Molded rubber products play a vital part in most industrial applications.

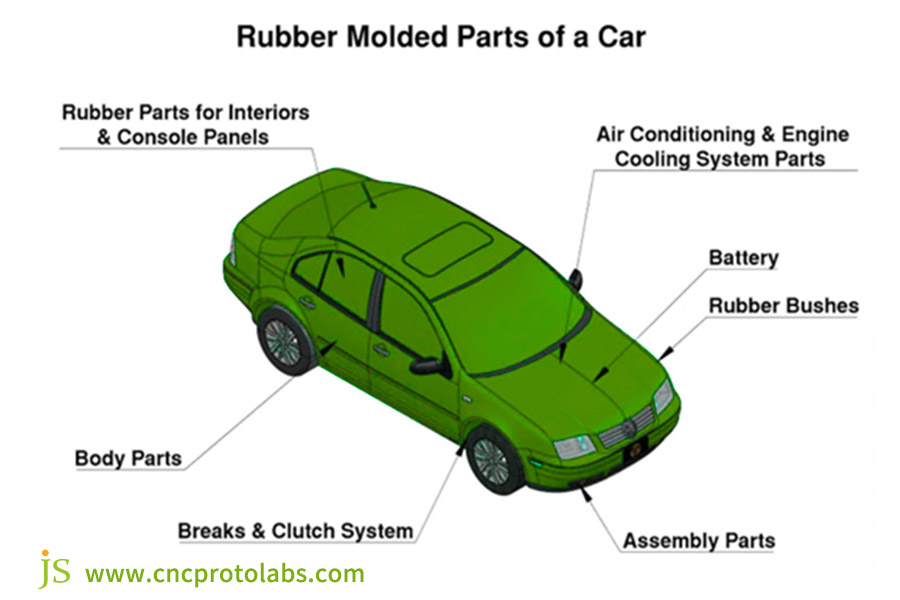

In the automotive industry, components of a car such as brakes, clutch seals, and battery washers cannot help but utilize rubber parts. The performance of rubber directly affects the durability, safety, and overall performance of the vehicle; In the aerospace industry, rubber products must be able to create complex, custom shapes with close tolerances. In the chemical industry, rubber is the ideal choice for gaskets, seals, and custom components in chemical processing systems.

In addition to durability, all of these application circumstances also require rubber products to be able to create components, parts, configurations, and designs suitable to the purposes at hand. The key to meeting those requirements is in the rubber molding process - the art of converting elastic materials into precision parts.

For engineers, designers, and manufacturers committed to producing high-quality rubber products, understanding the complexity of this process is crucial. This guide will provide a detailed explanation of the rubber mold production process, selection of core materials, comparison of the three major molding processes, and analyze the key factors that affect the cost of custom injection molding manufacturing.

To save you time, here is a quick summary of the key findings.

Summary Of Core Answers:

| Point | Description | The value to you |

| Core process | Using molds to form rubber under hot pressing. | Produce complex parts with high elasticity and high sealing performance. |

| Key materials | Silicone, EPDM, NBR, etc. | Meet strict requirements such as temperature resistance, oil resistance, and biocompatibility. |

| Challenge | Bubble elimination (degassing is key). | Ensure that the product is defect free and reliable in performance. |

| Manufacturing selection | Customized molds+professional production services. | Obtain injection molding parts that are cost-effective and meet the requirements. |

Why Is It Trustworthy? Practical Experience Sharing In Rubber Molding

JS, with its its several decades of design expertise and rubber material understanding, leverages current design and manufacturing technology to provide rapid prototyping and on-demand manufacturing molding services. We have our own technical personnel, advanced factories and machinery to ensure cost-effective production.

We know the flow behavior and vulcanization of rubber. With medical clients rejected for FDA acceptance by bubbles in 0.1mm grade silicone tubing, our patented gradient vacuum demolding system collapsed the size of residual gas to one millionth, helping 36 medical device makers pass Class III audits. Our speciality is in resolving trapped gas troubles in complex structures.

Additionally, our long experience in mold design, composition of materials, and process parameter optimization ensures that products manufactured by us are bubble-free, possess precise dimensions, and are according to performance specifications.

Full Analysis Of Rubber Mold Production

Precision molds are the cornerstone of rubber molding, and their design and manufacturing directly determine the formability, part quality, and efficiency. The mold must be able to achieve good material flow, easy demolding of parts, and minimize defects.

Mold Material Selection - Balancing Durability and Cost

| Steel mold (P20/H13/stainless steel) | Aluminum mold | |

Durability |

Hardened steel has become the most commonly used material due to its high hardness, wear resistance, and corrosion resistance. Extremely durable and capable of achieving high-quality surfaces. | Fast manufacturing, easy modification, but short lifespan and limited detail performance. |

Cost |

With a high price and long manufacturing cycle, it is suitable for large-scale injection molded parts production. | Low cost and suitable for prototype validation and small batch orders. |

Creating precision molds:

- Design first: During the design phase, it must be designed to design the parting surface and sprue in a way that the mold will have the ability to produce the part size and shape requested; In injection molding, it must be designed for the draft angle so that the parts will be removed smoothly from the mold without getting damaged; The core needs to design exhaust slots or vacuum interfaces so that the mold is able to exhaust fully.

- Accuracy machining: Computer numerical control (CNC) milling/turning of core body structure and forming cavity. Here, computer numerical control (CNC) machine tools are typically used for precise cutting, forming, and surface finishing of mold components to precisely create custom molds as per the design specifications, minimize the time consumed in the manufacturing of rubber molds, and render production efficient and accurate.

- Detail carving: EDM (electric discharge machining) machines small details or intricate textures.

- Surface treatment: The smoothness of the surface of the mold cavity will affect the texture and quality of the final product.The surface must be polished to the required smoothness to ensure easy demolding of the parts and to ensure that the formed components meet all specifications and quality standards.

- Degassing system integration: Processing precision exhaust grooves (depth 0.01-0.03mm) or installing vacuum sealing components. The exhaust mechanism can allow the trapped air during the molding process to escape, which is crucial for producing defect free parts.

- Assembly: Assemble all mold parts, including the top rod and cooling channel, to complete the use of the mold.

- Testing: including process capability research, visual and dimensional inspection, and functional testing, aimed at ensuring that molded parts are free of defects and surface imperfections, and meet specified tolerances and functional requirements.

Improper mold design is a catalyst for molding defects, which can be costly and difficult to solve as they are in the later stages. Therefore, a correct and appropriate mold design process is particularly important. At JS, we provide you with the best quality service, including mold design and production.

Process Comparison: In-Depth Analysis Of The Three Major Rubber Molding Technologies

There are three main types of rubber molding, including compression molding, transfer molding, and injection molding.

- Compression molding: One of the oldest and most direct methods of rubber molding. Place the pre weighed rubber material directly into the open mold cavity, close the mold, apply pressure and heat to shape the rubber into the desired shape.

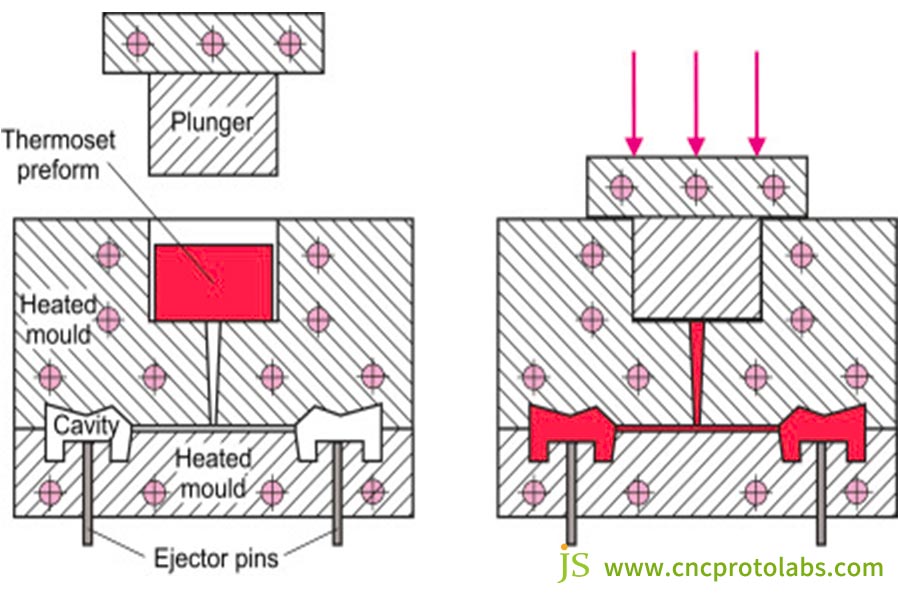

- Transfer molding: It bridging the gap between compression molding and injection molding. The rubber material is preheated and formed in an independent cavity, and then pressed into a closed mold cavity through a gate.

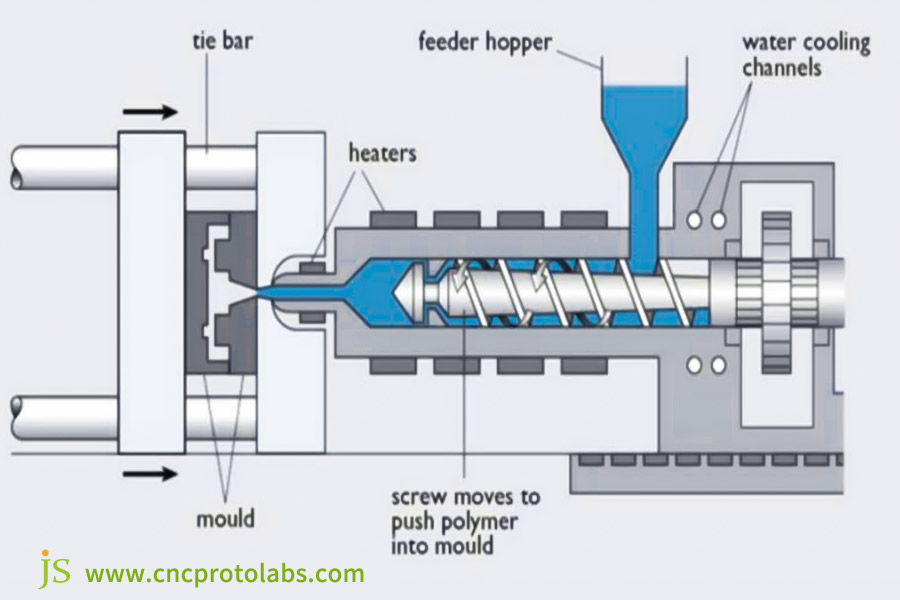

- Injection molding: It's an efficient and automated process suitable for large-scale production. The rubber material is continuously fed into the filling cylinder of the injection molding machine, and injected into the gating system of the mold through the injection nozzle to fill the mold cavity. After curing is complete, open the mold and demold the product. After the rubber is emptied, the machine can repeat the process.

The advantages and disadvantages of these three methods are analyzed as follows:

| Compression molding | Transfer molding | Injection molding | |

| Advantages | Simple mold, economical and efficient. | Compared with compression molding, it can achieve more complex designs; High process efficiency and short mold loading time; The dimensional accuracy is better than compression and less flash, and the flow process of the rubber material is conducive to the discharge of some gases. | The highest long-term efficiency, high degree of automation, and optimal accuracy. |

| Disadvantages | Long cycle, slightly lower accuracy, high dependence on natural exhaust of the mold, easy to produce burrs and bubbles. | The mold is complex, the material is prone to wear and tear, and the tolerances of the produced parts may not be strict. | The initial investment in molds and equipment is the largest (cost is shared among large quantities of products, with lower unit costs), and high-speed injection is prone to air entrapment, requiring the most stringent degassing requirements and often requiring vacuum assistance. |

| Applicable scenarios | Production of large, simple, and durable components. | Products that require high precision and support high output operation. | Suitable for mass production and high-precision components, it is crucial for manufacturing high-quality and durable parts used in industries such as automotive, electrical, medical, and consumer goods. |

In short, each method has its unique advantages and ideal application scenarios, and should be selected based on the required output, part complexity, and material specifications. Do you want to choose the best molding technology for your project? The JS technical team is always ready to provide professional solutions.

The Key To Success Or Failure - Rubber Mold Degassing Technology

Why is degassing the lifeblood of rubber molding?

- Bubble hazard: The retention of air or bubbles in molded parts is one of the most serious defects in the molding process, which can lead to product weakening, leakage, appearance defects, and premature failure.

- Rubber properties: less fluid than plastic, easily wrapped in air; Sulfurization produces gas.

Four mainstream degassing solutions:

- Mold exhaust groove: Micro grooves are set at key positions of the mold, with precision designed micro grooves (depth 0.01-0.03mm) to allow gas to escape but block adhesive.

- Vacuum assisted molding: After the mold is closed, vacuum is applied to completely eliminate the gas in the mold cavity and rubber material (optimal effect, especially suitable for injection molding).

- Pre degassing of rubber material: Vacuum treat the mixed rubber material before feeding to reduce the amount of raw material gas.

- Process parameter optimization: Control injection/transfer speed, pressure, and vulcanization temperature curve to reduce gas generation and encapsulation.

Professional tip: For critical medical or automotive components, vacuum assisted+precision mold exhaust is the golden combination to ensure zero defects.

Whether your application scenario is in an automotive processing plant or a hospital, as long as it involves rubber mold degassing technology, JS can provide a reliable solution.

FAQs

What rubber materials are available?

Different rubber compounds have different elasticity, tensile strength, and durability. For example, nitrile rubber (NBR) is resistant to oil and chemicals and is commonly used in the manufacture of O-rings, gaskets, and seals; Ethylene propylene diene monomer (EPDM) is heat-resistant, light resistant, and ozone resistant, and is widely used in steam systems, automotive panels and braking systems, electrical insulation, and other fields; Silicone rubber plays an important role in fields such as electronics, automotive, and healthcare due to its extreme temperature resistance, weather resistance, and biocompatibility.

Where can I find reliable suppliers of rubber molded products?

JS provides excellent online injection molding services. We offer one-stop customized rubber mold manufacturing from design review, mold manufacturing to mass production for your injection projects, and are particularly skilled in solving degassing problems. You can save enough time and money while obtaining high-quality products.

What are the factors affecting the injection molding price of rubber injection molded parts?

- Material cost: The cost of rubber materials used in the injection molding process is greatly affected by the type of material, market price, and usage.

- Mold cost: One of the largest expenses in injection molding. When it comes to customized injection molding manufacturing, mold costs will increase.

- Process selection: The initial investment in injection molding equipment and molds is relatively high.

- Degassing requirements: Vacuum systems increase costs.

- Output and tolerance: Higher precision will lead to higher costs.

Is it feasible to produce rubber parts in small batches?

- Aluminum mold compression/transfer molding or the use of shared mold solutions from online injection molding service providers can effectively reduce small batch costs.

- For small batch injection molding, 3D printing can be used to effectively reduce mold manufacturing costs.

Summary

Mastering the production of rubber molds, material selection, process comparison (especially injection molding), and core degassing technology is the key to obtaining high-performance, defect free rubber products. This is not only a process, but also a system engineering to ensure product reliability.

Whether you need to develop precision medical silicone components or durable industrial sealing solutions, JS provides professional rubber molding and customized injection molding manufacturing services. Get Injection Molding Price now, upload your design requirements, and our engineers will evaluate the optimal process solution for you, overcome the difficulty of degassing, and deliver perfect rubber parts!

Disclaimer

The contents of this page are for informational purposes only.JS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Longsheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com