Rapid prototyping services play an important role in world product development. Choosing the appropriate rapid prototyping services partner is the key to determining project budget and time to market. Often a dilemma arises in making a choice between suppliers in the US and rapid prototyping China in terms of cost vs. capability.

This article will attempt to look beyond the surface, using facts and case analyses to make a systematic comparison of the differences existing between China and the US regarding high-precision prototyping services, helping you make an objective decision.

When you are comparing prices on the rapid prototyping services suppliers, as well as the strength of the rapid prototyping companies, this guide will help you gain insight into the essence and make wise choices that are most beneficial for product success.

Key Answers Summary

| Key Decision Dimensions | Typical Comparison of US and Chinese Markets | Key Value |

| Cost Structure | China's total cost is 30-50% less, the US has a lower regional cost of logistics, yet a higher unit cost. | Taking a measure of costs helps in allocating budget. |

| Technical Capabilities | World-class capabilities are merging, the cost-effectiveness of China in mass production of complex components is excellent. | Learn to pick and forget the regional capability mentality. |

| Service and Reliability | Excellent service providers focus on responsiveness, with the best firms in China capable of overcoming the distance barrier. | Understanding the knowledge measurement criteria ensures the project's advancement. |

Key Takeaways:

- The cost discrepancy arises from the supply chains and operational costs:

China enjoys structural advantages in raw material purchasing, large-scale manufacturing, and labor costs, which are the foundation of the price competitiveness of rapid prototyping China.

- Precision is not a geographical attribute but an attribute of equipment and processes:

The ability to hold a tolerance of ±0.025mm or to achieve a surface finish of Ra 0.4μm depends upon whether the supplier has invested in top-of-the-line CNC and CMM systems and stringent process control.

- Unit price is less important than total cost and total time:

Preferring a rapid prototype company that offers one-stop solutions, such as providing integrated post-processing and assembly, greatly reduces the management complexity and overall project timelines.

- Early design collaboration is the greatest value lever:

Partnering with suppliers that can offer in-depth DFM analysis saves over 20% in costs and time upfront, regardless of location.

Why Refer To This Guide? JS Precision's Experience In Rapid Prototyping Services

With our 27 years of expertise in providing rapid prototyping services, JS Precision offers its services in over 50 countries around the globe, with successful completion of over 100,000 projects in high-precision prototyping services for industries such as the medical, automobile, and aircraft industries.

For instance, we previously made a complex structural prototype that has an accuracy of ±0.008 mm for a US-based aerospace components firm. The delivery of samples took only 5 days, which helped the client reduce their R&D time by 30%.

Our competitive edge is based on the integration of the cost-effective supply chain in China with a world-unified quality control system.

Our company has won official certifications such as ISO 9001:2015 and IATF 16949, involving an investment of over US$20 million in top-level equipment like the German DMG Mori 5-axis machine tool and the American CMM Coordinate Measuring Machine, so as to enable us to produce machine tolerance levels of ±0.005mm, satisfying the highest requirements for a high-precision prototyping services.

Our engineering staff represents an average expertise in this sector in excess of 12 years, and, prior to, we have optimized the design of an implant prototype for medical clients, decreasing costs of material by 25% and processing time by 20%.

Based on their rich experience in cross-border projects, we have built a mature cross-border communication and logistics system, so as to solve the problem of time difference and language difference, enabling international customers to enjoy the same convenient experience as local customers.

If you compare the prices of rapid prototyping service providers, or looking for a rapid prototyping company that combines cost advantages with technological strength, contact JS Precision's engineering team for a free, customized DFM analysis and cost assessment solution. Let us demonstrate our capabilities with real-world case studies.

How To Objectively Compare The Prices Of Rapid Prototyping Service Providers?

To select fast prototyping services, it is not possible and meaningful to base on unit costs alone, and an integrated approach must be adopted.

Key Elements of a Price Quotation:

- Material Costs: The cost differential between China and the US for the material of Aluminium 6061-T651 is 20-30%, giving advantage to China.

- Processing Fees: China's three-axis costs 8-30 USD/hour, while the five axis costs 35-50 USD/hour, which is more than 50% higher in the United States.

- Additional Costs: Programming, post processing, and the like ought to be clearly defined, so as to ensure that no secretly billed charges exist that could add.

Beware of Hidden Costs

- Communication Costs: A bilingual staff can easily eliminate risks created by time differences and language differences.

- Quality Costs: Low costs may result in either the scrapping of the prototype or a major loss.

- Time Costs: The production cycles in China are 30-50% shorter, which can partially counteract shipping times.

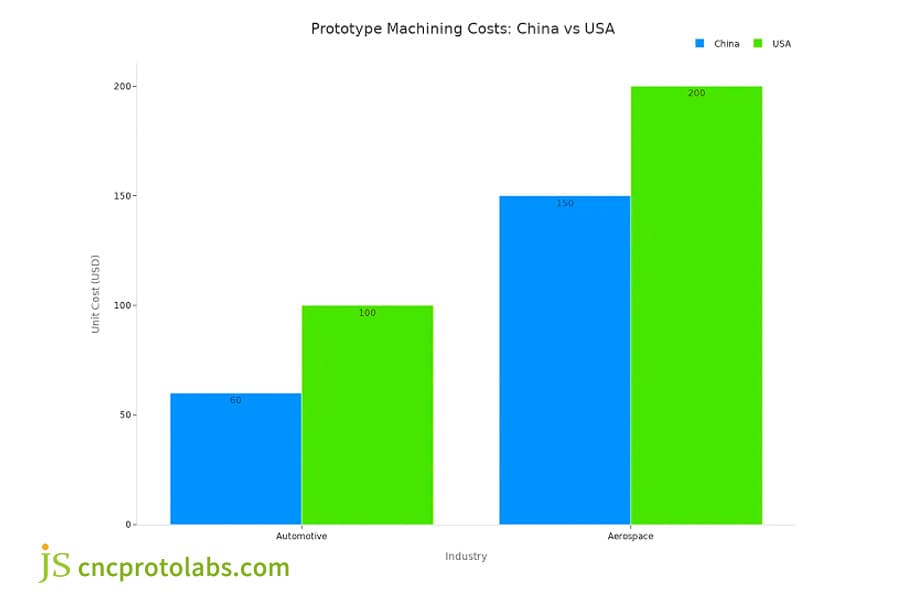

Cost Comparison of Rapid Prototyping in China and the US (Complex Metal Parts)

| Cost Composition | China ($) | USA ($) | Differences | Optimization Suggestions |

| Raw Materials (1kg) | 15-35 | 25-55 | 30-40% | Choose vertically integrated suppliers |

| Three-Axis Processing Time (1h) | 8-30 | 15-45 | 40-50% | Optimize design to reduce processing time |

| Five-Axis Processing Time (1h) | 35-50 | 60-85 | 40-45% | Centralized processing to improve efficiency |

| Anodizing/Part | 12-25 | 20-40 | 35-40% | Batch processing to reduce costs |

| Programming and Debugging Fee | 50-150 | 100-300 | 45-50% | Provide complete 3D files |

Want to accurately compare the prices of rapid prototyping service providers? Submit your part drawings to JS Precision immediately, and we will provide you with a transparent quotation that includes all details, while highlighting potential cost risk points to help you avoid decision traps.

Rapid Prototyping China: Does the Cost Advantage Hold Up Under Scrutiny?

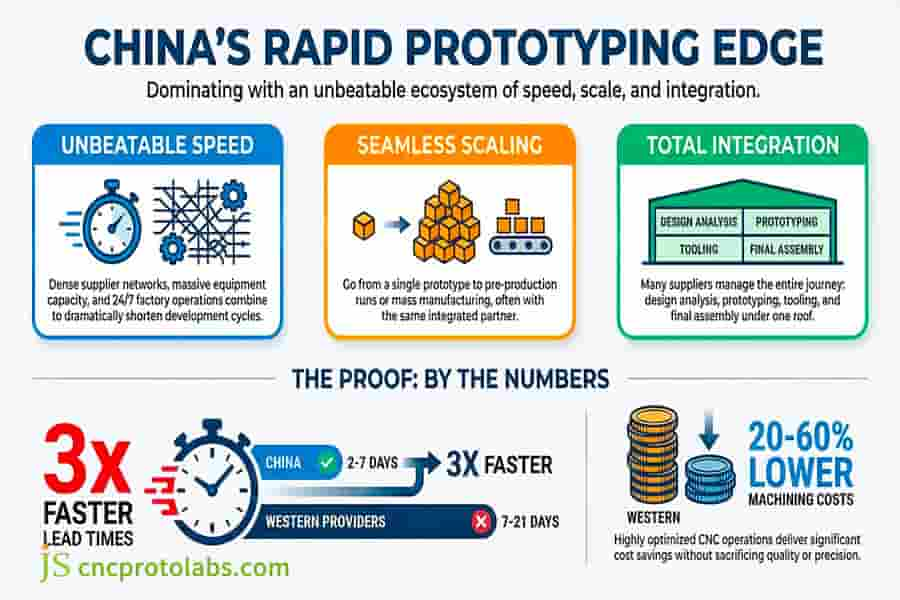

The cost advantage of rapid prototyping China comes from a mature ecosystem, while also requiring rational response to potential challenges.

Four Pillars of Cost Advantage

- Scaled Procurement: Raw material prices are reduced between 15-25%, along with an efficient supply chain that is centrally located.

- High Equipment Utilization: The high-end machines have high utilization rates, with high process experience.

- Vertical Integration: JS Precision’s one-stop service also removes middlemen markups.

- Lean Management: Digital methods decrease the expense of quality control and operations.

Challenges to Address

- Logistics Time Lag: The real-time project system at JS Precision overcomes this problem.

- Standard Differences: Select a service provider conversant in ASME Y14.5. JS Precision employs a bilingual staff.

Still have doubts about the cost advantages of rapid prototyping China? Let JS Precision provide a free cost calculation to verify with concrete data whether it can save you more than 30% of your budget while ensuring delivery quality.

Case Study:JS Precision Helps a North American Cleaning Robot Company Reduce Costs By 40%

Client Challenge:

A company in the North American cleaning robot market required the development of 20 prototype cleaning heads to undergo extreme environmental testing. The primary challenge lay in achieving resistance to corrosion and wear using 316 Stainless Steel, but the cost in the US was evaluated to be up to $28,000 with a development time of 8 weeks.

JS Precision's In-Depth Engineering Solution:

1.Material and Structural DFM Reengineering:

Taking into consideration stress models and wear models, JS Precision engineers recommended that instead of the entire stainless-steel structure, a 6061-T6 aluminum alloy combination with 316 stainless steel wear-resistant inserts for critical contacting surfaces be used.

Although keeping the hardness at HRC > 20, a reduction of 60% in material costs with an increase of over 3 times in processing speed was achieved.

2. Precision Manufacturing & Cooperation Processes:

For the interference fit between stainless steel inserts and aluminum substrates (with a tolerance control of ± 0.015mm), a five axis linkage CNC is used to complete high-precision cavity machining of the aluminum substrate in one go, ensuring an overall flatness of<0.05mm after assembly.

All components are immediately chemically passivated (in accordance with ASTM A967 standard) after machining and assembled in a clean workshop.

3. Full Digital Quality Control and Transparency:

Customers have visibility through a project portal to inspection reports from CMM inspection (critical mount hole position accuracy ≤ φ0.03mm), surface roughness information (Ra 0.8μm), and assembly videos in real-time to allow virtual inspections over a distant connection.

Quantifiable Results

- Cost: Total Cost down to $16,800, direct savings of 40%.

- Time of Delivery: Only 2 weeks passed before the order reached us in the US, which is 6 weeks early.

- Quality and Performance: Protos successfully completed waterproof testing to IP65 and accelerated abrasion testing, meeting the expected life of 150% beyond the required standard on the first attempt at acceptance testing.

Want to replicate similar cost reduction and efficiency gains? Contact JS Precision, tell us your project needs and pain points, and we will tailor a high-precision prototyping services solution for you, allowing you to control costs while accelerating time to market.

What Are The Core Differences Between U.S. And China Rapid Prototyping Services Markets?

The main difference in the rapid prototyping services ecosystem and models in the U.S. and China serves as the basis for the development of procurement strategies.

Supply Chain and Costs

- China: The industrial chain is complete, the cost of raw materials is low, and the scale advantage is obvious.

- U.S.: Labor and compliance expenses are high, an established local logistics system, appropriate for urgent deliveries.

Business Models

- Leading Chinese Companies: One-stop service for global clients, emphasizing cost-effectiveness.

- U.S.: Deeply cultivating the local ecology and skilled in rapid concept validation.

| Key Indicators | China Market | US Market |

| Overall Cost | 30-50% Lower | Higher |

| Production Cycle | 3-14 days | 5-21 days |

| Logistics Cycle | Air Freight 5-7 days / Sea Freight 25-35 days | Local 1-3 days |

| Areas of Expertise | Complex Parts, Mass Production | Proof of Concept, Local Collaboration |

How Can U.S. And China Capabilities Accelerate Your Product Development?

By combining the strengths of fast prototyping services in both the US and China, a hybrid supply chain is formed, which ensures the maximal advantages of prototyping and drastically compresses the timing of product development.

Utilizing Speed and Iteration Advantages

- US Local Services: This is for design verification components that are required in 48 hours or less, which provides a very short "design-manufacturing-testing" loop for initial assembly testing.

- High cost-effective service in China: suitable for designing relatively stable functional prototypes, small-scale trial production (50-500 pieces), durability testing and market testing at a cost and performance close to mass production.

Best Practices for a Hybrid US-China Strategy:

- Phase One (Proof of Concept): Employ local 3D print services or local CNC machining in the US to rapidly prove concept ideas.

- Phase Two (Engineering Validation): Distribute the design to a rapid prototyping agency in China, like JS Precision, to produce high-precision prototypes with real material performance testing.

- Phase Three (Production Validation): Use China's competitive costs and scale to perform the first batches of production for validation of the production line and supply chain.

How To Reduce Costs Without Sacrificing Quality With High-Precision Prototyping Services?

In the high-precision prototyping services, cost savings and quality enhancement do not work in opposite directions. A win-win situation is possible through scientific design optimization and planning.

Design for Manufacturability and Cost Optimization (DFM/DFC)

- Standardization and Simplification: Merge multiple parts into a single component to cut down on clamping time, and standardize the corner radii to, for example, R2mm for all corners to eliminate changing tools.

- Tolerance Rationalization: Tolerance the critical mating surfaces, such as press fits for bearings, at ±0.03 mm, but increase the tolerance of non-critical surfaces to ±0.1 mm. This often eliminates the requirement for precision milling, cutting cost.

Order and Supply Chain Strategy

- Batch Consolidation: Even for separate projects, combine orders to help distribute the fixed cost of programming and setup. Orders for 10 or more pieces can offer a substantial savings per piece.

- Phased Payment and Delivery: Create a production allowance only after the acceptance of the very first piece and thereby fix the cost and quality and avoid the phenomenon of scrapped batches.

- Choose a one-stop supplier: JS Precision provides a one-stop high-precision prototyping services, involving machining, sandblasting, and anodizing, thus relieving you of costs associated with managing suppliers.

How To Evaluate The Responsiveness And Reliability Of Rapid Prototyping Companies?

While selecting rapid prototyping companies, time and reliability are factors that end up determining success or failure, and it helps if some specific metrics are adopted in this respect.

Quantitative Indicators of Response Speed

- Quote Timeliness: It should not take professional rapid prototyping company more than 24 hours to answer a comprehensive request package. JS Precision guarantees a preliminary quote response within 12 hours.

- Communication Channels and Frequency: Does the company offer a project manager, use instant messaging communication methods, and send progress information on productions (like daily reports)?

- Problem Solving Time: Is a solution offered for potential problems that may be detected in the design documents in 4 working hours?

Key Checkpoints for Reliability Verification

- Quality System Certification: Does the company have authoritative certifications like ISO 9001? Does the company have a standardized reporting system for FAI (First Article Inspection) that includes CMM (Coordinate Measurement Machine) testing data?

- Technical Documentation Capability: Are the offered quotes, comments for drawing reviews, process suggestions professional?

- Past Client Cases and Assessments: Review their background in representing respective sectors and difficult projects, especially involving clients from Europe and America.

The following table shows JS Precision's service reliability index commitments:

| Service Index | Commitment Standard | Industry Average |

| Quote Response Time | ≤12 hours | 24-48 hours |

| Design Problem Feedback Time | ≤4 hours | 8-12 hours |

| On-Time Order Delivery Rate | ≥99.5% | ≥95% |

| Customer Satisfaction | ≥98% | ≥90% |

| Quality Pass Rate | ≥99.8% | ≥97% |

Worried about choosing the wrong rapid prototype company? Consider starting a small pilot project with JS Precision to experience our responsiveness and service quality firsthand before deciding on a long-term partnership.

FAQs

Q1: What are the typical logistics times and costs for sourcing rapid prototypes from China?

Air freight takes about 5-7 days, and the cost accounts for 10% -20% of the order amount. Sea freight takes about 25-35 days and costs 3% -8%. JS Precision has a regular emergency material warehouse, which can optimize logistics processes and shorten delivery cycles.

Q2: How can we ensure technical requirements are accurately understood when communicating with Chinese suppliers?

Provide detailed 2D drawings (including GD&T) and 3D STEP files. Choose suppliers like JS Precision with bilingual engineering teams and hold online technical review meetings to ensure accurate transmission of requirements.

Q3: How is intellectual property protected?

A Non Disclosure Agreement (NDA) is compulsory. JS Precision Follows strict protocols for encrypting and protecting file accesses. Deletion of project files after completion on demand ensures detailing in protecting clients intellectual properties.

Q4: What is the Minimum Order Quantity (MOQ)?

Usually, there are no MOQs in prototyping, and one-off orders are also accepted. For bulk orders such as 10 pieces or more, unit prices are significantly lowered. JS Precision provides tiered pricing to enable customers to enjoy further discounts based on the quantity of orders.

Q5: What material standards and surface treatments do you support?

We propose materials meeting the standards of ASTM, ISO, DIN, and others: aluminum alloys, stainless steel, and engineering plastics. Surface finishes include anodizing (US Mil-A-8625), electroplating, sandblast finishes, and more.

Q6: Can I visit your factory?

Of course. JS Precision encourages our customers to come and visit our CNC workshop, quality control lab, and assembly site in person or via video conferencing so that you can have a clear understanding of our production process.

Q7: Will time differences affect communication efficiency?

Our customer support team in the US is available for local working hours to ensure that we can be contacted readily. Our factory support staff work 24/7 to offset the effects of the time difference.

Q8: Does my prototype require special certifications (such as FDA, USP Class VI)?

Remedies may extend to the provision of biocompatible material (medical-grade PEEK or titanium alloys), cleanroom processing, or the preparation of associated paperwork to suit a given business or industry.

Summary

Geography has ceased to be a boundary to technological capabilities, but a dimension of strategic resource allocation.

The market advantages of Rapid prototyping services in China and the United States complement each other, and the manufacturing and cost advantages of Rapid Iteration in the United States and Rapid prototyping China form an efficient product development ecosystem.

Well, wise decision-makers will select a partner to bridge the geographical and cultural gap which then possesses international service capabilities. Equipped with 27 years of industrial experience, advanced technology, and equipment, transparent service processes, highly competitive cost advantages, JS Precision is your ideal bridge to the Chinese supply chain.

Take immediate action and use global resources to your advantage. Upload your design files to JS Precision, and we will provide you with a free DFM analysis, accurate quote, and delivery solution within 12 hours, and help bring your innovative ideas to market at a lower cost and faster speed with a fistful of advantages.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com