CNC precision turning parts are the core support of modern precision manufacturing.From precision shafts for minimally invasive surgical tools to critical valve cores in aerospace hydraulic systems, CNC Precision Turning Parts help modern industry run reliably using micron-level precision.

Only a profound understanding of every detail in the CNC turning process can assure final superior quality when the roundness, cylindricity, and surface finish of each part directly affect the performance of the whole system.

Combining years of practical experience serving over 500 clients in more than 20 industries, this guide aims to help you systematically master the key knowledge of CNC Precision Turning Parts and solve practical production challenges.

Core Answer Summary

| Technical Dimensions | Key Challenges | JS Precision Solutions |

| Process Stability | Tool Wear, Thermal Deformation, Vibration Suppression. | Total CNC turning process monitoring and optimization system for continuous stable machining. |

| Surface Quality Control | Roughness control, vibration mark elimination, dimensional consistency. | Professional precision turned components surface integrity control technology. |

| Material Adaptability | Differences in machining characteristics of different steel grades. | Targeted precision turning of steel parts process database. |

| Service Flexibility | Precision assurance and cost control for small-batch production. | Mature custom CNC turning quality control & rapid response mechanism. |

Your Manufacturing Partner: A Comprehensive Understanding Of JS Precision's CNC Machining Service Capabilities

More than 15 years of experience in practical CNC turning gives JS Precision the confidence to work with over 500 customers in more than 20 industries, such as medical, aerospace, automotive, and optical equipment.

10,000 precision shaft parts for a medical company have been produced by us with a pass rate of 99.8%. In addition, we have also machined high-temperature alloy parts for aerospace clients, with tolerances controlled within ±0.001mm.

Besides, we are familiar with the CNC turning process for over 30 types of steel, titanium alloys, and engineering plastics, and their processing performance data can be cross validated through the CES selector material database under Granta Design to ensure the scientific nature of process optimization.

The guide summarises many years of project experience and technical accumulation and is supported by real case studies for every point, so you can completely trust it to solve your needs in CNC Precision Turning Parts.

Need to quickly understand our service capability? Apply directly for the "JS Precision CNC Turning Services Capability Manual," and it will disclose 20+ industry case studies, along with equipment parameters.

Where Are CNC Precision Turning Parts Critical In Modern Manufacturing?

After understanding what JS Precision is capable of, you may wonder: what is the role that CNC precision turning parts play in modern manufacturing? In fact, it's almost indispensable in the production of high-precision parts. Below, I will explain it in three aspects: definition, application, and advantages.

Basic Definition and Process Characteristics

The essential difference between precision turning and conventional turning is in the level of precision and process control.

CNC precision turning parts can achieve a tolerance of ±0.001mm and the surface roughness Ra 0.2μm, while conventional turning tolerances are mostly above ±0.05mm, and surface roughness Ra1.6μm.

Precision turning makes use of real-time temperature compensation, SPC control, and dedicated tools, while conventional turning emphasizes efficiency, regardless of process monitoring. It is based on such a difference that CNC Precision Turning Parts can achieve high precision.

Main Application Scenarios

- Medical Devices: Production of implants and surgical instruments requiring biocompatibility and tolerances within ±0.003mm.

- Aerospace: For the machining of engine turbine shafts, other parts, using titanium alloy/high-temperature alloy to ensure stability in ultra-extreme environments.

- Automotive Industry: Manufacture fuel injection parts with tolerances within ±0.005mm for guaranteed precise fuel injection.

- Optical Equipment: Production of lens barrels and lens mounts, to ensure imaging accuracy, the form and position tolerances must be within ±0.002mm.

Performance Advantages Analysis

The advantages of CNC Precision Turning Parts are significant:

- High precision and can allow for direct assembly, thereby reducing subsequent processing.

- Excellent surface quality can eliminate polishing processes, reduce costs, and also reduce bacterial adhesion to medical parts.

- Good interchangeability guarantees the commonality of mass-produced parts and enhances the quality and efficiency of end products.

Figure 1: Precision turning can produce parts with unparalleled precision and extremely small tolerances, thus producing high-quality components suitable for high-performance applications.

What Factors Determine Stability In The CNC Turning Process?

Since the quality of the part made by CNC precision turning depends on a stable machining process, what determines stability during the CNC turning process? These three factors directly influence the precision of the final part, which I will break down for you.

Equipment Rigidity Foundation

The stability of the CNC turning process depends on the fundamental machine tool structure, guideway system, and spindle precision.

The machine tool adopts a cast iron bed to decrease the vibration, the guideway system is designed with linear guideways for assured accurate positioning, and the spindle precision is controlled within 0.0005mm to avoid spindle run-out that causes dimensional deviation in the parts.

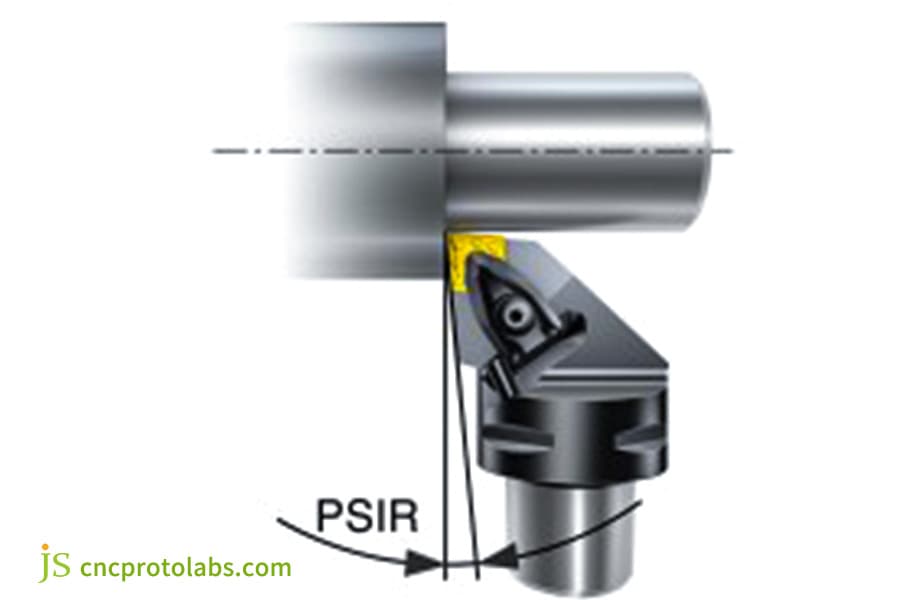

Tool System Optimization

The balancing of tool holders, geometry, and coating technologies are responsible for enhancing the stability of the cut.

The balance of the toolholder reaches the G2.5 level to avoid high-speed vibration. Tool geometry is designed based on material properties, for instance, a positive rake angle in stainless steel reduces drag. A hard coating like TiAlN enhances tool wear resistance and reduces machining errors caused by wear.

Process Parameter Science

It is necessary to optimize cutting parameters according to material characteristics and suppress vibration.

For aluminum alloys, the cutting parameters are within the range of 2000-5000 rpm with feed rates of 0.02 to 0.05 mm/r, while for steel materials, it is reduced to 500-1500 rpm. Installation of damping devices and adjustment of clamping force are carried out for suppressing the vibrations to ensure the stability of the CNC turning process.

Figure 2: Precision turning setup, including rough, semi-finish, and finish operations.

Which Industries Demand The Highest Standards In CNC Precision Turning Services?

The demand for CNC precision turning varies from one industry to the other. Several have particularly high standards due to the fact that the performance of parts in these industries directly influences safety and the core functionality of the product. Some specific examples are listed below:

Medical Devices

The requirement of the medical device industry for CNC precision turning is very rigid. Good biocompatibility is required for implants and surgical instruments, and 316L stainless steel or titanium alloy will be used commonly. For safe use, the surface should be free from cracks and burrs.

Aerospace Applications

Material and reliability are the key emphases of CNC turning services in the aerospace industry. Many parts are made of high-temperature alloys, titanium alloys, and other refractory materials that demand stable performance in extremely harsh environments, therefore, every part has to be rigorously tested to avoid accidents caused by quality problems.

Optics and Precision Instruments

The optics and precision instruments industry has extremely high requirements for the geometric tolerances of CNC precision turning. For example, lens barrels and lens mounts need to meet their form and position tolerances within ±0.002mm while their surface roughness must attain Ra0.1μm so that reflections or refractions of light are not affected.

How Is Surface Roughness Precisely Controlled In Precision Turned Components?

The surface roughness of precision turned components is very important to indicate the quality of the workpiece, especially in medical and optical fields. Then how do we precisely control it? These three aspects are the main methods.

Cutting Parameters Optimization

Such as spindle speed, feed rate, and depth of cut, will impact the surface roughness: higher rotation speeds are associated with smoother surfaces.

For example, surface roughness of Ra0.2μm is achievable with machining of aluminum alloys at 5000 rpm. The smaller the feed rate, the finer the textures of the surface will be. The depth of cut needs to be adjusted according to the material (0.1-0.3mm is right for hard steel).

Tool Technology Application

Geometry and edge treatment of precision turning inserts determine surface quality. A rake angle of 5°-15° and a clearance angle of 6°-12° reduce cutting forces. Edge dulling or honing (radius of 0.01-0.03mm) avoids excessively sharp edges that scratch the part surface.

Cooling and Lubrication Strategies

Different cooling methods are adopted, affecting the surface integrity and dimensional stability. Emulsions are used to cool ordinary steel parts to reduce heat deformation, oil mist is used to cool stainless steel to prevent tool sticking, special cooling oil for high-temperature alloys prevents surface oxidation or cracking.

Is there a requirement for surface roughness for some precision turned components? For instance, if you want to get a Ra less than 0.2μm, you can easily download the "Surface Quality Control Standard Manual," which explains test methods and acceptance procedures in great detail. If you want to check how effective our surface control is, you can order 1-5 samples first, and we will supply you free surface roughness test with a report.

Figure 3: The geometric angle of the precision cutting blade determines the surface quality.

What Process Differences Exist In Precision Turning Of Various Steel Grades?

The properties of various types of steel grades are very different, therefore, the methods of precision turning of steel parts differ greatly. Only by changing the process with respect to the type of steel grade can the precision of parts be guaranteed. Below, I will explain this in detail referring to the table.

| Steel Type | Machining Characteristics | Key Process Points |

| Austenitic Stainless Steel | High toughness, susceptible to tool sticking, severe work hardening. | Use high-speed steel tools, speed 800-1500 rpm cooling oil mist to reduce tool sticking. |

| Martensitic Stainless Steel | High hardness HRC30-45, sensitive to tool chipping. | Use carbide tools, feed 0.01-0.02 mm/r, temperature control. |

| Alloy Structural Steel | Good hardenability, cutting performance uneven. | Speed should be adjusted with the hardening degree, 1000-1200 rpm for hardened parts, TiCN coated tools. |

| Tool Steel | High hardness, HRC 58-65, very tough to machine. | Use CBN tools, low speed, 300-500 RPM. Large depth of cut, enhanced cooling. |

Series Stainless Steel:

In the case of austenitic stainless steel (304, 316L), use high-speed steel tools to raise the cutting speed and lower work hardening, in the case of martensitic stainless steel (410, 420), feed rates should be reduced to avoid tool breakage. Precipitation hardening stainless steel (17-4PH) must be aged after machining, taking deformation allowance during the process.

Alloy Structural Steel:

Alloy structural steel such as 45CrNiMoVA should consider the degree of hardening in adjusting parameters. Accordingly, slow speed and feed are used in areas that are subjected to treatment, and because of the high cutting force, the requirement involves high-strength cemented carbide tools.

Tool Steel Machining:

For tool steel, like T10 and Cr12MoV, adopt CBN tools with low speed and large depth of cut, simultaneously enhance cooling, using special cooling oil to avoid tool failure or part oxidation.

Need to machine specific steel grades? For instance, for 316L stainless steel and Cr12MoV tool steel, one can have a free "Precision Turning of Steel Parts Process Parameter Table" for tool selection and cooling solutions. If you are not sure which steel to choose, just explain the usage scenario of the part, and we'll suggest the suitable steels and analyze the processing costs.

How To Evaluate The Technical Capabilities Of CNC Turning Services Providers?

It is very important to choose a proper CNC turning services provider. How to judge its technical capability? The following three dimensions will help you make an accurate judgment.

Equipment Capability

Basically, spindle accuracy, positioning accuracy, and repeatability are critical. The high-quality service provider is able to offer machine tool spindle accuracy ≤0.0005mm, positioning accuracy ±0.001mm, and repeatability ±0.0005mm. They have CMMs, Optical Comparators, and other necessary inspection equipment to ensure the highest accuracy in part quality inspection.

Technical Team Level

Different levels of experience of process engineers, programming skills, and problem-solving abilities are very important. Experienced engineers can develop process plans quickly, a team of programmers can develop efficient machining programs, and they are able to find the cause and adjust the parameters to resolve problems in a very short time.

Quality Assurance System

Check the configuration of inspection equipment, the quality control process, and document management. A reliable service provider has first-piece inspection, process inspection, and final inspection processes. It will also record the machining parameters and inspection data wholly for easy tracing.

How To Maintain Precision In Small Batch Custom CNC Turning Production?

It is difficult for a small batch of custom CNC turning production to achieve both precision and efficiency. How can we achieve them? These three measures guarantee both the precision and efficiency effectively.

Guarantee of Process Stability:

Small-batch production requires special control of tools, parameters, and processes. Each batch of parts gets the dedicated tools ready beforehand to avoid mix-ups. Parameters are adjusted by trial cuts, and monitoring is done by sampling during the process to avoid batch scrap.

Rapid Response Mechanism:

Efficient conversion from order to process design is very important. Response to every order within 24 hours, and provide process solutions within 48 hours. The close communication with customers and confirm drawings and technical requirements as soon as possible to avoid delay.

Guarantee of Consistency in Quality:

Stringent first-article inspection, in-process inspection, and final inspection are implemented.Mass production starts after the first article has passed inspection. Random sampling throughout the process and a final 100% inspection ensure that the quality is consistent for every part.

Have small-batch custom CNC turning needs? For example, 10-500 pieces. Provide your order requirements and get our rapid quote and production cycle plan within 48 hours. If there is any inconsistency in precision for small batches, don't risk it, you can first customize 3-5 samples to verify it. Only after they pass the inspection would we confirm mass production.

Review Of Actual Cases: Achieving 99.8% Pass Rate In 10,000 Medical Instrument Shafts

Having discussed so much theory, I will be using an actual case to make your understanding more intuitive regarding the strength of JS Precision in producing CNC Precision Turning Parts.

Customer's Challenges

A certain medical device manufacturer needs to produce a batch of surgical instrument precision shafts made of 316L stainless steel (compliant with biocompatibility requirements), with a diameter tolerance of ± 0.003mm, a surface roughness of Ra0.2 μ m, and 100% passing of functional tests (including rotational flexibility and sealing tests).

The batch size is 10,000 pieces with only a 3-week delivery cycle. In the past, the customer had already contacted several manufacturers, but due to a lack of precision, many reworks needed to be done. The product launch plan was delayed.

Our Technical Solution

In order to solve the customer's problem, we first optimized the parameters in the CNC turning process: the spindle speed was set to 3000rpm, feed rate 0.01mm/r, and depth of cut 0.1mm to avoid work hardening that might affect precision.

For ensuring that the surface roughness will be within the requirement, we used a dedicated diamond tool with a cutting edge radius of 0.02mm.

Meanwhile, full-process temperature compensation was taken, and the workshop ambient temperature was displayed every 2 h. According to the change in temperature, machine tool parameters were adjusted to avoid thermal deformation.

Finally, a statistical process control system was established in which 50 pieces were sampled and inspected using a coordinate measuring machine to quickly find and adjust deviations.

Successful Data

In this production batch of 10,000 units, the dimensional compliance rate reached 99.9%, surface roughness compliance rate reached 99.8%, functional test pass rate reached 100%, and customer complaint rate dropped to zero. Furthermore, we finished delivery two days ahead of schedule, helping the client smoothly advance their surgical instrument launch plan.

The client has signed a long-term cooperation agreement with us, entrusting all the production of their precision shafts to JS Precision.

Figure 4: Medical Device Shaft

How To Initiate Your Project With Professional CNC Turning Services?

Having learnt so much, how do you work with a professional CNC turning services provider if you want to kick-start a project? These three steps can help move your project along smoothly:

Clear Technical Requirements

Please provide completed drawings-both 2D and 3D, along with technical requirements related to tolerances and surface finish. Also, the quality standards ISO 13485 and the delivery plan need to be clearly stated. Clear requirements enable service providers to quickly comprehend the project and avoid possible subsequent modification.

Process Solution Development

According to the characteristics of the parts, the service provider will develop process planning and optimization suggestions.

Using JS Precision as an example, the company analyzes part complexity and material properties to come up with a comprehensive solution for tool selection, setting parameters, and inspection methods. It will also put forth suggestions about cost reduction and efficiency enhancement through structural simplification or material adjustment.

Project Execution Guarantee

A standard process shall be established by the service provider for full-process quality monitoring and schedule management. Progress reports will be submitted at regular intervals during production, such as submitting every 20 percent completion report. First-piece, in-process, and final inspections shall be performed. A completed quality report and inspection data shall be provided upon delivery.

If you are still clarifying your needs, such as perfecting drawings and defining quality standards, schedule a one-on-one technical consultation now for free to help you clarify your requirements and complete the details.

FAQs

Q1: What is the typical tolerance achievable in CNC precision turning?

The general diameter tolerance is ±0.005mm. In applications requiring high precision, it is possible to reach the value of ±0.001mm, depending on the characteristics of the part and materials used in its manufacturing.

Q2: How do you ensure consistency in mass production of turned parts?

We ensure batch-turned parts consistency using statistical process control, an automatic compensation system, regular equipment calibration, and standardized operations.

Q3: How does precision turning differ from conventional turning?

Precision turning focuses on micron-level tolerances, excellent surface quality, and strict process control. In contrast, conventional turning focuses on higher efficiency in machining with lower precision requirements.

Q4: What is the lead time for custom precision turning projects?

Normally, it takes 3-7 days to deliver the prototype, and for small batches, it takes about 2-3 weeks, depending on the part complexity and the production load at the moment.

Q5: How do you measure and verify precision turned parts?

The precision turned components are comprehensively inspected and verified by the coordinate measuring machine, optical comparator, roughness tester, together with special fixtures.

Q6: Can you handle both prototype and production quantities?

Yes, we provide full-scale services from single-piece prototype manufacturing to mass production by meeting custom CNC turning requirements at different stages.

Q7: What quality certifications do you hold?

We are ISO 9001:2015 Quality Management System certified and ISO 13485 Medical Device Quality Management System certified to ensure our services are in compliance.

Q8: What sets your precision turning services apart from competitors?

Equipped with advanced equipment, deep process knowledge, and strict quality control, our technologically advanced CNC precision turning solutions are provided at a higher cost-performance ratio.

Summary

In precision manufacturing, every improvement at the level of the micron can be the key to a product performance breakthrough. Besides the test of equipment capabilities, CNC precision turning parts reflect the manufacturer's process depth and quality commitment.

With its comprehensive CNC turning process system, professional precision turning of steel parts technology, and rigorous quality control, JS Precision can help you solve a variety of challenges from process optimization to mass production, efficiently and reliably meeting your high-precision parts needs.

Choosing the right CNC turning services adds a solid guarantee to the success of your project.

Start your precision turning project now!

→ Upload your part drawings for professional process analysis and accurate quotes

→ Contact our turning experts for custom technical solutions

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com