Imagine this: Suppose a key component breaks down on Friday at 4 PM. Come Monday morning, the entire assembly line could be down. And then, you're faced with a one-shot, surprise bid opportunity where you've got to produce a working model within 72 hours.

Your first instinct would be, 'Quick! Find a metal fabrication shop near me!' But is 'close' actually going to equal 'fast'? There's a huge disparity in capability between dingy old machine shops and high-tech, fast-response manufacturing service providers.

This guide will serve as a radar, weeding out manufacturing partners who truly are capable of turning your blueprints into a reality within three days, and guiding you through navigating the 'three-day delivery' trap. With this guide, you will be able to clearly see that 'three-day laser cutting' is not an illusion, and who to call to make it a reality.

Core Answer Summary

| Core Dimensions | Core Dimensions | Key Elements | Time/Feature Highlights |

| 3-Day Delivery Feasible | Regular 3 days (48 hours during emergencies). | Material availability + 24-hour production. | Laser cuttable in 3 days. |

| Cost Accounting | Clear pricing. | Materials + Labor + Processing Difficulty + Post-Processing. | No surprises. |

| Factory Screening | Conformance to technical/process/case standards. | Equipment Model + Design and Measurement (DFM) Response Time. | Professional Case Validation. |

| Laser Cutting Benefits | Precision/High Efficiency. | ±0.1-0.3mm Accuracy. | Material Waste Rate ≤5%. |

Why Should You Trust JS Can Finish Laser Cutting Within 3 Days?

When you need custom sheet metal fabrication manufacturing on a tight timeline, your biggest fear is the service provider's hyperbole. But JS's 3-day guarantee is based on 12 years of actual experience and proven ability, it is indeed sincere.

JS Precision Manufacturing has worked with over 5,000 customers in the sheet metal fabrication business, including industries such as smart hardware and medical devices, whose precision and lead time to delivery are extremely critical. On emergency orders, we have produced 20 stainless steel brackets in 48 hours and 50 aluminum alloy connectors in 3 days.

Our internal team of engineers with an average of over 8 years of design-for-manufacturing (DFM) experience can assess files within 30 minutes and offer optimization recommendations, preventing design problems that create rework.

This guide is a summary of our 12 years of experience in handling emergency laser cutting projects. Every point is backed by case studies, so you can be assured of our follow-through on a '3-day delivery' policy.

For your single-off sheet metal fabrication production needs, trust JS's 12 years' expertise and real-time DFM verification technology. Submit your design files and we will have a price and planning prepared in 5 minutes and ship in 3 days.

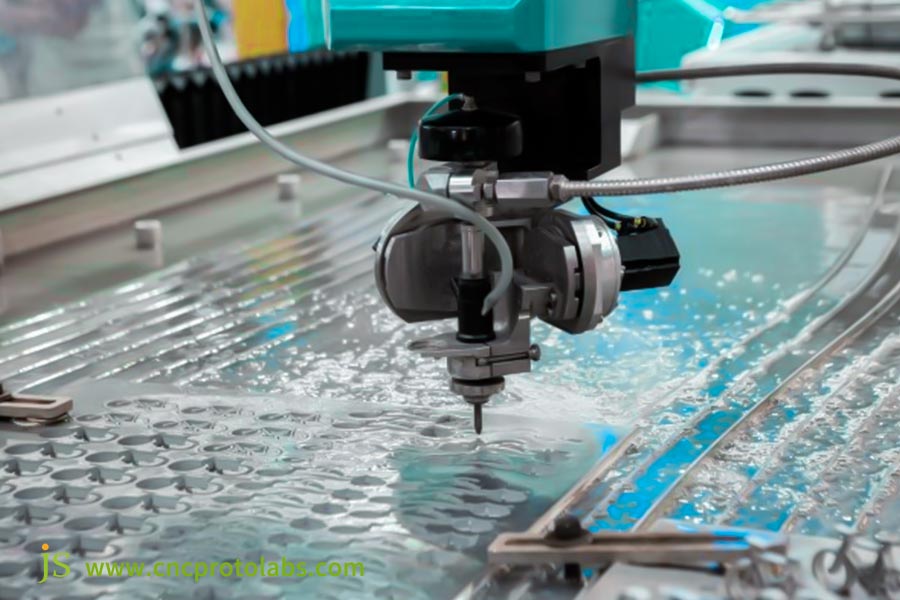

More Than Just Cutting: Why Laser Processing Is The Trend Of Contemporary Manufacturing

Already aware that JS can make 3-day shipping, you may wonder why new production will favor laser cutting over the old-fashioned ones. In fact, laser cutting better addresses the requirements of new manufacturing in precision, efficiency, and flexibility.

A comparison table objectively demonstrates its superiority:

|

Processing Method |

Precision Range |

Cutting Speed (1mm Thick 304 Stainless Steel) |

Material Compatibility |

Material Waste Rate |

Applicable Applications |

|

Laser Cutting |

±0.1-0.3mm |

3-5 m/min |

Metal, plastic, etc., can cut detailed shapes. |

≤5% |

Precise parts, small-order samples, complex designs. |

|

Punching |

±0.5-1mm |

1-2 m/min |

Metal only, detailed shapes require many molds. |

10%-15% |

Simple designs, mass production. |

|

Plasma Cutting |

±1-2mm |

2-3 m/min |

Thick metal only (≥6mm). |

15%-20% |

Heavy machines, thick plate cutting. |

For precision sheet metal fabrication parts, either for complex shapes or low-run, we have guaranteed service. We request that you contact us for customized solutions.

Busting The '3-Day Delivery' Myth: What Do Local Service Providers Do To Make It Possible?

If you go searching for online sheet metal fabrication services, usually what comes to your ears is '3-day delivery' which is eventually followed by delays. Although '3-day delivery' is no myth, it is essential that one is able to differentiate between 'falsely fast' and 'truly fast.'

The shortcomings of 'falsely fast' delivery

The '3-day delivery' of most service providers is only for the 'cutting phase' and not for including the important steps. There are three shortcomings:

- They don't account for DFM review time. The service providers require 1-2 days to review the DFM, and when they start looking for any faults, the delivery date has already passed.

- They don't account for preparation time for materials. If the required material is not in inventory, looking for it will require an additional 2-3 days.

- They don't account for post-processing time. Laser cutting requires deburring and anodizing, and having these done outside can add delivery times of over 5 days.

The entire process from design to delivery impacts laser cutting delivery times. 'Quick' descriptions which ignore any of these steps are not accurate.

The Core Requirements for 'True Speed'

JS's ability to deliver in 3 days relies upon the following four core requirements:

- Abundant materials inventory: Our local warehouse has 6061 aluminum alloy, 304 stainless steel, and more materials in 1 to 25mm thicknesses at all times, eliminating the need for procurement delays.

- Electronic processes: After customers upload their design files, the system generates quotes and schedules within under 5 minutes, eliminating manual delays.

- Timely engineer involvement: 24/7 Design and Function (DFM) engineers provide 30-minute turnaround feedback on optimization suggestions.

- Integrated post-processing: Our plant has in-plant deburring and anodizing facilities, enabling direct processing following cutting, thereby avoiding outsourcing.

When you search sheet metal fabrication online, JS's end-to-end delivery with expedited shipping will not fall into the 'pseudo-speed' trap. You can track production in real-time with a firm order in hand. Choose hassle-free, optimized metal fabrication.

Cost Clarity In All Aspects: Is Your Budget Accurate For Your Custom Metal Parts?

Once you are aware of the delivery time, your next concern is going to be price. Four factors are fundamentally the cause of the price of laser cutting:

| Main Factors That Affect Costs | Specific Factors Affecting | Cost Range (6061 Aluminum Alloy Components) |

| Material Cost | Type of material, thickness, and weight. | $2.5-4/pound (1mm thick: approximately $0.15/square centimeter). |

| Laser Cutting Labor | Number of holes, cutting length, and dimension. | $1.2-2/meter (labor cost adds 30% for more complicated parts with more holes). |

| Processing Difficulty | Inner corner radius and cutting accuracy requirements. | Basic coefficient: 1 (inner corner radius ≥ 1mm), 1.5-2 for more complicated parts (<0.5mm). |

| Post-Processing Costs | Deburring, grinding, anodizing, painting. | Deburring: $1.5-2/piece, anodizing: $5-8/piece, painting: $3-5/piece. |

Total Cost Formula: Total Cost = Material Cost + Laser Cutting Labor + (Basic Processing Cost × Processing Difficulty Coefficient) + Post-Processing Costs

5 Important Questions: Finding Reliable Metal Fabrication Shops Near Me

When you have served your role as a 'metal fabrication shop near me,' just do these 3 steps and ask the correct 5 questions to find reliable shops.

Step 1: Screen with Technical Questions (ask directly while calling)

- 'What model laser cutting machine do you have? What is the highest processing thickness and lowest precision?'—Good shops will tell you flat out (e.g., IPG model, max 25mm, accuracy ±0.1mm), do not accept evasive responses.

- 'What do they laser cut? Have they had fine-cutting success with 6061 aluminum alloy?'—Ensure that the shop has prior cutting experience on the target material to avoid failure.

Step 2: Apply Process Questions to Measure (Check Level of Digitalization)

- 'How quickly after I submit design files can I have a quote and scheduling? Can I track progress in real time?' — JS provides quotes in 5 minutes, and customers can monitor progress online. Less efficient factories reply in 1-2 days.

- 'If files of design are the problem, how long does it take to respond? Are there manufacturing, functional, and design engineers available to provide optimization advice?' — Professional factories will reply within 30 minutes, whereas unprofessional factories will only process and scrap the parts.

Step 3: Referral by Case Studies

- 'Did you ever make a laser cut piece with 3-day delivery to a customer from the same sector? Can you share it with me?' — Actual instances of experience demonstrate capability to do. Stores that cannot provide case studies will never stand a chance to provide 3-day.

- Process standardization and technical skills are more important than cost in selecting a metal fabrication company. Prioritize local manufacturers who can provide specific cases for easier communication and logistics.

Case Study: Salvaging a Smart Hardware Startup's Launch In 72 Hours

Customer Pain Points

There was an in-house smart home development team producing a second-generation smart thermostat. As they were running test cases a week prior to release, they discovered that the case made of aluminum alloy with ribs 1mm thick failed at -10°C and therefore failed to display reliability on the show.

They needed to come up with 10 reinforced casing units in 3 days or the launch would be delayed, their $2 million would be lost, and they would even risk losing investors' interest.

JS's Solution

After the customer contacted JS Precision Manufacturing, we immediately initiated an emergency response:

- Emergency Response: The customer had submitted a new design file (rib thickness 1.5mm) at 10:00 PM that evening. The system also created an automatic quote with an 'expedited' option. Once confirmed, the schedule was assigned to the workshop.

- Inventory Matching: It further showed that the required 5mm thickness 6061 aluminum alloy plate was in stock, and the workshop was operating overnight (three shifts operated 24 hours a day, thus urgent projects could be initiated at any moment).

- Design for Material Design (DFM) Intervention: The engineer inspected the file within 30 minutes and determined that the corner radius of 0.5mm in the rib reinforcement would fail. On call check, they recommended a modification to 1.5mm and approved a 3D model that was quickly confirmed by the customer.

- Inspection of the Entire Process: Production schedule was communicated to customer. They saw photos of the cuts on the next day. The entire 10 pieces were deburred and express shipped by noon on the third day.

Results

We had been offered samples a day prior to client launch, and conducted 4 hours of assembly and low-temperature testing (no crack at -10°C, tested in repeat of 50 times). Launch was successful, and the team had invested $5 million. Customer feedback: 'JS's 72-hour delivery saved our launch and our company's growth opportunities.'

With the same crisis project requiring custom sheet metal fabrication services, JS can respond to you within 72 hours. Partner with us to help you finish your crisis.

Choose JS: 3-Day Metal Fabrication Solutions

When you're in need of laser cutting service, why choose JS Precision Manufacturing over the likes of Xometry and RapidDirect? The comparison table adequately reflects JS's innate strengths:

| Comparison Dimensions | JS Precision Manufacturing | Xometry | RapidDirect |

| Laser Cutting Lead Time | 3 days (emergency 48 hours) | 5-7 days | 4-6 days |

| Typical Material Stock | 6061 aluminum alloy and 304 stainless steel are readily available, there is no procurement. | Partials are maintained, special orders are procurement in 2-3 days. | No inventory set, all orders must be procured in 3-4 days. |

| DFM Check Response Time | Reply in 30 minutes. | Reply in 24 hours. | Reply in 48 hours. |

| Online Production Tracking | Real-time view of cutting, post-processing, and shipping. | Shipping status only visible. | No online tracking, hand consultation required. |

| Emergency Service Fees | No rush fee additional. | 50% rush fee additional. | 30% rush fee additional. |

| Post Processing Integration | Done in-house, no outsourcing. | Deburring needs to be outsourced, +1-2 days. | Full post-processing outsourcing, +2-3 days. |

JS's specialities are concentrated in three fields:

- Faster shipping with no additional rush fee. Local inventory and 24-hour lead time decrease purchasing and outsourcing lead time, allowing customers to save sheet metal fabrication price.

- Improved professional service. Design and Function (DFM) engineers respond 48-96 times faster than others and resolve design issues on time.

- More open process. Web-based tracking keeps customers informed and reduces communication time.

FAQs

Q1: Is the 3-day delivery part of shipping time?

Usually not. '3-day delivery' specifically states that parts are made and shipped out within 3 working days, excluding week days and statutory holidays. Delivery time is based on your selected logistics channel (e.g., Tongcheng Express or SF Express Next-Day Delivery). Customer service can be reached to confirm the exact timing when ordering.

Q2: Is there a guarantee if the factory cannot deliver in 3 days?

Professional service providers will publically announce estimated delivery date and advance commitment. In case of delay due to the reason of the factory, legitimate manufacturers will proactively communicate and provide solutions such as compensating for partial processing fees and prioritizing urgent orders in the future.We recommend you make special declaration of delay liability in contract signing and pay extra attention to the implicit protections of the terms of service.

Q3: Because the factory is close to me, can I personally go view or pick up the parts?

Sure! JS as an industrial manufacturing service business welcomes customers to schedule factory tours (online or by phone). During the tours, you can obtain equipment specifications and production management information. Picking up parts yourself is a reasonable way of conserving delivery time and on-site inspection of part quality, which facilitates fostering trust of collaboration.

Q4: I'm most concerned about publishing confidentiality. Is it safe to post them online?

Good service providers also ensure data security and will provide you with a non-disclosure agreement (NDA) that details the usage scope, storage time, and leak responsibility. They even have bank-grade encryption in place to ensure that the uploading and storing are secure from any type of breach. You can request their security policies specifically before ordering so as to minimize any stress.

Summary

When crisis strikes, acquiring a true rapid manufacturing partner is not convenience, it's trust, a chance at success, and peace of mind that can't be beat. Don't let the word 'near' trick you, true 'near' is lean processes, smooth communication, and responsive service.

If you still worry about whether it is possible to get your laser-cut pieces within three days and need reliable online sheet metal fabrication services, phone JS Precision Manufacturing. Time is opportunity in the manufacturing industry, and JS is your partner to help you grasp it.

Disclaimer

The contents of this page are for informational purposes only.JS servicesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Jusheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com