Assume: an excavator shovel tooth,which needs to withstand tremendous impacts,and a machine base that needs to possess fine details and a very effective shock absorption.All are manufactured by the metal casting parts process,but is the inside material cast iron or steel?——It makes or breaks the final product.

Cast iron vs steel, is an endless topic in the field of custom metal casting manufacturing,and the answer is neither 'good' nor 'bad'.In the end,these two metals have done much to construct our society and economy,with each good at certain things,bad at others,and their own appropriate application situations.

Only when we understand the unique characteristics of a material and select the"right"material can we achieve optimal strength versus manufacturing economy in a product.A deep understanding of the core difference between cast iron vs steel is the first step in making the right decision.

On a daily basis at JS,we have to manage materials selection,and years of experience on the job and repeatedly resolving customers' issues have formed a materials science way of thinking.This is the essence of experience summary.In this article,we delve deeper into the main differences between the most important dimensions in actual projects,such as single performance,application scenarios,and cost,to help you clear the fog and make best decisions in terms of design and selection.

Core Answer Table:

| Characteristic | Cast Iron | Cast Steel |

| Main Components | High carbon (2-4%) + silicon, with carbon existing in the form of graphite | Low to medium carbon (<2%), carbon dissolved in iron |

| Key Mechanical Properties | Excellent compressive strength, shock resistance, and wear resistance | Higher strength, toughness, and ductility |

| Castability | Good fluidity, low shrinkage rate, easy to cast complex parts | Poor fluidity, high shrinkage rate, and susceptibility to defects |

| Processability | Relatively easy to process (especially for gray iron), but relatively brittle | Good processability and excellent weldability |

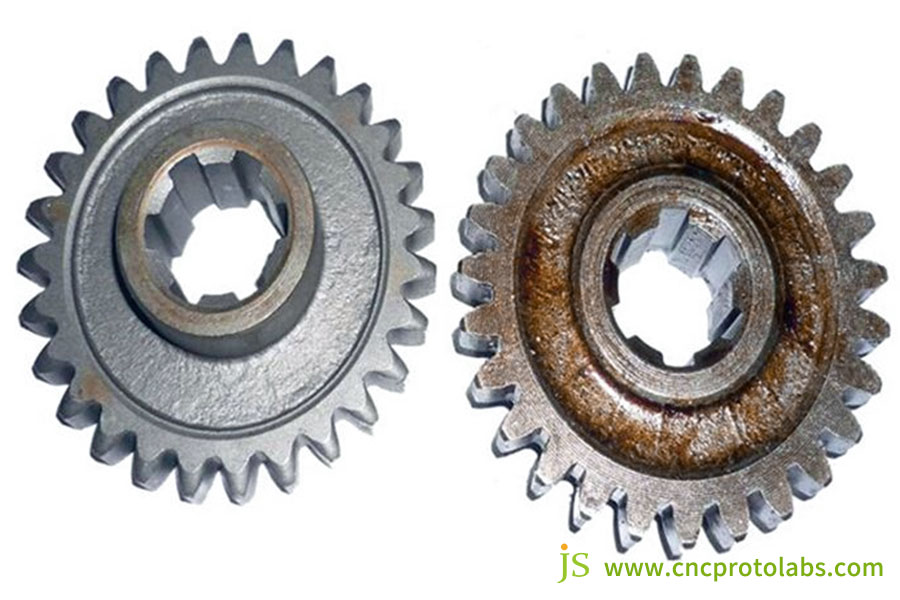

| Typical Application Scenarios | Engine cylinder block, brake disc, machine tool base, cooking utensils | Gears, structural components, pressure vessels, tools, wear-resistant parts |

| Cost Consideration (metal casting price) | The cost of raw materials and smelting is usually low | The cost of raw materials and process control is usually high |

Why Is This Comparison Guide Trustworthy? Based On 15 Years Of Practical Experience In Material Selection From The JS Team

When it comes to this important choice between cast iron vs steel, you want more than just theoretical parameters from books, but empirical judgments based on extensive practice.

JS team has been deeply involved in the field of custom metal casting manufacturing for 15 years and has completed over 3000 projects involving material selection. Our recommendations are based on real engineering data and failure analysis cases.

More than 70% of the materials engineering team members have a metallurgy or materials engineering background and regularly attend technical seminars organized by the American Foundry Society (AFS).

For example, in selecting materials for a heavy machinery customer, the original design by the customer tended to use low-priced cast iron to control the metal casting price. Our engineers found through finite element analysis that there was a high risk of tensile stress in key connection areas.

We ultimately recommend that the customer use cast iron in the main structure to maintain shock absorption and cost advantages, while using cast steel parts together with special welding processes in the high-risk connection areas. It avoids the potential cracking risk and increases the product service life threefold.

This material optimization solution based on deep engineering analysis is a reflection of our professionalism.

In addition, we have established a comprehensive "Material Process Performance" database that records the actual performance of various cast iron and steel parts under different working conditions, such as impact, wear, and corrosion.

In other words, when you consult with us, we can provide more than a general comparison between cast iron vs steel; recommendations can be given based on the specific working environment, load type, and requirements for the life of your product to avoid risks of "over design" or "insufficient material selection".

We are well aware that the right material is the cornerstone of ensuring product reliability and controlling the overall cost, including metal casting price and maintenance costs.

Main Difference: Carbon Content

In contrast to the iron used in daily life,the natural substance iron is normally in its oxidized form and has to be smelted and processed before it can be recovered.Iron is combined with carbon to produce a tougher and more practical alloy in most manufacturing industries.The difference in carbon percentage is the primary cause for the difference between cast steel and cast iron.

Cast iron is one of the oldest and most used alloys in the world with more than 2% carbon content,primarily iron carbon silicon,and most of the carbon is present as free graphite.Besides,it also has trace amounts of phosphorus and sulfur impurities.Cast steel contains a carbon content normally less than 2% in carbon iron alloys(in actual casting,it is also mostly between 0.1% and 0.5%).

Carbon is dissolved mostly in the matrix of iron and contains some minor amounts of silicon,manganese,iron sulfide,and phosphides.

Cast iron and cast steel castings appear almost identical on the exterior,but the seemingly insignificant detail of carbon content actually impacts directly upon the nature and properties of both.Of course, it also directly affects the material selection strategy.Let the JS engineering team recommend the most cost-effective and reliable material solutions for your project, avoiding the risks of 'over design' or 'material selection errors'.

Understanding In Depth: Properties And Applications Of Cast Iron And Cast Steel

Cast Iron

Cast iron is made by pouring molten iron into a mold and allowing it to cool so that it solidifies.This makes cast iron unique in texture and appearance,and therefore easily identifiable.

Because of superior insulation performance,high durability,and good compressive strength,cast iron is applied in the production of components that require higher strength,stability,and greater robustness in different industries.This pressure-proof and heat-proof metal of superior quality is also extensively applied in the production of heavy machinery,construction machinery,and infrastructure.

Cast irons are commonly classified into a variety of categories,with certain types of properties optimized to be utilized for a particular application.

Major types:

- Gray Iron:Flake graphite,excellent shock absorption,wear resistance,heat conductivity,cheap,simple to machine,and extremely common.

- Ductile Iron:Spherical graphite,more flexible and shock-resistant,has the castability of cast iron along with the strength and hardness of steel,and is fast becoming very common.

- White Iron:Carbon exists in carbide form with extremely high wear resistance and hardness but extremely brittle,applied normally in wear-resistant plates of lining.

- Malleable cast iron:it becomes strong and ductile by heat treatment process.

Characteristic:

- Mechanical properties

- High hardness:Cast iron is more hard compared to other"low-cost metals".

- Very high compressive strength:Cast iron has very high compressive strength,is capable of carrying heavy loads without deflecting,and is used in building and industrial applications where there is a necessity for high load-bearing capacity

- Wear resistance:Wear resistance against sliding friction.A graphite constituent within the cast iron matrix will form graphite dry lubricant and allow solid surfaces to slide against each other without degrading surface quality.Especially useful in zones of high impact.

- Castability

- Castability:Cast iron has lower melting and casting temperatures,excellent casting fluidity(favorable for complex parts),and less shrinkage.

- Processability

- Machinability:The graphite structure in cast iron is easily decomposed and decomposes uniformly.Especially softer cast iron,such as gray cast iron,is very easy to process quickly and accurately.

- Brittleness:Low tensile strength and impact toughness,especially for gray iron.

- Poor weldability:Cast iron is difficult for welding without cracking.

Common uses:

- Engine cylinder block:Cast iron is the most suitable material because it is resistant to high temperatures and pressures.

- Heavy machinery components:used for producing sturdy and long-lasting parts in the mining and agricultural industries.

- Bridge components and structural columns:provide sufficient support and stability.

Cast Steel

Cast steel is widely used in many industries and fields such as construction,manufacturing,and transportation due to its durability,ductility,high tensile strength,and corrosion resistance.It is also one of the materials with the highest recycling rates in the world,making it a sustainable choice for multiple uses.

Main types:

- Carbon steel:extremely strong and versatile.Mainly including low-carbon cast steel and medium carbon cast steel.

- Alloy steel:contains components such as chromium or nickel,which can provide enhanced performance.

- Tool steel:wear-resistant,suitable for cutting tools.

- Stainless steel:Due to its chromium content,it is corrosion-resistant.

Characteristic:

- Mechanical properties

- High tensile strength:It will not break under stress and pressure,making it very suitable for load-bearing structures in industries.

- High toughness/ductility:Under high stress,steel can undergo(temporary or permanent)deformation without fracture.Although in some applications,this may mean lower stiffness,it reduces the likelihood of cracking and implies better impact performance.

- Corrosion resistance:Stainless steel cast steel does not corrode and is very suitable for use in exposed outdoor conditions or humid areas,such as the ocean.

- Excellent ductility:able to withstand impact and fatigue loads.

- Casting performance

- Poor castability:high melting temperature,poor flowability,reaction with mold material,high solidification shrinkage rate(prone to shrinkage,porosity,and hot cracking).

- Processability

- Weldability:It has good weldability,making it easy to repair and connect.

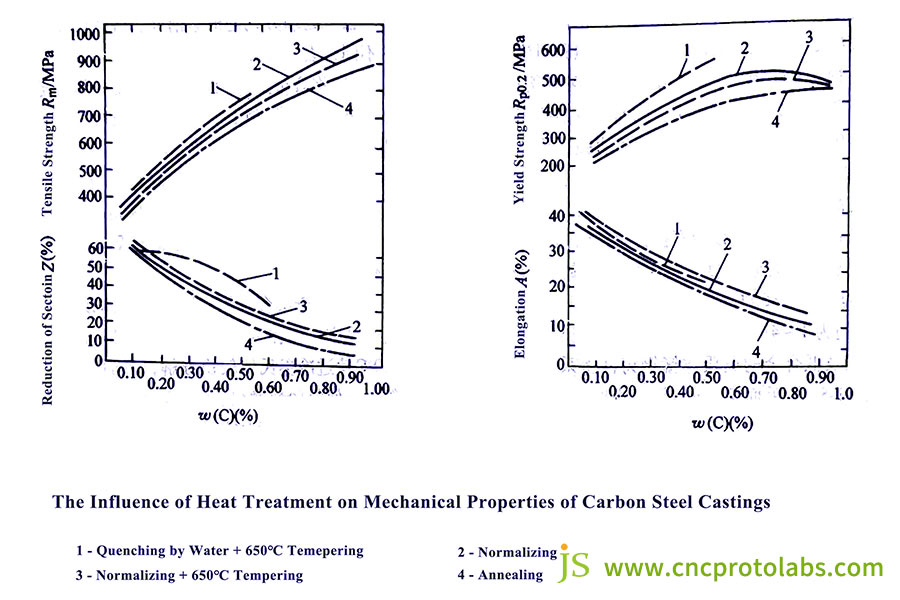

- High adaptability:The properties(hardness,wear resistance,corrosion resistance,etc.)can be greatly adjusted through alloying and heat treatment.

- Poor machinability:Not easy to cut,especially for steel with high carbon content,which increases tool wear and is more severe.It also requires stricter process control,resulting in increased production costs and metal casting prices.

Common uses:

- Building materials:Due to their strength and flexibility,cast steel is used in bridges,buildings,and mechanical equipment.

- Transportation:Due to its light weight,it is suitable for vehicle frames and their components.

- Mechanical and industrial components:Steel can be used to manufacture items that require extremely high strength and precision.

We have a well-established process system and quality control procedures(non-destructive testing,mechanical property testing,etc.)to guarantee the stable and dependable performance of the delivered metal casting parts,whether they are made of cast steel with stringent requirements or cast iron with exceptional fluidity.Welcome to contact us anytime!

Core Showdown:Key Differences Between Cast Iron And Cast Steel

This table provides a general comparison between cast iron and steel,with each category representing a range of alloys with different characteristics.

| Material Characteristics | Cast Iron | Cast Steel |

| Melting Point |

2200 degrees Fahrenheit |

2500 – 2800 degrees Fahrenheit |

| Strength | Better compressive strength | Better tensile strength |

| Resilience | Low ductility and limited elongation | Higher ductility and toughness |

| Impact Resistance | It exhibits obvious brittleness (except for ductile iron) and is not resistant to impact | Steel is more resistant to impact, especially sudden impact, than cast iron, making it suitable for making anvil blocks. |

| Castability | Easy to pour, low shrinkage, easy to cast | It is harder to cast than cast iron. |

| Wear Resistance | Better resistance to mechanical wear (especially for white iron) | It wears more easily than cast iron and requires surface hardening or alloying to enhance its wear resistance. |

| Corrosion Resistance | Fairly good, usually limited to surface rusting. | It is inferior for casting carbon steel, but stainless steel alloys have excellent rust-proof properties. |

| Workability | Easier to process | It is more time-consuming and requires higher-quality tools, with generally better machinability and weldability. |

| Solderability | Difficult to weld and does not crack | The weldability is better, ranging from poor to excellent. |

| Heat Preservation | heat preservation | Low thermal conductivity and heat capacity, suitable for applications requiring heat resistance |

| Versatility | Due to its brittleness, it is difficult to process and mold | Easy to mold, cut, and shape into different shapes and sizes |

| Weight | Under similar volumes, cast iron typically has a slightly lower density than cast steel | no significant difference |

| Cost | The cost of raw materials and casting processes required for producing the final product is relatively low | Production is more challenging and requires more labor and energy consumption, resulting in higher costs. However , if long-term usage and replacement costs are taken into account, in the long run, parts with higher manufacturing costs will ultimately have lower costs. |

Manufacturing Considerations:From Casting To Finished Product

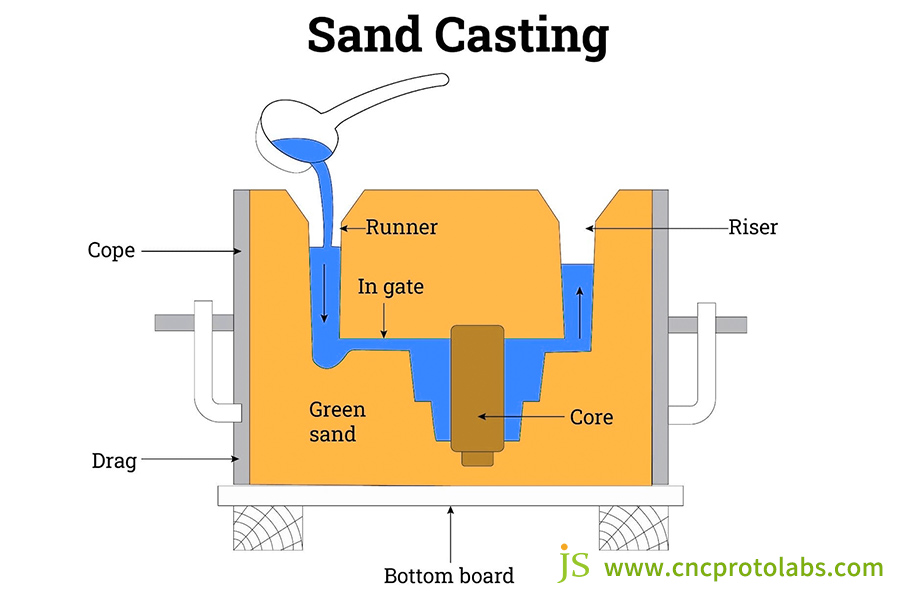

- Complexity of casting process:Cast iron has good fluidity,small shrinkage,and is easier to produce complex shaped,thin-walled parts,with a relatively high yield rate.The steel casting process is more complex and requires more precise design and process control of sprues and risers.

- Post processing and machining:Processing of cast iron and steel parts is common.Cast iron(especially gray iron)has good cutting performance and low tool wear.The machinability of cast steel is good,but alloy steel with higher hardness may increase the difficulty.The excellent weldability of cast steel is one of its major advantages.

- Heat treatment potential:Cast steel can significantly improve its performance(strength,hardness,toughness)through heat treatment such as quenching and tempering.The heat treatment effect of cast iron(excluding malleable cast iron and some ductile iron)is limited,mainly relying on composition control and inoculation treatment.

The above content provides a reference for your material selection. If you have any needs for casting parts, JS offers one-stop custom metal casting manufacturing, from drawing review, mold design and manufacturing, melting and pouring, post-treatment (cleaning, heat treatment, machining) to final inspection and packaging. We provide complete end-to-end services!

Case Study: Applying Cast Iron To Produce Wear-resistant Lining Plates For Mine Crushers

- Customer pain point:There is a mining equipment customer who has a crusher with a very important lining plate that wears out very rapidly.Using the common low-alloy cast steel parts,its lifespan is merely 3 months,and the frequent change leads to lengthy equipment downtime and excessive maintenance expense.

- Material selection issue:Parts are subjected to severe impact and heavy wear and friction by ores.Very high wear resistance combined with some impact resistance is required.Cast steel is impact-resistant but not wear-resistant.Ordinary cast iron is wear-resistant but too brittle and might break.

The solution proposed by JS:

- Material recommendation:Recommend and produce High Chromium White Iron.It consists of carbides as wear-resistant skeleton,with very high hardness(HRC>60),and is used specially for heavy abrasive wear.

- Process optimization:Use precision sand casting to ensure the controllability of solidification process with even distribution of carbides,and is supported by special heat treatment for stress relief,with toughness mildly improved while the hardness is ensured.

- Custom metal casting manufacturing:Precisely match the lining plate shape and thickness distribution to the wear zone.

- Result:The service life of the new lining plate has been prolonged to over 12 months(with a wear resistance of >200% increase),significantly reducing downtime and spare part costs,what demonstrating the importance of choosing the appropriate cast iron under harsh wear circumstances.

As Alex Miller,professor of management at The University of Tennessee,often emphasizes:Lean is about constant ticking, not occasional kicking.

FAQs

Q1: Under what circumstances should cast iron be given priority?

When excellent shock absorption (such as machine tool bases), good wear resistance (sliding friction parts such as cylinder liners and brake discs), production of complex shaped parts, and cost are important considerations.

Q2: Under what circumstances is cast steel a better choice?

- When components(like gears,hooks,and structural elements)must endure high tensile stress,impact loads,and fatigue loads.

- When they must be well-welded for assembly or repair.

- When heat treatment is necessary to significantly enhance a particular performance.

Q3: Can cast steel be substituted with ductile iron?

In many applications,particularly when strength and toughness requirements are not very high,it can be partially substituted.In general,ductile iron is less expensive than cast steel and has superior castability.It also has a certain amount of toughness and good strength.However,the final performance and weldability are typically inferior to those of premium cast steel.

Q4: How does the JS company's custom casting procedure work?

- Send in your specifications via email or the website,including drawings,3D models,technical information,and quantity.

- Our engineering staff performs a technical assessment and offers professional guidance on the materials,procedures,and cost of metal casting.

- Following order confirmation,move forward with mold creation and manufacturing.

- Ship following a rigorous quality check.You can see and understand every step of the process on our online metal casting services platform.

Summary

In the realm of metal casting,cast steel and cast iron are two pillars that each have advantages and no obvious superiority or inferiority.Because of its superior shock absorption,wear resistance,castability,and cost-effectiveness,cast iron is essential in the fields of stability and noise reduction.Because of its high strength,toughness,and plasticity,cast steel is increasingly the material of choice for applications needing high loading and reliability.The key to designing long-lasting,high-performance,and metal casting parts is understanding their intrinsic differences.

JS Company is your reliable custom metal casting manufacturing partner,regardless of whether your next project calls for the hardness of cast steel or the stability and dependability of cast iron.We have cutting-edge technology,professional experience,and a customer-focused service philosophy.You can now obtain metal casting price quotes on our online metal casting services platform.We believe that JS's professional casting capabilities will satisfy you.

Disclaimer

The contents of this page are for informational purposes only.JS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Longsheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com