Laser welding is one of the core processes in precision manufacturing, but its unstable penetration depth often leads to insufficient strength in sheet metal fabrication parts, early failure of products, frequent customer complaints, and a high cost of rework.

Just imagine the critical component breaking during testing because of poor control of penetration depth, which is leading to delays in the project and losses amounting to thousands of dollars. In precision manufacturing, we strongly feel that the depth of penetration is not a single fixed value, but a critical process variable that demands exact control. The key is "control".

The step-by-step guide below shows how JS Precision attains superior penetration depth control for clients around the world. It ensures your projects move forward with zero risk.

Summary of Core Answers

|

Section |

Core Concepts / Influencing Factors |

Key Parameters / Methods |

Application Value |

|

Core Mode |

Conduction Welding / Deep Penetration Welding. |

Conduction welding: depth of penetration ≤ 1 mm. Deep Penetration Welding: depth of penetration in the millimeter order. |

Choose the mode of welding based on the thickness of the workpiece (thin/thick). |

|

Influencing Factors |

Power of the Laser / Welding Speed / Beam Quality. |

Power of 1000 W supplied to 0.8 mm copper: depth of penetration 0.5-0.7 mm. |

Avoid burn-through/spatter and have a fine control over depth of penetration. |

|

Optimization Method |

DoE Experiment / Blue Laser. |

DoE experiment saves time by 40%. Blue laser (BPP < 0.9). |

Consistent penetration depth (±0.05 mm), improving efficiency by 40%. |

|

Maintenance and Calibrations |

Daily Cleaning / Weekly Calibration. |

Variation in laser power ≤ ±5%, clean lens daily. |

Regulate penetration depth variation to ≤ ±5%, reducing rework. |

Key Takeaways: Your Quick Action Guide

Before you dive into this guide, we've distilled the following key points to help you understand quickly what to expect in the realm of laser welding penetration depth control and the value JS Precision can bring:

1.Depth of fusion is a controllable key variable, not a fixed value: By precisely controlling parameters like laser power, welding speed, you can customize weld characteristics for different sheet metal fabrication parts like an expert, in order to find the best balance between strength, appearance, and cost, avoiding defects such as insufficient strength or burn through.

2.Overcoming high reflective materials is a manifestation of professional ability: facing challenges from materials such as copper and aluminum, simply increasing power often backfires. As an advanced precision laser welding company, we provide the latest technology such as blue lasers to dramatically improve energy absorption for reliable custom laser welding solutions for these materials.

3.The consistency of penetration depth (± 0.05mm) is the core indicator for measuring quality: It directly influences product yield, life span, and overall cost. A high-quality laser welding supplier like JS Precision translates into unparalleled process stability for your benefit, thereby reducing overall manufacturing costs.

4.The most effective control begins with professional consultation: the ultimate goal of theoretical knowledge is to successfully deliver your products. Act now and get your personalized laser welding services quote. Using your workpiece drawings and requirements, our experts will provide you with the most cost-effective solutions.

Why Believe This Guide? JS Precision Team's Best Practices Uncovered

In over 15 years of laser welding practice, we have accumulated a process parameter database covering 12 industries and over 300 different material combinations. This means that your project requirements are likely within the scope of our familiar solutions.

As an experienced precision laser welding company, we have provided custom laser welding solutions to aerospace clients, successfully increasing the precision of penetration control to ± 0.02mm and reducing rework rates by 30%. According to the International Organization for Standardization ISO 13919-1 standard, our process meets the requirements for high-quality welding.

We have also made effective solutions to over 30 complex questions. For example, in the project provided to medical equipment manufacturers, we optimized parameters to control the variation of melt depth within ± 0.05mm, helping customers reduce the sheet metal fabrication price by 15%.

This manual is the result of combining this operational data, customer feedback, and industry knowledge, all substantiated with real projects.Whether an online sheet metal fabrication consumer seeking a pilot small batch run or an at-scale custom sheet metal fabrication manufacturer, this guide is a reliable reference.

Download our Precision Laser Welding Company Success Case Handbook now to learn how to improve product yield through precise control.

Beyond The Surface: Revealing Laser Welding Penetration Depth

We first need to determine the straightforward definition of laser welding penetration depth:

It is the distance along the vertical between the surface of the workpiece and the deepest position at which the resulting pool of molten metal is after the laser beam strikes the workpiece. This distance determines directly whether the weld can support the requirements of sheet metal fabrication parts.

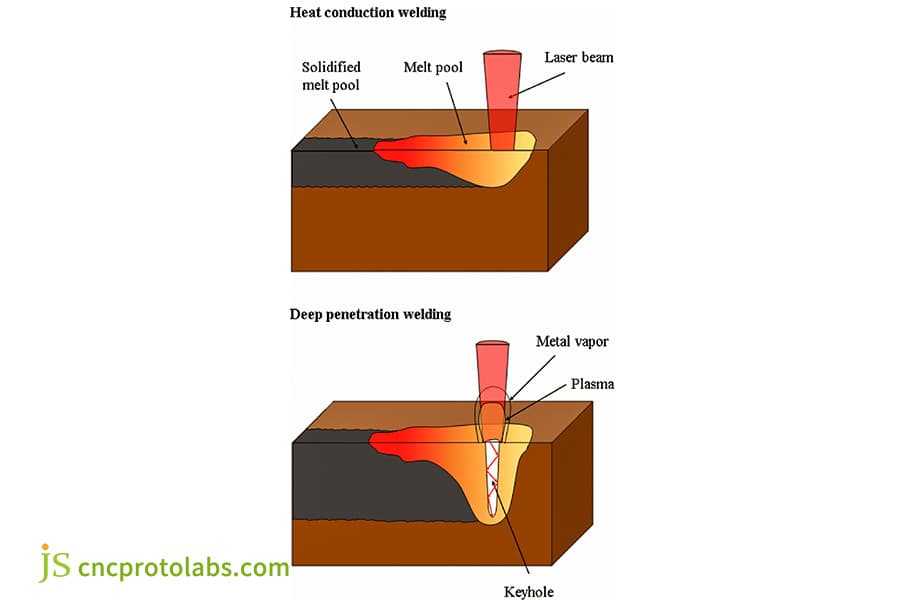

This depth of penetration relies chiefly on two basic welding modes, which are extremely different in the ability of penetration and applicability of use.

Selection of the right mode is the first and foremost important decision in the control of penetration depth. According to American Welding Society standard AWS C7.3, the mode should be selected based upon workpiece thickness and application scenario.

Comparison of the Two Core Laser Welding Modes:

|

Comparison Dimensions |

Heat Conduction Welding |

Deep Penetration Welding |

|

Penetration Depth |

Shallow, typically ≤1mm. |

Deep, between several and tens of millimeters. |

|

Energy Application |

The laser energy only acts on the surface and propagates inward through heat conduction. |

High concentration of energy density to form a keyhole, allowing for direct penetration into deeper layers. |

|

Weld Characteristics |

Shallow and wide with smooth surface. |

Narrow and deep with high aspect ratio. |

|

Applicable Applications |

Thin-walled sheet metal fabrication parts (e.g., 0.3-0.8mm stainless steel parts). |

Thick plate structural parts (e.g., 2-10mm carbon steel parts, battery modules). |

|

Representative Applications |

Sealing of sheet metal medical devices by welding. |

Chassis connections of sheet metal for new energy vehicles. |

Figure 1:There are two modes of laser welding: heat conduction welding forms a shallow melt pool, while deep penetration welding produces keyholes and plasma, penetrating deeper.

Why Is 'Depth' So Important? More Than Just Strength

The depth of laser welding has an impact greater than on weld strength alone, it sets to work immediately on workpiece performance, safety, and expense. It is defined through three significant factors:

Determining Structural Safety

For load-carrying sheet metal fabrication parts (e.g. automobile chassis connectors), a poor weld depth can create a 'weak point' in the weld that tends to crack under long-term vibration. When shallow penetration heat conduction welding is used on heavy plate parts (e.g. 5mm carbon steel), the weld does not reach into the workpiece and is highly prone to fracture during use.

Effect on Functional Conformance

Sheet metal fabrication parts from different industries have varying depth requirements: Copper busbars for new energy batteries require a penetration depth of ≥0.6mm, or overheating by way of high resistance will happen, non-uniform penetration depth in transport pipes for fluids may cause leakage, going against the food and medical industry standards.

Controlling Production Costs

Insufficient penetration depth can increase sheet metal fabrication price: too much power input in thin-walled components may quickly cause burn-through (scrap rate of 10%+), rework on thick plate components wastes labor, raising unit cost by 30%.

'Proper depth' holds the secret to finding a balance between laser welding quality and cost.

Desire to manage sheet metal fabrication price without sacrificing weld depth? JS will find the balance between cost and quality. Transparent processes and streamlined manufacturing provide complete control from communication to delivery.

Achieving 'Depth': Five Key Factors Influencing Penetration Depth

To precisely manage the penetration depth of laser welding, the following five fundamental factors should be well understood.

Laser Power

- Fundamental Correlation: With other parameters unchanged, more power tends to lead to deeper penetration. Yet, going beyond the critical value can cause greater burn-through and spatter.

- Practical Reference: Different powers are linked with a specific range of copper penetration depth. An appropriate power needs to be selected based on the thickness of the material.

Copper penetration depth for different laser powers (welding speed 1m/min, beam quality BPP = 1.0)

|

Laser Power (W) |

Copper Thickness (mm) |

Penetration Depth (mm) |

Applications |

|

500 |

0.5 |

0.3-0.4 |

Fabrication parts of thin-walled sheet metal fabrication parts. |

|

1000 |

0.8 |

0.5-0.7 |

Battery copper busbars. |

|

2000 |

2.0 |

1.2-1.5 |

Thick sheet metal structural components. |

|

3000 |

3.0 |

2.0-2.3 |

Heavy machinery sheet metal connectors. |

Welding Speed

- Core Relationship: Negatively with penetration depth—higher speeds relate with less energy input and lower penetration depth, lower speeds can easily burn through and increase the sheet metal fabrication price.

- Tip: Trial welding in small batches during production is needed to determine the optimal power and speed combination.

Beam Quality

- Measurement Criteria: Tested with the beam penetration (BPP) value. The smaller the BPP, the more the energy will be concentrated, and the deeper the penetration.

- Practical Utility: In welding copper, a blue laser with a BPP <0.9 can provide more than a 30% increase in penetration depth over an infrared laser with a BPP of 1.5, with less spatter. When JS Precision processes high demand sheet metal fabrication parts, low BPP equipment is preferred.

Material Properties

- Key Influences: The higher the reflectivity and thermal conductivity of the material, the more difficult it is to improve the penetration depth (e.g., copper has an infrared laser reflectivity >95% and thermal conductivity 401 W/(m·K), hardest to weld).

- Adaptation Strategy: Blue lasers are employed on copper workpieces. Aluminum alloys require power and speed adjustments to minimize heat dissipation.

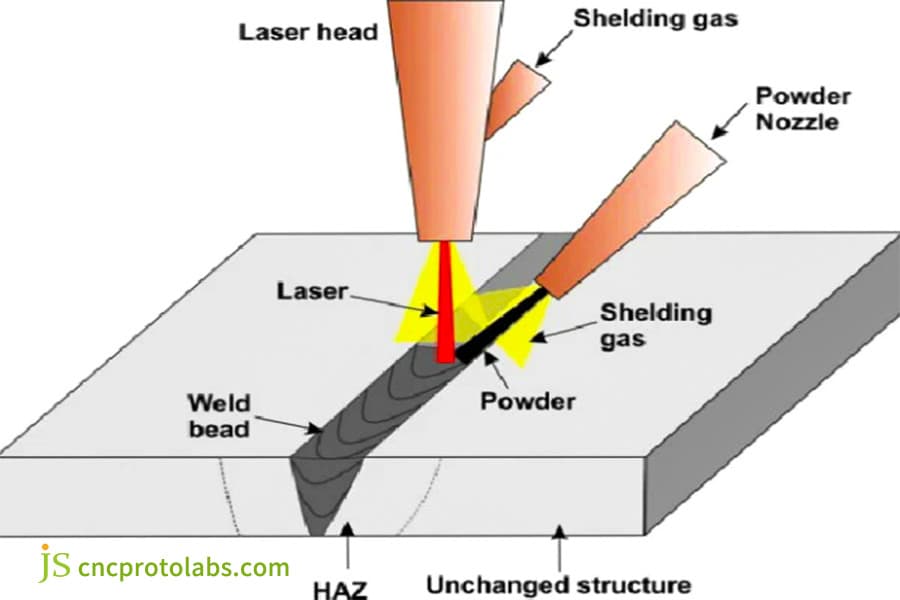

Shielding Gas

- Function and Choice: To prevent weld pool oxidation and stabilize the keyhole, argon (approximately $1.50/m³) is suitable for medium power and low power levels, while helium (approximately $8/m³) can increase penetration depth by 15%.

Figure 2:Schematic diagram of laser welding system, showing the working process of laser head, powder feeding nozzle, and protective gas working together to form a weld and define the heat affected zone.

From Theory To Practice: How To Optimize Laser Welding Penetration Depth

Optimization of penetration depth can be achieved through a systematic approach. The three approaches given below can be utilized for most sheet metal fabrication parts cases.

Parameter Combination Optimization

Core Technique: Using laser power, welding speed, and focus position as the parameters, try many times to get the optimal combination in terms of a balance between depth, quality, and efficiency.

Practical Outcomes: With the parameters for the best 0.8mm copper busbar determined, the 0.7mm depth was achieved, representing a 40% efficiency gain over the trial-and-error methods. This also reduces waste and minimizes sheet metal fabrication price.

Equipment Selection by Material Property

Choice Logic: Lasers are selected based on the reflectivity and thermal conductivity of the material. Blue lasers are utilized for copper (absorption rate improved to 35%). In the case of thick aluminum alloy plates, a beam shaping system is employed for the improvement of depth uniformity.

Service Benefits: In our online sheet metal fabrication services, JS Precision pre-matches equipment to sheet metal fabrication parts material to create a successful first-pass weld.

Application of Innovative Process Technologies

Key Process: '∞-shaped' oscillating welding increases laser contact time, and copper busbar depth stability improves to ±0.05mm from ±0.1mm. 'Layered welding' prevents shallow depth or burn-through on multi-layered components.

Application Example: Complex sheet metal fabrication parts can utilize two processes simultaneously to meet both weld depth and appearance requirements.

Depth Consistency: Daily Maintenance And Calibration

Daily Maintenance

- Cleaning of optical lenses daily (to reduce energy loss).

- Check of laser power weekly (adjustment if deviation exceeds ±5%).

- Accuracy check of motion system every two weeks (re-adjust if displacement deviation exceeds 0.02mm).

- Check of cooling system every month (water temperature 20-25°C).

JS Precision Guarantee of Maintenance

Early Warning System: Equipment parameters outside specified limits will automatically generate an alert to avoid quality risk.

Periodic Inspection: 10 common 0.8mm copper sheets have depth consistency checked every six months. In case of deviation exceeding 0.1mm, a comprehensive inspection is conducted to control depth variation to ±5%, reducing rework and sheet metal fabrication prices.

In addition to welding in custom sheet metal fabrication manufacturing, JS Precision also provides equipment maintenance guides. Partner with us for expert complete-cycle service.

Real Case Study: Deep-Piercing Welding Challenges For New Energy Vehicle Battery Modules

Customer Requirements and Initial Pain Points

A leading new energy company has challenged us, which reflects our demand for custom laser welding solutions. They had to weld 10 pieces of 0.3mm thickness aluminum battery structural module parts. The key requirements were 1.5mm penetration depth (complete penetration with a maximum of 5 pieces) and no welding distortion.

Project Challenges

- Material challenges: Aluminum has a thermal conductivity of 237W/(m·K), and laser energy diffuses very quickly, making it difficult to form a deep weld pool and achieve the required depth of 1.5mm.

- Structural Risks: Joint gap of ≤0.05mm between different layers of sheet metal fabrication parts caused laser energy leakage, which not only reduces depth but also increases the risk of porosity.

- Temperature Restrictions: Cells of the battery are sensitive to temperatures. Weld area temperatures exceeding 200°C can destroy cells and compromise the performance of batteries.

JS Precision Manufacturing Solution

Our team did not adopt standard processes, but designed a customized laser welding solution.

- Equipment Selection: 2000W BPP 1.0 infrared laser was selected along with a beam shaper system to shape the laser beam into a 0.5mm x 1mm rectangle. This maximizes the surface area of energy effect and reduces heat dissipation.

- Process Optimization: It employed a 'pre-pressing + layered welding' process—first applying 0.5MPa pressure on the zone to eliminate gaps, and welding three layers (0.5mm thick) to avoid extremely high temperatures from being produced by one weld.

- Temperature Control Measures: A 15°C cooling water channel was installed near the region of weld for draining heat in real-time, and keeping the surrounding temperature below 180°C and protecting battery cells.

Results

High-strength, spatter-free full-penetrating welding has been achieved, with consistent penetration depth of 0.7mm, equal interface width, and extremely low and consistent resistance, satisfying the battery's demands fully for high current and low loss. The yield rate has been increased from 70% to over 99.5%.

The success of this case fully demonstrates JS Precision's ability as a high-quality laser welding supplier to solve complex problems.

Upload your project background and challenges immediately to receive a detailed report on targeted high quality laser welding supplier case solutions.

Figure 3:Battery module structural components

How Do You Guarantee Your Products Receive The Optimal Weld Depth?

Explaining the Essential Criteria for Optimal Weld Depth

Perfect weld depth is not a single numerical value, but a triple standard of performance, stability, and cost.It must meet workpiece functional requirements (e.g., minimum resistance for conductive parts, maximum strength for structural parts), have a range of penetration depth variation ≤±0.05mm, reduce rework caused by erroneous parameters.

This means developing a clear standard framework through the combination of laser welding attributes with custom sheet metal fabrication manufacture specifications.

JS Precision's Three Core Capabilities for Perfect Weld Depth

Proper Material-Equipment Matching: JS Precision uses a material database (steel, aluminum, copper, etc.) to match lasers to workpieces with varying reflectivity and heat conductivity (e.g., reflective parts have blue lasers). This correctly converts the energy and avoids shallow weld depth resulting from 'equipment mismatch'.

Process Innovation and Optimization: Meeting challenging welding environments such as high thermal conductivity and thin walls, we have developed processes such as '∞-shaped oscillation' and 'layered welding' to mitigate molten pool instability, maximize weld depth uniformity, and extend to online sheet metal fabrication services and mass production.

Calibration of Scientific Parameters: With the application of Design of Experiments (DoE) rather than trial-and-error methods, we quickly adjust parameter sets such as power, speed, and focus with an enormous time saving in commissioning, even weld depths, and material.

Full-Scenario Weld Depth Assurance Support

JS Precision processes involve the entire procedure from first design to mid-term control of production up to maintenance after production.

Small orders may be readily compared to parameters through an online system, whereas volume-based customized mass production is controlled through automated production lines. Maintenance guidance for machine tools is also provided in an attempt to prevent weld depth deviations through lengthy use, which makes it possible to produce ideal weld depth under any condition.

Choose Your Precision Laser Welding Partner

When selecting a partner, of course, technical capabilities are fundamental, but the true value is in their ability to build a long-term and reliable support system for you. These three pillars are core guarantees we provide to our customers.

Pillar 1: Reusable Process Assets, Accelerating Project Implementation

With over 15 years of project experience, our extensive library of process parameters covers more than 300 material and structural combinations, which means your project probably will not have to start from scratch. We can quickly provide a validated base of parameters that will substantially shorten the R&D cycle and let you get a jump-start.

Pillar 2: Custom Development Capabilities for Unknown Challenges

We also know very well that creative projects often don't have standard answers. Thus, the strong custom R&D capability forms the backbone of our engineering team, which equips us to offer unmatched custom laser welding solutions to tackle unique challenges in welding high thermal conductivity, thin walls, or dissimilar metals.

Pillar 3: A Preventative Quality Assurance System

For us, quality is much more than final inspection. It is a designtype philosophy-a preventative system throughout the whole process, including material warehousing and process monitoring down to finished product shipment.

Through exact standardized operations and continuous monitoring, we ensure that every product delivered to you possesses traceable high quality, fundamentally reducing the risk.

Next Steps: Converting Insights into Your Competitive Advantage

The result of all technical discussions should be the successful implementation of projects. If you are serious about moving forward, the best way to do so is by having detailed discussions with us.

From here, please submit your project information and receive a detailed laser welding services quote that contains not only transparent pricing but also targeted process recommendations and reliable lead times.

FAQs

Q1: Why does high power sometimes produce shallower or unstable weld penetration?

This is because of the "plasma shielding effect." Too much power vaporizes the metal, creating a plasma "energy barrier" on top that reflects the laser and impedes penetration. Thus, precise matching of parameters is much more important compared to simply increasing power.

Q2: How to detect and measure the penetration depth of welds?

The most accurate method is destructive metallographic examination, including cutting the workpiece in a way to inspect weld penetration and being utilized for precise verification. Ultrasonic testing,and other non-destructive methods are commonly used in industry, which do not require damage to the workpiece and are more suitable for sampling and deep evaluation of batch products.

Q3: What is the maximum possible thickness in laser welding?

This depends on material, laser source, and process. With single-pass welding, fiber lasers can weld 20-30mm thickness carbon steel and 15-20mm aluminum alloys. With multi-pass welding or high-power arrays of lasers and ideal processes, theoretical weld thickness has no maximum.

Q4: Why it is so very difficult to laser weld copper and aluminum?

The intrinsic reasons are two-fold: First, copper and aluminum have very high reflectivity for lasers (copper's infrared laser reflectivity is over 95%), which results in energy reflection and loss, second, they have high heat conductivity, which results in the dispersal of heat quickly. Increased power density and custom processes are required to form and maintain a stable 'pinhole effect.'

Q5: What is the difference between the pricing strategy for small-batch prototypes and mass production?

The price for small batches includes the cost of process development and debugging. In mass production, the optimized parameters solidify, reducing unit costs through economies of scale. We have transparent tiered pricing.

Q6: How do you ensure the security of your design drawings and your intellectual property?

We consider our clients' IP as our lifeline. We guarantee security of your designs through strict confidentiality agreements, encrypted file systems, and isolated production management. We have successfully served numerous leading technology companies.

Q7: What is your after-sales policy if the weld quality is substandard?

We guarantee 100% quality. In case of poor quality caused by our process problems, we can rework or remake the weld for free and undertake the relevant costs, which ensures that your project can be carried on with zero risk.

Q8: Besides drawings, what other information do you need to provide an accurate solution and quotation?

In addition to drawings, please provide the following for an accurate solution: material specification, surface treatment requirement, estimated annual usage, and target cost. This will help us identify process challenges and plan production capacity to match you with the most cost-effective customized laser welding solution.

Summary

Penetration Depth is not an absolute number, but a 'manipulable variable' able to be modified within a flexible parameter as per the needs of sheet metal fabrication parts. For every manufacturing practitioner, controlling the scientific logic and optimization techniques behind laser welding is about taking this 'sharpest blade of light' from technology to an art.

Whether you are working on small-batch production or high-volume custom manufacturing, if penetration depth problems crop up in laser welding, JS Precision can provide individualized solutions. We understand that only the 'proper' penetration depth will provide the best quality at the lowest cost for your product.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com

Resource