As a leading metal casting method,die-casting is transforming the parts manufacturing world in sectors from autos to consumer electronics with its advantages of high efficiency,precision,and durability.

Summary Of Core Answers

| Aspects | Core Content |

| Core Advantages of Die Casting | Compared to sand casting, die-casting has significant advantages in dimensional accuracy, efficiency, and material utilization, making it suitable for complex structures. |

| Main Die Casting Types | Hot chamber die casting is suitable for small parts made from low-melting-point alloys, while cold chamber die casting is suitable for large parts made from high-temperature alloys. |

| Die Casting Material Selection | Strength and other factors should be considered. Aluminum, zinc, magnesium, and copper alloys are commonly used, each with its own application scenarios. |

| Optimal Die Casting Applications | Suitable for large-volume, complex, high-precision parts in industries such as automotive, electronics, and aerospace. |

| Die Casting Project Considerations | Attention should be paid to design optimization, production management, supplier selection, and quality inspection to ensure project progress. |

Why Trust This Article?Experience From The JS Team

We have vast experience in high-pressure casting at JS,dealing with orders from precision aerospace parts to intricate auto housings.We are well versed in aluminum,zinc,and magnesium alloy casting characteristics.Our facilities run around the clock with modern die-casting machinery,and each process is governed by stringent ISO9001:2015 standards.

JS is a pressure die casting specialist and an ISO9001:2015 business that ships rapidly from prototype to series production.We pursue excellence and use experience to ensure the quality of metal casting parts.Engaging us makes your project more reliable.

Core Benefits Of Die Casting:Why Die Casting Rather Than Other Processes?

Die Casting vs. Sand Casting

1.Dimensional Accuracy: Die casting's high pressure forces the molten metal to adhere tightly to the mold,with dimensional tolerances of ±0.1 mm per 25 mm and very thin,even walls.Sand casting is subject to warping,which generates greater dimensional errors,thicker walls,and less for post-production tolerance.

2.Production Efficiency: Molding the die casting mold is time-consuming,but a single cycle takes tens of seconds only,hence best suited for manufacturing large quantities of parts.Sand molds are simple to make ready,but the cooling cycle for each part is lengthy,and hence suitable for small batch production.

3.Surface Quality: Die-castings,protected by the metal mold,have a flat surface,meeting most requirements without post-processing.The surface of sand castings is roughened by sand particles and often must undergo post-processing such as pickling and polishing.

4.Cost-Effectiveness: The metal molds used in die-casting require an enormous initial investment,but the cost per unit is low for large quantities.Sand casting,in contrast,has lower mold cost but higher labor cost in small-scale production,so it is more advantageous.

Die Casting vs. CNC Machining

1.Material Utilization: Die-casting produces minimal waste(5%-10%) in the runners and gates,which can be reused and remelted,with a material usage rate of over 90%.CNC machining is a subtractive manufacturing process,and material loss for complex parts is typically over 50%,especially for precious metals.The cost difference is immense.

2.Batch Efficiency: Once the die-casting mold is ready,production can be automated,hundreds of parts are produced in one hour,and thus it is for large batches.CNC machining is convenient to produce small batches,but large batches take long cycle time.

3.Inherent Structural Complexity: Die casting has the potential to combine complex structures into a single piece,reducing assembly costs.CNC machining of complex cavities is costly and typically involves several assembly operations.

4.Prototyping: Die casting cannot be utilized during prototyping.The design modifications have to be re-molded,and this incurs costs and lead times.CNC machining only requires the CAD model modified,which offers greater flexibility.

Die Casting vs. Stamping:

- Product Complexity: Die casting can produce complex shapes with cavities,curved surfaces,and bosses.Only flat and curved shapes can be produced by stamping.Deep cavities and shapes with irregular forms tend to crack.

- Material Waste: Die casting produces negligible waste,which is 100% recyclable.Stamping produces 20%-30% scrap due to cutting sheet metal,and recycling is expensive.Thin metal strips exhibit a higher wastage rate.

- Materials Used: Die casting is limited to low-melting-point non-ferrous metals.Stamping processes high-strength metals such as steel and iron but high-hardness alloys(such as stainless steel) are prone to mold wear.

- Cost Structure: Die cast mold expense is high,both because production of complicated parts in one shot lowers assembling cost and because mold expenses are high both for stamping equipment and molds.However,complicated parts can be processed step by step using many sets of molds,driving the total cost of production high.

Comparison of Die Ca sting Advantages with Other Processes

| Comparison Dimensions | Die Casting | Sand Casting | CNC Machining | Stamping |

| Dimensional Accuracy | High (±0.1mm/25mm), thin and uniform walls | Low (±1mm+), thicker walls | Very High (±0.001mm) | Medium (suitable for simple shapes) |

| Production Efficiency | Fast for large batches (hundreds of parts per hour) | Fast for small batches (dozens of parts per day) | Flexible for small batches (several hours per part) | Fast for simple parts (hundreds per minute) |

| Material Utilization | Over 90%, scrap can be remelted | 70%-80% | 30%-60% (subtractive manufacturing) | 60%-70% (high scrap) |

| Complex Structure Capability | Capable of producing complex parts with cavities and curved surfaces | Suitable for large and complex parts, but with low accuracy | High cost for processing complex cavities | Limited to simple geometries |

| Initial Equipment Cost | High (mold + furnace + die casting machine) | Low (sand mold equipment) | Medium-to-high (CNC machine tools) | Medium (Stamping machine) |

JS enhances the superior accuracy and efficiency of die casting.Our parts are rugged and precise,readily achieving tolerances of 0.05-0.3 mm.We provide transparent metal casting prices.Having us in your corner frees your manufacturing from concerns.

Mass Market Die Casting Types:Hot Chamber vs. Cold Chamber

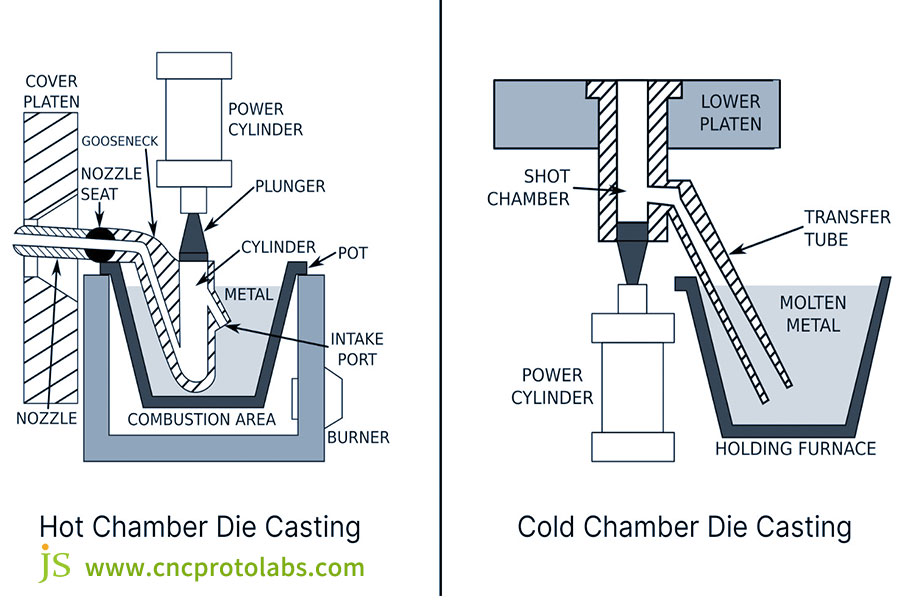

Hot Chamber Die Casting

1.Basic Concept: For alloys with low melting point(<450°C),e.g.,zinc,tin,and lead,it is used in the manufacturing of small-to medium-sized parts(e.g.,casing of electronics and USB stick casings).

2.Key Features: Short production cycle(30-60 seconds/cycle),suitable for large batch production.good surface finish.Inexpensive equipment cost(integral design).However,this method is applicable only for low melting point alloys,and weights of components are typically less than 5kg.

Cold Chamber Die Casting

1.Basic Concept: For high-temperature alloys(melting point>600°C),such as aluminum,copper,and magnesium,and capable of making larger and more complex shapes(such as engine blocks and heavy mechanical components).

2.Key Characteristics: High material flexibility,part weights of tens of kilograms.extended mold life.Good mechanical properties(controlled cooling,strengthens the parts).However,the cycle time is long(60-120 seconds/cycle)and the equipment price is high(furnace part of the equipment).

JS is very experienced in both cold-chamber and hot-chamber die-casting.We provide online metal casting services,whether it is to produce small aluminum-magnesium alloy components or large zinc alloy components,we are able to efficiently produce them for your needs.

Material Selection:Key Considerations For Die-Casting Alloys

Core Considerations

- Toughness and Strength: The loads and stresses the part must withstand determine the material's strength requirement(e.g.,engine parts of a vehicle require high-strength aluminum alloys).Moreover,the material must withstand the higher temperatures and pressures involved in die casting.

- Fluidity and Melting Point: Low-melting point materials(e.g.,aluminum,zinc)are easier to process,while good-fluidity materials(e.g.,magnesium alloys)penetrate complex mold cavities better,reducing short-cut defects.

- Corrosion Resistance: Select corrosion-resistance materials based on the application environment(humidity,high temperature,chemical corrosion)to minimize premature part failure.

- Cost-Effectiveness: Zinc and aluminum are easily processable and ideally suited for mass production.Magnesium and copper are costly and involve specialized tooling,and therefore are particularly well suited to small-production,high-precision parts.

- Environmental and Long-Term Performance: Employ highly recyclable materials(zinc and aluminum recycling rate>85%),and where applicable,choose long-term properties like wear resistance(e.g.,390 aluminum alloy)and creep resistance(e.g.,magnesium alloy).

Common Alloys for Die-Casting and Their Applications

- Aluminum Alloys: They possess a favorable strength-to-weight ratio,good temperature resistance,high thermal and electrical conductivity,and are thereby applied for cold-chamber die-casting.They are used in widespread application throughout the automotive industry,e.g.,transmission housings and water pump housings.

- Zinc Alloys: Affordable,easy casting,excellent surface finish,outstanding corrosion resistance,ductility,and excellent impact strength.Suitable for the mass production of detailed small parts(e.g.,consumer electronics housing and automobile interior trim parts),with excellent electroplating compatibility.

- Magnesium alloy: The most lightweight structural metal,with excellent rigidity and damping properties,excellent impact resistance,and hot chamber die casting compatible..It is the best choice for weight-loss articles used in aerospace and automotive applications,and boasts long mold life(no sticking).

- Copper alloy: High conductivity and corrosion resistance,but high melting point and expensive,cracking during die casting and therefore not widely utilized.They are primarily used in electronic and electrical devices(cable assemblies,sockets)and heat spreading devices.

JS uses advanced aluminum,zinc,and magnesium alloys in high-pressure casting,resulting in high-strength materials and high accuracy.No matter how complex the part is,we can realize high-strength and surface-smooth products.Contact us today.

When To Use Die Casting:Best Application Scenarios

Die casting is suitable for some applications,and its advantages are best realized when the following conditions are met:

Core Applications Suitable for Die Casting

- Large-Scale Production: Die casting mould costs are initially high,but the unit price will be lower with higher production volume.When there are more than 1,000 pieces produced each day and more than 10,000 pieces produced in total,die casting has notable advantages in efficiency and costs.

- Complex Parts of High Precision: Parts with tight tolerance(±0.1mm)and complex shape(e.g.,hydraulic valve blocks and medical device casings)can be produced in a single operation by die casting,avoiding assembly errors.

- Material Compatibility: Die casting alloys such as aluminum,zinc,and magnesium are the materials used,and certain specifications of strength,corrosion,and weight are met(e.g.,light-weight magnesium alloys for aircraft components).

Typical Application Industries

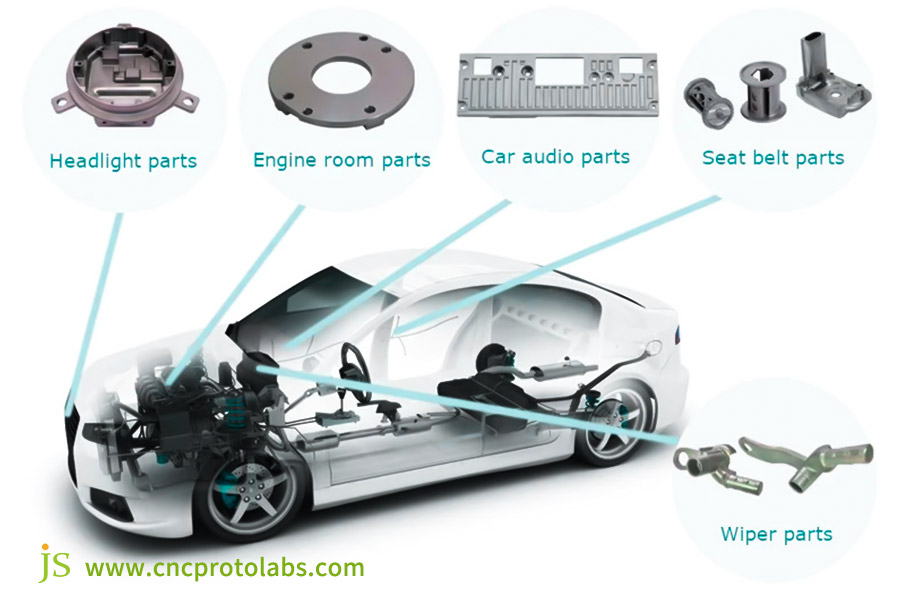

- Automotive: Manufacturing of key components such as engine blocks,crankshafts,and transmission housings.Aluminium and magnesium alloys assist in light weighting the vehicle and thus enhancing fuel efficiency(for every 100kg weight reduction,fuel use saves 0.6L/100km).

- Electronics: Manufacturing of mobile phone casing,connectors,heat sinks,etc.Zinc and aluminium alloys' high accuracy and surface finish fulfill looks as well as functionality.

- Aerospace: Manufacturing lightweight structure parts(e.g.,drone body).The low mass and high stiffness of magnesium alloys maximize equipment lifespan and stability.

- Medical: Making accurate components such as pacemakers and ultrasound machines.Consistent die-casting ensures reliable operation.

- Industrial Equipment: Making parts such as gearboxes for farm equipment and hubs for mining machinery must withstand harsh conditions.The strength and resistance to corrosion of aluminum alloys guarantee such conditions to be fulfilled.

JS Die Casting specializes in complex,high-volume pieces in the automotive,aerospace,and other markets.Our customized solutions deliver strength and precision,adaptable to various circumstances.Please get back to us.

Getting Started With Your Die-Casting Project

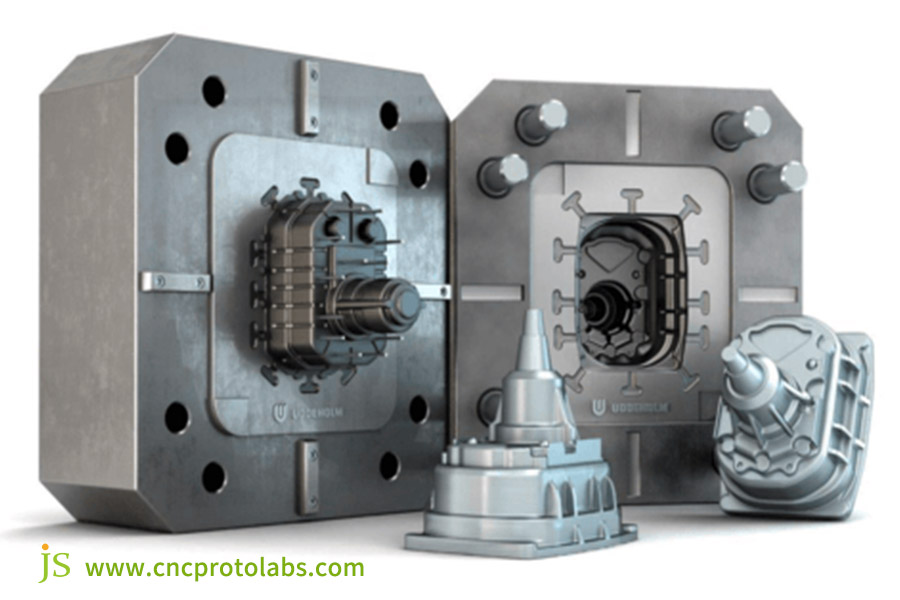

Design Key Points

- Mold Compatibility: The mold should be able to resist high temperature and high pressure(die-casting molds for cold-chamber need to resist more than 600°C),having uniform dimensions.Draft angle(1-3 degrees,greater for intricate parts)has to be provided in part design to ensure ejection and avoid die jamming.

- Structural Detail Optimization: The radii and corners need to be rounded(use large radii where stress is high)to reduce stress concentration.Wall thickness should be uniform(≥1.016mm for small aluminum parts,≥0.381mm for small zinc parts)to avoid sudden thickness changes that could cause shrinkage.

- Parting Line and Post-Processing: The parting line should be on non-exterior surfaces to minimize the impact of flash.Threads and undercuts should be created primarily by the mold core in order to minimize post-processing(cost and lead time-increasing).

Production and Cost Management

- Batch Planning: Select a process based on the volume of production—if under 10,000 pieces a year,alternate processes are feasible.if over 100,000 pieces a year,die casting is more cost-effective.Also,include provision for mold maintenance(the mold has to be inspected every 100,000 pieces).

- Costing: This includes mold costs(30%-50% of the total investment),material costs,energy and labor consumption(cold chamber die casting uses more energy than hot chamber die casting),ensuring the entire budget is covered.

Supplier and Quality Control

- Supplier selection: Choose industry-veteran suppliers(e.g.,IATF16949 certification is required in the auto sector)who provide end-to-end solutions from mold design to post-processing,reducing communication costs.

- Quality Inspection: In manufacturing,dimensional integrity(coordinate measurement),surface finish(visual inspection or measuring surface roughness),and mechanical integrity(tensile test and hardness test)must be verified.Critical parts are pressure tested and fatigue tested for dependability.

Start your die casting project and let JS help you with it from start to finish.From optimization in design to the checking of the quality of production,we are professional and reliable,and we can provide fast quotes.Choose us for seamless project progression.

FAQs

Q1:How durable are die-cast parts?

Die-cast parts are very strong,especially cold-chamber die-cast magnesium alloy and aluminum components.They depend mostly on the selected grade of alloy,the casting design,and process control.They are usually equivalent to or greater than corresponding forgings.

Q2:What is the minimum wall thickness with die-casting?

It depends on the material and thickness of the part.Zinc alloys are 0.5mm or less,aluminum alloys approximately 0.8-1.0mm,and magnesium alloys similarly.Smaller wall thickness requires more precise tooling and process control.

Q3:How much would a die-casting mold approximately cost?

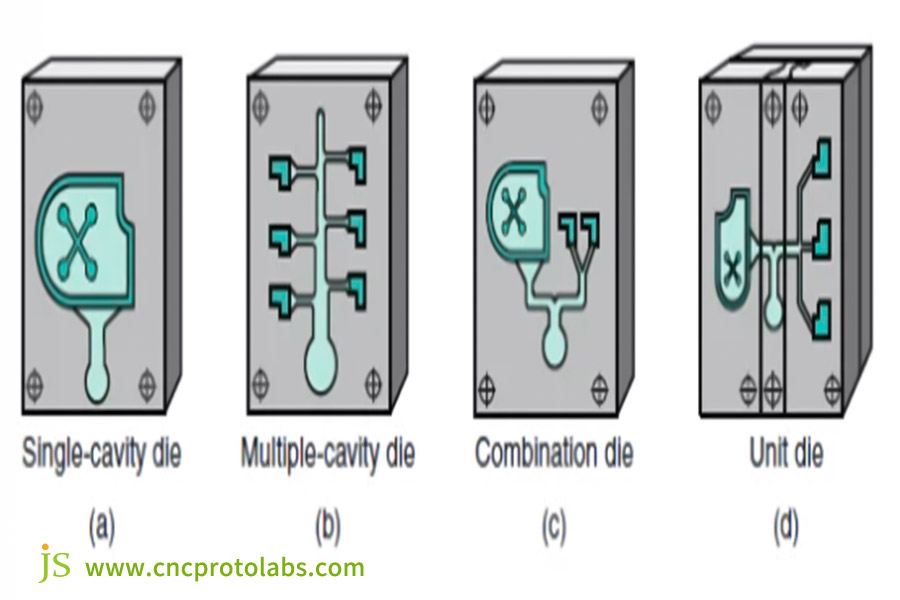

Mold costs vary greatly,from thousands of dollars to hundreds of thousands of dollars.This will depend greatly on part size,complexity,number of cavities per mold,mold material(grade of steel),and surface finish requirements.

Summary

Contact us, upload your design drawings, get a quick quote, and help your custom metal die casting manufacturing project succeed!

Disclaimer

The contents of this page are for informational purposes only.JS servicesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Jusheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com