For most people, the name stainless steel means sturdy, durable, and never rusting, while galvanized steel sounds more cheaply.But if your use needs to withstand heavy loads in harsh environments, or you're on a budget,this presumptuous choice may cost you a huge price.

This guide will provide a complete comparison of stainless steel and galvanized steel properties to metal casting to help you understand the pros and cons of the two materials and make the best choice for your next important project. We will also incorporate JS's metal casting expertise to provide a handy reference point.

Overview Of Core Answers

| Comparison Measurement | Stainless Steel | Galvanized Steel | Main Findings |

| Tensile Strength | 515-550 MPa (304/316 grades) | 300-500 MPa | Stainless steel is stronger and heavier-duty. |

| Corrosion Resistance | An oxide film is formed by chromium, so plating is unnecessary. | The sacrificial protection is given by the zinc coating, and it may rust if scratched. | Stainless steel gives long-term corrosion resistance. |

| Relevant Environments | Corrosive, high-humidity, high-temperature environments. | General, dry, non-corrosive environments. | The more severe the environment, the greater the advantages of stainless steel. |

| Cost-Effectiveness in the Long Term | High initial cost, lifetime over 50 years. | Low initial cost ($50-100/㎡), lifetime 10-20 years. | Stainless steel is more cost-effective for long-term use. |

Which Type Of Steel Is More Suitable For Your Project? JS Engineers Are Here To Help You

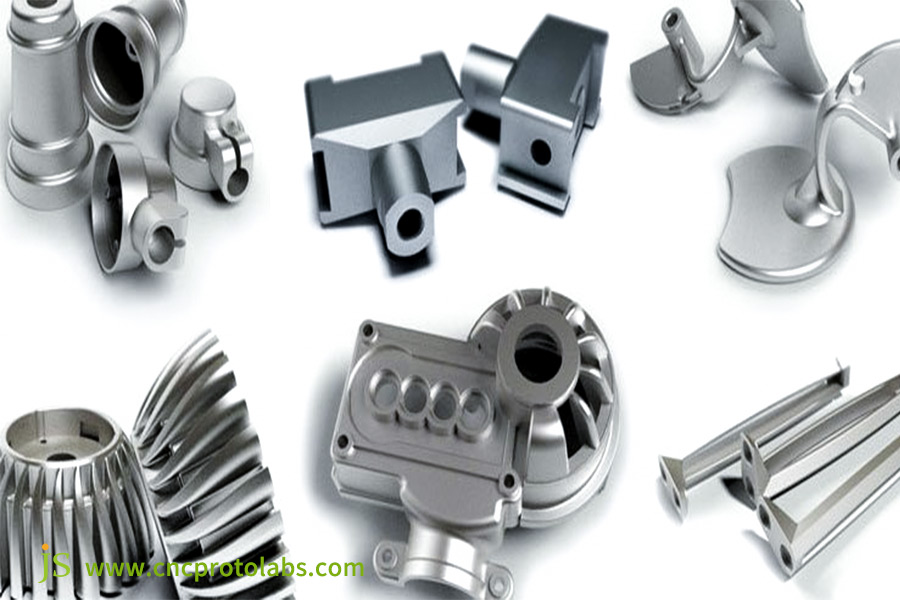

JS possesses over 15 years of direct experience in metal casting and materials choice, providing metal casting solutions to over 5,000 projects across 20 industries, including aerospace, automotive, and medical devices.

For example, in the vehicle manufacturing sector, JS has created metal casting parts such as engine blocks for a leading automotive manufacturer. With precise process control, JS achieved dimensional tolerances of 0.05 mm. In the medical device sector, we have produced stainless steel castings for a medical device firm and cleared rigorous biocompatibility testing.

This manual, based on the collective practice of JS engineers on this massive project, offers a thorough list of working applications of galvanized steel and stainless steel, offering you good counsel on material selection. You can trust its professionalism and working expertise.

With our long background in metal casting, JS can provide precise solutions for projects from industries worldwide. If you require any, do not hesitate to reach out and we will create personalized metal casting parts to facilitate your project to run smoothly.

Manufacturing Differences: Galvanized Steel And Stainless Steel Manufacturing Process

It is extremely crucial to grasp the manufacturing processes of both materials in material selection, process adjustment, and metal casting price estimation for metal casting projects.

Stainless Steel Manufacturing Process

Stainless steel processing entails careful control of composition and process with four basic steps:

Raw Material Melting: Fusing iron, chromium (minimum 10.5%), and nickel (and nickel in some grades) between 1500-1600°C. The cost of raw materials affects the pricing of custom metal casting manufacturing.

Blank Forming: Casting molten steel at one go and cooling to semi-finished products. Controlling the rate of cooling so that there are no defects, and precision decides the material production of online metal casting services.

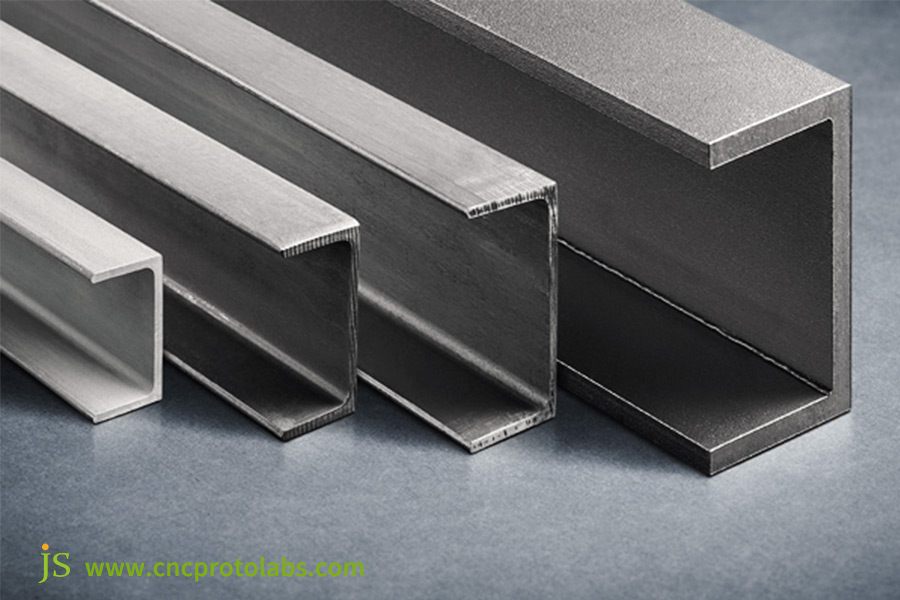

Rolling: Cold- and hot-rolling the slab into medium-thick or thin steel plates (for example, stainless steel sheet metal 0.5-3mm), partially annealing to meet metal casting requirements.

Surface Treatment: Brushing, polishing, or pickling and passivation enhance corrosion resistance, making precision materials available for custom metal casting.

Galvanized Steel Manufacturing Process

Galvanized steel contains a carbon steel base and relies on zinc plating to shield against corrosion. It is done as follows:

Substrate preparation: Melting the carbon steel, casting the billet, and rolling. No precious alloys, low raw material costs, and more economical metal casting prices.

Surface pretreatment: Degreasing, pickling, and passivation improve bonding of the zinc layer and prevent peeling of the plating on metal casting parts.

Galvanizing: The mainstream is hot-dip galvanizing (440-460 ℃ zinc solution, layer thickness 50-100 μ m), some use electroplating galvanizing, which can be selected according to the needs of online metal casting services.

Post-treatment: Passivation and cooling, and light oiling to prevent white rust. It is an elementary metal casting parts product and should be used for cost-saving projects.

JS understand the nature of casting of these two materials and have the ability to tailor processes based on custom metal casting manufacturing needs in order to produce good quality metal casting parts in an efficient manner. We welcome inquiry and collaboration.

General Comparison: Comparing The Six Major Differences Between Galvanized Steel And Stainless Steel

To better provide you with a comparison of the differences between stainless steel and galvanized steel, and to help you make the perfect choice for your metal casting project, here is the comparison of them in six major areas.

| Comparison Dimensions | Galvanized Steel | Stainless Steel |

| Corrosion Resistance | The surface zinc layer sacrifices itself to protect the steel. Loss of zinc layer may lead to rusting. | The chromium content forms a tight-packed chromium oxide layer, which protects against corrosion. Surface scratches can heal naturally. |

| Usable Environment | Suitable for dry, non-corrosive conditions, e.g., typical roof and fences of buildings. | Suitable for wet, corrosive conditions, e.g., chemical pipes and coastal equipment and other metal casting parts. |

| Appearance | Silvery white. The adhesion of the zinc layer affects the appearance, white rust can form on it over a period of time. | The appearance is shiny with brushed and mirror finishes for a permanent look. |

| Processing Difficulty | The zinc layer is prone to losing adhesion during processing, and so intricate metal casting becomes difficult. | Good processing performance and forming of intricate shapes make it suitable for creating complex metal casting parts. |

| Service Life | 10-20 years under normal conditions, drastically reduced under harsh conditions. | Over 50 years under normal conditions, and capable of having a long service life even under harsh conditions. |

| Recycling | The zinc plating will have to be removed, hence recycling is costly and complex. | Recycling is cheap and simple, and no change in performance after recycling. |

The above contrast shows significant differences between the two types of steel. The choice between the two types requires serious consideration, such as operating conditions and the lifespan requirements of the project.

Is Stainless Steel Actually "Stronger" Than Galvanized Steel?

Most people are concerned with the "strength" of the material when choosing metal materials, and it is the same for galvanized steel and stainless steel. Especially in metal casting usage, the strength of the material has a direct correlation with part performance.

It must be understood that "strength" is a general term and includes tensile strength, compressive strength, impact resistance, etc.

Comparison of Tensile Strength

The tensile strength of normal galvanized steel is typically between 300 and 500 MPa, while that of normal 304 stainless steel is greater than 515 MPa, and that of 316 stainless steel greater than 550 MPa.

Comparison of Compressive Strength

Stainless steel performs even better in the case of compressive strength. In the case of high-pressure piping applications, for example, stainless steel castings are capable of sustaining higher internal pressure without deformation or cracking. It is one of the main reasons stainless steel is the choice for metal casting parts in the majority of high-pressure equipment.

Material Selection for Different Scenarios

But in other usual uses where the strength requirement is low, galvanized steel may also be utilized to meet the requirements. Moreover, galvanized steel is relatively less costly, appropriate for low-cost projects and mild operating conditions.

But for projects with higher strength requirements, especially those involving severe operating conditions, stainless steel is a better option. JS has rich experience in the production of high-strength metal casting parts for stainless steel.

If material strength is what you need for your project, JS is here to provide you with solutions. We can produce high-strength metal casting parts and stainless steel sheet metal to suit your needs. Feel free to call us to place an order.

Behind The Scenes: Where Does The Cost Gap Exist?

When you are working on a metal casting project, budget is very important. There is a cost difference between galvanized steel and stainless steel. Understanding why makes you watch your purse strings more closely.

Cost of Raw Materials Difference

In terms of raw material cost, stainless steel possesses valuable metals such as nickel and chromium, and therefore it is much more costly compared to regular steel. The raw material for galvanized steel is ordinary steel, which only increases the cost of galvanizing process and has low raw material cost.

Difference in Processing Cost

As for the processing cost, stainless steel is difficult to process, and complex metal casting requires accurate equipment and experienced techniques and is costly. The processing of galvanized steel is simple and, excluding the galvanizing, similar to regular steel processing with lower costs.

Market Price and Long-Term Cost-Effectiveness

From the perspective of metal casting price, the cost of galvanized steel is $50-100 per square meter, while stainless steel sheet is $150-300, a significant difference. Yet, stainless steel lasts longer, hence cheaper in the long run.

JS gives transparent metal casting price quotations, offering you a proper viewpoint about the cost structure. Whether stainless steel or galvanized steel metal casting services are needed, we have solutions at affordable costs. If you are interested, feel free to get in contact with us for specific pricing.

Stainless Steel Vs Galvanized Steel: Which Is More Suitable For Casting And Die-Casting?

In die casting and casting, the performance difference between different materials is broadly varied, having a direct influence on the quality and efficiency of metal casting parts. We compare stainless steel with galvanized steel in the following.

Comparison of Casting Fluidity

Fluidity of casting is the ability of molten metal to enter the mold cavity. Stainless steel possesses poor fluidity, and high-alloy stainless steel underfills and requires improvement in the process.

Galvanized steel, being an alloy of general steel, possesses poor fluidity, but its galvanized coating is easily volatilized during the process of casting, producing toxic gases, which bring about porosity in the casting and make the casting difficult.

Die-Casting Process Suitability Analysis

Traditional die casting is appropriate for non-ferrous metals such as aluminum, zinc, and magnesium, whose melting points are low and fluidity high. Stainless steel has a melting point of 1400-1500°C, and common steel has a melting point greater than 1300°C. High temperature will see die casting molds corrode well and lower the service life.

Other than that, it is difficult to control the liquidity of molten metal, and therefore it is difficult to produce high-precision and high-quality die casting products. For complex parts, some other metal casting technologies like precision casting are required.

Problems and solutions for casting porosity

Both steels can cause porosity, primarily due to gas entrapment during solidification or trapped gas during pouring. JS prevents metal casting part porosity defects and ensures quality by eliminating degassing of molten metal, reasonably design the exhaust channel of the mold and controlling pouring velocity and pouring temperature.

Case Study: The Extreme Challenges Of A Rocket Engine Turbopump

Project Background

A key component of a next-generation high-thrust liquid oxygen/kerosene rocket engine was being designed by an aerospace technology company—the main turbopump case. As a turbocomplicated piece with numerous serpentine paths for cryogenic fluid transport, this component had to satisfy an enormously strict operating specification.

It had to withstand ultra-cold liquid oxygen's high-frequency alternating stress and hot, oil-contained gas, exposing it to a gigantic range of fluctuation in temperature, plus interior pressures exceeding 50 MPa.

These conditions put extremely strict demands on material properties and accuracy of processing of the component, which ordinary metal casting parts were far from meeting.

JS's Decision

For this challenging metal casting project, JS's engineering team carried out extensive research and study, and two alternatives were suggested as shown below:

1. Option A (cast carbon steel with subsequent galvanizing)

Conclusion: Completely rejected in the initial discussion.

Reason for rejection: Intrinsic hardness and corrosion resistance of carbon steel are poor. Secondary galvanized coating will tend to flake off in extreme temperature and pressure conditions. Moreover, harmful substances may be produced at high temperatures, which can affect the normal operation of the engine.

2. Option B (Special Cast Stainless Steel)

Material choice: High alloy austenitic stainless steel, for example, CF8M, cast equivalent of 316 stainless steel.

Material Benefits: Excellent strength at high temperature and high corrosion resistance with nominal pressure and temperature conditions.

Process Fabrication Benefits: Refinement, compact geometry through precision casting (lost wax casting), replicating internal flow paths precisely, eliminating from later mechanical processing and welding processes, conserving time, and reducing quality risk. The process is appropriate for the production of these complex metal casting parts.

Last Plan and Outcomes

Completed Plan: After careful evaluation and comparison, the special cast stainless steel solution was ultimately selected.

Principal Process: Hot isostatic pressing (HIP) is a second-step treatment process in casting processing for treating the casting under high pressure and temperature uniform pressure.

Process Outputs: Porosity and microscopic shrinkage in the casting were eliminated successfully, and the casting's denser structure was obtained with high-pressure structural quality and reliability guaranteed in major areas.

End Result: The main turbine pump casing produced had undergone stringent testing and all the performance parameters were within design specifications and in line with rocket engine application standards. Such performance was greatly appreciated by the customer and demonstrates JS's ability in custom metal casting manufacturing.

Ultimate Guide: Choosing The Best Metal For Your Project

Now that you've learned the differences in properties, price difference, and casting suitability difference between stainless steel and galvanized steel, here is a step-by-step guide to choosing the ideal metal for your metal casting project. The steps are:

Select by Project Usage Environment

- If the project would be used in a corrosive wet area such as in chemical pipes or ocean machines, stainless steel would be better since it is very corrosion resistant and can last for a very long time.

- If the project would be used in a non-corrosive dry area such as in fences and supports of normal buildings, galvanized steel would be enough and cost-effective.

Select by Strength and Service Life Requirements

- If the project demands high strength or longer service life, such as components of high-voltage equipment or the main mechanical components, stainless steel's longer service life and high strength will fully support.

- If the project is not meant to demand high strength and only short service life can be tolerated, say, galvanized steel can be utilized to meet general conditions at economical cost. Be careful with the cost of the project.

Comprehensive Judgment based on Project Budget

- If the project budget is sufficient and there are high requirements for material performance,stainless steel is the solution.

- If the project will accommodate low resources and mildest operating environments, then galvanized steel is the more cost-effective solution.

No matter what material you are working with, JS is prepared to provide to you expert online metal casting services and custom metal casting manufacturing services to assist you in successfully delivering your metal casting project.

FAQs

Q1: Are stainless steel castings more resistant to corrosion?

Actually, stainless steel castings are resistant to corrosion and the chromium oxide film on their surface can prevent oxygen and other corrosive media from coming into contact with the internal metal. Castings of stainless steel, therefore, are ideal to employ in conditions where corrosion danger exists and are an exceedingly good choice for most metal casting applications.

Q2: Which type of casting is more thermally stable?

In high temperature environments, the performance of stainless steel is more stable.Elements like chromium and nickel in stainless steel, apart from enhancing corrosion resistance, also affect the high-temperature strength and high-temperature oxidation resistance. Stainless steel is less likely to be deformed, softened, or oxidized damaged even after extended exposure at elevated temperatures.

Q3: What is "white rust" on galvanized steel? Is it poisonous?

"White rust" on galvanized steel is zinc oxide, primarily zinc oxide and zinc hydroxide, that forms as the zinc coating is reacting with water and air oxygen. It's a sign that the zinc coating is self-sacrificing to protect the steel. It is not detrimental to the steel structure itself and will not reduce the strength or service life of the steel. It will, though, degrade the appearance of the galvanized steel.

Q4: How does JS control metal casting defects?

JS employs a series of cutting-edge technologies and rigorous test procedures to control metal casting defects. X-rays are applied to monitor the filling and solidification of liquid metal in real time during casting, identifying defects and making relevant adjustments. Full-size inspections are also conducted after completion of the casting. All these processes can effectively reduce casting defects to ensure quality of metal casting parts.

Summary

There's no clear winner in the stainless steel vs. galvanized steel debate, there's only the best choice for your specific project. It's a delicate balance between initial cost, long-term value, performance requirements, and the operating environment.

If your project requires high strength in a harsh environment, stainless steel is the preferred choice. For mild environments and limited budgets, galvanized steel can also suffice.

JS has extensive experience in metal casting. If you require stainless steel or galvanized steel metal casting parts, or if we need to perform online metal casting services, we can provide you with the finest custom metal casting manufacturing services to ensure your project is a success.

Disclaimer

The contents of this page are for informational purposes only.JS servicesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Jusheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com