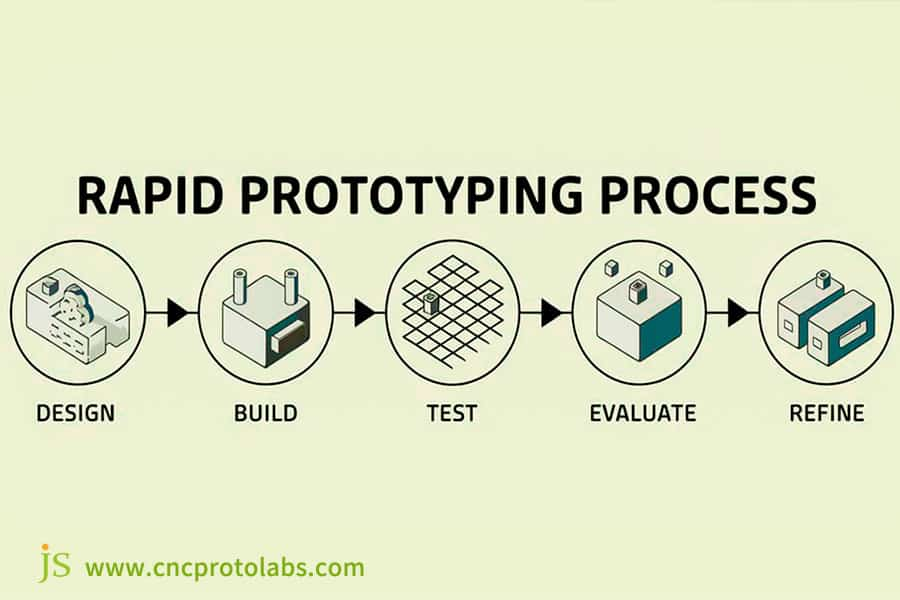

Broadly defined, metal rapid prototyping is a combination of technologies and services that shorten product development cycles. Its core objective is "accelerating learning, not just accelerating manufacturing," and it's a significant branch of rapid prototyping.

JS Precision views it as a "highway" between proof-of-concept and functional testing, among other stages. Real speed means total delivery time from submitting your drawings to getting qualified parts, which includes quotation, programming, machining, quality inspection, and logistics.

Overview of Technology: The following article is based on the comparative analysis between CNC machining rapid prototyping, metal 3D printing rapid prototyping, and rapid sheet metal prototyping to help you find the appropriate technology path.

At JS Precision, the following metal rapid prototyping services are provided: from CNC machining through metal 3D printing, including rapid sheet metal prototyping. We can help tailor solutions to meet your needs and accelerate your project.

Figure 1: Rapid prototyping process follows an iterative cycle,design,build,test,evaluate,refine.

Five Key Considerations Before Choosing Metal Rapid Prototyping Technology

Having understood the concept of metal rapid prototyping, five key considerations must be confirmed prior to the selection of technology in order to avoid rework or cost overruns:

- The Main Purpose of the Prototype: to check the appearance, to inspect the assembly, or for functional testing, such as taking structural loads? Different purposes require different technology choices.

- Material Performance Requirements: Must this prototype possess identical mechanical properties to those of the mass-produced part, such as fatigue strength, thermal conductivity? Its performance directly influences technology compatibility and the metal prototyping cost.

- Geometric Complexity: Does the design represent a complex, curved surface difficult to realize by traditional processes, or an "impossible part" with deep cavities and micropores? It is the complexity that will dictate whether 3D printing is necessarily used.

- Budget and Time Trade-offs: What is the budget range for metal prototyping costs? Is speed an absolute priority, or can a balance be struck between cost and time?

- Post-processing Requirement: If secondary processing such as sandblasting, anodizing is acceptable and can be budgeted to achieve surface finish or dimensional accuracy, post-processing will affect delivery time and cost.

Technology Showdown: CNC Machining Rapid Prototyping Vs. Metal 3D Printing Rapid Prototyping

After illustrating some key considerations, we now focus on two mainstream technologies and compare them to help you find the right solution:

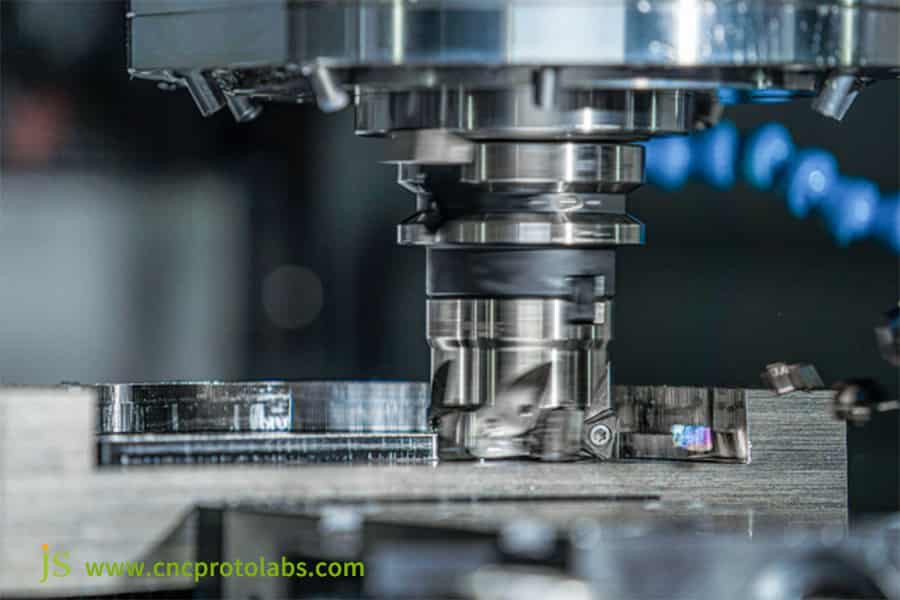

CNC machining rapid prototyping: The defender of precision and strength

Advantages:

- Efficiently machines common metals such as 6061 aluminum alloy and TC4 titanium alloy, with mechanical properties like the tensile strength and hardness of parts consistent with mass-produced parts essentially.

- The best surface quality and dimensional accuracy, reaching ±0.005mm for tolerance.

- Wide range of material choices, from ordinary steel up to high-temperature alloys.

Challenges:

- It is impossible to machine closed structures with a depth-to-cavity ratio over 10:1 by traditional CNC tools, which makes reaching complex internal flow channels difficult.

- Great material waste, with machining removal rates often reaching 30%-50%, results in great cost losses of high-value materials.

Metal 3D printing rapid prototyping: The liberator of complex geometry

Advantages:

- Very high design freedom, such as aerospace topology-optimized scaffolds and personalized medical implants, can be integrally molded without splicing.

- Material utilization rate of nearly 95% or more, greatly reducing waste of high-value metal powder.

Challenges:

- The limited availability of the platform, where most of the equipment is limited to a maximum size of 500mm×500mm×500mm and faces difficulties in meeting the needs of big parts.

- The surface quality requires post-processing, and the roughness after printing reaches Ra12.5-Ra25μm, requiring milling and polishing to enhance precision.

- Material properties may be anisotropic, with mechanical properties differing between the printed and vertical directions.

- Simple geometric parts are expensive, costing 20%-40% more compared to single parts manufactured by CNC.

Hybrid Manufacturing Strategy by JS Precision

We do not ask customers to choose between the two. We often recommend that customers use metal 3D printing rapid prototyping to make the complex features, such as internal flow channels, and then use high-precision CNC machining to refine the key mounting interfaces and threaded holes.

For example, for a certain automotive sensor prototype, the main body was 3D printed, with threaded holes CNC-machined for precision finishing, thereby achieving both complex structures while ensuring fitting accuracy, at a cost 25% lower than pure 3D printing.

JS Precision is a hybrid manufacturing expert, combining CNC machining rapid prototyping and metal 3D printing rapid prototyping to create effective solutions for complex parts to deliver quality prototype machined parts efficiently.

Figure 2: CNC (Computer Numerical Control) machining is one of the most commonly used methods in metal prototyping.

Engineering Behind Speed: How JS Precision Manufactures Exceptional Prototype Machined Parts

Understanding technological differences, let's explain the engineering processes that JS Precision applies to assure quality and speed in prototype machined parts.

1. Digital Production Line: With the uploading of your CAD files, manufacturability analysis and preliminary quote will be automatically generated. This will cut down the time from "inquiry to quote" from hours down to minutes, hence increasing the efficiency upfront.

2. "Optimized for Speed" Programming: A professional rapid prototyping services programming team is knowledgeable in efficient toolpaths and cutting parameters that ensure the best processing efficiency while maintaining quality.

3. Parallel Operation & Intelligent Scheduling: While parts are being processed, the quality department prepares the inspection plan side by side, and the post-processing team prepares consumables for seamless integration to reduce waiting.

4. Standardized Automated Quality Inspection: Using non-contact measurement methods like blue light scanners, we inspect prototype machined parts quickly for the key features that ensure a closed-loop data feedback system that can forestall quality issues.

Precise Budgeting: In-depth Analysis Of Six Key Factors Affecting Metal Prototyping Costs

Costs represent one of the essential factors to be considered in prototype manufacturing projects. The following analysis looks into six factors which influence the metal prototyping cost, with specific cost data included from JS Precision:

- Material Costs and Machinability: Imported high-strength aluminum alloys are much more expensive than standard national materials, special materials like titanium alloys require much longer times for processing and therefore are more expensive.

- Part Geometric Complexity: The more numerous the features, higher the aspect ratios, and thinner the walls, the more exponential the rise in programming and machining time, hence the cost.

- Size and Quantity: Large areas of machine tool work increase costs, smaller quantities increase per-part programming and setup costs.

- Tolerances and Surface Finish: It is costlier to achieve ±0.025mm than to produce parts at ±0.05mm, mirror finishes are costlier than the standard milled surfaces.

- Post-processing and Secondary Machining: All procedures, which include anodizing, sandblasting, and electroplating, raise the metal prototyping cost.

- Project urgency: involves a rush order, requires night shifts or weekend work - includes rush fees and thus raises overall costs.

Cost and Transaction Parameters Comparison for Metal Prototyping Technologies

| Technology Type | Applicable Materials | Unit Cost (USD) | Minimum Order Quantity (pieces) | Delivery Time (days) | Key Cost Influencing Factors |

| CNC Machining Rapid Prototyping | Aluminum Alloy 6061 | 50-200 | 1 | 3-7 | Feature Quantity, Tolerances, Machining Time. |

| CNC Machining Rapid Prototyping | Titanium Alloy TC4 | 200-500 | 1 | 5-10 | Material Unit Price, Machining Difficulty. |

| Metal 3D Printing Rapid Prototyping | Aluminum Alloy AlSi10Mg | 100 - 300 | 1 | 5 - 12 | Part Volume, Support Ratio. |

| Metal 3D Printing Rapid Prototyping | Titanium Alloy TC4 | 300-800 | 1 | 8-15 | Powder Cost, Printing Time. |

| Rapid Sheet Metal Prototyping | Stainless Steel 304 | 30-150 | 5 | 2-5 | Bending Times, Welding Points. |

JS Precision Prototyping Service Price Composition

| Price Components | Fee Schedule | Included Content |

| Material Cost | Aluminum Alloy 6061: $2.5/cm³ | Actual material used + 10% wastage. |

| Material Cost | Titanium Alloy TC4: $8.0/cm³ | Actual material used + 15% wastage (3D printing). |

| Machining Cost | CNC Machining: $80/hour | Programming, machine operation, tool wear. |

| Machining Cost | 3D Printing: $120/hour | Equipment operation, parameter adjustment, support removal. |

| Post-processing Cost | Sandblasting: $8/piece | Surface roughness Ra3.2-6.3μm. |

| Post-processing Cost | Anodizing (Natural Color): $15/piece | Oxide layer thickness 8-12μm, corrosion resistant. |

| Quality Inspection Cost | Basic Dimension Inspection: $20/piece | Measurement of 3 key dimensions + inspection report. |

Figure 3: To give an accurate quote for a rapid prototyping project, it must have a 3D part drawing.

How To Scientifically Compare CNC Machining Rapid Prototyping Quotes

After understanding the cost-influencing factors, master the scientific ways of comparing CNC machining rapid prototyping quotes to avoid the traps of low prices:

Beware of "Apple and Orange" Comparisons

Material grade and supplier, machining characteristics, tolerance standards, quality inspection report level, and delivery terms should be completely quoted, and lacking this may result in extra charges later on.

Unveiling the "Hidden Costs"

Ask if the quotation price includes DFM feedback, standard deburring, and basic dimensional reports. These are often charged extra by low-price suppliers and can lead to unexpected higher final costs.

Assess the "Knowledge Value" of the Supplier

Suppliers who actively provide advice to optimize the design for cost savings and/or delivery time are worth much more in the long run than cheap executors who process only according to drawings, helping one avoid potential risks.

Transparent Pricing by JS Precision

The online quotation platform clearly breaks down the cost of materials, machining, post-processing, management, and so on, thus, every penny is transparent with no hidden charges.

Above all, the quotation price of CNC machining rapid prototyping by JS Precision is transparent, clearly specifying the material cost and machining cost, meanwhile offering professional DFM advice for you to effectively control the metal prototyping cost while ensuring quality.

Five Capability Dimensions To Assess The Best Metal Rapid Prototyping Suppliers

Before selecting a quote, consider evaluating metal rapid prototyping suppliers on five dimensions to determine their best-in-class service level:

- Technical Breadth and Depth: Is the company proficient with both CNC and metal 3D printing rapid prototyping? Can they make hybrid manufacturing suggestions? Extensive technical knowledge means adaptability in solutions.

- Quality Assurance System: Are they AS9100 or ISO 13485 certified? Can they provide a comprehensive first-article inspection report? Certification and reports are guarantees of quality.

- Digitalization and Automation: Some hallmarks of modern rapid prototyping services are online quoting, order tracking, and digital process cards that will enhance collaboration efficiency.

- Engineering Support Capabilities: Is the team staffed with senior engineers performing detailed DFM analysis and not just process engineers? Professional engineers will be in a position to support you in optimizing your designs.

- Project Management and Communication: Is a dedicated project manager assigned? If so, is the response time prompt? Smooth communication avoids misunderstandings and delays.

JS Precision enjoys technical breadth and depth in rapid prototyping services, with a complete quality assurance system and professional engineering team that can offer you reliable metal rapid prototyping services.

Protecting Your Creativity: How JS Precision Safeguards Your Security Via A Confidentiality Agreement

Whenever dealing with suppliers, creative ideas and designs must remain confidential. JS Precision protects your intellectual property in three major ways:

- Legal Level: Providing standard but customizable confidentiality agreements with extensive terms that clearly outline the scope, obligations, duration, and liability upon breach of confidentiality, keeping your rights legally intact.

- Technical Aspect: Design files will be kept on an encrypted local server, with very tightly controlled permission roles for access. After processing, the related data can be completely deleted upon your request to avoid leakage.

- Cultural Aspect: Except for sales to operators, every employee is trained in confidentiality upon joining and also signs personal confidentiality agreements to make confidentiality awareness part of the company's DNA so that security is ensured at every step.

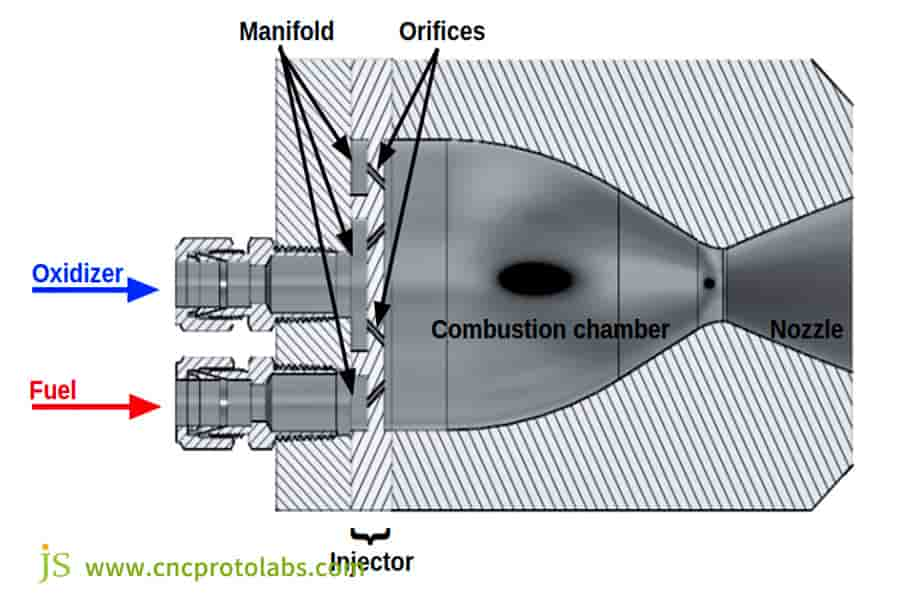

Industry Case Study: 1+1>2—Metal 3D Printing And CNC Precision Machining Integration Into A Prototype Rocket Engine Injector

The case study below explores the implementations of several metal rapid prototyping technologies done at JS Precision to intuitively help you understand the added value of our service.

Customer Challenge

A prototype copper alloy rocket engine injector should be fabricated by a commercial aerospace company. Internally, the part has over 300 small cooling channels (each 0.8mm diameter) which can only be made by 3D printing. The mounting flange externally requires a tolerance of ±0.01mm, and interface threads for high strength assembly.

Besides, it has to be delivered within 15 days in view of the hot-testing schedule, which cannot be met by traditional single-technology methods simultaneously.

Solution by JS Precision

We use a hybrid manufacturing process:

- First, high thermal conductivity copper alloy powder is used for metal 3d printing rapid prototyping (SLM technology). The best laser parameters ensure that internal channels are block-free and pore-free.

- Internal channels are checked using a CT scan after printing for their integrity in order to eliminate hidden defects.

- The blank is then clamped in a five-axis CNC machining center, where precision milling of the flange surface and tapping of threaded holes with special tools are carried out to ensure dimensional accuracy.

- Finally, critical dimensions of the parts are measured using a coordinate measuring machine, checking for conformance to design specifications.

Results and Value

Delivered the prototype in just 12 days and cooled satisfactorily during hot testing, assembly and installation without errors were done to enable the customer to confirm the design feasibility 3 days in advance and not to lose millions of dollars due to project delays.

It perfectly shows JS Precision's engineering capabilities in mastering various metal rapid prototyping technologies, thus offering optimal comprehensive solutions to clients.

Figure 4: a diagram of the design for rocket engine injection system

FAQs

Q1: What is the fastest metal rapid prototyping delivery cycle from document to delivery?

For small and simple aluminum alloy parts, such as a 50mm diameter and 10mm thick disc, JS Precision can provide delivery in 24 hours with the Level 1 expedited service to meet urgent verification needs.

Q2: For my structural prototype, which one is more appropriate: CNC machining or 3D printing?

In case the mechanical properties your prototype needs to resist very high loads, such as tensile strength ≥ 300MPa, or performance consistent with mass-produced parts, the more suitable route would be CNC machining. On the other hand, when a complex internal structure is difficult to realize through traditional processes, 3D printing takes precedence.

Q3: In what materials do you offer rapid sheet metal prototyping services?

We provide the service of rapid sheet metal prototyping for materials including but not limited to aluminum sheets (1060, 5052, 6061), stainless steel sheets (304, 316), cold-rolled steel sheets (SPCC), and copper sheets (T2). We also provide subsequent assembly services like bending, welding, and riveting.

Q4: How to reduce the cost of my metal prototype?

Save cost through design optimization, such as avoiding cavities with an aspect ratio > 5:1, setting up the tolerance according to actual needs, select economic material, such as using 6061 instead of 7075 aluminum alloy. Communicate with our engineers regarding Design for Manufacturing at a very early stage.

Q5: What does your quotation include about quality control?

Our basic quotation includes the initial inspection in 3 key dimensions, visual inspection without obvious scratches or burrs, and a simple quality inspection report. Full-dimensional inspection or material performance testing is a paid quality inspection service.

Q6: Is small-batch mass production supported?

Yes, JS Precision seamlessly moves from rapid prototyping to small batches, from 10 to 500 pieces, with smooth verification from prototype to mass production. Small batches also have volume discounts.

Q7: Which of the following is the most distinctive value in JS Precision?

The most unique value is our engineering-driven solutions. We are more than a manufacturer but act as an extended engineering consultant for your team to optimize designs and help control costs while accelerating innovation and ensuring that projects are done right the first time.

Summary

In the race for innovation, the partnership with a powerful metal rapid prototyping company is an advantage that will contribute in large measure to acceleration in the success of your product.

With 15 years of practical experience, a comprehensive technology matrix, and transparent service processes, JS Precision builds the most efficient bridge for you from idea to prototype. If you need high-precision prototype machined parts, we offer you the right solution to control your costs, shorten your cycles, and ensure the first try is a successful one.

Get a quick quote and kick-start your rapid prototyping project now!

Upload your 3D files for online, transparent, and fast quotation. A price quote will be provided, together with an initial DFM analysis by our engineering team. Let's make those great ideas of yours a reality as soon as possible!

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com