Core Answer Summary

| Topic | Main Content |

| Principles of Galvanizing | Submersion of metal in molten zinc creates protective coating. Zinc acts as a sacrificial anode for protecting steel. |

| Advantages of Galvanized Steel | Excellent corrosion resistance, favorable workability, attractive appearance, and long life. |

| Galvanizing Processes |

Hot-dip galvanizing: Durable and suitable for complex shapes. Electrogalvanizing: Thin, uniform coating with low corrosion protection. |

| Causes of Rusting | Atmospheric corrosion, poor quality of zinc coating, mechanical stress, changes in temperature, impurities, and exposure time. |

| Life Extension Measures | Consider the environment during design, close control of production process, protective zinc coating when transported and installed, and regular maintenance. |

| Cost-Effectiveness | Extremely high initial cost, very low long-term maintenance, superior to conventional steel and other forms of corrosion protection for most applications. |

Is This Galvanizing Rust Prevention Guide Accurate?

JS has earned a good reputation in online sheet metal fabrication services. This isn't hypothetical experience, it's from hand-on experience in various industries, like construction, agricultural machine, chemicals, and wind. We've established a mature system of custom sheet metal fabrication, particularly in custom sheet metal fabrication.

From cross-sea bridge galvanized steel pieces to blades of agricultural equipment, chemical pipelines, and wind power flanges, we have handled galvanizing needs for a vast range of complex situations. Every process is a down-to-earth exercise, allowing us to understand the appropriate process parameters and treatment processes for galvanized steel pieces in different geometries and environments.

It is the result of hundreds of joint efforts with customers and down-to-earth troubleshooting. Customer testimonials are the best indicator of our experience. We find that businesses we have worked with frequently state that our galvanizing service perfectly addresses their requirements, with rust-proofing exceeding expectations.

We value the importance of effective communication and have now effectively introduced our online sheet metal fabrication services.Simply place your order using the web portal, and our technical support group will be responding instantly with online proposals and live processing updates, including sheet metal fabrication cost breakdown.

Galvanized Steel Sheet: Steel's 'Self-Healing Armor'

Galvanizing Technology and Galvanized Metal

Galvanizing is a well-proven, cost-effective, and durable corrosion protection technology for metal components. Galvanizing is essentially a surface treatment technology that involves immersing metal in molten zinc solution to form a protective coating on the metal surface.

Zinc is an excellent barrier against rust and other forms of corrosion, and galvanized metal is very rust-resistant. The zinc coating is a sacrificial anode, or it corrodes first before the iron or steel beneath to avoid rust.

Galvanized metal is one of the most inexpensive and prevalent types of metal to market. Galvanized steel also offers added strength, durability, and looks that are not found in other types of single metal.

How Galvanized Steel Works

Galvanized steel is created by immersing treated and pickled raw steel into a massive amount of molten zinc. The zinc becomes hardened and set, forming firmly attached to the surface while also laying down a bright, hard film. The zinc protective layer functions as a "suit of armor" tailored to the steel that protects it from external corrosion. The zinc 'armor' is employed primarily in two ways:

- Hot-dip galvanizing: The most general and durable process, suitable for plain objects and intricate shapes. The steel is completely immersed in molten zinc to form a metallurgical bond. Picked out of the solution, pure zinc oxidizes with air to form a thin layer of zinc oxide.

- Electrogalvanizing: An electric current is passed through an electrolyte, where zinc ions are plated onto the steel surface, similar to a powder coating. The process creates a thinner, smoother coating with more uniform coverage, but none of the corrosion resistance of hot-dip galvanizing.

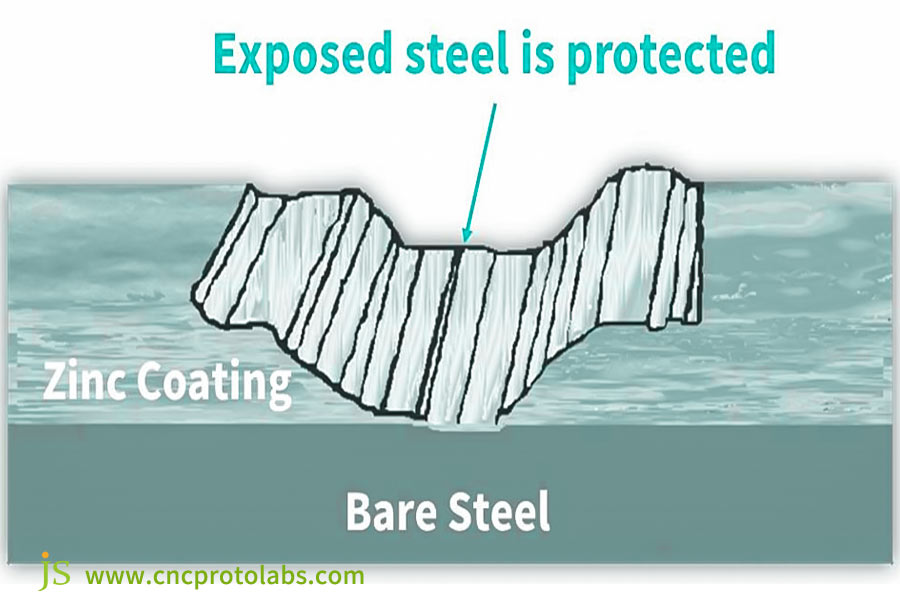

The 'Self-Healing Ability' of Galvanized Steel Coating

Even more impressive is that, unlike other coatings, the galvanized steel coating possesses self-defense and healing capabilities.

Hot-dip galvanizing creates a self-healing seal between steel and zinc. This means that when the zinc coating comes into contact with water, it forms an additional layer of protection. This layer enhances the material's resistance to corrosion and rust.

This process of self-healing erases corrosion even before it begins. Under other coatings, scratches permit water to enter and begin to deteriorate the steel. A single rust spot can propagate very quickly, compromising the whole structure.

Principal Galvanized Steel Sheets Benefits

Galvanized steel sheets offer several significant benefits.

First, they offer excellent corrosion resistance, maintaining structural integrity for a long time in harsh conditions such as humidity, rain, and corrosive gases.

Secondly, they possess satisfactory processability, and thus can be cut, bent, stamped, and processed in numerous ways for fulfilling numerous different engineering needs.

Besides that, galvanized steel sheets offer a finer appearance with smooth, even finish, and thus are desirable for uses where appearance matters.

Besides this, they offer a longer service life with significantly fewer replacement and maintenance frequency compared to conventional steel sheets, thus the cost benefits.

JS is manufactured with high precision, allowing the zinc layer to tightly adhere to the steel and enhance its 'self-healing' ability, creating high-quality 'self-healing armor' of steel for you.

Why Galvanized Steel Sheet Rust?Five Major Causes Of Failure

Let's clear up some definitions beforehand. Corrosion occurs when metal interacts with its environment (usually water and air), corroding with time. When it does happen with steel, it leaves behind rust on it, a type of corrosion in which iron reacts with oxygen to form iron oxide that corrodes the steel.

Galvanized Steel Isn't Rustproof

As discussed before, the zinc layer on the galvanized steel prevents the steel from being penetrated by moisture and oxygen. In contact with water and air, the zinc also forms a protective zinc oxide or zinc carbonate layer that safeguards the steel.

Even though the zinc coating is scratched, it still protects the steel by a sacrificial process. Zinc is a more reactive metal than iron and therefore corrodes first, sacrificing itself to protect the steel from rusting.

Does this mean galvanized steel will never rust? No. Galvanized steel can still rust under certain conditions.

Over time, the zinc coating disintegrates, exposing the metal underneath to water and oxygen. If the metal is exposed to these for an extended period of time, it will rust. Galvanized metal can also rust if it comes in contact with certain chemicals or other metals that can damage its protective coating of zinc.

Causes Of Rusting Or Corrosion Of Galvanized Steel

What are the causes of galvanized steel corroding or rusting? There are five prime culprits:

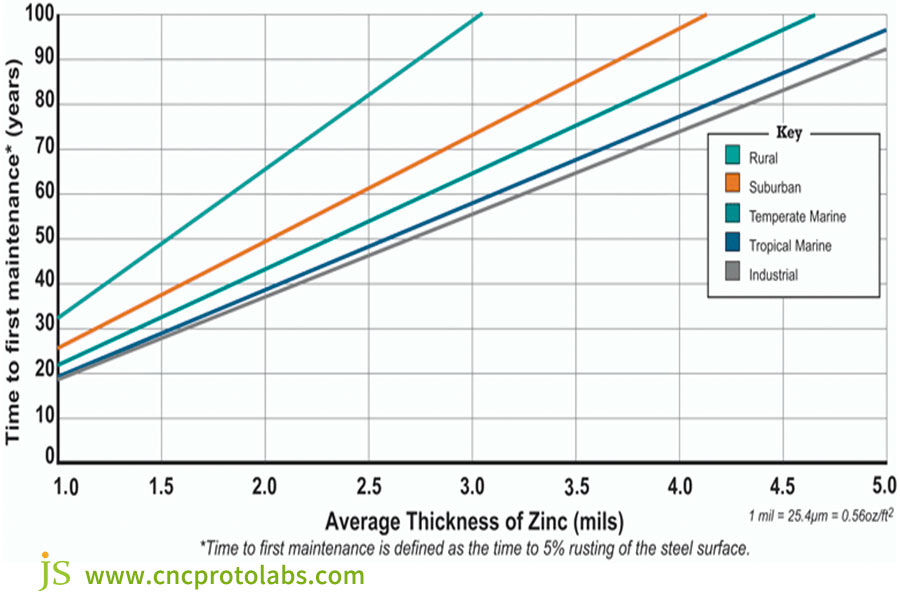

- Environmental Conditions:

In very corrosive environments, such as coastal areas (full of salt) and industrial areas (with poisonous fumes like sulfur dioxide), these corrosive media can gradually wear down the zinc coating. When the layer of zinc has corroded to the point where it can no longer protect the underlying steel, rust takes hold.

| Environment Type | Expected Lifespan |

Characteristic

|

| Rural Areas | Over 50 years | Low humidity, less pollution,zinc deterioration is negligible. |

| Urban/Industrial Areas | 20 to 40 years | Air pollution and acid rain accelerate zinc corrosion. |

| Coastal/High Humidity Regions | 10 to 20 years | Moisture and salt accelerate corrosion,heavy coatings are advisable. |

- Zinc Coating Quality:

The corrosion resistance of galvanized steel relies largely upon the quality of zinc coating deposited during galvanizing. A thick and even coating will be less prone to rust than one which is thin and irregular. Maintaining even thickness and conformity to industry standards is assured through quality control in the process of galvanizing.

- Mechanical Damage:

During shipping, installation, or use, galvanized steel sheets may be subjected to mechanical stress such as impact and friction, resulting in scratches and debilitation of the zinc coating. When the zinc coating is damaged, the steel underneath is exposed directly to the outside environment, accelerating rust.

- Temperature Fluctuations:

Galvanized steel integrity can be affected by excessive temperature fluctuations. Abrupt temperature changes cause thermal expansion and contraction that stress the zinc coating and subsequently lead to cracking or delamination. Furthermore, exposure to high temperatures is found to accelerate the corrosion rate of galvanized steel, especially in manufacturing environments with heat-generating operations.

- Presence of Contaminants:

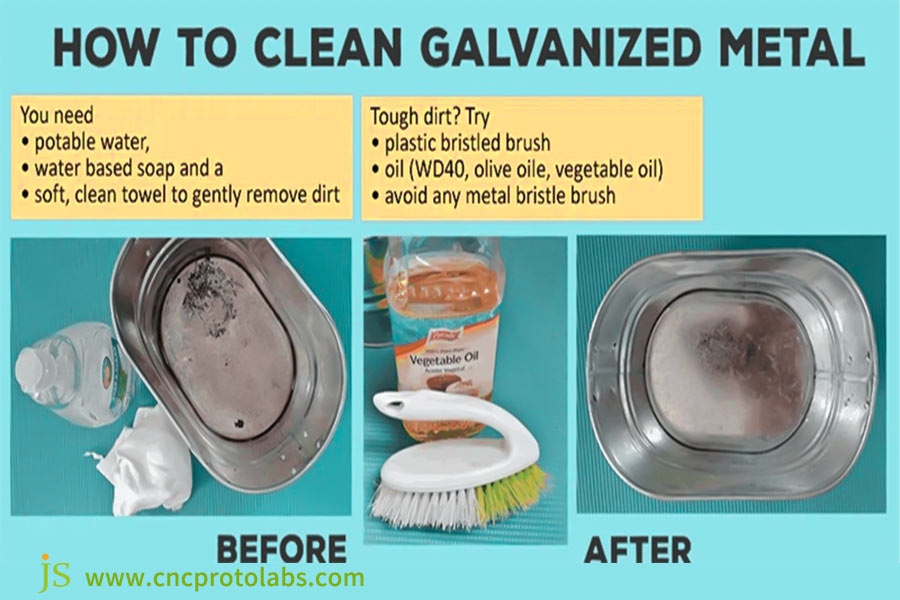

Surface contaminants on galvanized steel may jeopardize corrosion resistance. Grease, oil, grime, and other impurities may inhibit the adhesion of the zinc coating to the steel surface and render it more susceptible to rust. Cleaning and surface preparation before galvanizing are essential to remove contaminants and enable maximum adhesion of the zinc coating.

- Time Factor:

Even in ideal conditions, the zinc coating will some day start corroding over time. As soon as the zinc coating gets consumed to some extent, it cannot again shield the steel, and rust will eventually develop.

JS, with 15 years of experience, anticipates risks, customizes solutions for special scenarios, reduces the possibility of rust from the source, and safeguards your galvanized parts.

Keys To Extending Lifespan: From Design To Maintenance

The following common sense tips can assist in prolonging the service life of galvanized steel in industrial, commercial, and outdoor applications.

Take into account environmental features

For example, for extremely corrosive environments, use thicker galvanized steel coated with more zinc. Design the structure in a manner such that there are no weak corrosion-prone spots like water and dust traps. Ensure structural stability and strength so that structural deformation damage to the zinc coating is minimal.

Regulate the galvanizing process firmly during production

Ensure uniform zinc coating thickness and strong adhesion to minimize process defects. Companies should establish a comprehensive quality inspection system and rigorously test each batch of galvanized steel to ensure product quality meets relevant standards and design requirements.

Pay attention to protecting the galvanized coating

During transportation and installation,prevent steel plate impact and friction. Isolate with wooden blocks, partitions, and other materials. Install with the right tools to avoid scratching the zinc coating. Distortion of the zinc coating that cannot be avoided during installation should be immediately rectified, such as zinc-rich paint, to prevent rusting.

Post maintenance is equally important

Inspect the galvanized steel plates at regular intervals to discover surface damage and corrosion. Repair the damage or scratches at once. Clean surface dust and dirt at regular intervals with clean water to rinse or neutral detergent for wiping in order not to allow corrosive materials to accumulate.

In addition to that, in some special environments, galvanized steel plates also may get periodic anti-corrosion treatment, for example, applying anti-corrosion paint, to further avoid corrosion.

JS provides full collaboration in design, production, transportation, installation, and post maintenance, from prototype to production, to ensure the maximum lifespan of your galvanized parts.

Cost-effectiveness: Is Galvanizing The Best Option?

From a cost-effectiveness point of view, whether galvanizing steel plates is the best solution depends on a thorough evaluation of several factors.

Galvanized Steel vs. Regular Steel:

Galvanized steel is more expensive than standard steel, primarily due to the fact that the galvanizing process is more expensive. Galvanized steel, in the long term, is nevertheless cheaper. Its longer lifetime reduces the need for replacement and maintenance, hence minimizing the cost of future maintenance and downtime.

Where high corrosion resistance is required like in bridges and chemical plant equipment, the use of ordinary steel requires frequent replacement and anti-corrosion coating, which not only sums up to a high cost but also impacts equipment performance. While galvanized steel requires a greater initial investment, it demonstrates superior performance over a long time, resulting in lower overall costs.

Of course, in less corrosive applications and more benign operating conditions, plain steel would be more economical. Other anti-corrosion coatings, such as painting and chrome plating, have their strengths and weaknesses too in different applications.

Painting is less expensive upfront, but with a quicker maintenance cycle and requiring frequent repainting. Chrome plating is more resistant to corrosion but more expensive and complex.

Galvanized Steel vs. Stainless Steel, Aluminum:

| Material | Galvanized Steel | Stainless Steel (Type 304) | Aluminum |

| Corrosion Resistance | Excellent | Excellent | Excellent (oxidizes but protects) |

| Cost | Low | High | Medium |

| Strength | Very High | Very High | Medium |

| Weight | Heavy | Heavy | Light |

| Best Suited for | Cost-conscious structural applications, building construction, farm fencing, and automotive parts | Food processing, pharmaceuticals, marine application, and architectural decoration | Aerospace, window frames, and applications that require lightweighting and corrosion resistance |

If the application requires high strength and excellent corrosion resistance, long-term cost efficiency, and budget is also a main priority, galvanized steel is generally the most suitable choice.

Briefly, although galvanized steel is protected by a zinc coating, it can still rust under certain conditions. However, with proper design, standardized manufacturing, and maintenance, its life can be extended successfully. Galvanized steel definitely has an advantage for most low-cost uses.

JS balances initial investment and long-term returns with 15 years of experience. Choose JS to convert every investment into lasting value for metal components.

FAQs

Q1: If galvanized steel used in a coastal construction rusts within three years, does this constitute a defect in quality?

The environment will probably be over the tolerance level. Twin protection with 'galvanizing + coating' or aluminum-magnesium alloy is recommended beyond 500 meters from the seaside.

Q2: How do I ensure quality galvanizing through online sheet metal fabrication services?

Request a report of coating thickness test (according to ASTM A123) and request procedure instructions for cut edge protection.

Q3: How is rust repaired on galvanized sheet metal welds?

Use a proprietary zinc repair compound and ordinary welding is strictly not allowed!

Q4: How is galvanized metal different from non-galvanized metal?

The galvanized coating makes steel corrosion-proof. This keeps rust, a possible problem that can weaken the metal. Since non-galvanized steel is not covered, it may require servicing more frequently to prevent corrosion.

Summary

Galvanized steel is not rust-proof, but its life can be significantly prolonged through certain precautions. It is therefore an excellent choice for optimising corrosion protection performance in relation to cost. Its protective effectiveness can be optimized by correct application and upkeep.

JS has the largest range of standard and specialty galvanized steel materials to precisely suit your specific application needs. Capitalizing on our effective online sheet metal fabrication services, we offer complete assistance from design adjustment to final product delivery in the custom sheet metal fabrication manufacturing process. Our transparent sheet metal fabrication pricing allows you to clearly view cost details.

Contact us to start effective online collaboration and leverage our expert solutions to ensure your project's long-term success.

Disclaimer

The contents of this page are for informational purposes only.JS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Longsheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com