When the aircraft engine turbine blade operates stably at high temperature and pressure, when the chassis of a new energy vehicle with light weight ensures overall security in general, and when protection and appearance of the casing of delicate electronic instruments meet each other—these are all problems that rely on one crucial decision: how to achieve a perfect balance between performance, precision and cost through aluminum casting?

In manufacturing sectors, the stresses placed on aluminum casting are equally extremely varied depending on the situation. Some experience rapid corrosion in moist environments due to an unsuitable grade of alloy, while others fall short of their high-precision requirements because they misutilize the casting process. Others are financially-strapped due to overlooking cost factors.

This article is going to navigate the decision puzzle of aluminum casting, from material selection to process comparison, in order to reveal the secrets of finding the best process for your project.

Core Answer Summary

| Aspect | Performance | Precision | Cost |

| Alloy Selection | ADC12 (moderate strength), A356 (impact), 514.0 (corrosion). | Adapt to process precision, A356 adapts to high-precision processes. | ADC12 (low-cost), A356 (high-cost). |

| Process of Casting | Die casting (300-400 MPa), investment casting (350-450 MPa). | Die casting (±0.05-0.1 mm), investment casting (±0.02-0.05 mm). | Die casting (low batch cost), sand molds (low batch cost). |

| Technology of the Mold | H13 steel molds (improve casting density and offer quality). | CNC/EDM mold control accuracy is up to ±0.02 mm. | H13 steel molds (costly), quartz sand molds (cheap). |

| Surface Treatment | Anodizing (improve corrosion resistance and performance). | Sandblasting (Ra 3.2-6.3 μm), anodizing (Ra 1.6-3.2 μm). | Sandblasting (low cost), anodizing (high cost). |

Why Adopt This Aluminum Casting Guide? Distilled From JS's Practical Experience

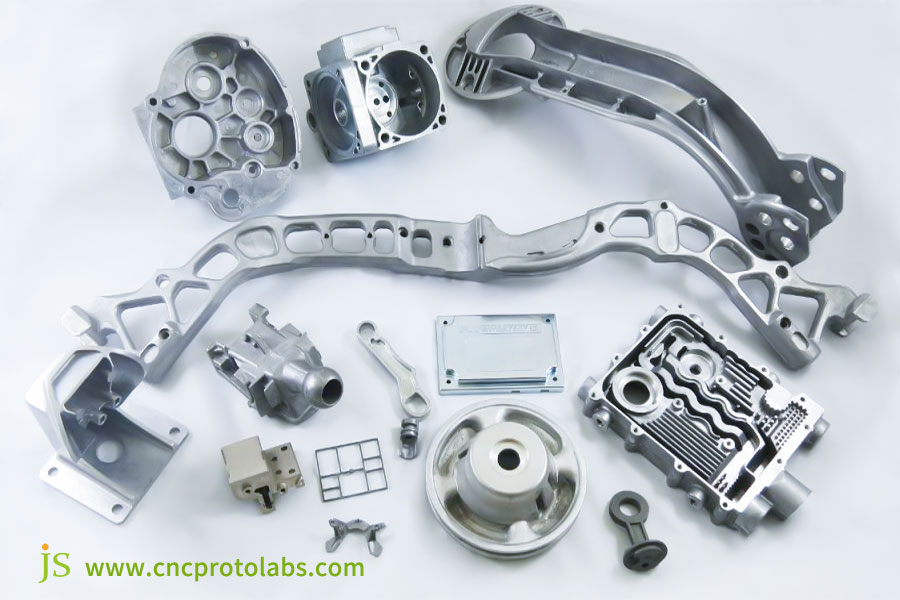

JS has accumulated rich practical experience through over ten years of practice in aluminum casting. We specialize in four primary processes: die casting, sand casting, investment casting, and low pressure casting.

We can fit the optimal solution to a specified need. For example, when precision investment casting custom-fitting components for aerospace clients, we can hold tolerances to 0.05mm. Our portfolio of products is around a series of metal casting parts, like aviation-grade turbine blades, car transmission housings and electronic device brackets.

This book is JS's collective technical expertise and experience derived from over a thousand actual projects. From cost saving to process design, it's backed by real-world examples, providing you with successful, tried-and-tested aluminum casting solutions.

JS has profound experience in the process of aluminum casting and skills in these four basic processes. Our online metal casting services provide you with quick quotes within an hour. Simply provide your specifications, receive a customized proposal, and start ordering. We will provide you with a reliable solution.

How To Choose A Casting Aluminum Alloy Grade?

Choosing the correct casting aluminum alloy grade is fundamental to ensuring aluminum cast quality. Different grades vary significantly in composition, mechanical properties, and other attributes, having a direct influence on metal casting parts performance.

Core Selection Criteria

1.Mechanical Performance Specifications:

- For structurally critical applications (e.g., structural parts), select a high tensile and yield strength grade.

- For low-load applications (e.g., cosmetic parts), employ a low-strength but easily manufacturable grade.

2.Environmental Conditions:

- Exposure to water or chemicals (e.g., marine uses) requires a high-corrosion-resistant type.

- High-temperature use (e.g., engine parts) requires a high-temperature-resistant type to avoid performance failure.

3.Processing and Casting Characteristics:

- High fluidity aluminum alloys (e.g., ADC12) are best for intricate thin-walled components.

- Low-shrinkage aluminum alloys reduce deformation and are best suited for high-precision parts.

Common Casting Aluminum Alloy Grades and Applications

| Aluminum Alloy Grade | Main Alloying Elements | Maximum Tensile Strength (MPa) | Corrosion Resistance | Applicable scenarios | Castable Process |

| ADC12 | Si, Cu | ≥220 | Medium | Car transmission housings, electronic enclosures | Die casting |

| A356 | Si, Mg | ≥230 | Good | Aircraft wheels, aircraft components | Sand casting, low pressure casting |

| A380 | Si, Cu, Fe | ≥240 | Medium | Domestic appliance components, industrial valves | Die casting |

| A413 | Si | ≥170 | Fair | Thin components of toys, small pump bodies | Die casting |

| 514.0 | Mg | ≥175 | Very good | Marine equipment components, pipe fittings | Sand casting, investment casting |

Not clear about the alloy grade? JS's experienced metal casting production staff welcomes you to get assistance from us to make the right decision. Provide your part specifications, we provide expert recommendations, and fabricate top-quality metal casting parts for you.

What Are The Processes With Which Aluminum Is Available To Be Cast?

Having determined the alloy grade, selection of the suitable process of casting is crucial to achieve the optimum outcome of aluminum casting.

Here follows the comparison of five casting process parameters:

| Casting Process | Production Efficiency | Casting Accuracy (Dimensional Tolerance) | Unit Cost (Batch of 1,000 Pieces) | Part Weight | Core Strengths |

| Die Casting | High (30s-5min/piece) | IT11-IT13 | Low ($0.7-2.8/piece) | 0.1-10kg | High batch efficiency and high accuracy. |

| Sand Casting | Low (several hours to days/piece) | IT14-IT16 | Medium ($2-7/piece) | 1-1,000kg | Low cost, good for large parts |

| Investment Casting | Very Low (1-2 weeks/piece) | IT9-IT11 | High ($7-28/piece) | 0.01-5kg | Very high accuracy, ideal for complicated parts |

| Low Pressure Casting | Medium (10-30min/piece) | IT12-IT14 | Medium ($2.8-8.5/piece) | 1-50kg | High-quality and dense castings. |

Key Technologies For Aluminum Casting Mold Manufacturing

The mold is the 'skeleton' of aluminum casting, and the quality thereof will directly influence the precision and stability of metal casting parts.

Mold Material Selection

- Die casting molds: H13 hot work die steel, heat-resistant (>650°C) and high hardness (HRC42-48), suitable for large-scale production (>100,000 cycles).

- Sand molds: Made of quartz sand with resin (compressive strength ≥2MPa, suitable for high precision) or water glass (low cost, suitable for low-precision large components).

- Investment casting molds: Use 6061 aluminum alloy or P20 steel to ensure precision of the wax pattern.

Mold Precision Control

- Equipment of processing: Use a high-precision CNC machining center with positioning accuracy ≤ 0.005mm. Complex cavities are machined using EDM to attain a cavity tolerance of 0.01-0.03mm.

- Dimension compensation: Machine the cavity based on the aluminum alloy shrinkage rate (1.2%-2.5%). For example, a 100mm casting requires a 102mm cavity (2% shrinkage).

- Assembly precision: Gap of parting surface ≤ 0.02mm to prevent leakage, coaxiality tolerance of guide pin and sleeve ≤ 0.01mm in order to prevent misalignment.

Mold Cooling System Design

- Channel layout: Close to the cavity (15-25mm) and periodic, with special focus on cooling thick-walled areas for preventing shrinkage cavities.

- Cooling medium: Water for die-casting and low-pressure casting (20-40 ℃), natural cooling or air cooling for sand casting.

- Temperature control: Strategically positioned sensors control the temperature of the die-casting mold at 200-300°C.

JS leverages the most advanced aluminum casting mold production technology to ensure mold accuracy and durability. Contact us and render your production of casting easy.

Why Is Aluminum Casting So Successful? Comparison With Other Casting Processes

In the industry of metal casting, aluminum casting is a competitor to wrought aluminum and iron casting, and in that comparison, its advantages are clear.

Forged Aluminum and Cast Aluminum

| Comparison Measures |

Aluminum Casting |

Forged Aluminum |

Overview of Essential Differences |

| Process of manufacturing | Liquid forming, relies on a cavity mold | Solid pressure forming, requires forging equipment. | Cast aluminum can have complex shapes, whereas forged aluminum requires plain shapes. |

| Mechanical Properties | 200-300 MPa mean tensile strength, good toughness | 300-500 MPa tensile strength, good toughness. | Better mechanical properties are found in forged aluminum and can be utilized for load-carrying parts. |

| Shape Complexity | Can cast complex cavities and thin-walled parts (0.5 mm). | Can cast simple shapes only, not with complex cavities. | Cast aluminum has the capability of taking a more complex shape. |

| Production Batch | 10,000-100,000 units. | 1 million to 10,000 units. | Cast aluminum offers greater batch flexibility. |

| Unit Price (1,000 pieces) | $1.4-7 per piece | $7-28 per piece | Cast aluminum is less expensive. |

| Applications | Auto exterior, appliance parts | Car connecting rods, high-strength aircraft parts. | For light use, choose cast aluminum, for heavy use, choose forged aluminum. |

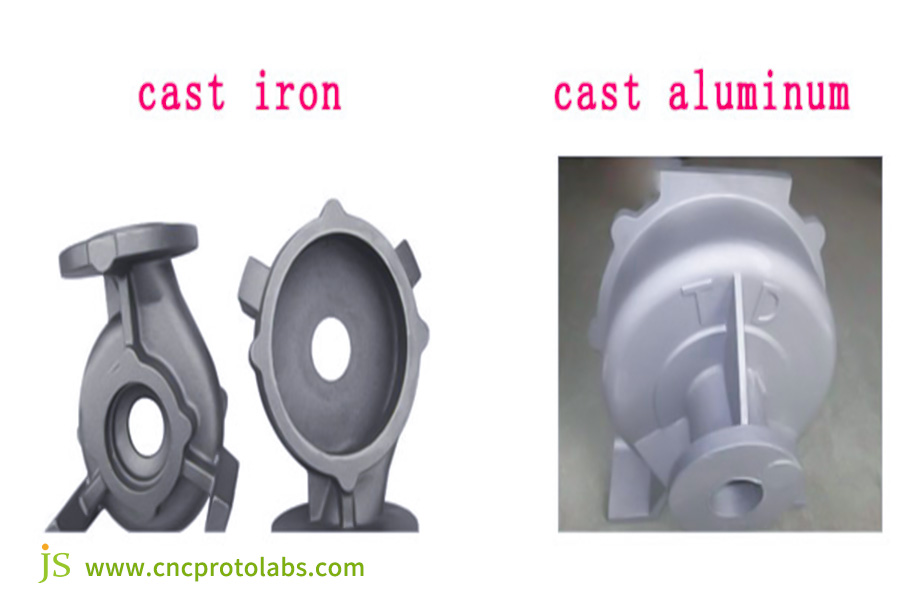

Aluminum Casting and Iron Casting

| Comparison Dimensions | Aluminum Casting | Cast Iron | Key Differences Summary |

| Material Density | 2.7g/cm³ | 7.8g/cm³ | Cast aluminum weighs roughly one-third the weight of cast iron, much lighter. |

| Corrosion Resistance | Good (good following surface treatment) | Poor (prone to rust) | Cast aluminum is suitable for wet conditions. |

| Mechanical Properties | Tensile strength 200-300MPa, low brittleness | Tensile strength 150-250MPa, high brittleness | Cast aluminum excels in impact strength. |

| Thermal Conductivity | 200W/(m・K) | 50W/(m・K) | Cast aluminum is suitable for heat sinks (i.e., radiators). |

| Processing Difficulty | Easy to process, low tool wear. | Difficult to process, high tool wear. | Cast aluminum is less costly to process subsequently. |

|

Metal Casting Price(100kg component) |

$280-700 | $140-280 | The cost of material is lower for iron casting, and cost performance overall is better for aluminum casting. |

| Applications | Electronic radiators, machine bed tooling |

Heavy machinery bases, light parts for cars |

Choose aluminum casting for light applications, and iron casting for heavy loads. |

Aluminum casting has special strengths, and JS can provide excellent aluminum casting services. Request process comparison, and we will show you a systematic analysis. After cooperation negotiation, order to meet your requirements for metal casting.

Five Surface Treatment Methods For Aluminum Castings

After aluminum casting, the casting surface should be treated to enhance performance and beauty. Here is the comparison of five parameters for surface treatment:

| Surface Treatment Option | Corrosion Resistance | Appearance | Cost per Unit (USD) | Processing Cycle (per Unit) | Applications |

| Sandblasting | Average | Matt/Matte,uniformly rough | 0.15-0.5 | <5 minutes | Pre-coating treatment, medium appearance requirements. |

| Anodizing | Excellent | Different colors, high hardness | 0.7-3 | 15-30 minutes | High corrosion resistance, high appearance requirements. |

| Spraying | Good | High gloss/matte/textured rich colors | 0.5-1.5 | 5-10 minutes | Mass production decorative parts. |

| Electroplating | Good - Excellent | Smooth and delicate finish, metallic texture | 1.5-7 | 20-60 minutes | High quality, functional requirements. |

| Chemical Conversion Treatment | Poor | Colorless/light yellow, no decorative effect | 0.015-0.07 | 2-5 minutes | Pre-coating treatment, basic protection |

Cost-Benefit Analysis: How To Choose The Most Economical Process?

When choosing an aluminum casting process, there must be a careful weighing of cost against demand. The following is an underlying analysis:

Cost Structure

Die casting costs: 10%-50%, and die casting is most costly ($7,000-70,000) whereas sand casting is the cheapest ($14-700). Unit cost becomes lower when batch size is higher.

Material costs: 30%-60%, where aluminum alloy material is $3,000-4,000 per ton, sand casting material $0.07-0.15 per kg of molten aluminium, and investment casting material $0.7-1.5 per kg of molten aluminium.

Labour and equipment costs: 10%-30%, with die casting highly automated (labour cost 5%-10%), while investment casting labour makes up the majority (30%-40%).

Subsequent processing costs: 5%-20%, with investment casting having the lowest price ($0.15-0.7 per unit) and sand casting having the highest ($1.5-4 per unit).

Batch and Cost Relationship (1kg Medium Complexity Aluminum Casting)

| Production Batch (Pieces) | Die Casting (USD/Piece) | Sand Casting (USD/Piece) | Investment Casting (USD/Piece) | Low Pressure Casting (USD/Piece) |

| 100 | 70-140 (High Mold Cost) | 4-7 | 14-28 | 11-21 |

| 1000 | 7-14 | 3-6 | 11-21 | 7-14 |

| 10000 | 1-4 | 4-9 (High Labor Cost) | 9-17 | 4-9 |

| 100000 | 1-3 | 7-15 (Low Efficiency) | 7-15 | 3-6 |

Economic Process Selection for Different Scenarios

- Small batch complex parts: Sand Casting (Simple Parts) or Investment Casting (High-Precision Parts),

- Medium batch medium precision parts: choose die casting (thin-walled parts) or low-pressure casting (thick-walled, high-quality parts).

- High-volume standard parts: choose die casting, which has low unit prices ($1-3/piece).

Affordable aluminum casting? JS can make the process easier for you. You provide us with batch and part information, and we'll return to you a cost estimate. When you've approved your blueprint and placed an order, we'll guide you to quality with metal casting price in mind.

Case Study: Why Are 95% Of Aircraft Parts Investment Cast? JS's Case Study Explains Why

Customer Background and Core Needs

A leading domestically based aircraft engine producer needed to produce a new series of turbine guide vanes (heat dissipation critical parts) and had very stringent specifications for aluminum casting precision and performance.

The vanes were hollow with precision-cooling channels that were less than 0.8mm in diameter. Wall thickness tolerance was ±0.05mm, and there were no pores or cracks visible on the surface.

Earlier casting processes, due to issues of constructing runners and exceeding tolerances, were capable of a first-pass pass rate of only 65%, which was sub-aviation quality. An optimized metal casting solution was urgently needed.

JS Precision Manufacturing Technical Solution

Based on customer specifications and the process nature of investment casting, JS Precision Manufacturing developed a complete process improvement plan:

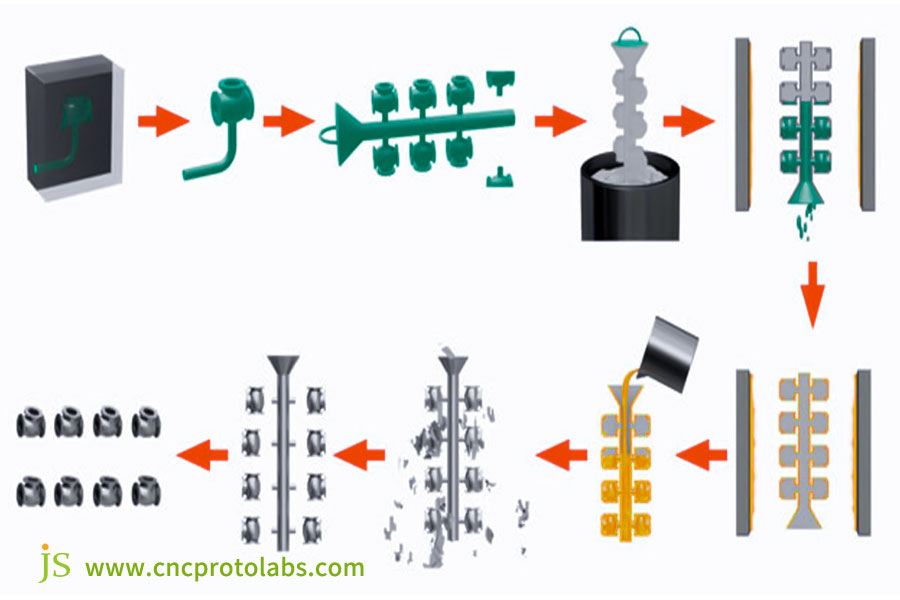

1.Wax Pattern Fabrication:

The traditional mold making was avoided, and the wax patterns were built with SLM metal 3D printing technology and precision control of ±0.03mm. This ensures precise shaping of the cooling channels and avoids blockage or deformation from traditional mold making.

2. Shell Process Optimization:

High-purity alumina refractory material alone was selected, and 'multi-layer coating + high-temperature hardening' process was utilized to try to create a uniform thickness casting shell (controlled at 5-8mm). This provides mold stability in the casting process as well as prevents mold cavity deformation owing to aluminum molten washout.

3. Mould Filling and Pouring Control:

Melting A356 cast aluminum alloy in a vacuum environment in order to prevent the formation of oxidative impurities due to reaction between the molten aluminum and air. Slow pouring and low pressure were also used, allowing the free flow of the molten aluminum into micro-channels and preventing pore formation.

4. Second heat treatment:

After cooling of the casting, it undergoes a T6 heat treatment process in an attempt to raise tensile strength of aluminum alloy to ≥260MPa in a bid to ensure aircraft components' mechanical capability performance.

Final Results and Value

Following the implementation of this solution, turbine guide vane production experienced three remarkable breakthroughs:

1. Qualification Rate Was Raised Dramatically:

The first-pass qualification rate was raised from 65% to 98.5%, significantly reducing rework costs, and indirectly reducing the unit cost of metal casting price by 22%.

2. Performance and Light Weight Conformity:

Weight of blade units reduced by 30% from the base solution (in sync with the light weighting target of the aeronautics industry), all the channels for cooling were unobstructed, and tolerance in wall thickness was maintained entirely within ±0.05mm.

3. Uniform Mass Delivery:

The sword resisted high temperature and fatigue tests in the aerospace sector and has since then been used in a series of aircraft engines with a cumulative delivery of more than 5,000 units, testifying volumes regarding the reliability of investment casting in the complex process of aluminum casting.

FAQs

Q1: What is the minimum possible wall thickness of aluminum casting?

Minimum thickness of aluminum castings depends on the process. Die casting may be 0.5mm whereas sand casting is a maximum of 3mm or even more. Investment casting is fairly accurate and accommodates 1mm easily, which in turn is adequate for most thin-walled parts' specifications.

Q2: What are some typical aluminum casting defects? How can they be avoided?

Intermittent defects of aluminum castings are cold shuts, shrinkage pores, and air pores. In order to reduce the occurrence of defects in different stages, it is essential to have maximum mold gating and venting, composition control and degassing of molten metal, and proper control of casting temperature, pressure, and cooling.

Q3: How much is the strength of aluminum castings?

Heat treatment is responsible for aluminum cast strength. The tensile strength is 300-400 MPa after treatments like T6, which enhances hardness and resistance to deformation. This is utilized for the majority of industrial applications with the addition of light weight and mechanical strengths.

Q4: What should be the professional level of a foundry?

A foundry's professionalism is established by its equipment, personnel, quality certifications, and case studies. JS boasts up-to-date equipment, qualified personnel, full certifications, and solid case studies. We are better in all aspects and display consistent expertise.

Summary

The best method for casting aluminum is never a single answer, but a precise match between demand and solution.As long as we stick to the "demand-oriented" approach, aluminum casting can become a booster for product competitiveness.

JS is your go-to partner in your quest for the 'best aluminum casting solution.' We offer custom metal casting manufacturing services,with over a thousand actual case studies to guarantee quality. Call us now to ensure that your metal casting parts get the ideal amount of precision, performance, and cost!

Disclaimer

The contents of this page are for informational purposes only.JS servicesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Jusheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com