Silicone rapid prototyping is an essential technology for any prototyping involving flexibility, sealing, or biocompatibility.

From the sealing of gaskets in medical devices to waterproof components in consumer electronics, obtaining high-quality silicone prototype fast will significantly speed up your R&D process and reduce your development risks.

The following guide walks through the entire process of silicone rapid prototyping to help you understand the core knowledge of silicone rapid prototyping.

It also shares how JS Precision, through advanced rapid tooling technology and professional experience, provides a one-stop solution for you from concept to custom silicone parts, avoiding detours and efficiently advancing your project.

Answer Key Summary

| Comparison Dimensions | Silicone Rapid Prototyping Technology | JS Precision's Professional Solution |

| Technical Essence | It is the general term used for rapid prototyping silicone rubber parts in small batches using rapid tooling technology. | Solutions range from 3D printed molds to aluminum rapid tooling, exactly matching project stages and requirements. |

| Core Process | End-to-end from CAD models to vacuum casting or injection molding. | Optimized integrated process, covering design review, mold manufacturing, silicone molding, and post-processing. |

| Mold Strategy | Rapid tooling has major cost and speed advantages over conventional steel molds and therefore is an effective choice for prototyping and small-batch production. | We recommend the most economical tooling solution based on production volume and cycle time, proactively controlling upfront investment for our clients. |

| Professional Requirements | There are strict requirements in medical-grade silicone prototype concerning material certification, clean production, and testing of biocompatibility. | We have an ISO 13485 certification, make use of USP Class VI silicone, and support early biocompatibility assessments for medical devices. |

Why Trust This Guide? JS Precision Shares Core Rapid Prototyping Processes

Over 10 years, JS Precision has been deeply involved in the area of Silicone Rapid Prototyping and rapid prototyping. We are not only ISO 9001 quality system certified but also have served over 500 clients from the medical, automotive, and consumer electronics industries, accumulating over 10 industry cooperation certifications in the medical and automotive sectors.

In the automotive sector, we have developed functional prototypes for battery pack waterproofing structures and cushioning components for three new energy vehicle firms, and helped them shorten their test cycles by 40%.

In the consumer electronics sector, we have optimized the tactile feel of soft components in more than 300 handheld devices, including watchband designs for two smart wearable device manufacturers.

Of course, these are not empty talk, they are the result of our repeated efforts to address customer pain points. This guide is a breakdown, summary, and overview of these experiences, covering definitions and processes to do with fixing issues that you will actually encounter, thus, you can totally trust it.

If you need Silicone Rapid Prototyping services, JS Precision can meet your needs with extensive experience and authoritative qualifications. You just need to provide a 3D model, we will do design analysis and then go into production, transparent steps will be taken on each project to help you get quality silicone prototype in an efficient way.

What Is Silicone Rapid Prototyping And When Do You Need It?

Having discussed the credibility of the guide, you must be wondering what Silicone Rapid Prototyping really is and when to use it. I will explain it clearly below in two parts.

What is Silicone Rapid Prototyping?

Silicone rapid prototyping refers to a set of technologies that use various rapid manufacturing molds to produce small batches of silicone parts. It is the necessary step prior to the final hard tooling to confirm design, functionality, assembly, and market feedback.

This technology has helped many customers identify flaws in the design before mass production, thereby saving them from greater losses later on.

Typical Application Scenarios

1.Functional testing: Includes seals, waterproofing structures, and cushioning components that are necessary for the correct performance of real-life applications.

As an example, we have tested silicone seals for automotive sensors on behalf of automotive electronics customers, simulating rainy driving conditions to ensure that those indeed are waterproof and highlight the design deviations well in advance.

2.User Experience Evaluation: Testing the tactility and ergonomics of soft components in handheld devices with respect to making the product more comfortable to use.

3.Preclinical Trials: The development of prototypes of medical devices for animal or laboratory testing in order to prepare for subsequent medical certification.

4.Marketing and Crowdfunding: Making quality display samples for promotional activities or crowdfunding sites to attract prospective customers and investors.

Figure 1:A silicone prototype is a physical model of a product made from silicone material. You can use it to test designs, evaluate functionality, and validate ideas before mass production.

From Digital To Physical: How Are Silicone Prototypes Made?

Now that you know when you need a silicone prototype, the next question is how it's made from a digital 3D model to a physical silicone part. There are two main methods, which I'll explain below.

Vacuum Casting

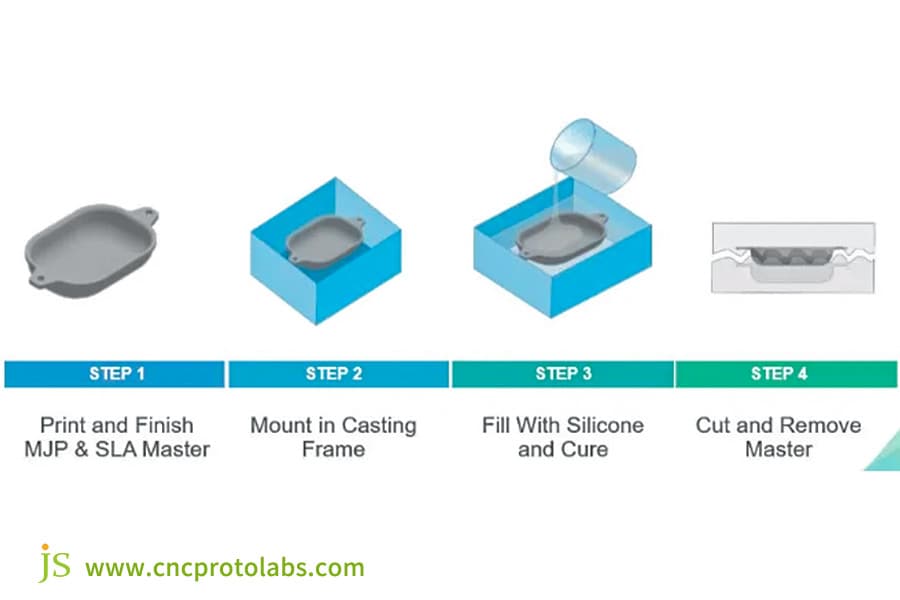

A soft silicone mold is replicated using a master template, usually 3D printed or CNC machined. Liquid silicone is then injected into the cavity and cured under vacuum.

We control the vacuum degree below -0.095MPa to avoid air bubbles, which is very important for a silicone prototype appearance pass rate of over 99%. This process is usually recommended for many customers with small-batch needs.

- Advantage: Extremely low mold cost, fast speed, and perfect for getting 5-30 prototypes made from silicone, with excellent appearance and performance.

- Disadvantages: short mold life-approximately 15-25 cycles, unsuitable for mass production.

Rapid Prototyping

Production is done with the use of rapid tooling, such as aluminum mold or soft steel mold, and a dedicated liquid silicone injection molding machine.

For example, for the production of silicone buttons with metal contacts for consumer electronics customers, we use precision tooling to ensure that insert coaxiality error is ≤0.05mm. This kind of approach will be more suitable for customers who have certain batch requirements.

- Advantages: Good consistency in part quality, can be molded with inserts, longer mold life (hundreds to thousands of cycles) serving as a bridge to small-batch production.

Figure 2:RTV silicone casting, a cost-effective and rapid production method that excels in crafting visual representation prototypes quickly.

The Engine Of Speed: What Is The Process For Rapid Prototyping Silicone Rubber Parts?

After understanding the two manufacturing methods, you might want to know how JS Precision specifically completes the rapid prototyping silicone rubber parts step by step. Now, I will introduce our standardized six-step process to help you understand what each step entails.

1. Design Analysis and DFM: We will review your 3D model, perform dimensional pre-compensation considering the 1.5-3% shrinkage rate for silicone, and give suggestions for draft angle modification and revision in parting line position according to the nature of the silicone to avoid consequent problems in production.

2. Master/Mold Processing: Depending on the process you require, we apply photopolymerization technology SLA/DLP/LCM (layer thickness 0.05mm, surface roughness Ra less than 0.8μm) or CNC machining to manufacture high-precision master molds or rapid tooling.

3. Material Preparation and Color Matching: Choose liquid silicone of suitable hardness and performance. For example, Shore 50A silicone is recommended for anti-slip handles. Precise color matching is also performed to make sure it meets your appearance and usage requirements.

4. Vacuum Casting/Injection Molding: Silicone molding is executed within an environment strictly controlled, such as a cleanroom, to ensure quality in all the parts produced.

5. Curing and Post-treatment: Heat treatment and curing are done, followed by edge removal and flash cleaning to make the parts more uniform.

6. Fully Inspected and Delivered: Rapid prototyping silicone rubber parts are inspected dimensionally, in appearance, and functionally to meet your requirements prior to delivery.

How Does Rapid Tooling Compare To Traditional Molding on Cost?

Once you understand the process, cost is no doubt your top concern: just how much difference is there between the cost of rapid tooling and traditional molding? Below, for your convenience, I have included a quantitative comparison in tabular form.

Quantitative Comparison of Cost Differences

| Comparison Item | Rapid Tooling | Traditional Steel Mold |

| Upfront Mold Investment | Low to Medium 60%-80% reduction. | Very High. |

| Mold Manufacturing Cycle | Several days up to 2 weeks. | 3-8 weeks. |

| Cost/Unit | Medium to High - Suitable for small batches. | Very low - Suitable for very large batches. |

| Flexibility of Design Modification | High, low cost of modification, fast pace. | Low, high cost of modification, slow pace. |

Strategic Significance

Rapid tooling allows the production of hundreds to thousands of custom silicone parts cost-effectively before large investments in steel molds. In this way, proper market testing and design iteration is possible, significantly reducing overall project risk and financial pressure.

For example, one customer in consumer electronics used our rapid tooling to create 200 prototypes of a silicone watchband and saved almost $30,000 in upfront investment. In fact, many customers use this method to optimize their designs before mass production.

If high upfront mold investment is a concern, JS Precision's rapid tooling service will lower mold costs by 60-80%, produce custom silicone parts in record time, reduce project risk, and is suitable for small-batch needs.

Figure 3:From an economic perspective, rapid prototyping typically requires lower initial investment, while traditional mold manufacturing requires significant upfront investment in manufacturing.

What Are The Special Requirements For Medical-Grade Silicone Prototype?

If your project relates to the medical field, special requirements that relate to the medical-grade silicone prototype have to be understood. It has a direct relation to subsequent testing and registration, these things cannot be taken lightly. Three core requirements are explained below.

1. Material Certification: The raw material of silicone should be biocompatible, USP Class VI certified, ISO 10993 certified, or FDA certified. This forms the very basis of medical safety.

2. Clean Manufacturing: Manufacturing, in particular post-curing, is to be done in a Class 10,000 cleanroom (ISO Class 8) at constant temperature and humidity conditions of 23±2℃ and 50±5%, respectively, to avoid microbial and particulate contamination.

3. Full Traceability: Complete documentation, from material batch numbers and mold parameters down to the production batches, involves supplier information, inspection reports, and the names of operators. This means that all custom silicone prototypes are traced with ease, which is very important for medical device registration applications.

Designing For Success: What Are The Key Guidelines For Custom Silicone Parts?

Early design plays an important role in the creation of high-quality custom silicone parts. Many problems can be traced back to incorrect design. Here are some basic design guidelines to keep you from making some common design mistakes.

1. Even Wall Thickness: The wall thickness should be kept between 0.5 and 5mm. If the thickness is too small, it's easy not to fill up completely, if the thickness is too large, it's easy to form an air bubble.

Once, we optimized a sealing gasket from 0.3mm to 0.6mm to solve molding defects for a client. That ensured that the shrinkage was even for the part without any mark, warping, or internal stress. This is the foundation of ensuring part performance.

2. Adequate Draft Angle: At least 1° to 3° must be provided to ensure that the part can be smoothly ejected from the mold to avoid tearing and loss in production.

3. Reasonable Parting Line Design: The optimal positioning of the parting line should be determined in cooperation with engineers and placed on a non-critical appearance or functional surface to avoid affecting product use or aesthetics.

4. Avoid sharp internal corners: For parts with a wall thickness less than 1mm, the radius (R) should be ≥0.2mm, for parts with 1-3mm wall thickness, the radius should be ≥0.5mm. The corners must be sufficiently rounded to distribute stress, improve material flow, and extend mold life.

5. Consider insert molding: During the design phase, when metal or plastic inserts are put in, certain areas of precise positioning structures must be reserved to ensure insert stability.

In addition to producing custom silicone parts, JS Precision offers design review services for the optimization of details in wall thickness and draft angles that allow for a smooth, high-quality production process in creating your custom silicone prototypes.

Finding The Right Partner: Where To Get High-Quality Custom Silicone Prototypes Services?

Having design and process knowledge is important, but choosing the right service provider is equally crucial. A good partner can save you a lot of trouble. Below, I will tell you the five criteria for selecting a high-quality service provider to help you find a reliable partner.

1. Technical and Process Breadth: Do you provide vacuum casting along with rapid molding? We have 3 vacuum casting machines and 2 injection molding machines, capable of producing different batches of orders in parallel to fulfill your needs at various stages and avoid frequent changes in service suppliers.

2. Material Knowledge and Inventory: Do you offer an assortment of different hardness, color, and property medical-grade/food-grade silicones? We are in stock with USP Class VI and FDA-certified silicones, covering hardness from 10A to 80A, and we also offer high tear-resistant and high-temperature resistant silicones for quick matching according to your needs.

3. Industry Experience and Qualifications: Have you got experience serving the medical, automotive, or consumer electronics industries with corresponding quality system certifications to ensure reliable service?

4. Engineering Support Capabilities: Does your team provide detailed manufacturable design reviews-not just fabrication based on your drawings-to help you optimize your designs?

5. Transparency and Collaboration: Is your pricing transparent? Is the communication effective? Can you be a reliable extension of your R&D team to keep yourself abreast of project developments?

JS Precision fully meets all five standards necessary for a premium service provider, with diverse processes, abundant material inventory, and industry qualifications. They offer engineering support and seamlessly collaborate to provide the best option for obtaining custom silicone prototypes.

Case Study: From 12 Weeks To 12 Days – Accelerating A Medical Pump Diaphragm To Clinical Trial

Having discussed so many theories and methods, let me use a real case to give you an intuitive feeling of the value of Silicone Rapid Prototyping.

Challenges Faced by the Client

A medical startup developing a novel infusion pump required a precision silicone diaphragm prototype for preclinical testing.

Traditional mold-making solutions had a lead time of 12 weeks with tens of thousands of dollars in cost, which would not only delay progress toward funding milestones but also have the potential to miss critical certification deadlines. The anxious project team was pushing forward constantly.

JS Precision Solution

Since receiving the enquiry, JS Precision has gone through deep communication with the client and identified the core pain points: urgent delivery and high cost.

Accordingly, we applied the rapid tooling approach by making an aluminum alloy material for the simple mold core. The machining accuracy of the aluminum alloy mold core is controlled within ±0.02mm to meet the requirement for diaphragm sealing performance.

In the meanwhile, since the prototype was for a medical test, we chose biocompatible liquid silicone that is certified by ISO 10993. The whole production process, including post-curing, was done in a Class 10,000 cleanroom, LSR injection molding was used in order to make the prototype suitable for the needs of medical testing.

Final Results and Data

Finally, we finished the delivery of 50 prototypes in only 12 working days, saving almost 80% of the time compared to traditional methods, and saving 85% on mold costs.

After receiving the prototypes, the client successfully completed the first round of animal trials and reported that "the prototype performance completely matched the design expectations." Later, based on our professionalism, the client entrusted us with the prototype production of their cardiovascular device project.

If any similar challenges are faced concerning time or cost, JS Precision rapid tooling service can assist you in quickly delivering compliant silicone prototype by shortening lead times and saving costs as showcased in this case study, thus contributing to project success.

Figure 4:Injection molded medical silicone diaphragm

FAQs

Q1: What is the typical lead time for silicone rubber prototypes?

There are different lead times depending on which manufacturing process is required. For silicone rubber prototypes vacuum casting, the typical lead time is from 3 to 7 days. If rapid injection molding is required, lead times take about 2-3 weeks depending on the part complexity.

Q2: How many copies can I get from vacuum casting?

In making silicone prototype via vacuum casting, a single silicone mold can make 15 to 25 parts of high quality, the number depending upon part complexity and operation.

Q3: What is the difference between rapid tooling and production tooling?

Rapid tooling would normally use aluminum or mild steels that are low-priced, rapid turnaround, and appropriate for prototype creation or small-batch production. Production tooling involves hardened steel. This provides a long lifetime, thus making this material suitable for large-scale manufacturing of millions of components.

Q4: Can I get transparent or colored silicone prototypes?

Yes, JS Precision provides transparent, semi-transparent, and various color silicone prototype depending on aesthetic and functional needs.

Q5: What are the key design considerations for silicone parts?

When designing custom silicone parts, uniform wall thickness, enough draft angle, and correct corner radius and parting line design are important. These prevent shrinkage marks, tearing, and other problems.

Q6: What hardness levels are available for prototypes made of silicone?

JS Precision provides silicone prototype with common Shore hardness ranges from the very soft Shore 10A to the harder Shore 80A. You can choose according to your actual needs.

Q7: Do you provide material certifications for medical-grade silicone?

Yes, for medical projects, JS Precision will be able to provide a full set of biocompatibility certifications like USP Class VI and ISO 10993, which meet the requirements for medical-grade silicone prototype.

Q8: What is the maximum size of silicone prototypes you can produce?

The capabilities of vacuum casting and rapid prototyping at JS Precision include making silicone prototype, which range in size from several millimeters to about 500 millimeters. This can meet the size requirements of most customers.

Summary

Silicone rapid prototyping is a crucial capability in turning innovative ideas into reality. In today's increasingly competitive market environment, speed, quality, and professional guidance are all indispensable.

No matter your needs for silicone prototype or custom silicone parts in medical, automotive, or consumer electronics, the know-how of JS Precision will enable you to reach your goals. We are committed to being your strategic partner in developing flexible and sealed components, mitigating risks, and creating value from the design stage onwards.

Complicated process decisions shouldn't hold you back from innovating. Send us your silicone part design files today and receive a comprehensive solution complete with professional DFM analysis and a transparent quote. Join JS Precision and accelerate your process to turn your next great idea into a tangible reality.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com