A 2mm thick steel plate quotation was made to a buying manager. A spot check on the materials after they were received showed an average thickness of just 1.92mm. The issue was at first disregarded by him until the finance department discovered that the products were mostly underweight, which implied lower strength and virtually wasted whole lots of material.

This is a metal gauge thickness error that is "funny".This 0.08mm variance was not an "error" but a "cost." In sheet metal processing and metal casting, slight variations in high-volume orders can translate into tens of thousands of dollars wasted in material and risk.

This article will help you learn about quotes and specifications so that you can easily understand how metal gauge thickness errors impact your cost. It will also provide solutions to reduce risk and save costs.

Core Answer Summary

| Dimensions | Best Case Scenario (No Errors) | Reality (With Errors) | Effect on Your Costs |

| Cost of Material | Paid for 1000kg of steel. | received only 980kg (due to insufficient thickness). | Direct Loss: Paid 2% "air" charge. |

| Processing Cost | Laser cutting/bending parameters are predictable. | Parameter adjustment can cause defective products. | Indirect Loss: Wastage of labor hours, reduced yield rate. |

| Product Performance | Satisfies design strength requirements. | Structural strength has been compromised, thus causing hidden dangers. | Possible Risks: Product recall, loss of reputation. |

| Transaction Fairness | Transaction is conducted according to specifications agreed upon. | Information asymmetry exists which favors the seller. | Trust Cost: Requires additional effort for testing. |

JS Data: How Much Does It Cost To Achieve a 0.1mm Decrease In Thickness?

JS has over 15 years of metal casting expertise, working for a variety of industries including automobile manufacturing, outdoor cabinet production, and medical device processing. Not only do we know the thickness standards of various metal casting parts,but we have also provided incoming material thickness inspection and cost reduction solutions to over 500 clients.

This guide is based on our extensive practical experience and has been validated through multiple industry case studies. You can trust the data and procedures presented here to be a good guideline for your buying decisions.

In metal purchasing, everybody is not aware of how closely thickness error and price are related. Let us utilize actual figures to illustrate the actual cost impact of every 0.1mm reduction in thickness below.

JS possesses an extensive wealth of experience in metal gauge thickness testing and custom metal casting manufacturing. Should you require precise cost analysis or customized services, choose JS and we will provide you with professional assistance to enable cost-saving procurement.

The Language Behind Metal Gauge Thickness

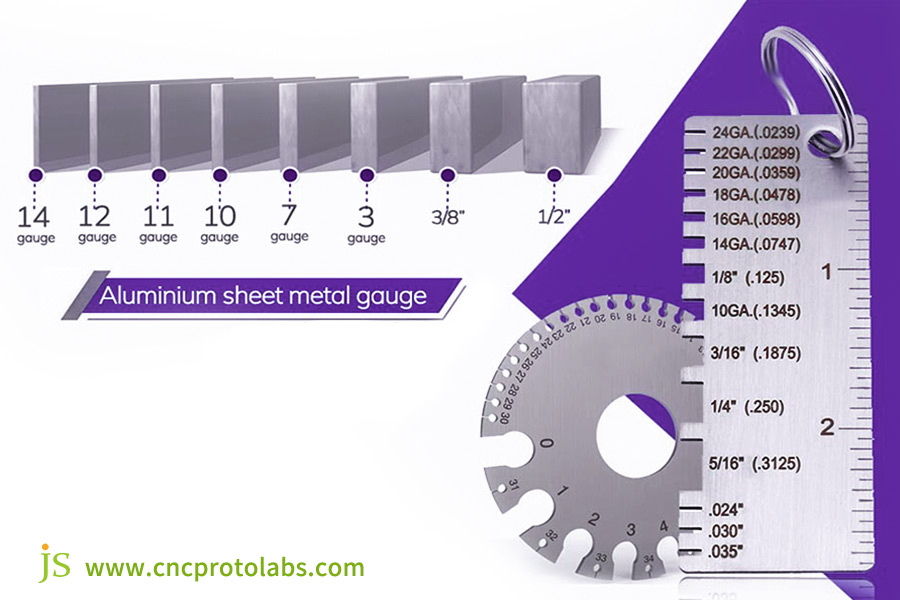

Understanding metal gauge thickness is the secret to avoiding purchasing errors. Everyone is familiar with the gauge number but do not understand the standard differences behind it,and this can easily lead to loss of money.

Translating gauge numbers (e.g., 20 gauge vs. 22 gauge)

The history of gauge numbers traces back to the 19th century wire manufacturing industry, when wires of varying diameters were run through a template in an attempt to define the gauge. The greater the gauge, the smaller the wire diameter.

That evolved into the modern measure for metal gauge thickness.Today, many countries and industries use different standards, such as the US ASTM standard and the Chinese GB standard.

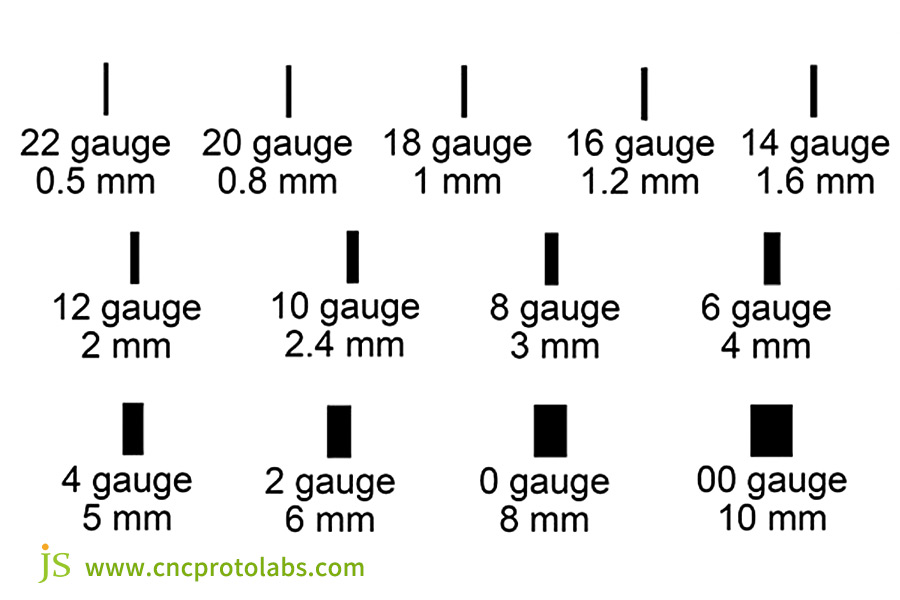

Taking low-carbon steel as an example, according to the US ASTM standard, the nominal thickness of 20Ga is about 0.91mm (0.036 inches), while 22Ga is about 0.76mm (0.030 inches).For stainless steel, 20 gauge is roughly 0.89 mm, and 22 gauge is roughly 0.71 mm.

This means that the same number of gauges can be considerably different in terms of thickness depending on the material.

Metric vs. Imperial

Metal gauge thickness is two systems: metric (mm) and imperial (inches). Both are standard across most areas and sectors. One must clearly differentiate between them when buying to avoid miscalculations.

For instance, 20-gauge mild steel has an imperial measurement of 0.036 inches and a metric measurement of 0.91mm. 22-gauge mild steel has an imperial measurement of 0.030 inches and a metric measurement of 0.76mm. Not clearly defining the measurement system can cause suppliers to supply the incorrect size of material.

Nominal Thickness vs. Actual Thickness

Nominal thickness refers to theoretical thickness as indicated on the product specification. For "2mm cold-rolled steel," the nominal thickness is 2mm. Actual thickness is the actual material thickness, which may vary from the nominal thickness based on manufacturing and tolerance levels.

For example, a supplier may supply "2mm cold-rolled steel" whose actual thickness may be between 1.9mm and 2.1mm (tolerance ±0.1mm). Such variation can have an immediate impact on cost of purchase as well as product performance.

How To Properly Measure Metal Thickness To Prevent Unfair Transactions

Accurate metal thickness measurement is crucial for fair trade. Flawed measurement processes may lead to hidden thickness faults and therefore hiding costs.

Introduction of Measuring Tool

- Ultrasonic Thickness Gauge: Used on all metals, especially metal casting parts. It has the potential to penetrate the surface and measure internal thickness with a precision rate of ±0.01mm.

- Micrometer: Appropriate to measure flat metal plate. Its helical substructure makes it possible to measure with ±0.001mm precision.

- Laser Thickness Gauge: Non-touch, best to measure thickness on continuous production lines so that real-time measurement of variation in thickness is possible and poor-quality batches can be prevented.

Method of Measurement (The Key to Building Trust)

While measuring, keep the "multi-point sampling" concept in mind because metal materials may have non-uniform thickness.

Concrete steps: First, select 5-8 equally spaced measuring points on the material surface (shun edges and defects). Second, with an appropriate tool, check successively one by one the thickness of each point.Third, use the average value as the actual material thickness.

Such a process reflects the material thickness better, raises confidence among buyers and suppliers, and avoids disputes occurring because of variation in single-point measurement.

JS provides professional metal thickness measurement services, whether you purchase through online metal casting services or collaborate offline,we can offer convenient inspections for your cast metal parts to make sure the material thickness you receive is as desired, leading to a confident purchase.

Close Examination Of How Thickness Tolerance Impacts Your Bill

Thickness tolerance may seem like a collection of numbers, but it actually plays a significant role in your bill of purchase, especially in bulk purchase, where the difference in cost caused by tolerances could be magnified.

Positive vs. Negative Tolerance

Positive tolerance is when the thickness is greater than the nominal thickness, for example, nominal 2mm sheet metal of thickness 2.05mm.Negative tolerance is the thickness less than the nominal thickness, e.g., 1.95mm actual thickness.

In sheet metal processing, negative tolerance is the main risk for the purchaser. The purchaser is getting nominal thickness paid for but receiving thinner material, providing a "premium" price and possibly quality product issues from a lack of material strength.

Cost Calculation Model

Formula: Cost Impact = (Nominal Thickness - Actual Average Thickness) / Nominal Thickness × Total Material Price

The following illustrates the cost impact of various actual thicknesses (taking the example of purchasing 10 tons of 2mm nominal thickness steel plates at $1,000/ton):

| Nominal Thickness (mm) | Actual Average Thickness (mm) | Purchase Quantity (tons) | Unit Price (US$/ton) | Total Material Price (US$) | Cost Impact (US$) | Material Strength Reduction Percentage |

| 2 | 2.00 (No Error) | 10 | 1000 | 10000 | 0 | 0% |

| 2 | 1.95 (Negative Tolerance) | 10 | 1000 | 10000 | 250 | 2.5% |

| 2 | 1.92 (Negative Tolerance) | 10 | 1000 | 10000 | 400 | 4% |

| 2 | 1.88 (Negative Tolerance) | 10 | 1000 | 10000 | 600 | 6% |

Batch-to-batch effect

In bulk production, such as cars and cabinets, this loss is multiplied exponentially.

For example, an automaker purchases 1,000 tons of steel plate per month. If the nominal thickness is 0.08mm thinner than actual thickness, at the above unit price, that is a monthly loss of $40,000, or $480,000 per year. That certainly makes significant demands on the cost control of the company.

JS provides detailed thickness tolerance costing services that will Assist you in accurately calculating the implicit costs in the metal casting price. Be it in bulk or small volumes, JS will provide you with clarity in your cost structure and avoid unnecessary losses.

Case Study: Cost Difference Between 20-Gauge And 22-Gauge Steel

20-Gauge and 22-Gauge steel are commonly applied gauges of sheet metal work. Differences in thickness directly affect material, processing, and cost of design, and hence a proper evaluation has to be conducted at procurement time.

Comparison of Thickness

According to ASTM guidelines, the nominal thickness comparison of different materials at 20 and 22 gauge is as below (double units are mentioned for easy reference in different conditions):

| Material Type | 20 Gauge Thickness (mm/inch) | 22 Gauge Thickness (mm/inch) | Difference in Thickness Between Same Material (mm) |

| Mild Carbon Steel | 0.91 / 0.036 | 0.76 / 0.030 | 0.15 |

| 304 Stainless Steel | 0.89 / 0.035 | 0.71 / 0.028 | 0.18 |

| Aluminum Alloy (6061) | 1.02 / 0.040 | 0.81 / 0.032 | 0.21 |

Material Cost

Taking low-carbon steel as an example (with a fixed density of 7.85g/cm ³ and a market standard unit price of $1/kg), the cost differences of different specifications and the cost data from the perspective of bulk procurement are reflected:

| Cost-Related Parameters | 20Ga Mild Steel | 22Ga Mild Steel | Cost Changes Due to Specification Differences |

| Thickness (mm) | 0.91 | 0.76 | 22Ga is 0.15mm thinner than 20Ga. |

| Weight per Square Meter (kg) | 7.14 | 5.96 | 22Ga is 1.18kg lighter than 20Ga. |

| Unit Price (USD/kg) | 1 | 1 | Same. |

| Cost per Square Meter (USD) | 7.14 | 5.96 | 22Ga is 1.18 less than 20Ga. |

| Cost per 100 Square Meters (USD) | 714 | 596 | 22Ga is 118 less than 20Ga. |

Processing Cost

22 steel is thinner, with a laser cutting speed about 15% faster than 20 steel, and requires about 20% less pressure for bending, and can save power and processing time. For example, processing 100 square meters of plate per day, 22-gauge steel being used, the processing time will be saved by around 2 hours, and the energy expenditure will be reduced by around $30.

But it should be noted that if the 22-gauge steel becomes too thin, such as in the case of load-bearing beams in exterior cabinets, some welding for reinforcements may be included. This will increase $5 the processing cost per beam, negating the material cost saving.

Design Cost

When 22-gauge steel is not meeting product strength requirements, e.g., panels for outdoor cabinets that support 50kg of equipment, testing shows deflection of more than 3mm (industry maximum allowable is 2mm). Therefore, it must be replaced with 20-gauge steel.

Otherwise, deformation of the panel and tilting of equipment can occur afterwards, with a one-time after-sales adjustment fee of approximately $200. If a large lot has problems, the total after-sales expense will be over five times that of the initial material cost saving.

Thus, the appropriate gauge should be determined based on the product's function at the design phase.

JS can recommend the most cost-effective metal gauge thickness appropriate to your product design specifications. Whether you need special metal casting parts or efficiency-optimized processing options, buying from JS can provide you with cost-efficient and effective solutions.

How JS Determines The "Right" Metal Gauge For Your Project

Selecting the "right" metal gauge is essential to keep costs down and products up to par. JS Precision Manufacturing will carefully examine several dimensions to ensure you make informed decisions.

Functionality Prioritization

Strength, hardness, and corrosion resistance are the prime considerations. For example, metal casting parts for medical devices require corrosion-resistant stainless steel and thickness adequate for load-bearing. For chassis parts for cars, strength is the prime consideration and appropriate gauge and material are selected.

Determination of Manufacturing Process

Different manufacturing operations require different metal gauges.

Bending process requires metal to have a certain degree of ductility, excessive thickness makes bending more difficult. Welding requires weldability of the metal to be considered, some overly thin stock can easily cause weld-through issues. Surface treatment(such as painting and galvanizing) require consideration of whether metal thickness can hold temperature shifts throughout processing without warping.

Weight and Cost Reducing

Without loss of functionality, thinner and lighter specifications may be chosen in order to save material and shipping costs.

For example, in load-free exterior cabinet panels, if 22-gauge steel will meet the required rigidity, there is no need for choosing 20-gauge steel. That will save around $5 on the material cost per cabinet, which will be a significant saving in mass production.

JS's online metal casting services allow you to submit your project specifications easily, and our experts will immediately determine the "right" metal specifications for you. Choosing JS's custom metal casting manufacturing service allows you to save money without sacrificing product performance.

Successful Transaction Case: How JS Helped A Client Recover 15% Of Hidden Costs

Client Background

One outdoor cabinet plant had been purchasing about 50 tons of 2mm thickness cold-rolled steel each month from a fixed supplier. Recently, the customer noticed that product prices increased by approximately 8% and the yield rate decreased from 90% to 82%.

After several time checks on the manufacturing process, the customer couldn't find the cause behind it, and hence they sought assistance from JS.

JS Investigation

1. Inspection on Incoming Material:

We conducted ultrasonic spot testing on the client's 2mm cold-rolled steel stock. The resultant ultimate average actual thickness was as low as 1.88mm, with fluctuation range in thickness at 1.82mm-1.95mm, far outside the client's ±0.1mm tolerance.

2. Cost Analysis:

According to the cost calculation model, total cost of materials = 50 tons × $1,000/ton = $50,000. Cost impact = (2 - 1.88) / 2 × $50,000 = 0.06 × $50,000 = $3,000. This means the customer is paying an extra "premium" of roughly 6% per ton of material and losing an extra $3,000 per month.

3. Performance Testing:

We had subjected 1.88mm cold-rolled steel to stiffness testing and found that its bending resistance was 12% lower than nominal 2mm steel. This was resulting in cabinet deformation at assembly, thereby reducing yield, increasing rework cost, and increasing component loss.

Solution and Result

We provided the customer with a complete inspection report allowing the client to renegotiate with the original supplier, who ultimately agreed to settle on the basis of the actual average thickness and reduced the price by 4.5%.

On the customer's cabinet usage conditions (outdoor load-bearing and wind-resistant), we recommended cold-rolled steel with a tolerance of 2mm ± 0.05mm which would meet the strength needs. We also helped the customer source a new supplier, which guaranteed highly stable thickness for metal casting parts.

Maximum Advantage:

Although the new supplier's unit cost was 2% higher than the original supplier ($1,020/ton), the uniform thickness increased cabinet yield from 82% to 98%, reducing rework cost by approximately $1,500/month.

Besides the price reduction by the original supplier, the customer's overall monthly cost was reduced by 15%, and consistency of product quality was significantly improved, significantly enhancing customer satisfaction.

FAQs

Q1: What is the average thickness of metal gauge?

Thickness of metal gauges (such as steel plate) typically comes with standard gauge numbers (such as GAUGE) but no "general" thickness exists, as it will depend upon the material and the standard.The actual thickness must then be determined from a conversion table based upon the type of material (e.g., mild steel, stainless steel) and the relevant international standard employed (e.g., ASTM, GB).

Q2: Does the same gauge number apply to various materials?

No. For some different materials, such as steel, aluminum, and copper, the same GAUGE number does not necessarily relate to the same actual thickness because gauge standards take material density and use into account. 20GA mild steel is approximately 0.91mm, 20GA aluminum plate is approximately 1.02mm, and 20GA copper plate is approximately 0.81mm.

Q3: Would specifying the gauge number on an order be sufficient?

No. You must state both the standard (e.g., ASTM, GB) and the material because the same gauge number can be widely different in thickness depending on material and standard. For example, 20GA steel plate is 0.91mm thick based on ASTM standards but 0.88mm thick based on GB standards. Omitting these specifications could cause the supplier to send the incorrect item, impacting production.

Q4: How can I be certain of the thickness of the material I receive when I purchase online?

In online buying, JS is the top priority for accurate thickness. We provide authoritative material certificates describing the thickness of the metal gauge, material, and standard, and offer professional measurement and verification at no charge on delivery. JS's skilled team will precisely match metal casting parts with your needs and provide extensive after-sales services.

Summary

The impact of metal gauge thickness errors on cost is far greater than most realize. Not only can it potentially cause a "premium" on purchase, it can cause issues with product quality as well as greater cost down the road.

From reading from numbers on specifications to accurate measurement, from cost analysis to choosing specifications, each step requires knowledge and experience. Knowledge, verification, and selecting the right partners are required to protect your investment.

JS is committed to providing customers with cost-effective metal casting products like metal gauge thickness testing and custom metal casting manufacturing to help you circumvent the risk of thickness error and prevent additional costs in metal casting prices.

Disclaimer

The contents of this page are for informational purposes only.JS servicesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Jusheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com