The prototype manufacturing can be more than just ‘prototype manufacturing’—

In cases when medical equipment makers are stagnating because of microfluidic chip prototype clogging ratios in excess of 30%, in automakers when they are modifying simulation models for new structures to confirm them, and when start-ups are postponing product introductions, high-quality prototype manufacturing services can often be what will carry them through.

This guide will break away from the conventional definition that "prototype is prototype" and move towards "a calibration benchmark of the physical world" and "a preliminary test bed for manufacturability."

It will describe how engineers could take advantage of various prototype manufacturing services available to attack and verify possible points of failure related to structure, temperature, and fluid.

It will also describe an engineering process to guide you to find partners to solve major technical issues. The innovation of rapid prototyping technology also added to this by incorporating efficiency and accuracy.

Core Answer Table

| Core Questions | Core Knowledge Points | Core Actions |

| What is Prototype Manufacturing? | It is the low-cost tool that can determine if the Design FM verification via calibration simulation is correct or not. | You need to introduce prototype manufacturing as the necessary, not optional, step of the R&D process. |

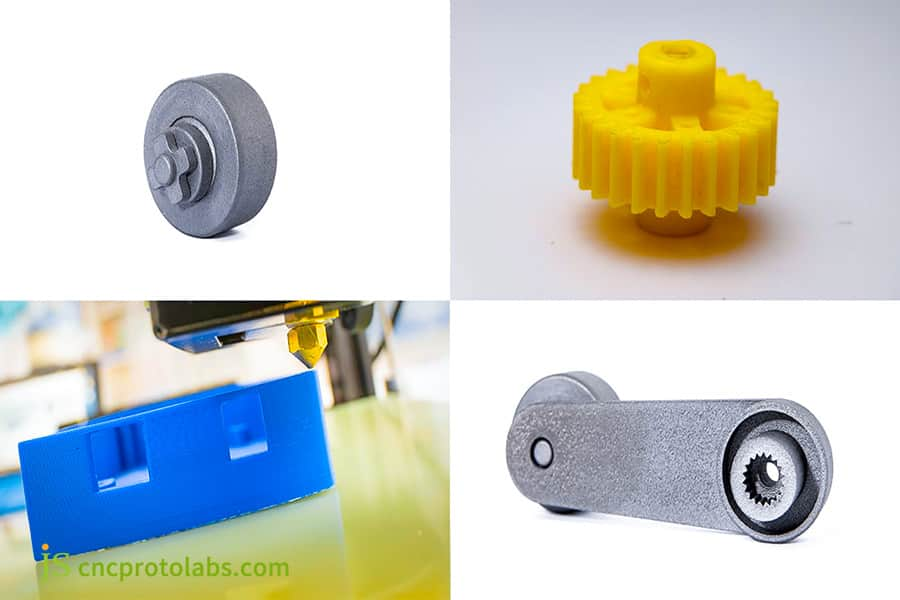

| How to Select the Process? | Based on the physics involved, 3DP is best in build complexity, CNC in strength and accuracy, while RP processes are best in mass production. | Decisions must be made in the "geometry-materials-cost" triangle. |

| How to select materials? | Benchmark on performance, use the principle of good enough, and use specialty materials effectively. | Suppliers must be required to furnish material data sheets, and the priority order for verification must be clearly spelled out. |

| How to evaluate suppliers? | Technical expertise is more valuable than cost, look at the value of engineering services, testing resources, and digital continuity. | A technology check list can be used for due diligence, and suppliers can be "interviewed" with technical questions. |

Key Takeaways:

- Prototyping manufacturing is a form of strategic verification of engineering, its application involves risk reduction rather than sample generation.

- The selection of a process requires an understanding of the principles and limitations of the process, there cannot be a generic process.

- Material data serves as the basis for decisions, while the performance of the prototype must be objectively measured against the verification items.

- Superior manufacturing prototype companies are part of the engineering staff, their strength is their early technical help and data assistance throughout the entire process.

- Achieving success from prototype through mass production requires the continuity of the “digital thread.” This “digital thread” takes the form of design and process data.

Why Believe In This Guide? JS Precision 's Professional Qualifications And Practical Experience

While looking for a partner for prototype manufacturing, professionalism and experience are two prerequisites. JS Precision has been long associated with this industry for 15 years and is certified for medical grade manufacturing under ISO 13485 and aerospace grade quality system certification under AS9100.

We support Fortune 500 firms and above 1000 hard tech startups with more than 3000 prototype orders.Of these, our micro-fluid chip prototype project decreased the rate of failure from 30% to 2%, cut the cycle time of medical device prototyping by 40%, and ensured the accuracy of Automotive Structural Component Prototypes within ±0.015mm.

We have a Class 100 cleanroom facility and digital process management capabilities to support traceability through all phases of manufacturing—from design optimization for prototypes all the way through to quality inspection.

Because of our capabilities within full-chain engineering services, many R&D organizations today consider us an extension of R&D capabilities within their organizations.

Our expert knowledge in rapid prototyping technology allows us to react within 48 hours in case of urgent R&D demands, effectively producing prototypes of high accuracy and reducing the R&D time of our customers by an average of 35%.

Want to ensure your prototype manufacturing project avoids pitfalls? Submit your 3D part drawings and verification requirements now, and JS Precision engineers will provide a free DFM analysis report to help you mitigate design risks, accurately calculate costs and delivery times, and make R&D decisions more informed.

What Is The True Engineering Value Of Prototype Manufacturing?

Aside from "making prototypes," manufacturing prototype is an essential tool for engineering. The real purpose of prototyping manufacturing is to address the most problematic issues in R&D at the most optimal cost.

From Simulation Data to Physical Calibration

The prototypes act as the reference for the correction of simulation models for CAE simulations. Using the simulated results for comparisons with experimental results, model correction helps enhance simulation predictions for design iterations. This is the highest value of the manufacturing prototypes campaign and a key manifestation of rapid prototyping technology empowering research and development.

The Proving Ground for Design for Manufacturability (DFM)

Before investing in expensive mass production molds, prototyping manufacturing can expose and solve manufacturability issues such as injection shrinkage, stress cracking, and assembly interference in advance, which can save tens of times the cost and time in the later stage.

Many firms have thus bypassed any major deviations in product development work on their products and avoided the cost of mold modification to address the design errors during the mass production stage through this step, which has reduced the cost of the trial production stage of their projects on average by 20-40%.

Want to learn more about how prototype parts manufacturing can reduce R&D risks for your product? Contact JS Precision to request the "DFM Validation Checklist," noting your industry and product type, to obtain a targeted prototype validation solution, ensuring every R&D investment yields tangible results.

How Do Core Prototyping Processes Work? A Physics-Level Analysis

Correctly choosing the process is the most critical factor for successful prototype parts manufacturing. The physical principles in different processes decide their applicable scenarios. Let's go into details of the essential logic of the mainstream manufacturing processes to assist you in accurately matching your needs.

Additive Manufacturing (3D Printing)

- SLA/DLP: The curing depth of laser/optical scanning is generally 50-100 micrometers. Post-curing has an impact on the residual stress and tensile strength-changing up to 20%. It is suitable for high-precision appearance prototypes.

- SLS/MJF: Powder is preheated to near its melting point. Controlled cooling of the laser melting zone and heat-affected zone achieves anisotropy of <10%, resulting in nylon parts with performance close to injection-molded parts.

- FDM: The interlayer bonding strength will be the most important. Increasing the temperature in the nozzle by 30-50° C above the melting point and optimizing the layer thickness (0.1-0.3mm) can improve Z-axis strength.

Subtractive Manufacturing (CNC)

Aluminum alloy machining requires high speeds (18000+ RPM) and high feed rates, whereas stainless steel/titanium alloys require low speeds (with large depths of cuts) and specialized tool coatings.

The vacuum fixture suppresses vibration and enables the achievement of an accuracy of ±0.025mm for thin-walled prototype parts. Tool radius compensation directly influences surface roughness (Ra 0.8-Ra 3.2).

Rapid Tooling & Urethane Casting

Silicone mold life is 15-30 cycles. Poor thermal conductivity of silicone can easily cause uneven curing of prototype plastic parts, which requires resin formulation to simulate the properties of the target plastic (Shore hardness A50-D80).

We can add fillers like glass fiber and carbon fiber according to customer requirements to optimize mechanical properties. Meanwhile, through mold zone temperature control technology, we effectively reduce the probability of air bubbles and shrinkage defects, increasing the prototype pass rate to over 98%.

Still unclear about which process to select for your prototype parts? Simply upload your geometry model and performance specifications for the part. JS Precision will give you three free options for comparison in terms of accuracy, price, and lead time for each process.

Why Is Material The Deciding Factor For Prototype Parts?

Material selection directly determines the validity of prototype parts verification. In particular, prototype plastic parts are closely related to material selection in day-to-day prototyping manufacture. The core of material selection is "performance matching" instead of "appearance similarity."

Performance Mapping: Bridging the Prototype-Production Gap

| Material Type | Tensile Strength (MPa) | Elastic Modulus (GPa) | Heat Deflection Temperature (°C) | Impact Toughness (kJ/m²) |

| Photosensitive Resin (SLA) | 50-80 | 2.5-4.0 | 50-80 | 1.5-3.0 |

| CNC POM | ~70 | 2.8-3.2 | 110-120 | 5.0-7.0 |

| 3D Printing Nylon 12 | ~48 | 1.6-1.8 | 120-130 | 3.5-5.0 |

| Mass Production PA66-GF30 | ~160 | 8.0-10.0 | 220-240 | 10.0-15.0 |

The "good enough" principle governs material selection: the verification of appearance concerns dimensional stability, functional testing needs to match key mechanical/thermal properties, while durability testing must consider fatigue and aging characteristics.

Advanced Materials for Demanding Prototypes

- High-Temperature Environments: PEI (ULTEM 1010) for FDM/ CNC, with an HDT of 217°C, is excellent for peripheral engine components.

- Biocompatibility: Medical-grade SLA resin, sterilizable CNC PEEK resistant to 134°C steam sterilization.

- Electromagnetic Performance: The volume resistivity of carbon fiber/carbon nanotube composite material is as low as 1 Ω·cm and EMI shielding effectiveness is higher than 30 dB, meeting the electromagnetic compatibility verification requirements of consumer electronics and military products. Different shielding levels can be precisely matched by adjusting the filler ratio.

Who Is a Capable Prototype Manufacturing Partner? A Technical Evaluation Framework

Price is just a reference when choosing manufacturing prototype companies, technical strength is the core. The high-quality prototype manufacturing services provider you are looking for should be your extended engineering team.

Technical Checklist

- Engineering Dialogue Capability: Can they participate in design reviews, identify DFM issues such as uneven wall thickness and sharp corners, and provide optimization solutions?

- Quality Verification Capability: Do they provide standard 3D scanning reports, industrial CT inspection, and third-party material certification reports?

- Integrated Process Chain: Do they have the capability to provide a one-stop service including 3D printing, CNC machining, surface treatment, and assembly?

Ensuring Continuity: The Digital Thread

The best manufacturing prototype companies are creating a "digital history" for all prototype parts manufactured, including process parameters, heat treatment records, etc. This will be very important when transitioning from prototype to production.

We ensure continuity in the digital thread and integrate prototype data into mass production equipment seamlessly, reducing process transfer risks significantly.

Case Study: From 30% To 2% Failure Rate—A 40-Day Prototype Redemption For a Microfluidic Chip

Background and Challenges:

The microfluidic chip prototype of a certain IVD startup company is facing problems of channel blockage (>30% failure rate) and poor bonding sealing, resulting in significant drift in detection results.

The chip channel is only 150 μ m x 200 μ m, requiring an inner wall Ra<0.4 μ m, the material needs to be biocompatible and transparent, and it also needs to simulate the mass production injection molding bonding process.

JS Precision's Solution:

1.Process Selection:

In the selection of the process, ultra-high precision microSLA was used, with a thickness of 25μm, scanning speed of 8000mm/s, and a wavelength of 405nm using a UV source in controlling the accuracy in the channel dimensions within ±10μm, with a positional error of ≤ ±2μm.

2.Materials and Post-processing:

Medical biocompatible photosensitive resin was chosen, meeting the cytotoxicity standard ISO 10993-5:2009, Class 1. Also, an alternating dual frequency ultrasonic-assisted post-cleaning method was designed (40kHz & 80kHz, alternating mode, time 120s).

There was segmented photothermal processing at 60℃ for 2 hours and additional 80℃ for 1 hour, in order to have the residua <5μm inside the flow channel and the stress ≤ 2.8MPa.

3.Bonding Verification:

- The acrylic cover plate was machined through CNC high-speed milling at 24000RPM and a feed rate of 0.15mm/r. Ensure that the flatness of the cover plate is ≤0.005mm.

- Based on the actual hot-press bonding parameters for mass production, simulate a customized pneumatic fixture with a pressure accuracy of ±0.01MPa (temperature 85 ℃, pressure 0.3MPa, holding pressure for 30s). No leakage occurred under 0.5 MPa pressure after 100 cycles of testing, and the bonding strength reached 1.2 MPa.

- Simultaneous online visual inspection: an average roughness Ra of 0.32μm was measured inside the flow channel wall, and the results met the project's requirement.

Results:

We were able to deliver, in the end, five functional engineering prototypes inside 40 days and reduced the flow channel blockage rate to less than 2%. With the prototype data, we optimized mass production mold design also. We have accelerated the product launch by at least four months.

Is your manufacturing prototypes project facing similar technical challenges? Call the JS Precision technical hotline, explain your product pain points and verification requirements in detail, and we will develop a customized solution for you, using our practical experience to help you overcome R&D difficulties and accelerate product launch.

What Are The Frontier Challenges In Prototyping Today?

With perpetual improvements being made by various products developments, challenges for prototype plastic parts and prototyping manufacturing become more cutting-edge and hence promote perpetual advancements.

Multi-Material or Heterogeneous Integration

How can one create a prototype for a fully integrated ‘mechanical, electrical, software’ system that integrates rigid parts, seals, and sensors? Solutions lie with PolyJet multi-material printing or with the hybrid process that combines 3D printing with precision tiling.

Micro-Scale & Ultra-High Precision

A feature size of below 10µm and a surface roughness of Ra below 0.1µm are needed for prototypes of medical microfluidic devices and micro-optical components. Micro-nano-level CNC machining and two-photon polymerization are overcoming this barrier.

Prototypes for Real-World Environmental Durability Testing

Prototypes for auto exterior parts and outdoor electronics must simulate UV exposure for 1000 hours and undergo 1000 thermal cycles from -40°C to 85°C. These prototypes must have reliable data for material degradation or undergo modifications for such testing.

By using weather-resistant materials and weather-resistant coating processes, we can keep the error between prototype aging tests and mass production pieces to within 10% to guarantee the effectiveness of verification.

The following is a comparison of the core performance data of mainstream weather-resistant materials:

| Material Type | UV Aging 1000h Color Difference ΔE | Tensile Strength Retention Rate after 1000 Thermal Cycles (%) | Low Temperature Impact Strength (-40°C, kJ/m²) | Damp Heat Resistance (95%RH/85°C, 500h) Appearance Grade | Applicable Prototype Scenarios |

| Weather-resistant ABS | 1.8-2.5 | 88-92 | 12-15 | Grade 1 (No bulging, cracking) | Automotive interiors, outdoor small appliances |

| PC/ABS Alloy | 1.5-2.2 | 90-94 | 18-22 | Grade 1 (No discoloration, chalking) | Automotive exteriors, electronic device housings |

| Glass Fiber Reinforced PP | 2.0-2.8 | 85-90 | 8-11 | Grade 2 (Slight discoloration) | Automotive bumpers, outdoor structural components |

| Weather-resistant PC | 1.2-1.8 | 92-96 | 25-30 | Grade 1 (No performance degradation) | Optical components, high-end outdoor equipment |

| Modified PA66 | 1.6-2.4 | 86-91 | 14-17 | Grade 2 (No cracking, slight water absorption) | Outdoor connectors, mechanical structural components |

Would you like to face these cutting-edge challenges and improve the competitiveness of your prototype parts manufacturing projects? Then get in contact with JS Precision to arrange a technical seminar. We will share the latest application examples of the process, allowing you to create more opportunities in the field of prototype manufacturing.

FAQs

Q1: What is the average cost and lead time for prototype manufacturing?

The price could go from hundreds to tens of thousands of US dollars, depending solely upon how complex the process is, the material being used, and the parts involved. Small orders of precision CNC aluminum parts will take approximately 3 to 5 days, while complex assembly parts involving multiple materials may take anything between 2 to 3 weeks.

Q2: How do I choose the most suitable prototyping process for my project?

On the basis of three variables, such as geometry complexity, material behavior, and costs and time, the most important factors of choice would be as follows: 3D printing for high geometry complexity and low-batch production, CNC machining for high-performance and high-precision metal parts, and vacuum casting for low-batches that imitate a plastic part only.

Q3: Can 3D printed prototypes be used for final functional testing?

Yes, but the conditions of the test must be equalized based on material knowledge. For many structural tests, the material used in the SLS nylon and the material used in the SLA high-temp resin can be used, but for dynamic fatigue and the weather resistance, the material must be checked.

Q4: How much difference is there in the performance between prototype materials and mass-production materials?

The difference may be very large. For instance, in the process of casting PU to imitate ABS, the strength may be similar, but for different categories in the impact toughness and resistance to longtime aging, the aim is to determine and seek the most important index of the current verification stage.

Q5: How to ensure the accuracy and quality of prototype parts?

You can request a first-article inspection report, such as a 3D scan comparison color difference image, Critical Dimensions CMM report, and Material certification document(s), from the supplier. The information can prove directly the quality level of the prototype parts.

Q6: Can surface treatments (painting, electroplating) be performed on prototype parts?

Yes, often required. However, different substrates need different levels of adhesion with different types of pretreatment processes, like photo-sensitive resin, nylon, etc. This needs to be confirmed with the suppliers as part of the deal.

Q7: What is the most crucial factor for a smooth transition from prototype to mass production?

The most important thing is the continuity of design data and the accumulation of manufacturing data. It is necessary to ensure that design changes during the prototype stage are fully recorded and to obtain key process parameters as a benchmark for mass production, forming a complete digital thread.

Q8: What are the main advantages of prototype manufacturing in China?

The basic benefits lie in the full integration of supply chain management, tremendous cost-effectiveness, and the velocity of response and iterations. The top manufacturers such as JS Precision have also developed the process technologies and competencies parallel to the world.

Summary

What defines the heart of high-quality prototype manufacturing services is how well it combines engineering and the science of materials and precision manufacturing. They transform abstract ideas into testable, iterated, and trustworthy physical entities, providing the earliest and most important guarantee for the ultimate success of the product.

The finest Chinese manufacturing service organizations, such as JS Precision, find themselves ever more crucial in serving as the necessary extended research and development arm of global hard tech groups with their tightly integrated process chains and in-depth understanding of the fundamentals of engineering.

Get in touch with JS Precision today and begin the world of technical discussion. Let JS Precision help you in accomplishing the rapid realization of innovation ideas using precision prototyping manufacturing.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com