Two seemingly identical metal pieces, one having a moon-like surface at the microscopic level, the other mirror-smooth. If they are employed in an engine running at high speeds, the former might fail prematurely because of excessive friction, while the latter passes silently into its planned lifespan. This micrometer level difference often determines the success, reputation, and cost of a product.

This is surface finish science and art. It directly affects a part's wear and tear, sealing, corrosion resistance, fatigue strength, and appearance.

This booklet will unlock all of the surface finish chart secrets, ranging from cracking tough symbols to thinking in terms of cost-effectiveness, so that you can make the most intelligent manufacturing choices every time. This booklet will allow you to master basic know-how and apply JS's expert services to improve part quality.

Core Answer Summary

| Comparison Aspects | Macro Finishing | Micro Finishing |

| Focus | Global shape features such as geometry, flatness, and contour. | Surface features such as microscopic peaks and valleys, roughness, and waviness. |

| Measuring Tools | Coordinate Measuring Machine (CMM), Optical Flatbed, Micrometer. | Surface Roughness Tester (Profilometer), Atomic Force Microscope (AFM). |

| Characteristic Parameters | Straightness, Flatness, Millimeter (mm) Units. | Ra, Rz, Rq, etc., Micrometers (μm) or Microinches (μin) Units. |

| Influence Factors | Machine Tool Accuracy, Tool Deflection, Thermal Stress. | Tool Shape, Feed Rate, Cutting Parameters, Abrasive Grit Size. |

| Primary Purpose | Ensure Parts Fit Properly and Functionally. | Optimize Friction, Lubrication, Fatigue Life, Appearance, and Sealing Performance. |

Why Trust This Guide? JS Technical Team Chart Interpretation

JS technical team has over 15 years of hands-on experience in surface treatment. We optimized aerospace precision aluminum alloy parts' surface finish for sealing performance under high pressure and high altitude. We have also solved the issue of engine block surface texture for the automotive industry, improved heat dissipation efficiency, and prolonged service life.

We have served clients in over 30 industries and performed over 100,000 surface finish parts throughout our years of operations, accumulating extensive experience in treating surface finish for different materials and different operating conditions.

This guidebook is the culmination of our team's compilation of this practical experience and expert knowledge based on a number of authoritative surface finish charts. Whether you need to specify the appropriate surface finish parameters or solve existing surface quality issues, this guidebook is a reliable guide.

JS, with extensive industry expertise and extensive experience in surface finishing parts, can provide custom surface finishing manufacturing solutions. Choose our online surface finishing services and allow our experienced team to take care of your manufacturing needs.

What Is Surface Finish? Why Is It a Manufacturing "Fingerprint"?

Surface finish is the microscopic geometric characteristic of a machined product. Like a manufacturing "fingerprint," it reveals the processing technology, material characteristics, and target application, allowing you to control part quality and performance.

Basic Definition

Surface finish measures the smoothness and flatness of a component's surface. Apart from its appearance, it also directly affects sealing, wear resistance, and corrosion resistance. Seals, for example, require high finish to seal tightly, while wear parts require exactly the right amount of roughness to improve friction.

Core Composition

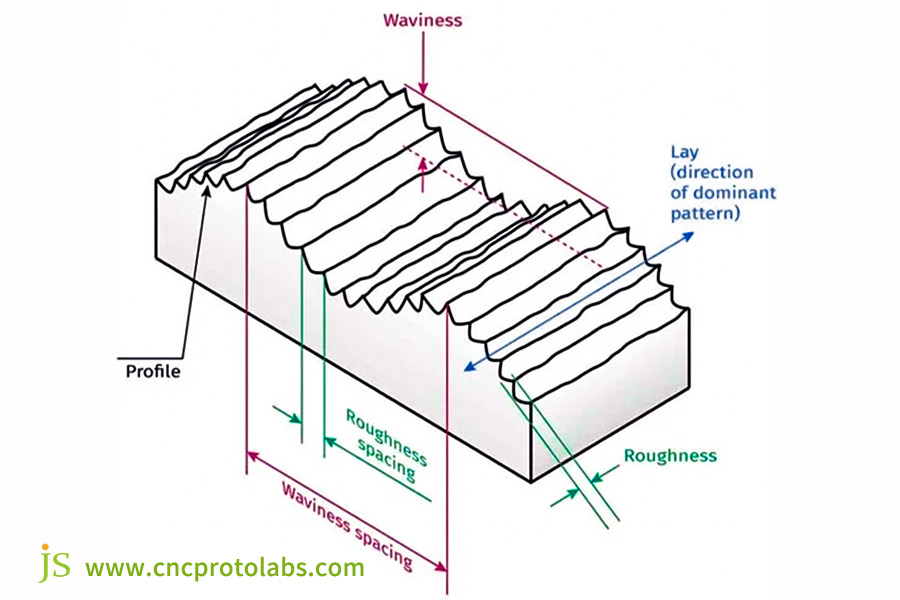

- Roughness: Microscopic surface irregularities having a wavelength of 0.001-0.1 mm, resulting from machining tool marks (e.g., milling cutter marks).

- Waviness: Mesoscopic undulations having a wavelength of 0.1-10 mm, resulting from equipment vibration and insufficient part stiffness, affecting assembly accuracy and appearance.

- Texture: The directionality of machining marks (e.g., lathe circular marks and milling machine parallel marks) dictates wear resistance and sealing performance. As an example, if the texture of the sealing surface is oriented parallel to the direction of flow, it may have the potential to increase the leakage risk.

Quantifying Tactile Feel: How To Accurately Measure Surface Roughness

To ensure that the surface finish of the part is as needed, you must first measure the roughness of the surface accurately. There are three ways to measure and each of them is appropriate to a particular set of circumstances, you can select one based on what you require:

| Measurement Method | Strengths | Weaknesses | Uses |

| Contact Measurement | Accurate, repeatable data. | Slow, might scratch surface. | Precision parts (bearings, seals). |

| Non-contact Measurement | Rapid, no surface damage. | Costly equipment, very sensitive to light. | Soft material parts molded gently (plastic, copper). |

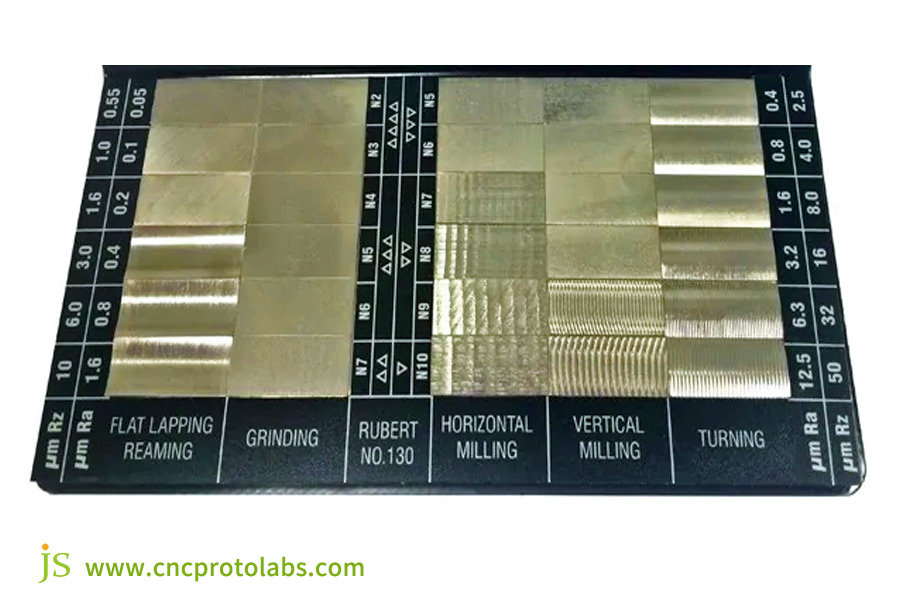

| Comparison Method | Simple to operate, cheap. | Rough results, operator-dependent. | Initial checks, rapid batch checking. |

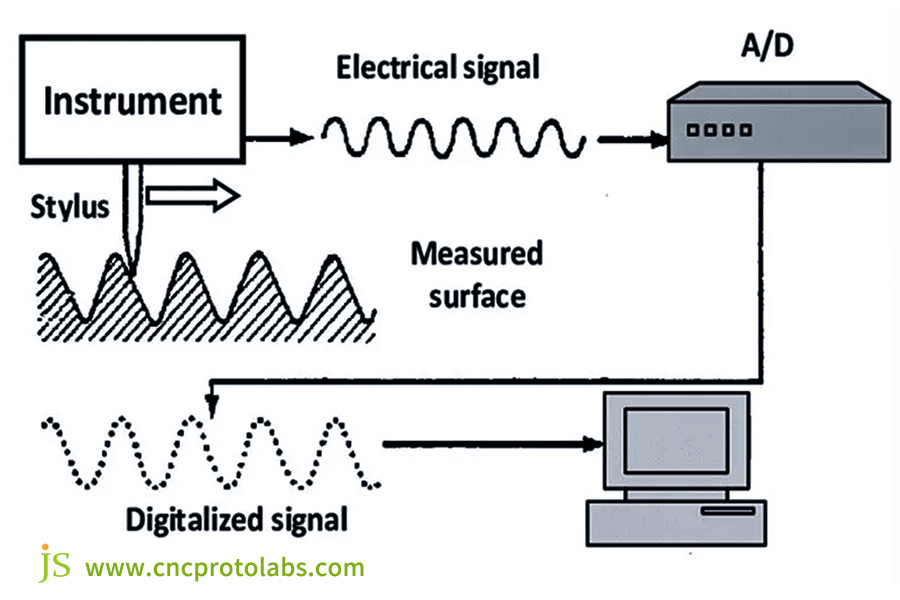

- Contact measurement is the prevalent method, calculating roughness by traversing a probe to record surface undulations.

- Non-contact measurement is a high-tech method, employing laser and optical technology.

- Comparison method employs a surface roughness comparison sample (Ra template) for determining the grade by visual and feel comparison.

JS offers professional contact and non-contact testing instruments to provide you with accurate roughness measurement for your surface finishing parts. We also have online surface finishing services, allowing you to access test results whenever you desire.

Breaking The "Code": Translating Surface Finish Symbols And Abbreviations

The surface finish symbols and abbreviations on engineering drawings are a "code." Understanding what they are becomes critical to accurately interpreting the requirements.

Detailed Description of Basic Symbols

- √: General symbol, indicating a surface to be machined, but not specifying a specific process.

- √ with a dash: Material must be taken away (e.g., milling, grinding, turning).

- √ with a circle: Material removal is unnecessary (e.g., the as-cast surface of a forging or casting, or the surface of an injection molding plastic part).

- √ with a spherical symbol (Ø): Spherical surface, requesting a roughness indicator.

Parameter Abbreviations Required

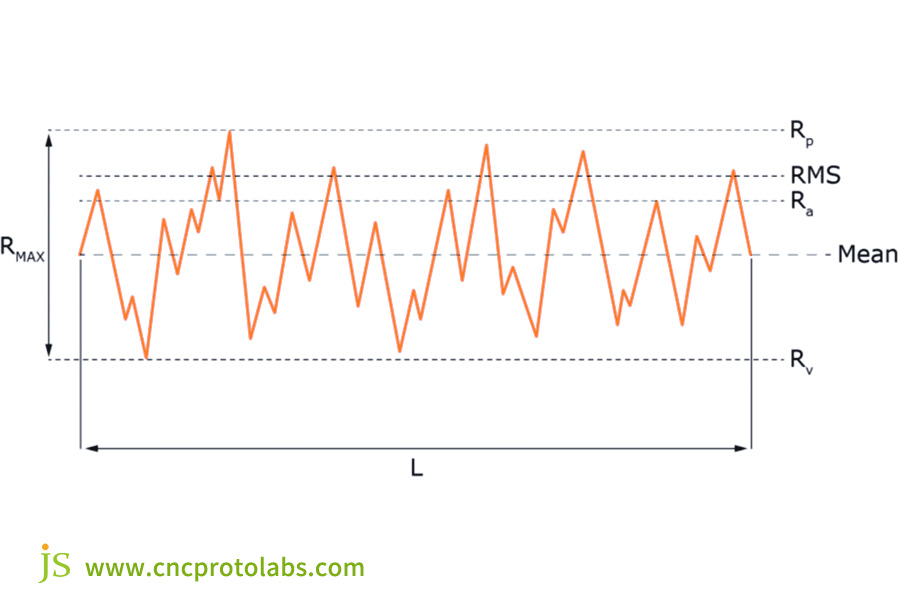

- Ra (Arithmetic Mean Deviation): The arithmetic mean of the distance of the points on a contour to the reference line in the sampling length. It is the most common measurement, the lower this value, the smoother the surface (for example, Ra 0.8μm is smoother than Ra 3.2μm).

- Rz (Maximum Height): Sum of maximum peak height and maximum valley depth within sampling length. Applied to components subject to impact loading.

- Rq (Root Mean Square Deviation): Square root of the arithmetic mean of squares of distances between contour points and the reference line within sampling length, which is more sensitive to peaks and valleys and reflects more comprehensively.

- Less common but key parameters: Rsk (skewness) indicates profile asymmetry (positive figures indicate multiple peaks, negative figures indicate multiple troughs). Rku (kurtosis) indicates profile sharpness (large figures indicate increased wear).

Example symbol interpretation

Employ "√̄ Ra 0.8μm Rz 6.3μm ∥ 2.5mm" as an example:

- "√̄ " indicates material must be removed.

- "Ra 0.8μm" is the arithmetic mean deviation.

- "Rz 6.3μm" is the maximum height.

- "∥" indicates that the texture is parallel to the plane of view.

- "2.5mm" is the sampling length.

JS engineers know various abbreviations and symbols for different surface finish and can aid you in the correct interpretation of drawing specifications. We also provide custom surface finishing manufacturing service where we customize machining solutions to your symbol requirements such that parts are manufactured as per design specifications.

Common Language: Master Key Surface Finish Standards

Each country and industry has specific standards for surface finish. Understanding these standards avoids confusion and losses in collaboration:

| Standard Type | Main Standard Number | Core Features | Applicable Regions/Industries |

| International Standard (ISO) | ISO 4287 | Standardized and universal parameters, with definitive Ra/Rz definitions and measurements. | Global (predominantly Europe and Asia). |

| American Standard (ASME) | ASME B46.1 | Specific grain direction and process method notation. | Appropriate for the United States and North America. |

| Industry-Specific Standards | Medical: ISO 10993-1 | High-finish quality, emphasizing sterility and biocompatibility. | Used in the medical device industry. |

| Industry-Specific Standards | Aerospace: SAE AS9100 | Corrosion and wear resistance, for extreme environments. | Used in the aerospace industry. |

Surface Finish Cost Drivers - In-Depth Analysis

Cost is a factor when choosing a surface finish, the rule of thumb is usually "the smoother, the more expensive." Knowing cost drivers will allow you to optimize costs while satisfying functional requirements.

The "Smoother, the More Expensive" Rule

A Ra of 3.2μm (routine milling) will run about $5 per part, a Ra of 0.8μm (milling + fine reaming) will run about $8, and a Ra of 0.025μm (mirror polishing, multi-steps) will run over $20.

Cost Drivers

- Processing Time: The higher the finish, the more operations required, and the longer the processing time (e.g., Ra 3.2 → 0.8 requires fine reaming and increases processing time by more than 30%).

- Equipment Investment: Accuracy machining and measurement tools are expensive (e.g., non-contact laser measurement tools can be more than 50% more expensive than traditional contact instruments).

- Material Removal: High precision machining requires additional material removal (such as removing 20% more material from stainless steel Ra 0.4 than 1.6).

- Labor Cost: High-precision machining encompasses using skilled technicians that increase the labor cost.

Key Recommendations

Define a "good enough" instead of a "best" finish.Very high finishes are costly without the need to be more functional.

For instance, while a typical bracket with an Ra 6.3μm is acceptable, insisting on a Ra 0.8μm will simply incur unnecessary expense. The functional requirements of the parts, such as sealing and wear resistance, should be communicated with the manufacturer before determining the appropriate smoothness.

JS can provide you with an open surface finishing price estimate. We will recommend the appropriate surface finish grade by your functional requirement, containing your costs while preserving part performance and avoiding unnecessary expenses.

Beyond Flat Surfaces: Surface Finish Challenges For Complex Curves And Internal Channels

Many parts contain structures such as complex surfaces, deep holes, and small threads.These "hidden" surfaces are critical to performance (e.g., the interior wall of a pipe affects fluid flow), but can be challenging to measure and process.

Problem

Traditional contact probes cannot penetrate curved pipes, deep holes, or thread gaps, nor fully touch complex gear tooth surfaces, and therefore yield erroneous measurements. Bad surface finish can easily lead to fluid flow problems and premature component wear.

For example, bad surface finish on curved pipes in hydraulic systems is likely to increase fluid flow resistance, hold contaminants, and decrease system life.

Innovative Solutions

1. Replication Technique:

Copy the contour of the surface with a special film, remove the film and measure it with ordinary equipment to indirectly obtain the roughness, The technique can be used for deep holes and curved pipes, where there is simple operation at low cost.

2. 3D Optical Scanning:

High-precision machine is utilized for the purpose of scanning and producing a 3D model. Roughness is examined using specialized software. This process is quick and precise and appropriate for irregular curves and complex gear tooth surfaces.

Achieving Goals: Key Considerations For Specifying Surface Finish

To comply with surface finish needs, you need to carefully analyze the following parameters and establish rational requirements:

Identify Functional Requirements of the Part

Functionality is the key issue: seals (e.g., hydraulic valve seal surfaces) require an Ra of 0.8μm or less for a proper fit and zero leakage, wear parts (e.g., rolling bearing surfaces) require an Ra of 0.4-1.6μm to maximize friction and wear rate (too high will result in slippage, too low will result in wear).

Consider Material Properties

Different materials have different processing difficulties and finish requirements: aluminum alloys are soft and easily achieve a Ra of 0.4μm, stainless steel is hard, and to achieve a Ra of 0.4μm more steps and technology are needed, which is more expensive. When specifying, one must note the material characteristics so that the requirements are feasible.

Cost and Performance Balance

Increased level of finish costs more, so a balance has to be made. As an example, in decorative parts, a Ra 6.3μm is satisfactory for visuals. While a Ra 0.8μm addresses appearance better, it is very costly without a performance gain. Therefore, a decreased level of finish should be selected.

Identify the Processing Technology Feasibility

Various processes have varying finish ranges: milling (Ra 1.6-6.3μm), grinding (Ra 0.2-1.6μm), and polishing (Ra 0.025-0.2μm). Don't use requirements which are not possible or inordinately costly. For instance, a requirement for Ra 0.2μm through milling processes is unrealistic.

JS can provide you with professional surface finish requirements based on your part's functional requirement, material properties, and cost tolerance, and the processability of the technology. Or, you can quickly search for suitable surface finishing charts through our online surface finishing services to help achieve your goals.

Case Study Review: A Millimeter's Battle - The Surface Finish Of A Hydraulic Valve Manifold Redeems

Customer Pain Point

A otherwise normal valve manifold of a hydraulic system manufacturer developed poor internal leakage, and there existed a 20% system failure rate, numerous customer complaints, and over $50,000 per month of after-sales expense.

The manufacturer first suspected inferior quality of the seal ring. Replacing a number of brands with no success, initial investigations revealed the seal surface.

Problem Analysis

JS engineers inspected the faulty valve manifold and concluded that the bottom of the seal groove had a finish of only Ra 3.2μm (the mill default) and had huge chatter marks (waviness). Microscopic valleys of the rough surface prevented the seal ring from distorting fully and filling, allowing high-pressure oil to escape along microscopic leak paths.

JS's Solution

1. Redefining Standards: Based on sealing requirements, the sealing surface finish was improved from "milled" (Ra 3.2μm) to Ra 0.8μm and a new waviness requirement of ≤5μm for a smooth sealing surface.

2. Change Process: The "one-shot milling process" was substituted with "milling + fine reaming." Milling is employed to take off most of the material initially and then fine reaming of the sealing groove bottom to scrape off tool marks and chatter marks, improving the finish.

3. Cost Tradeoff: It was 40% longer to process a single valve block after the change in process, and it was $20 rather than $23 (15% more expensive). However, the customer's original after-sales repair cost for every defective valve block was $100, and the added processing cost was far beyond after-sales savings.

Final Results

After the improvement, all valve blocks' sealing surface finish was within specification, the leakage failure rate was nearly zero, and monthly after-sales expenses reduced from $50,000 to less than $1,000.

The customer satisfaction and brand reputation were improved immensely, order quantity increased by 30%, and overall expenses reduced due to reduced after-sales service. This case verifies the immense worth of correct specifying of surface finish.

FAQs

Q1: I have marked "polished" on the drawing. Is that sufficient?

Far from enough!"Polished" is a subjective and qualitative term, and expectations vary wildly from supplier to supplier. This type of specification can easily lead to bad part finishes, which lead to controversy and manufacturing errors. A good idea is to specify requirements by means of explicit values (e.g., Ra 0.4μm) in order to enable suppliers to know what's required consistently.

Q2: What if I am unable to give an exact Ra value?

The ideal practice is to provide the functional requirements of the part or a sample for reference. If the function and service conditions are established, the supplier can recommend an appropriate finish grade based on these parameters. If qualified samples are provided, the supplier can accept the sample parameters to ensure that the produced part matches the sample.

Q3: What do I need to provide for my share to get an accurate quote?

You must provide us with clear 2D engineering drawings clearly labeled with: surface roughness symbol and value, material type and hardness, specific surfaces which require the desired finish, and annual volume demand. JS platform engineers will combine this information with their own processing abilities to make a recommendation for the optimal surface treatment process and provide you with a true quotation.

Summary

Surface finish is more than a cosmetic comment on a drawing, it is a critical performance contract among design and manufacturing. To be fluent in its terminology, cost, and impact is vital to meet best-product optimization, cost control, and dependability. It tells us that accuracy is actually all about very small things the naked eye can't observe.

JS offers total services, from surface finish gaging and process development to final machining. Irrespective of whether you require standard surface finishing parts or custom surface finishing manufacturing, we can fit the bill with our expertise and deep understanding.

Our surface finishing on the internet gives you progress monitoring at any point in time, and transparent surface finishing prices allow you to be in command of costs. When you choose JS, you are spared the expense of using surface finish and can take your product quality to the next level.

Disclaimer

The contents of this page are for informational purposes only.JS servicesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Jusheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com