When a car survives the rigors of rough high-speed potholes, a seemingly insignificant zinc alloy component in its seatbelt buckle striving devotedly to protect its passengers. Meanwhile, on a curtain wall of a skyscraper, an old stainless steel component maintains its original straightness and luster for several decades. Behind all these lies the tacit power of materials science.

Stainless steel and zinc alloy metal, both giants of the engineering industry, share the same metallic glow, but their functioning, cost, and attitude towards utilization are worlds apart.

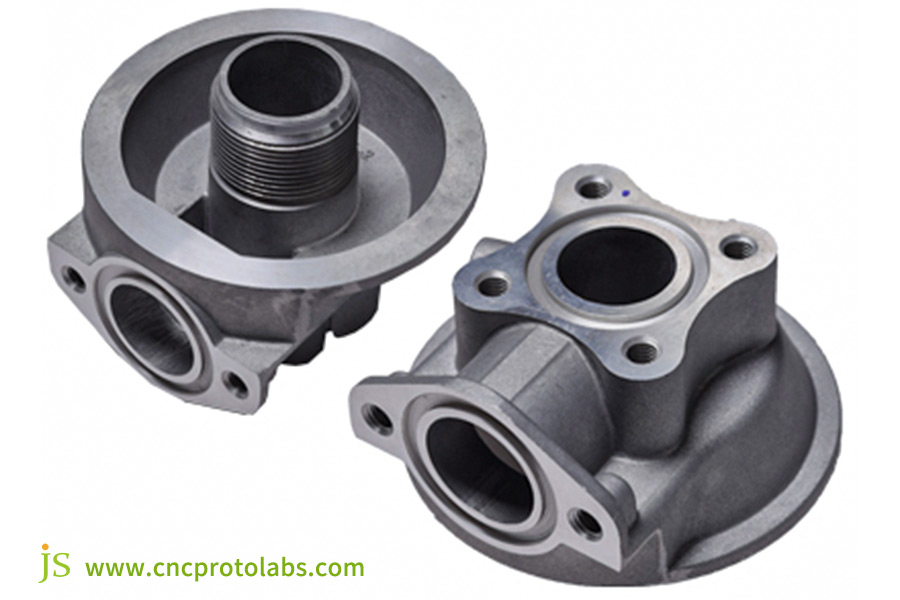

Drawn from JS Precision's own practical experience with metal casting, this manual will let you quickly compare the differences between zinc alloy and stainless steel, teach you how to choose the right material based on your product requirements, and avoid cost additions or product failure due to inappropriate material choice.

Core Answer Summary

| Comparative Dimensions | Zinc Alloy | Stainless Steel |

| Core Essence | A zinc-based family of alloys with additional alloying elements such as aluminum, copper, and magnesium. | A 10.5% or greater chromium content in terms of a family of corrosion-resistant steels. |

| Main Processes | Die-casting: Perfect for complex, thin-walled, high-accuracy components with very substantial cost advantages when manufactured in quantity. | Machining, stamping, laser cutting, and casting: Multiple alternatives of processes adjusted to suit different batch sizes. |

| Mechanical Properties | Typical strength, typical hardness, typical ductility, thus a typical brittle material. | Typical strength, typical hardness, typical ductility, thus a typical brittle material. |

| Corrosion Resistance | Typical, requiring surface treatment (e.g., electroplating or painting) in order to enhance and change the appearance. | Naturally resistant to corrosion (gracias al layer of passivation), particularly favorable for aggressive environments. |

| Cost Structure | Inexpensive per-item material cost, but high mold cost, hence very well-suited for production in high volume. | High material cost, but with higher flexibility in per-item processing, hence low volume runs may be more costly. |

| Weight and Feel | Heavy (high density), with heavy feel, typically achieved by electroplating. | Moderately light, with natural "cold" metallic feel. |

| General applications | Door handles, faucet trims, model toys, vehicle interior parts, gears. | Medical instruments, kitchen appliances, building curtain walls, exhaust pipes, chemical devices. |

Zinc Alloy Or Stainless Steel? JS Precision Can Help

JS Precision has more than 15 years of metal casting production experience with advanced technical expertise in zinc alloy high-pressure die-casting and precision machining of stainless steel.

We supply customers in diverse industries including smart home, consumer electronics, and automotive, manufacturing over 500 metal casting parts annually. Our metal casting parts range from heavy-duty car interior components to tiny sensor enclosures.

For example, we had already manufactured zinc alloy seat belt buckles for one of the leading automobile makers in 100,000 pieces per month with tolerances of ±0.05mm. We had also manufactured stainless steel precision brackets for consumer electronics clients where we achieved intricate structures through stamping and welding processes.

This guide is not a theoretical pile up but an experience product of our team in thousands of cases of material selection. Whatever small-batch prototyping or production you're undertaking, you'll find it a competent reference.

For custom metal casting parts, JS Precision's custom metal casting manufacturing services involve processing both zinc alloy and stainless steel. From project designing to product implementation, we offer professional service. Let's work together.

Zinc Alloy: Not Just A Metal, But Also An Engineering Material

After the mention of JS's metal casting skills, let us know more about zinc alloy. Its role in manufacturing is not just that of a metal, it's an engineering material whose importance lies in the fact that it makes complex components possible to produce.

Zinc Alloy Composition

Zinc alloys are based on zinc and additions of aluminum, copper, and magnesium, by way of examples, are typically utilized in order to achieve the highest performance. The type and proportion of each constituent, its function, and the conditions of application vary as seen in the table below:

| Added Element (or Base Element) | Recommended Content Range (Mass Fraction) | Primary Function | Typical Application |

| Zinc | 95%-98% | Supplies the alloy matrix, offering metal properties for application. | All zinc alloy metal casting parts. |

| Aluminum | 3%-5% | Creates the strength of the alloy and casting fluidity, enabling molding of complex structures. | Automotive sensor housings, complex consumer electronics enclosures. |

| Copper | 1%-2% | Raises the wear resistance and hardness of the alloy, ensuring component durability. | Automotive seat adjuster gears, seatbelt buckles. |

| Magnesium | 0.02%-0.05% | Inhibits alloy "aging" and increases long-term stability. | Long-duration automobile interior trim bases. |

The well-balanced combination of these contents makes zinc alloys ideal for many metal casting uses, aiming at part performance and application requirements precisely.

Detailed Analysis of Zinc Alloy Casting Processes

High pressure die casting is the most common process in zinc alloy casting. High-pressure die casting begins with melting the zinc alloy. The molten metal is highly pushed into a accurate mold cavity at high pressure (typically 30-150 MPa). After the metal solidifies and cools, the mold is opened and the casting pulled out.

High pressure die casting provides high production efficiency, one die casting per second. It can also make complex metal casting parts with high accuracy (tolerances up to ±0.02mm), suitable for mass production of zinc alloy metal components.

If you require precision-high, complex metal casting parts made of high-quality zinc alloy metal, JS Precision utilizes our proven high-pressure die-casting technology to produce precision-high, complex metal casting parts. We provide expert service through every phase from design optimization to production delivery.

Stainless Steel: Why Is It Called "Stainless"?

After discussing zinc alloy, let's talk about stainless steel. The secret of its legendary "stainless" fame lies in its unique composition and passivation film. Its processing technology is also unique, which makes it different from the die-casting process of zinc alloy.

Brief Composition and the Miracle of the "Passivation Film"

Stainless steel contains mainly iron and chromium (a minimum of 10.5%), with certain grades incorporating also such elements as nickel and molybdenum. Chromium oxidizes in air, creating an extremely thin (typically 3-5nm) and solid chromium oxide film on the surface of the stainless steel. This is the "passivation film."

This film prevents additional oxidation of the metal within, thus achieving the "stainless" effect and making stainless steel an excellent metal for galvanizing.

Major Processing Technologies

Processing technologies for stainless steel and zinc alloys are drastically different, as shown in the following table.

| Process Type | Materials | Major Advantage | Disadvantages |

| High-Pressure Die Casting | Zinc Alloy | Extremely high efficiency, can form complex structures. | Can be used only for low-melting-point metals such as zinc alloy metal. |

| Machining | Stainless Steel | High precision, suitable for small batch customization. | Large processing time and high cost. |

| Stamping | Stainless Steel | Rapidly produces simple thin-plate components. | Internal complex structures difficult to achieve. |

| Welding | Stainless Steel | Can produce complex large-scale structures. | Thermal control must be employed to prevent intergranular corrosion. |

Head-To-Head: Six Key Performance Comparisons Of Zinc Alloy And Stainless Steel

Having familiarized ourselves with the overall information on both materials, we carry out an in-depth comparison of zinc alloy metal and stainless steel from six key performance aspects to allow you to make a better choice on which material best meets your product needs:

Strength and Durability

Zinc alloy is of medium strength and can meet one's everyday needs at room temperatures, but its strength is ill-controlled when temperatures go above 100°C, resulting in lower durability.

Greater strength is offered by stainless steel, with grades 304 and 316 being capable of supporting high pressure and impact, offering stable performance at both room and high temperatures, and far outlasting zinc alloy in durability.

Cost and Volume Effects

The raw materials used in zinc alloys are cheap, and coupled with the addition of high pressure die casting, are conducive to mass production. Since the annual production is over 100,000 units, unit cost is as low as $1-3 with a significant cost economy.

However, stainless steel is costly in terms of raw material and complex processing, and hence unit cost is typically 2-5 times greater than zinc alloys. Therefore, mass production has little influence on cost saving.

Detail and Design Freedom

Zinc alloys, through high-pressure die-casting, have the capability to produce complex curved surfaces, thin walls (as low as 0.5mm), and complex internal structures with excellent design freedom.

Stainless steel can handle simpler structures, but complex internal structures need to be machined and assembled into numerous parts, which places greater design restrictions.

Corrosion Resistance

Zinc alloys oxidize easily and are of low corrosion resistance. Surface treatment such as electroplating is needed to improve corrosion resistance, and the final effect depends on the quality of the coating.

The corrosion resistance of stainless steel is caused by its passive film, and this performs best in dry environments. Even though it can form pitting corrosion under chloride ions or due to eroding of the passive film, its overall corrosion resistance is much superior to zinc alloys.

Weight and Aesthetics

Zinc alloy weighs around 7.14g/cm³ in density, thus heavier for the same amount, but it possesses a "premium" appearance. Electroplating makes it possible to achieve stylish appearances such as chrome or black titanium.

Stainless steel weighs around 7.93g/cm³ in density, thus heavier than zinc alloy for the same volume by an insignificant margin. Brushed or reflective finishes provide a plain metallic appearance.

Processing Efficiency

Zinc alloy high pressure die casting can provide high processing efficiency and can be applied to high-volume production at high speed.

Stainless steel processing involves multiple processes and thus has a long process from raw material processing to molding, which makes it inefficient and suitable for low-volume production.

How To Easily And Accurately Differentiate Galvanized Steel Parts From Zinc Alloy Die Casting

In actual manufacturing, we typically have to distinguish galvanized steel parts from zinc alloy die casting parts. The following four methods are simple and effective:

1.Weight Method

For pieces of similar size, the density of zinc alloy is approximately 7.14g/cm³, which is more than galvanized steel (steel's density is approximately 7.85g/cm³, and due to the zinc plating being so thin, the overall density is closer to steel). Zinc alloy pieces are therefore significantly heavier.

2.Magnet Method

Most of the stainless steels (such as 304) are slightly magnetic or non-magnetic. Galvanized steel, depending on the steel, is highly magnetic. Zinc alloy itself is not magnetic, and hence magnet attraction can be used to sort them out easily.

3.Appearance and Detail Observation

Zinc alloy die castings typically have ejector pin marks (small marks at the back of the component) and parting lines (narrow lines along the perimeter of the component), allowing very detailed hollow structures. Galvanized steel components are mostly stamped or bent, producing sharper edges and corners and simpler internal hollow structures.

4.Destructive Testing (Not Recommended)

Scraping the edges of a part with a file reveals a silvery-white interior of the zinc alloy, while the interior of the galvanized steel is dark gray, similar to steel. The color difference between the two materials is evident, but this method can damage the part.

Hidden Champion: The Extraordinary Application Of Zinc Alloy In The Automotive Industry

Although weaker than stainless steel, zinc alloy's excellent castability and particular properties have made it a "hidden champion" in the automotive industry. It is primarily used in the following areas:

1.Interior: Certain of the automobile components such as buttons, seatbelt buckles, and interior trim bases are routinely made from zinc alloy. Zinc alloy's excellent castability allows delicate structure in components, while after electroplating, it gives a beautiful metallic texture that satisfies the styling requirements of automobile interiors.

2.Locks and Security Systems: Zinc alloy is used in small gears in automobile door locks and seat regulators on a regular basis. Some zinc alloys contain copper and possess excellent wear resistance and self-lubrication, ensuring long-term and stable operation of locks and regulators.

3.Engine Peripherals: Zinc alloys are also used in engine peripheral parts, such as carburetor components and sensor housings. The zinc alloys undergo a special treatment to offer some degree of heat resistance (can sustain 120-150°C) and sealing characteristics, fitting the engine operating environment.

There is a rare point that zinc alloys exhibit superplasticity. Under some temperature (around 250-300°C) and low-velocity tensile conditions, their elongation exceeds 100%, and they can be formed into complex shapes. This characteristic gives zinc alloys a unique advantage in the manufacturing of specialty-shaped automotive parts.

JS Precision's custom metal casting manufacturing business is capable of providing a range of zinc alloy automotive parts on a tailored basis for the needs of the automotive industry, from internal buttons to sensor cases, up to high-grade requirements and facilitating greater automotive product quality.

Dispelling Common Myths: Choosing The Ideal Material For Your Project

The majority of people become entangled in myths while deciding on materials, such as thinking "stainless steel is definitely better." The reality is that, depending upon the actual requirements of the product, material selection is done. You can apply the following four questions in order to make the best decision:

Question 1: Is there heavy pressure or a strong impact needed for your product?

If yes, then stainless steel is a top priority because its strength and durability have space for such requirements. Otherwise, zinc alloy is a better option.

Question 2: Is your level of annual production more than 100,000 units?

If so, zinc alloy is extremely cost advantageous, and economies of scale around high-pressure die-casting really can bring unit costs down. If lower levels of annual production are in question, stainless steel offers greater process flexibility.

Question 3: Does the shape involve complex curves, thin walls, or a complicated internal structure?

If yes, then zinc alloy die-casting is ideal since it can mold intricate shapes in a single operation. In case the design is simple, stainless steel stamping or machining will be more suitable.

Question 4: Will the product be exposed to chemicals or moisture for a long time, and surface treatment cannot be accomplished?

If the answer is yes, then stainless steel is a necessity because its corrosion resistance can make it play its role effectively in harsh surroundings. If surface treatment can be accomplished, then zinc alloy electroplating can also work according to your needs.

Small-batch customization or high-volume manufacturing, JS's online metal casting service is an option that can suit your needs. We will recommend the optimal material and process depending on your product requirements and provide transparent metal casting prices without charging you time and money.

Case Study: Material Selection For a High-End Car Aromatherapy Diffuser Housing

Background

A company was to launch a high-end car aromatherapy diffuser. They required a metallic appearance, a "premium" hand touch (customers would be overweight in hand), and a multi-level design (with different internal grilles for diffusion of aroma).

Having a production capacity of 200,000 pieces annually, they would have low cost with high quality. Between welding and stainless steel stamping and zinc alloy die casting, a choice had to be made by the company.

JS Precision Solution Analysis and Choice

JS Precision carried out a detailed analysis of two possibilities:

Stainless Steel:

Excellent texture and strong durability, not easily damaged after long-term use. However, the complex inner multi-layer grille is difficult to manufacture using stamping. The grille must be stamped out into multiple pieces and then welded and assembled together.

Not only is the processing level higher, but also the costs are very expensive (estimated unit cost at $5). Additionally, the stainless steel parts are relatively light in weight (approximately 10% lighter than equivalent-sized zinc alloy parts), falling short of "premium" positioning.

Zinc Alloy (preference of JS Precision):

The entire intricate housing can be die-cast in one go with high pressure die casting, along with it an exquisitely formed internal multi-layer grille without assembling. A metallic appearance close to stainless steel can be attained with the aid of ideal electroplating processes such as chrome and black titanium.

The zinc alloy parts weigh heavily, in accord with high-end image. At a production level of 200,000 pieces, the price per unit of the part is only $2.5, a far cry from the stainless steel variant.

Final Decision and Outcome

The company ultimately settled for the zinc alloy die-casting option. With the success of the launch of the product, it received positive market acclaim because of its endearing details (symmetrical and elegant internal grille), excellent touch (weighty feel), and worthwhile price (30% cheaper compared to similar stainless steel options).

More than 10,000 units were sold in the first month. This case really shows that choosing right material is not a choice of the "best," but the "most appropriate," and the best choice was zinc alloy.

If you are in need of identical product development requirements and require custom metal casting parts, JS Precision offers you complete services from idea evaluation to manufacturing and shipping. Whether zinc alloy metal or stainless steel parts, we can meet your price and quality needs.

FAQs

Q1: Are zinc alloy die-castings environmentally friendly?

Zinc alloy die-casting is very environmentally friendly. As zinc is a metal that can be infinitely recycled, recycling takes only 30% of the energy required by virgin zinc production. Besides saving the excavation of mineral resources, it reduces carbon emissions for production, in accordance with the path of green development of new manufacturing.

Q2: What are the two most important differences from the aspect of surface treatment?

Surface treatment must be done for zinc alloy die-casting. It can be oxidized and rusted in its body, which makes it look dull. Electroplating, spraying, and other treatments have to be done to provide an ornamental finish as well as additional corrosion protection. The surface treatments in stainless steel are mainly for functional purposes or appearance enhancement. The body is already quite presentable and corrosion-resistant.

Q3: Is stainless steel rust-proof by itself?

No. Stainless steel does rust when it is subjected to some conditions,e.g., chloride ions (seaside brine, detergents), or if the passive layer is damaged due to mechanical wear, so that the inner iron is exposed to air and rusts, a form of "pitting." But its corrosion is much unlike that of plain carbon steel, and under typical use, its life is much longer than that of carbon steel.

Q4: Can stainless steel components in existing products be substituted with zinc alloy components just to lower costs?

Absolutely cannot be easily replaced! This is a fundamental engineering decision that needs to be reconsidered. Due to the remarkable performance difference between stainless steel and zinc alloy, direct substitutability might result in inferior products. For example, part substitution of a pressure-bearing stainless steel part by zinc alloy can result in fracture. It would also call for mold and process redesign.

Summary

There is no absolute winner between zinc alloy and stainless steel, only the best match based on specific project requirements (performance, cost, batch size, design).Zinc alloy is an "economist of form and scale," while stainless steel is a "defender of strength and endurance."

JS Precision specializes in custom metal casting manufacturing like zinc alloy die casting and stainless steel processing. You may select online metal casting services or metal casting prices, and we will be in a position to serve you professionally.

Get in touch with us today to submit your product concept and details. We shall send a professional proposal with recommended materials, process analysis, and costing estimation in order to ensure you make the most appropriate decision!

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com