Micro CNC machining is the core of precision manufacturing. In aerospace microsensors, a deviation of even 0.02mm in the 1.8mm countersink hole can cause signal failure, in medical implants, dimensional instability in the tiny countersink holes directly affects human biocompatibility.

The above scenarios denote how important precision small part manufacturing is, and how central CNC machining can be to accuracy. This calls for a careful choice of a CNC machining parts supplier who is proficient in micro CNC machining.

This article breaks down the core of perfect countersink hole machining, detailing how JS Precision provides reliable custom CNC machining parts with cutting-edge small CNC machining technology to solve micron-level machining challenges.

Core Answer Summary

| Core Challenges | Common Misconceptions | JS Precision's Solutions |

| Micro-scale Precision Control | Using conventional machining parameters and cutting tools leads to burrs and unstable dimensions. | By using micro diameter cutting tools and optimizing cutting dynamics, a stable tolerance of ± 0.01mm can be achieved. |

| Perfect Countersink Hole Forming | Ignoring influence of tool wear and spindle coaxiality on taper hole quality. | CNC countersinking techniques along with online monitoring techniques provides uniform chamfering at the hole opening with precision in depth. |

| Processing of Complex and Small Parts | Most people believe that complex geometries necessarily imply either a loss in precision or extremely high costs. | Multipurpose five-axis micro-milling and innovative clamping will allow finding an appropriate balance between complexity and precision in the manufacture of customized CNC machining parts. |

| Small-Batch Cost-Effectiveness | It is believed that the cost of CNC machining for small batches is inevitably high. | We provide transparent, modular pricing and unit cost reduction through process optimization, making small-batch productions equally economical. |

Key Takeaways

- Perfect countersunk holes are a systemic engineering problem in that they represent the optimal possible synergy between the geometry accuracy of the cutting tool, the spindle dynamics, material properties, and cooling systems.

- The core of microfabrication is stability: more important than pursuing extreme parameters is controlling vibration, thermal deformation, and tool wear to ensure consistency in every piece.

- Collaborating on designs early on could cut costs by over 30%: this is because including manufacturability recommendations within the design process can mitigate machining difficulty and challenges associated with custom CNC machined parts.

- Vendor selection means selection of engineering partners: it means that good CNC machining parts suppliers should be capable of supplying not only quotations but also overall technical support such as DFM analysis.

Why Trust JS Precision Machining For Your Customized Parts

JS Precision has 15 years of involvement in the CNC machining industry, particularly focusing on micro CNC machining and precision small part manufacturing. We have served over 5000 clients for our custom solutions that range from aerospace to healthcare equipment to high-quality electronics.

We have over 120 high precision machining machines that include 30 ultra-high speed five axis micro CNC machining centers which possess a Repeatability error of no more than ±0.002mm at a speed of 30,000-60,000 RPM.

As for the quality control criteria, we strictly follow the guidelines of ISO 6789, which is Assembly tools for screws and nuts - Manual torque tools.We also have developed a full-fledged testing process with modern testing devices such as laser confocal microscopes and coordinate measuring machines with microprobes, with an accuracy of measurement of ±0.001mm.

Thus, all custom CNC machining parts made by us are made with precision as per the design parameters. The product qualification ratio over the last three years has been consistently over 99.8%, and the customer repurchase ratio is over 75%.

In addition to this, we also have a technology team of over 50 senior engineers ready to offer customers comprehensive technical services from DFM analysis to production optimization.

We also once helped a medical customer's titanium alloy micro connectors increase the customer's production yield from 65% to 99.8% and decrease overall costs by 25% due to our solution for machining countersunk holes.

Want to confirm our technical advantage as well as the benefit of services? Please get in touch with JS Precision’s technical consultants to share with them your requirements for custom CNC machining parts. In return, we shall offer you a free DFM analysis and price quote. In addition, we can also send you machining case studies that comply with the ISO 6789 standard.

How Does Micro CNC Machining Achieve Precision Manufacturing Of Small Parts?

The micro CNC machining process is the basis for precision production of small parts and usually requires high-end machinery, professional cutting, and scientifically designed processes.

1.Machine Tool and Spindle: The Key to Millimeter Differences:

Micro CNC machining machine tools need rigidity, 0.1μm linear encoders, and 30,000 to 60,000 RPM spindles. The equipment owned by JS Precision can reduce cutting vibration, accurately control trajectory, reduce cutting force of micro diameter tools, and ensure accuracy.

2.The Art and Science of Micro-Diameter Cutting Tools:

<1mm carbide and/or diamond cutting tools are the basics. Runout of precision cutting tools is under <0.003mm. Parameters of material compatibility are given in the table below:

| Machining Material | Tool Material | Recommended Coating | Tool Diameter Range (mm) | Maximum Runout Requirement (mm) | Applicable Cutting Speed (m/min) |

| 6061 Aluminum | Carbide | DLC | 0.2-1.0 | ≤0.003 | 150-250 |

| 304 Stainless Steel | Carbide | TiAlN | 0.3-1.0 | ≤0.0025 | 80-120 |

| Ti-6Al-4V Titanium Alloy | Diamond-Coated Carbide | AlCrN | 0.5-1.0 | ≤0.002 | 50-80 |

| POM Plastic | Carbide | Uncoated | 0.2-1.0 | ≤0.003 | 200-300 |

Precise matching of tool parameters can improve machining accuracy and tool life.

3.Strategic Cutting and Cooling:

With the use of a 'small depth of cut, high feed rate' method and the application of atomised cooling or low-temperature cold air technologies, chip removal and temperature have been appropriately managed, thereby assuring dimensional stability.

What CNC Countersinking Techniques Can Achieve Impeccable Assembly?

Accurate countersinking holes determine the reliability of whole assembly. The core of CNC countersinking techniques includes tool selection, parameter setting, and path optimization.

1.Selection of Tool: 90° or 120°? Not Only an Angle Issue

90° countersinking drills suitable for general assembly, while 120° for high-strength connection in aerospace applications. Diamond-coated tools are chosen to machine aluminum alloy to enhance surface finish while TiAlN coatings are chosen to machine stainless steel to extend the tool life.

2.Golden Rule of Parameters: Spindle Speed, Feed Rate, and Pecking Drill Cycle

Different materials and tools require specific machining parameters, as shown below:

| Material | Tool Specification | Spindle Speed (RPM) | Feed Rate (mm/rev) | Applicable Scenarios |

| 6061 Aluminum | 3mm diameter, 90° countersunk drill | 8000-12000 | 0.03-0.05 | General electronic components |

| 304 Stainless Steel | 2mm diameter, 90° countersunk drill | 4000-6000 | 0.01-0.02 | Mechanical structural parts |

| Ti-6Al-4V Titanium Alloy | 1.5mm diameter, 120° countersunk drill | 3000-5000 | 0.008-0.015 | Medical devices |

Countersunk holes with large depth-to-diameter ratios require a pecking drill cycle to avoid chip clogging and affecting machining quality.

3.Program Path Optimization

JS Precision adopts helical interpolation for the infeeding process and a rational return motion to prevent burrs and chatter marks when the hole is opened.

Interested in learning more about the exact CNC countersinking techniques? JS Precision can be contacted to ask for the downloading of the “Countersinking Technology White Paper.

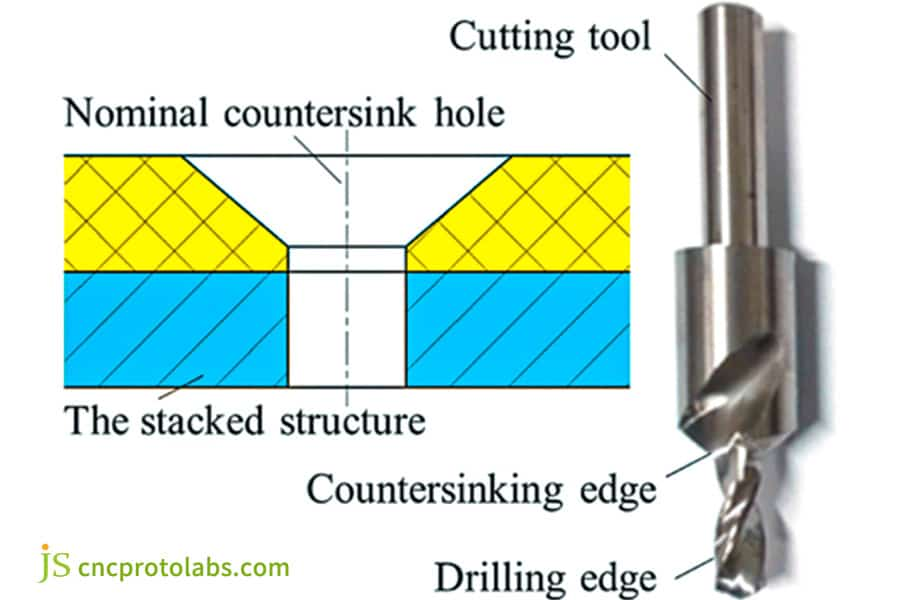

Figure 1 Engineering schematic diagram analysis of countersunk hole structure, stacking hierarchy, and tool drilling and chamfering functions.

Traps And Countermeasures: What Factors Can Ruin a Countersunk Hole In Small CNC Machining?

countersinking hole problems in small CNC machining include burrs around the hole opening, vibrations or marks on the taper surfaces, and dimensional accuracy issues. JS Precision's workarounds for these problems are as follows:

Problem 1: Burrs and Tearing at the Hole Opening

Burs on the hole opening: Contributing factors may include dull cutting tools, improper cutting parameters, or work material toughness. Remedial measures for this problem would involve frequent replacement of cutting tools, optimization of cutting parameters, or secondary finishing operations on precision components.

Problem 2: Poor Taper Surface Roughness or Vibration Marks

Marks on taper surfaces: Caused by overhang, lack of clamping rigidity, or resonance based on parameters. Correct by reducing tool holder length, improving clamping stiffness, and avoiding resonance parameters.

Problem 3: Inconsistent Depth and Diameter

Inconsistent dimensions: Due to tool wear, spindle motion, or inconsistent workpiece datum. Solution: Improving tool life through regular tool changes, inspecting the spindle to establish correct workpiece datum.

Figure 2 CNC machine tool drill bit facing metal workpiece for machining countersunk hole.

How To Control The Absolute Depth Of Countersunk Holes In Precision Small Part Manufacturing?

The absolute depth of the countersunk hole affects the flatness of the screw and is a key indicator for precision small part manufacturing, requiring adherence to standards ISO 8015. JS Precision control depth using three techniques.

- Tool Presetting and Online Compensation: The tool presetting length of ±0.001mm was complemented by wear-contingent online programming correction as well as real-time online correction by means of a contact probe to an accuracy of ±0.005mm.

- Depth Control Strategy in Programming: The CAM function "Machining Bottom Surface" is used for depth control, and "normal feed" is adopted for ramp and curved surface machining to ensure equal depth.

- Material Springback and Verification: Springback is accounted for on the first production of tough material, along with the verification process done through an optical profilometer and a coordinate measuring machine to satisfy the tolerance.

How To Achieve Fast And Economical Production By Optimizing The Small CNC Machining Process?

The company, while retaining the accuracy provided by precision small part manufacturing, has optimized the small CNC machining process through three dimensions to ensure fast and economical production at JS Precision.

- Intelligent Nesting: CAM software helps in optimizing blanket layout, thus improving material usage efficiency from 40% to 65%, idle time of machine tools, and overall efficiency.

- Automation and Rapid Changeovers: The use of zero-point quick-change fixtures and robots for loading and unloading helps to reduce the time for changeovers to a matter of minutes. Equipment effectiveness rises to over 85%.

- Intelligent tool magazine management: Tool magazines that offer 120 or more tool positions, coupled with management software, are capable of automatically retrieving the tools, tracking the life span of the tools, and minimizing downtime due to waiting for tool change.

Want to decrease costs and boost efficiency for your small CNC machining business? Get in touch with the process engineers at JS Precision and share your needs for custom CNC machining parts with them. We at JS Precision can optimize machining for you and offer you solutions that can decrease machining cost.

What Should You Do When Your Custom CNC Machining Parts Break Through Conventional Design?

Deep holes, thin-walled components, and other complex custom CNC machining parts are even more difficult to work on. JS Precision overcomes all these difficulties with ease using our state-of-the-art technology and customized solutions.

- Five-axis micro cnc milling: Finishes five surfaces in a single setup, overcoming positioning error problems in repetitive operations for curved surfaces.

- Customized fixtures: These fixtures help in uniform force application, preventing metal deformation. Examples: The vacuum expansion fixtures, etc.

- Micro-EDM complement: Used for micro-holes with high aspect ratios ≥0.1mm or for processing hard materials, Micro-EDM can also be considered as a complement of CNC milling machining.

How Much Does CNC Machining Cost Calculate For Small Batch Orders?

The cost of small-batch custom CNC machining parts can be optimized. JS Precision breaks down the "How Much Does CNC Machining Cost" breakdown and provides cost reduction solutions.

1.Cost Composition Formula Analysis:

The cost composition and optimization potential for different batch sizes are shown in the table below, clearly presenting the core impact logic of costs:

| Order Batch (pieces) | Material Cost Percentage (%) | Machine Tool Labor Cost Percentage (%) | Engineering Preparation Cost Allocation Percentage (%) | Fixture Cost Allocation Percentage (%) | JS Precision Optimization Potential (%) | Core Optimization Measures |

| 1-10 | 15-20 | 25-30 | 35-40 | 10-15 | 20-25 | Modular engineering preparation, shared fixtures |

| 11-50 | 20-25 | 30-35 | 20-25 | 5-10 | 15-20 | Intelligent nesting, optimized processing parameters |

| 51-100 | 25-30 | 35-40 | 10-15 | 3-5 | 10-15 | Automated loading and unloading, batch material procurement |

Costs include materials, machine tool labor, engineering preparation, and fixture costs, all of which are directly related to materials, equipment, and processes.

2.The Cost-Saving Advantage of JS Precision’s Optimization Solution: JS Precision indirectly minimizes various other expenditures by optimizing DFM, for instance, by saving 30% of man-hours by changing over a 4-axis machine to a 3-axis machine.

3.Pricing Advantages for Small Batch Orders: Standardized processes + modular preparation, Suitable for quantities of 1 to 100 units, Reasonable pricing without high minimum price point.

Do you want to know how much does CNC machining cost your small batch order? Simply provide JS Precision with your requirements for custom CNC machining parts, including your quantities, and JS Precision will provide a clear and detailed breakdown of the cost for your small-batch processing needs.

Figure 3 Batch processed metal parts with countersunk holes arranged neatly.

How To Get An Instant Estimate Of Your Custom CNC Machining Parts With Just One Click?

JS Precision has established an effective online quotation system to engage in convenient and transparent online quotations for custom CNC machining parts.

- Preparing Your “Perfect Request for Quotation Package”: A complete request for quotation package should contain 2D drawings with tolerance, STEP format 3D drawing, material/treatment of surfaces requirements, and quantity requirements.

- Online Portal Upload and AI Intelligent Analysis: Once the images are uploaded online, the AI system is capable of automatically analyzing the part features and generating an initial quote with suggestions regarding DFM within minutes.

- Smooth Transition from Estimate to Formal Order: After the initial quotation, an assigned account manager is in contact with you to answer any questions and facilitate a smooth transition from quotation to order.

Case Study: JS Precision Achieves 0.05mm Countersunk Hole Depth Tolerance For Titanium Alloy Connectors

Customer Challenge

A medical equipment client requires machining a miniature connector made from a titanium alloy (Ti6Al4V). The connector contains four holes with a diameter of φ1.5mm, of 90° countersink type, with a depth tolerance of ±0.05mm.

The client was working with the CNC machining parts supplier. The original suppliers’ products were having a mere 65% yield due to the complexity of machining the titanium alloys, which was leading to leakage in the assembly due to the depth of the micrometer tolerances on the hole openings.

JS Precision Solution

To meet this requirement, JS Precision formed a team of technical experts and designed a tailored solution.

- Equipment: Rather than using conventional drilling and tapping centers, we opted for a highly rigid five-axis micro CNC machining center to boast spindle axials.

- Tools:Ultra-sharp titanium alloy countersinking drills with internal cooling holes were used. The runout of tools was kept to below 0.002mm.

- Process: Professional CNC countersinking techniques were carried out by low-speed cutting, medium feed rate, peck drilling, and programming the cutting path to be helical entry to minimize burrs on the hole openings due to conventional drilling.

- Simultaneously, we established an online compensation mechanism that automatically calls a probe to check the depth of a countersinking hole every 50 parts machined and performs tool wear compensation.

Results

With this solution, the first set of samples, comprising 500 pieces, fully satisfied depth tolerance requirements at 100% burr-free hole openings. Additionally, after large-scale production of 10,000 pieces, yield rates exceeded 99.8%, assembly efficiency for customers enhanced by 40%, and costs dropped by 25%.

If you are also dealing with some issues in precision machining, you may also email us for some custom CNC machining parts needs. Our team will present a solution for you to overcome any technology-related issues.

Figure 4 Titanium alloy (Ti-6Al-4V) miniature connector with 90 ° countersunk hole

FAQs

Q1: What is the minimum size that you can process stably?

JS Precision is equipped with micro CNC machining, allowing for the precise machining of details down to 0.1mm features, with a finished piece size of 1mm, possessing tolerance control accuracy of ±0.005mm, which is sufficient for machining requirements for precision small-sized components.

Q2: How to ensure that small parts are not blown away or deformed during processing?

In the machining of small components, we adopt micro-vacuum fixtures, low-melting-point alloy fillers, or soft jaws. Additionally, we strive to optimize the machining parameters so as to alleviate machining stresses as well as prevent components from being blown away or warped.

Q3: What surface treatments can be applied to small components?

The surface treatment solutions that we provide for micro-parts include micro-arc oxidation, electroless nickel plating, PVD coating, passivation, and precision sandblasting, among others, based on the size, type, and use.

Q4: What exactly does the "engineering preparation fee" in the quotation include?

The "Engineering Preparation Fee" that has to be paid as per the offer includes the engineering time consumed for the CAD/CAM programming, process planning, generation of special tools and fixtures, first piece machining, and full size inspection/verification.

Q5: What is the typical delivery time for small batch orders?

Small order quantity is 5-50 pieces with standard material and process. It usually takes 7-15 working days, including surface treatment time. And for urgent needs of customers, we can provide expedited service, which could shorten the delivery time to 3-7 days.

Q6: How do you detect such tiny features and tolerances?

We have ultra-high magnification optical measuring instrument, laser confocal microscope, and coordinate measuring machine with micro-probe (0.3mm diameter). Our inspection accuracy is one order higher than machining accuracy, which guarantees the precise inspection of minute features and tolerances.

Q7: If my design needs to be modified, how much will it affect delivery time and cost?

You can send all of your design change requests via a specific channel. We will review the effect of the changes in 4 hours. Minor changes, such as the dimensions of corner radius, are usually free of charge, if there is any structural change, a new quotation and delivery time will be offered. All the process is transparent and open.

Q8: Do you support combination orders of mixed materials or multiple parts?

JS Precision fully supports orders combining mixed materials or multiple parts. We can efficiently deal with the machining of small parts in different materials and designs, sharing the engineering preparation resources to offer convenience and optimize overall costs for our clients.

Summary

Success or failure depends on a few micrometers, precision is everything. Perfect countersunk hole machining can never be the pinnacle of a single technology but rather an assemblage of equipment, tools, processes, and experience.

Equipped with micro CNC machining, JS Precision develops professional techniques, an attitude of rigor, and efficient service to achieve ultimate precision on each small part.

No matter whether you have some difficulties with machining countersunk holes or seeking cost-effective solutions regarding custom CNC machined parts, pay attention to JS Precision being one of the trustworthy CNC machining parts supplier.

Experience precise, transparent, and efficient manufacturing services now. Please visit the JS Precision website and upload your part design files. You will get a detailed quotation in hours, including manufacturability analysis and optimization suggestions. Take the first step in turning your precision design into a perfect reality.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com