A perfect sheet metal bend creates a rigid chassis, silky brackets, and flawless assembly. But a runaway springback or a tear and the whole production batch is on the scrap heap! Bending defects not only kill yield, but also add cost and lead time. Sheet metal bending is simplicity itself, and yet it is a complex interplay of materials, dies, and process control.

Core Answer Summary

| Aspects | Core Content |

| Complexity of Sheet Metal Bending | Needs special press brake and related molds to control bending pressure, rate, and sequence. |

| Variations in Material Selection | Stainless steel is stiff and low in elongation and may crack,aluminum has low elastic modulus and small plastic range and can cause uncontrolled springback. |

| Factors Influencing Bending Defects | Material properties, process conditions, condition of the mold, equipment accuracy, operator skill, and environmental conditions. |

| Five Main Bending Defects | Angular deviation (springback), loss in strength (cracking), difficult assembly (distortion), internal R-angle deformation, and dimensional deviation. |

| Defect Prevention Plan | Considering precautions from the entire chain of processes, which also includes design (e.g., rational radius) and process (e.g., adjustment in parameters). |

Why Is This Guide Trustworthy?

JS has acquired good practical know-how in precise metal bending. We know the bending behavior of over 40 materials. In terms of the process, we have optimized bending parameter settings for sheets of assorted thicknesses (0.3-10mm).

We can precisely adjust the V-die opening, bending speed, and pressure with an accuracy of ±0.1mm. We have performed bending operations with over 15 different surface treatments and understand how anodized coatings impact bending and how to prevent powder coating flaking when bending.

From small, delicate components for medical equipment to enormous volume, standard ones for industrial machinery, we can quickly identify the solution.

Based on our hands-on know-how, this book offers tested methods from material selection and parameter tuning through fault elimination, hence a handbook of confidence.

Need sheet metal bending? JS has more than 40 materials, 3-7 day shipping, and ±0.1mm accuracy. Receive sheet metal fabrication quotes within minutes—you won't regret it.

Sheet Metal Bending: More Than ‘Pressing Down’

Sheet metal bending is a sophisticated operation including the organized interaction of numerous parameters, much more than a mere 'press.'

From a machinery aspect, a press brake is needed specifically for the purpose, and its accuracy and tonnage directly affect the bending outcome. The slide stroke of the press brake and flatness of the worktable have to be adjusted specifically for the material and size processed.

During the process, selection of bending tooling is very important. Different bending angles and thicknesses require molds of different shapes and sizes, such as V-shaped and U-shaped molds. The mold's precision will be directly copied to the workpiece; wear or dimensional errors can cause defects.

Accurate control of the bending force and point of application is also essential in the bending operation. The bending force, if too low, will not bring the workpiece to the desired angle, and a bending force that is too high will cause excessive deformation or even cracking.

Furthermore, bending sequence matters. For multi-bend parts, an acceptable bending sequence must be followed to avoid ruining the previous bends and making sure each component's size and angle meets the required standards.

Don't let sheet metal bending become a problem. JS offers reliable sheet metal fabrication parts with 15 surface finishes. We also provide online sheet metal fabrication services for fast quotes and efficient production. Contact us now.

Material Selection: Why Does Stainless Steel Always Crack, And Aluminum Rebounds Uncontrollably?

The differences in physical and chemical properties of different materials result in different issues they exhibit during sheet metal bending processes.

Stainless steel is prone to cracking, primarily due to its intrinsic nature. Stainless steel is hard and strong but possesses comparatively low elongation. During bending, there is excessive stress introduced inside the material. When there is stress beyond its tolerance limit, it leads to cracking.

Aluminum is prone to uncontrolled springback. Aluminum has a low elastic modulus. During bending, the material undergoes plastic deformation as well as significant elastic deformation. The elastic deformation is reversed upon removal of the external load, leading to springback.

Furthermore, aluminum also has a narrow plastic range. Leaving this range even slightly can lead to fracture in bending, further complicating springback control. Furthermore, the amount of springback also relies on the chemical makeup of the aluminum alloy, and the addition of some of the alloying elements can also affect its elastic recovery capability.

For a simpler comparison between the bendability of stainless steel and aluminum, refer to the following table:

| Material | Strength | Elongation | Elastic Modulus | Frequently Asked Questions |

| Stainless Steel | Higher | Lower | Higher | Prone to cracking |

| Aluminum | Lower | Higher | Lower | Uncontrolled springback |

Dissatisfied with material choice? JS is familiar with the properties of stainless steel, aluminum, and other metals and provides custom sheet metal fabrication manufacturing services to avoid cracking and springback with fast quotations.

The Drivers Behind Bending Defects: 6 Important Affecting Factors

Bendingdefects are not accidents,they are largely caused by the following six primary factors:

1.Material properties: Chemical structure and mechanical properties (for example, strength, hardness, and elongation) of the material effectively dictate bending quality. Materials vary in terms of ability to conform to bending, as just explained, for example, stainless steel versus aluminum.

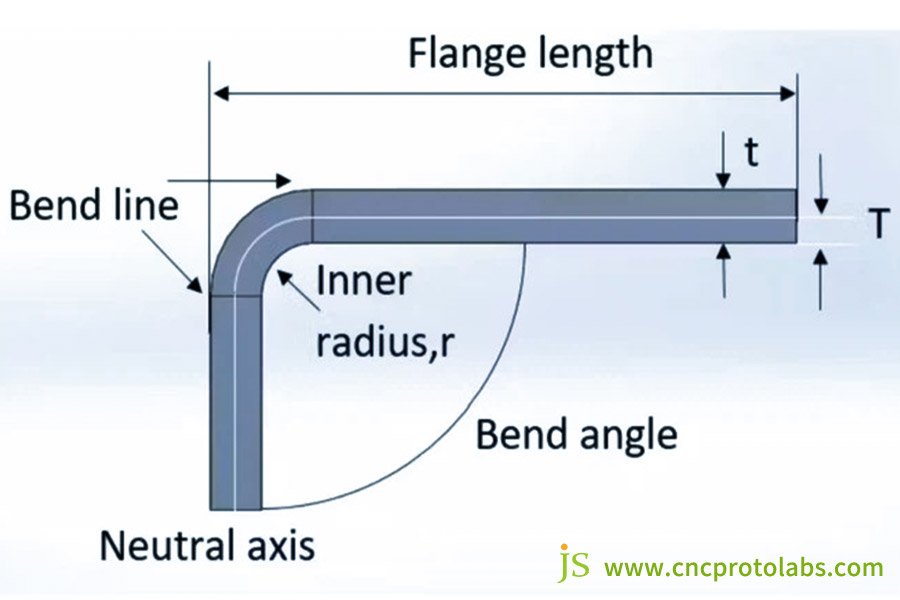

2.Bend process parameters: These include bend angle, bend radius, bending force, and bending speed. Misestimation of these parameters can directly lead to a variety of defects. For example, an over-minuscule bend radius creates cracking, and bending force that is too minimal results in angle deviation.

3.Condition of the Mold: Mold accuracy, wear, and surface finish can also affect bending results. Low accuracy of the mold results in workpiece dimensions errors, and poor surface finish of the mold causes friction between the material and mold, resulting in scratches or deformation.

4.Equipment Precision: The precision of the press brake's positioning and slide movement greatly contributes to the quality of workpieces. Inaccurate equipment can lead to unstable bending angles and dimensional inaccuracies.

5.Operator Ability: The operator skill and experience also affect the quality of bending. Misoperation of the process parameter settings, mold installation, and commissioning can lead to various defects.

6.Environmental Conditions: The surrounding temperature and humidity also affect the bending process. For example, low temperature increases the brittleness of certain materials, which will crack upon bending.

Want to avoid bending defects? JS employs state-of-the-art machinery to control every step of the process, providing online sheet metal fabrication services at an affordable price. Trust us with confidence.

Five Deadly Bending Defects: Critical Identification And Cause Analysis

Springback:The First Accuracy Killer

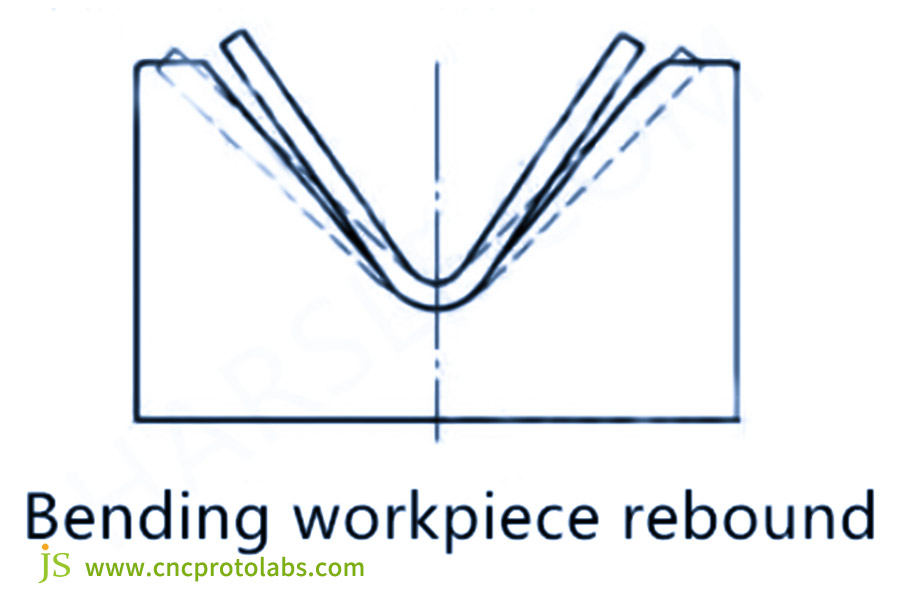

Springback is the phenomenon where the actual workpiece angle is different from the desired angle after elastic recovery when bending.The smaller the elastic modulus and higher the yield strength of the material, the larger the springback phenomenon, one which is highly common in aluminum and aluminum alloys.

Cracking:Direct Strength Loss

Cracking is a defect in the material which results during bending, considerably weakening the strength of the workpiece.When there is insufficient plasticity in the material to accommodate the deformation during bending, cracks will form at stress concentration points. Stainless steel, due to its high strength but relatively poor plasticity, is very prone to cracking.

Twisting:Assembly Nightmare

Twisting is a deformation of an irregular twist of a workpiece during bending that causes serious assembly issues.In a situation where deformation is not equally distributed throughout the material during bending of a workpiece, internal stress will be developed and warping will occur.

Inner Radius Deformation:A Hidden Quality Hazard

Inner Radius Deformation is when the inner radius of the curved surface of a workpiece is less than design requirements.Excessive inner radius or too small inner radius has an adverse effect on workpiece quality. Excessive radius leads to uneven stress distribution under service conditions, while too small radius causes stress concentration.

Dimensional Deviation:Difference Between Drawing and Actual Product

Dimensional deviation is a difference between the actual dimension of a workpiece and the dimension shown on the drawing.Dimensional deviation is caused by various causes that involve the absence of equipment positioning accuracy, mold dimensional defects, and operator error in measurement.

Worried about defects affecting parts? JS focuses on solving various problems, with reasonable sheet metal fabrication prices to ensure that sheet metal fabrication parts are qualified. Come and consult now.

Defect Terminator: An All-Round Prevention Solution From Design To Production

For Springback

- Design the bending radius: Select an appropriate bending radius based on material properties to avoid springback due to an excessively small or large radius.

- Use a compensation method: Consider springback in mold design and design the mold and produce the mold angle correspondingly smaller than necessary to offset the impact of springback.

- Use a correction process: Correct the workpiece after bending to reduce springback by subjecting the workpiece to a certain amount of pressure.

For Cracking

- Use the appropriate material: In workpieces prone to bending, use materials whose elongation is high with good plasticity.

- Increase the bending radius: In meeting design requirements, increase the bending radius proportionally in order to reduce material stress.

- Heat the material prior to bending: Preheat some high-hardness and high-strength materials prior to bending to improve their plasticity.

For Distortion

- Bend sequence optimization: Optimize the sequence of multi-angle bends to offer uniform force distribution on the material and reduce internal stress.

- Enhance die positioning: Get accurate die positioning to prevent workpiece movement during bending that can lead to distortion.

- Use symmetrical bending: For symmetrical works pieces, use symmetrical bending in order to allow symmetrical material deformation.

For Inner Radius Deformation

- Supply mold corner radius accuracy: The radius of the mold corner should be according to design requirements and have a smooth surface so that material wear is minimized.

- Control bending force: Control the bending force appropriately to avoid deformation of the internal rounded corner due to excessive or insufficient force.

- Select materials with good plasticity: Materials with good plasticity are more likely to create stable internal rounded corners when bending.

For dimensional deviation

- Improve equipment accuracy: Periodic calibration and maintenance of the press brake guarantee positioning accuracy and movement.

- Ensure mold quality: Strangely control the precision of mold manufacturing, regularly inspect mold wear, and change worn molds early.

- Enhance measurement and inspection: More regularly measure during the production process to detect early dimensional deviations and eliminate them.

| Defect Type | Core Preventative Measures |

| Springback | Correctly design the bending radius, die angle compensation, add a correction step |

| Cracking | Employ high-elongation material, increase bending radius, preheat treatment |

| Twisting | Optimize the bending sequence, strengthen die positioning, use symmetrical bending |

| Inner R-angle deformation | Ensure die radius accuracy, control bending force, select materials with good plasticity |

| Dimensional deviation | Improve equipment accuracy, ensure die quality, strengthen measurement and inspection |

Want to prevent defects? JS offers a full-chain solution, professional from design to production, custom sheet metal fabrication manufacturing, expertise in sheet metal bending, and transparent pricing. Choosing us will put your mind at ease.

Case Study: The 'Corrective' Experience Of Aluminum Housings Of Medical Devices

Customer Pain Point:

A high-end monitor aluminum alloy casing (5052-H32, 1.5mm thickness) experienced severe springback (89°→94°), edge micro-cracks, and excessive assembly clearance in a limited trial production.

Defect Analysis: No springback compensation (for a 90° straight press). The line of bending was parallel to the rolling direction (edge stress concentration). Incorrect V-die selection (V-mouth width = 12mm < 8*t = 12mm, resulting in high pressure).

JS's Solution:

DFM Optimization: Refabricated the bending line to form a 45° angle with the rolling direction of the material to reduce the edge stress concentration, on the basis of the elastic modulus of 5052-H32, a springback compensation angle of 1.2° was incorporated in the die design, changing the target bend angle to 88.8°.

Process Upgrade: Replaced the V-die with a 15mm V-mouth width (meeting the 8*t = 12mm requirement) to reduce pressure per unit area, changed the bending speed from 5mm/s to 3mm/s for more uniform material deformation, added a preheating step to heat the material to 120°C before bending to increase material plasticity.

Intensified Inspection: Installed an additional real-time angle measuring instrument on the production line, conducting angle spot checks on every 10th product, enabling timely process parameter adjustment.

Results:

Mass production batch angle tolerances were maintained at ±0.5°, meeting all design specifications. Edge micro-cracking was effectively eliminated by optimizing mold and process parameters, achieving zero micro-crack. Assembly clearances were rigorously controlled at 0.2mm, meeting assembly precision specifications.

The yield of the customer in production increased significantly from 65% in pilot production to 98%, reducing material waste and rework by a great extent, as well as product delivery cycles.

Find a reliable partner after going through this case study? JS possesses extensive sheet metal bending experience, fast quotes, and guaranteed quality. Join us today!

FAQs

Q1: Why aren't the bending angles of the same materials batched?

Three main reasons: Material thickness variations (±5% is the highest), mold wear and lack of timely replacement, and lower equipment backgauge repeatability. Incomings inspection and equipment inspection should be doubled.

Q2: Is the K factor to be 0.33 or 0.4? How is it established?

The K factor isn't constant! It depends on the material, thickness, R-angle, and mold. Recommended values: ≈0.43 for soft aluminum, ≈0.35 for SPCC, and ≈0.38 for stainless steel. Best reliable process: Test bends and measurements → infer the K value → enter it into the CAM system.

Q3: Are special processing steps required for non-90° bends (acute/obtuse angles)?

Yes! Steep angles need to be produced using a special sharp top die and a V-shaped narrow bottom die. For obtuse angles, it is recommended to perform step-by-step pressing and overpressing by 2-5° to prevent springback. For big angles, material thickness tolerance must be ±3%.

Q4: JS treats high-springback materials (e.g., phosphor bronze) in what way?

A stepped compensation method (step-by-step bending) + a hydraulic press with the capability to correct + local annealing (non-contact laser annealing) have been applied successfully in mass production to manufacture elastic contact parts.

Summary

The majority of sheet metal bending defects are not costly to repair, rather, they need improved setup, intelligent design, and prevention. Wrinkles, burrs, poor angles, or cracks are not only production defects, they're preventable expenses.

Knowledge of these typical sheet metal forming defects can actually cut defects in half and enhance the quality of sheet metal bent components, enabling them to achieve production and assembly specifications.

Need precision sheet metal fabrication parts? JS has a wide range of services, providing transparent sheet metal fabrication prices that can meet various needs. Choose us and keep your project moving more smoothly.

Disclaimer

The contents of this page are for informational purposes only.JS servicesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Jusheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com