CNC turning has permeated into the core of modern manufacturing—think about a complicated metal blank, in a few minutes turned into a smooth and precise mechanical part with dimensional tolerances smaller than the diameter of human hair.

From precision connectors in medical implants to automotive engine shafts, this computer-driven rotary machining process is setting standards for the production of high-precision parts.

How does it work? What value can it add to your project? More importantly, how can you make sure you're getting parts of the highest quality and best cost-effectiveness? This guide fully demystifies CNC turning and reveals why JS Precision, based in China, is your perfect partner for seamless design-to-finish.

Core Answer Table

| Overview | Key Technologies | Value Created for You |

| Precision Capability | Precision CNC turning realizes precision within ±0.025mm, depending on the high rigidity of the equipment and closed-loop control. | Ensures part consistency and precision assembly. |

| Cost-Driven | Material, design complexity, order volume, and tolerance requirements determine the cost of the service. | Helps you optimize your design to control your budget. |

| Main Equipment | The modern turning center integrates turning, milling, and drilling functions. It can allow complex parts to be one-time formed. | It improves efficiency and precision of the complex part and shortens the cycle time. |

| Process Scope | Encompasses different types of turning, and special tools are provided to meet special requirements like end face grooving. | Capable of overall machining on various designs. |

| Process Solutions | It solves problems like thin-wall deformation and deep groove machining by process optimization and specialized tools. | Ensuring the successful machining of complex parts and reducing risks. |

| Benefits of Partnering with JS Precision | By integrating advanced equipment, professional process, and efficient supply chain, value-for-money services are offered. | Obtain a reliable manufacturing partner capable of balancing quality and cost. |

Precise CNC Turning By JS Precision: Core Parameter Analysis

To truly master CNC turning, the control of core parameters is the foundation. The process parameter optimization of JS Precision follows the relevant specifications for single point turning tool life testing in the International Organization for Standardization (ISO) ISO 3685:1993 standard, which provides a theoretical basis for the scientific selection of cutting parameters.

In more than 15 years of development, JS Precision has optimized over 2000 sets of CNC turning process parameters, forming customized solutions for different materials and part structures.

For instance, in ultra-thin shaft parts with a diameter of 0.5mm, we adjusted the parameter settings of the spindle at 12000rpm and feed at 0.005mm/rev with professional micro-tools to achieve ultra-high precision of ±0.003mm.

In mass production of automotive transmission gear shafts, by optimizing cutting speed and cooling solutions, we increased production efficiency by 30% and controlled the scrap rate to below 0.1%.

These working experiences about real projects have given us deep understanding of pain points in every aspect of CNC turning. Therefore, this guide contains no abstract theory but only the practical knowledge which could be directly applied. You can completely rely on our professional judgment.

Want to have the main CNC turning parameters that will be suitable for your parts as soon as possible? Please provide the material and precision requirements of the part, and we will send a free parameter reference scheme. In addition, there is a free "Process Parameter Optimization Manual" for your direct use.

What Is CNC Turning? A Rotary Process In Modern Manufacturing

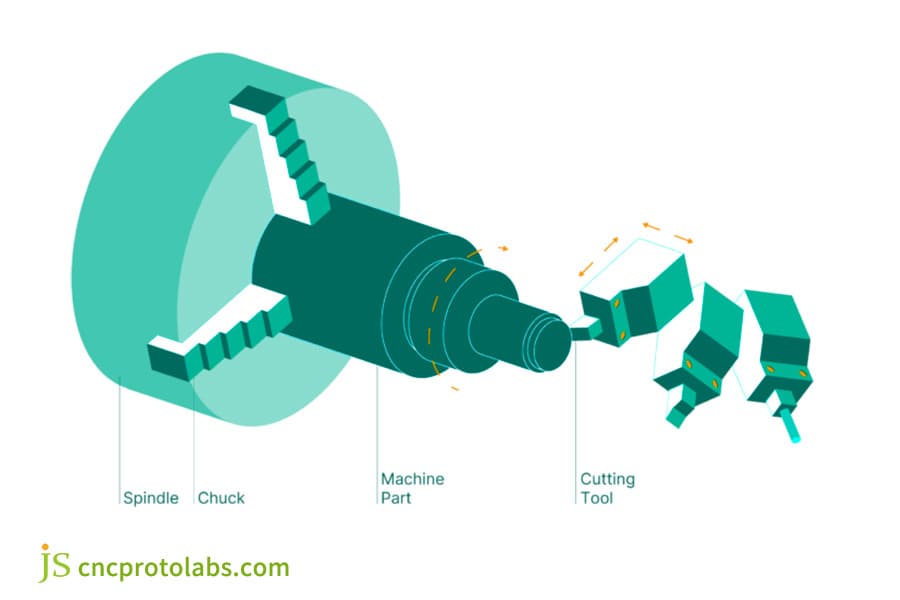

The first step in using the process of CNC turning effectively is to understand its essence. It involves a precision process of machining wherein, by the use of computer programs, one directs a machine tool, and relative to the cutting tool, the rotating workpiece is enabled to move. By material removal, rotationally symmetrical parts, such as cylinders and cones, form the result.

It is based on a very simple working principle: conversion of the CAD model to G-code followed by drive through the CNC system to eventually carry out the machining.

In contrast, traditional machining has three primary advantages of CNC turning: high repeatability means consistent precision in batches of parts, the ability to machine complex shapes, including grooves and threads, and superior surface finish reduces subsequent grinding operations that lower production costs.

Figure 1 The working principle of CNC turning. The cutting tool moves in a straight line along the surface of the rotating workpiece and cuts the material along the circumference.

How Does Precision CNC Turning Achieve Micron-Level Precision?

Precision CNC turning precision at the level of a micron is the synergistic effect of three pillars that construct a robust precision assurance system: machine tool, system, and cutting tool.

Rigid Structure and Thermal Stability

Machine tool rigidity and thermal stability are the foundation of precision. The bed of the CNC lathe is made of high-strength cast iron with hardened and ground guideways, and high-precision ceramic bearings to minimize vibration. The constant-temperature cooling system keeps temperature fluctuations within ±0.5℃, and prevents thermal deformations.

Closed Loop Control System and Feedback

The closed-loop control system is the very core of precision, which, in an equipped way with a linear encoder and high-precision encoder, provides real-time feedback on tool and workpiece position. It immediately compensates for even the slightest deviation in its course and reaches positioning accuracy as high as 0.001mm for precision CNC turning.

Tool Selection and Wear Management

High performance tool, wear control is directly related to precision. We focus on coated carbide and CBN/PCD tools. With high hardness and wear resistance, sharpness in high-speed cutting is guaranteed.

Meanwhile, the sensor on the machine tool monitors tool wear in real time, immediate replacement right after reaching the threshold will prevent the precision from degradation.

What Determines The Cost Of CNC Turning Services?

The prices for CNC turning services are not set arbitrarily but flow from such factors like materials, the complexity of machining, and batch size. Being aware of these factors will help you manage your costs better.

Materials and Preparation: From Blank to Finished Product

Material costs are fundamental. Different materials possess quite different costs, for example, titanium alloys are far more expensive than ordinary steel. A large discrepancy between the blank size and the finished product may result in waste. An appropriate blank improves utilization and reduces unit price.

Geometric Complexity: Time is Money

These are increased by the number of part features, special structures like deep holes, slender shafts, and thin walls and strict tolerances that raise programming and machining time and, therefore, costs.

Batch Size and Post-Processing: Economies of Scale and Added Value

Batch production can spread fixed costs such as programming and fixture preparation, the larger the batch size, the lower the unit price. The post-processing steps such as painting, electroplating, and heat treatment will add up the cost depending on the type of the process.

| Cost Breakdown | Key Influencing Factors | Cost proportion (reference) |

| Material Costs | Type of material, size of blank, utilization rate. | 30%-50% |

| Machining Costs | Number of features, tolerance requirements, structural complexity. | 20%-40% |

| Setup Costs | Programming time, fixture preparation, trial cutting and debugging. | 10%-20% |

| Post-processing Costs | Heat treatment, surface treatment, assembly. | 5%-15% |

Want a clear cost breakdown of CNC turning services? Specify the batch size of the parts, material, and machining requirements, submit your request form, and we'll give you a detailed quote within 2 hours to help you identify the key cost-saving points.

CNC Turning Center Vs. Traditional Lathe: Evolution And Selection

The selection of turning machining equipment is directly related to efficiency and cost. The evaluation of equipment performance can refer to the specifications for the inspection conditions of CNC lathes in the International Organization for Standardization (ISO) ISO 13041-1:2020 standard, which provides an international benchmark for equipment capability assessment.

Accordingly, there are many uses of CNC turning centers and traditional lathes, and selecting between the two should be determined by needs.

Traditional lathes have flexible operations and low investments, making them suitable for small-batch machining of simple shaft and sleeve parts. Accuracy greatly depends upon the skill of the operator, repeatability is poor, complicated parts are difficult to machine, and efficiency is relatively low.

Modern CNC turning centers represent an evolution of turning machining, integrating milling and drilling power turrets and a Y-axis to achieve mill-turn machining. Multiple operations can be completed in a single setup, reducing positioning errors and significantly improving efficiency, making them particularly suitable for complex parts and mass production.

| Comparison Dimensions | Traditional Lathe (Manual/CNC) | CNC Turning Center |

| Machining Capacity | Suitable for simple rotating parts, no composite machining capabilities. | Mill-turn machining, can handle complex parts. |

| Accuracy Level | Medium accuracy, about ±0.05mm. | High accuracy, up to ± 0.005mm. |

| Production Efficiency | Fairly good when producing small batches, low when producing large batches. | Very efficient at mass production and saves setup time. |

| Applicable Situations | Simple parts, small batch prototyping. | Complex parts, mass production, high precision. |

Figure 2:With the advancement of numerical control (CNC) technology, manufacturers are facing the dilemma of choosing between the simplicity of traditional lathes and the advanced automation of turning centers.

How To Avoid Workpiece Deformation During Turning Machining?

Thin-walled parts and slender shafts are easily deformed during turning machining. It is very important to determine the cause initially in order to take measures for its elimination.

Deformation Root Cause Analysis

The main reason for workpiece deformation includes: excessive cutting force leading to elasto-plastic deformation, uneven clamping force leading to stress deformation, accumulated cutting heat leading to thermal expansion and contraction, and release of internal material stress causing deformation.

The risk of deformation varies among different types of turning. For instance, deep hole boring is easily subjected to deformation because of concentrated cutting force, and large end face turning is greatly influenced by the heat generated during cutting.

Process Strategies and Solutions

1. Optimize clamping support: Use hydraulic soft jaws, center rests, follow rests, etc. For thin-walled parts, make use of expansion mandrels or special tooling to distribute pressure evenly.

2. Scheduling of Scientific Process: According to the principle of "inside-outside, alternating symmetry," it is divided into three stages: roughing, semi-finishing, and finishing. Arrange stress release between processes and adopt cross-feed for easily deformable processes.

3. Optimized Cutting Parameters: Small depth of cut, high spindle speed, and appropriate feed reduce radial force, while high-pressure coolant controls the heat generated during cutting.

JS Precision's Professional Practices

JS Precision has established a solution library for different types of turning deformation problems. Based on process simulation, risks are predicted, fixtures for special purposes are designed, and a database of cutting parameters is established.

We has successfully dealt with the machining of over 1000 easily deformed parts and reached an accuracy of ±0.01mm in deformation control.

Worried about the deformation of a workpiece during turning machining? Call our technical hotline, tell us the part structure and material, and we will share targeted solutions. You can also get the "CNC Turning Deformation Control Manual" for free.

What Are The General Tolerances For Precision CNC Turning?

Precision CNC turning has its tolerance level, which directly impacts the assembly and performance of parts. Most of the metal materials can achieve or do better in the class of ISO 2768-mK under standard conditions at JS Precision, with typical ± 0.025mm tolerance, which can be optimized to ± 0.005mm or even better.

| Material Type | Standard Tolerance Range | Optimized Tolerance Range | Applicable Scenarios |

| Alloy Aluminum | ± 0.025mm | ± 0.005mm | Drones, Electronic equipment |

| Stainless Steel | ±0.03mm | ±0.008mm | Medical Equipment, Industrial Components |

| Titanium Alloy | ±0.035mm | ±0.01mm | Aerospace, High-End Equipment |

| Engineering Plastics | ±0.04mm | ±0.015mm | Automotive Interiors, Electronic Housings |

Material property, part dimensions, feature geometry, and measurement methods are all factors that influence tolerances. Communicating tolerance requirements with suppliers early can prevent unrealistically tight tolerances from inflating the cost of parts.

Figure 3:Through meticulous process management and investment in advanced equipment, manufacturers can continuously achieve micrometer level precision.

How To Choose The Right Face Grooving Tool For CNC Turning?

The face grooving tool for CNC turning is the key to end face groove machining, which requires higher tool selection due to tool overhang and limited chip space.

Three things to consider in choosing:

- Groove width and depth dictates the tool size and rigidity, deeper and wider grooves require stronger rigidity.

- Workpiece material determines insert material: ordinary steel: coated cemented carbide, Difficult-to-machine materials: CBN/PCD.

- Machine tool power and stability determine tool compatibility. Lack of power or poor stability requires tools with good vibration resistance.

We recommend the use of a dedicated anti-vibration tool with internal cooling holes for difficult-to-machine materials or deep groove machining, wherein coolant reaches the cutting edge directly to cool the tool while removing chips. If you are unsure how to choose, please consult JS Precision expert.

Having problems while choosing a face grooving tool for CNC turning? Please provide the groove width, groove depth, and workpiece material information with us, and our experts will recommend suitable tool models and provide cutting parameter references to improve machining stability.

Case Study: Delivery Of A UAV Aluminum Alloy Servo Housing With ±0.01mm Tolerance Within 24 Hours

Rapid delivery of parts at high precision is one of the core requirements of many customers. This UAV servo housing project perfectly demonstrates JS Precision's rapid response and precision machining capabilities.

Customer Needs

One of the well-known UAV manufacturers urgently needed a 7075 aluminum alloy servo housing to test a new UAV prototype, with three core requirements:

- Lightweight design, part wall as thin as 1.2mm.

- High precision,the requirement is for an internal cavity dimensional tolerance of ±0.01mm.

- Extremely short delivery time, requiring prototype delivery within 24 hours, otherwise it would affect the subsequent testing schedule.

JS Precision Solution

Faced with the urgent customer's need, we promptly engaged in a rapid response process.

- Process Planning: A multi-axis CNC turning center is utilized for performing turning, milling, and drilling operations in one setup to avoid repeated positioning errors and to considerably reduce the machining time.

- To prevent deformation, we have designed a dedicated elastic fixture and adopted a high-frequency and shallow-depth cutting strategy. Cooling is done after every 0.1mm of cutting to effectively control the deformation of thin-walled parts.

- Regarding quality control, we apply online probes for in-machine inspection of critical dimensions, therefore real-time inspecting each machined part to guarantee the precision CNC turning tolerances meet standards.

Successful Accomplishments

From receiving customer drawings, to the delivery of the first 10 pieces of qualified parts, we completed the process in only 22 hours-just on schedule to fulfill the requirements of the customers.

The delivered parts, after inspection, showed that all the internal cavity dimension tolerances were controlled within ±0.008mm, and the surface finish reached Ra0.8μm, fully meeting design requirements.

By using these parts, customers successfully completed prototype testing, saving precious time for products to get into the market. Then, they signed a long-term cooperation agreement with us.

Do you need high precision CNC turning parts rapidly? Send your project timeline and technical parameters, and we can replicate the efficient process in this case study, offering delivery services for rapid prototyping within 24 to 72 hours to speed up the implementation of your project.

Figure 4:7075 aluminum alloy servo protection cover

Why Choose JS Precision For Your Next Turning Project?

Among many vendors offering CNC turning services, JS Precision has an edge due to comprehensive advantages in technology, quality, and cost, hence, a one-stop service can be provided from design optimization to the delivery of finished products, making machining more worry-free and highly efficient.

Technical Equipment and Process Capabilities

We have 30+ advanced CNC turning centers and mill-turning composite machines, including 12 5-axis mill-turning composite machines that can efficiently deal with various types of turning operations and complex parts.

The average industry experience of our engineering team is more than 8 years, and the process database can provide a match for different part machining solutions quickly.

Quality Assurance System

Quality is the cornerstone of our business. A closed-loop quality process has been established: spectral analysis and hardness testing of raw materials upon arrival, SPC statistical control in processing, and comprehensive testing of finished products using coordinate measuring machines before leaving the warehouse to guarantee the consistency in the precision CNC turning parts.

Cost and Supply Chain Advantages of Made in China

We offer very competitive pricing by leveraging a localized supply chain and large-scale production.

Long-term relationships with superior material suppliers provide procurement costs for the Group that are 10%-15% below the industry average, while larger production output improves equipment utilization and reduces unit processing costs, enabling customers to save 15%-20% without compromising international quality standards.

FAQs

Q1: What is the difference between CNC turning and CNC milling?

The basic difference lies mainly in the method of motion and in the parts that can be worked on. Workpiece rotation and tool movement are involved in the CNC turning to perform the job on rotating parts while tool rotation and workpiece movement are involved in the CNC milling for the machining of complex three-dimensional contours such as planes and grooves.

Q2: What materials can be turned by the CNC turning machine?

It embraces nearly all engineering materials, including different types of steel, aluminum alloys, copper alloys, stainless steel, titanium alloys, other metals, and engineering plastics such as ABS and POM, plus some composite materials.

Q3: How to prepare drawings or documents for CNC turning?

Detailed 2D engineering drawings are recommended, containing dimensions, tolerances, surface roughness requirements, etc., if possible, it is preferred to provide a STEP or IGES format 3D CAD model. Only clear technical requirements can guarantee the quality of machining.

Q4: Is CNC turning appropriate for small-batch prototyping?

Ideally, it requires no custom mould for CNC turning. Production can be done immediately after programming, which effectively shortened the prototype delivery time and controlled the costs. It is an ideal choice of small-batch trial production.

Q5: How to avoid the bending of long shaft work pieces during turning?

Primary methods of preventing bending are: by giving extra support through a follow rest or centre rest, optimization of parameters of cuttings for reducing radial forces, and progressive stages of roughing and finishing for releasing internal stress.

Q6: Would unit cost decrease with rising order volume?

Yes, because fixed costs of CNC turning services (such as programming and fixture preparation) are distributed among more parts, the larger the volume ordered, the lower the fixed cost per unit. This will result in a significant drop in the unit price.

Q7: How does JS Precision handle orders and communication from overseas?

Our services include professional, technical, English language support and communication using internationally accepted drawing standards. The documents are transmitted via encrypted channels to ensure that the communication occurs seamlessly with information security. We have served over 20 countries.

Q8: What other supporting services does JS Precision offer besides machining?

One-stop service we can offer covers everything from material procurement to turning machining, heat treatment, surface treatment-anodizing and electroplating, etc., assembling parts to final inspection, meeting each customer's needs.

Summary

CNC turning goes far beyond the simple shaping of metal into a round form, it is a modern art that incorporates precision engineering, material science, and smart manufacturing.

Understanding the key principles and considerations points the way to informed decisions on everything from medical device parts, which need the tightest tolerances, to automotive parts, which need mass production efficiency.

CNC turning can be a contributor to the success of your project only when done with a technically capable and experienced partner. Equipped with state-of-the-art machinery, rich process experience, and unremitting pursuit of high quality, JS Precision is ready to provide professional CNC turning services for you and work together with you through any technical challenge.

Take action now and let your ideas spin precisely!

Please send your part drawings or CAD models to our engineering team, and you will receive a free detailed quotation that includes manufacturability analysis and optimization recommendations. Partner with JS Precision for the perfect blend of precision, speed, and value.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com