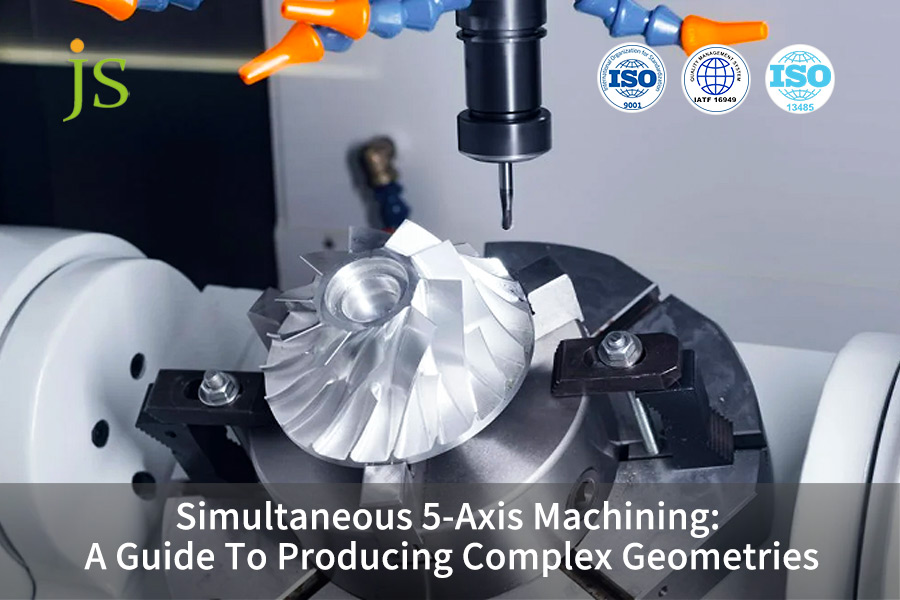

Simultaneous 5-axis machining has become the core technology of manufacturing complex geometric parts in industries such as aerospace, medical devices, and high-end automobiles.For example, imagine the need to machine an aero-engine impeller with complicated curved surfaces or an orthopedic implant requiring very high precision.

Conventional machining methods would require several clamping operations and the coordination of multiple machines, which is not only inefficient but also prone to cumulative errors.However, the 5-axis CNC machining technology can finish a complex workpiece through flexible movement along five axes in one operation, which not only ensures precision but also shortens the cycle time.

The proper selection of a 5-axis machining strategy is not only critical to part accuracy but also has a direct bearing on product performance and development costs. This article will take you deep into an exploration of the technological boundaries of complex contour 5-axis machining and reveal how professional 5-axis CNC machining services can create core value for your projects.

Core Answer Summary

| Technical Dimensions | Key Considerations | JS Precision Professional Solutions |

| Equipment Selection | Machine tool precision, dynamic performance, advanced control system. | Using a high-precision simultaneous 5-axis machining center to ensure stability in machining. |

| Process Strategy | Economic balance between continuous and stationary 5-axis machining. | Optimizing the combination of 3+2 axis machining and continuous 5-axis processes based on part features. |

| Special Materials | Process adaptability for difficult-to-machine materials such as titanium alloys. | Proprietary 5-axis machining titanium alloy process database and tooling solutions. |

| Precision Control | Ensuring micron-level precision, with integrity to surface. | High-precision 5-axis CNC full-process precision control system. |

How To Improve Precision And Reduce Costs With Simultaneous 5-Axis Machining? JS Precision Experience Sharing

As a manufacturer focused on 5-axis CNC machining services,JS Precision's quality management system strictly adheres to the requirements of the International Organization for Standardization (ISO) ISO 9001:2015, which lays the foundation for us to continuously provide high-quality services.

We have more than 15 years of experience in the field, providing services for over 500 customers worldwide from many industries such as aerospace, medical, automotive, and precision instruments.

Precision Machining Projects Over 1200 projects of complex parts machining have been completed, including high-precision products such as titanium alloy aerospace impellers, carbon fiber composite medical stents, and aluminum alloy precision molds.

In these projects, we've used Simultaneous 5-Axis Machining technology to help customers improve part accuracy from ±0.01mm to ±0.002mm, while simultaneously reducing production costs an average of 35% in the process.

For instance, while machining blades with titanium alloy for the aerospace industry traditionally required 280 hours, our optimized Simultaneous 5-Axis Machining solution reduced the machining time to 90 hours while decreasing unit cost by 45%.

This manual is a summary of our years of practical experience. Each point can be found in real project cases with data support, so its professionalism and practicality can be fully trusted.

Want to master the cost reduction and efficiency improvement techniques of simultaneous 5-axis machining in a very short time? Contact JS Precision immediately and submit your part's 3D model. Our senior engineers will provide you with a free customized process solution to help mitigate machining risks and improve production efficiency.

What Are The Critical Factors In The Choice Of Simultaneous 5-Axis Machining Service?

Choosing a reliable Simultaneous 5-Axis Machining service is critical to guarantee product quality and project schedule. The professionalism of 5-axis CNC machining technology requires service providers to possess comprehensive technical capability with a robust quality assurance system.

The following are the core evaluation dimensions summarized by JS Precision:

Technical Capability Evaluation System

- Machine Tool Performance Indicators: Positioning accuracy, repeatability, and dynamic response characteristics are core parameters. The precision equipment manufactured by JS Precision achieves a positioning accuracy of ±0.002mm and repeatability of ±0.001mm.

- Advanced Control System: The device has high-speed and high-precision algorithms, forward-looking control, and collision protection functions through Siemens and FANUC systems, providing comprehensive protection.

- Cumulative Process Experience: A strategy library has been established for complex curved surfaces, deformation prevention of thin-walled parts, and efficient rough machining, which enables rapid solution development.

Quality Assurance Capability

- Online Measurement Technology: Each machine is integrated with an on-machine high-precision measuring system that can track and make real-time compensations for deviations.

- Thermal Error Compensation: Various thermal compensation technologies are used to offset the influence of both spindle thermal expansion and changes in ambient temperatures.

- Tool Management: Real-time monitoring of the tool status and automatic reminders of tool replacement will avoid machining defects caused by wear.

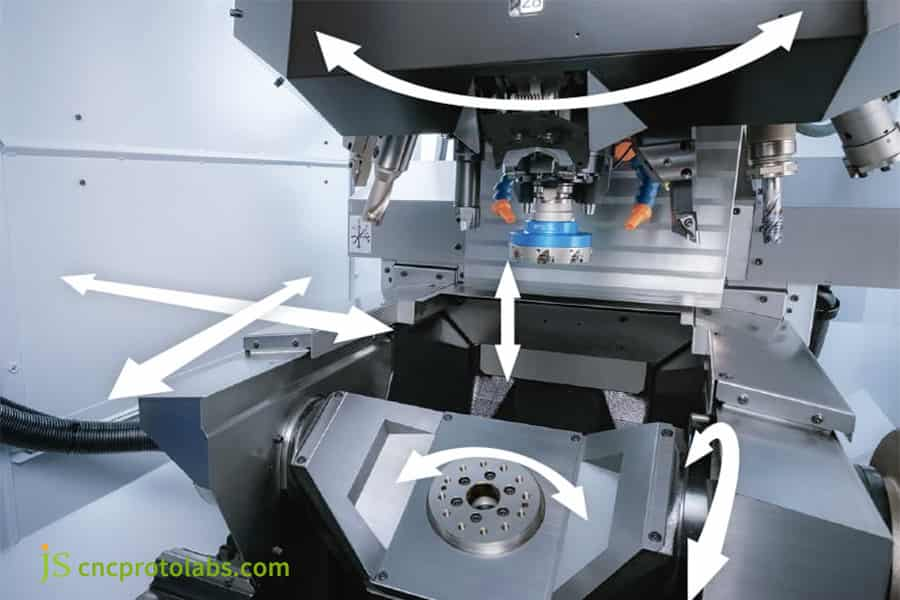

Figure 1:The image shows the operational axes of a 5-axis machining center.

How To Truly Determine The Cost-Effectiveness Of Simultaneous 5-Axis Machining

The cost-effectiveness of Simultaneous 5-Axis Machining needs to be evaluated from a life-cycle point of view. The following are the core dimensions of analysis summarized by JS Precision:

Life-Cycle Cost Analysis

- Enhanced Machining Efficiency: Multifunctional machining within a single clamping saves 30%-60% of the time taken through traditional methods. For instance, complex box-shaped parts, whose machining used to take about 8 hours, are machined in 3 hours.

- Reduced Quality Costs: Reducing the number of clamping operations lowers scrap rates by 25-40%. In batch production of 500 pieces, scrap costs decrease from $2000 to $400.

- Simplified Tooling and Fixtures: The need for special fixtures is reduced by 60-80%. The cost of fixtures for aerospace parts is also reduced from $5000 to $1000.

ROI Assessment Model

| Production Scale | Conventional Machining Cost (USD/piece) | Simultaneous 5-Axis Machining Cost (USD/piece) | Cost Savings Percentage | ROI Cycle |

| Small Batch (< 5 pieces) | 1500 | 1200 | 20% | 1-2 months |

| Medium Batch (50-500 pieces) | 800 | 500 | 37.5% | 3-6 months |

| Large Batch (over 500 pieces) | 500 | 500 | 40% | 6-12 months |

Accuracy Comparison: Which Simultaneous 5-Axis Machining Center Delivers Optimal Performance?

The choice of the right simultaneous 5-axis machining center is critical to accuracy and efficiency. The following is a comparison of mainstream brand technology characteristics:

High-class European brands, such as DMG MORI and GF Machining Solutions

The main advantages are precision stability and long-term reliability. Such features as high-precision linear scales, high-quality cast iron beds, and first-class thermal compensation technology contribute to positioning accuracy, which reaches ±0.002mm.

Applications involve very high-precision industries, such as aerospace and medical, the estimated purchase cost may vary from US$800,000 to 1,500,000.

Japanese precision models (such as Brother and Makino)

Outstanding dynamic performance and surface quality control.With high speed spindles and rapid traverse, the effective cutting allows the achieving of surface roughness below Ra0.2μm. For the automotive parts and electronics industries, the estimated cost is US$500,000-800,000 as a purchase cost.

Domestically made high-end models (for example, Kede CNC, Huazhong CNC)

Their advantages are cost-effective and the service is localized. Precision and stability of their simultaneously 5-axis machining center keeps improving, the positioning precision reaches ±0.005mm, which meets the needs of mid-range precision parts.

Purchase cost: about US$400,000 to 700,000, localized service can make sure the response is fast and the maintenance cost is low.

JS Precision has simultaneous 5-axis machining center from multiple brands, enabling it to fit a project's needs flexibly. If the customer does not know which equipment is suitable, please feel free to contact our technical team directly for a solution that will meet your precision requirements, batch size, and budget.

Figure 2:Full five axis control can finely process difficult to reach features, such as the corners of cavities or protrusions.

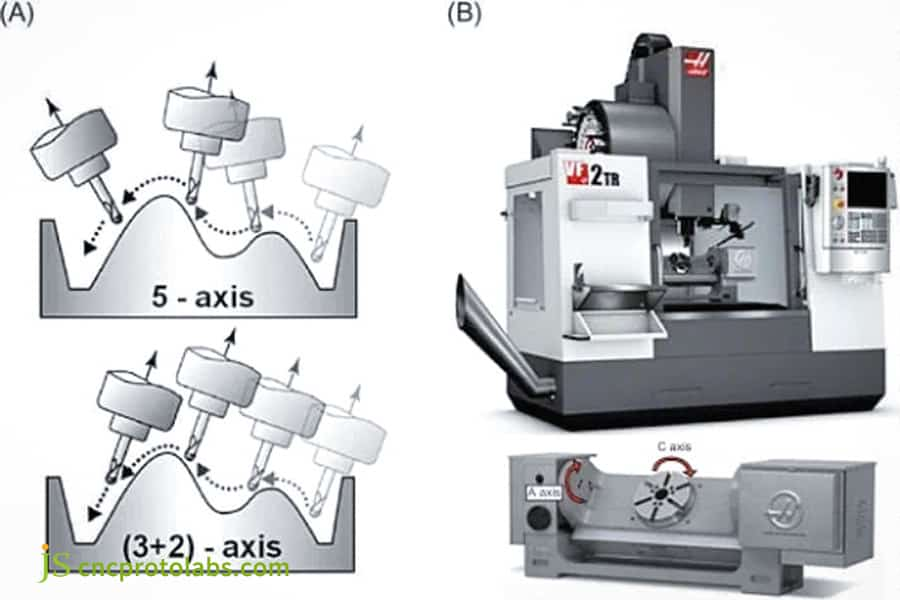

When Is 3+2 Axis Machining More Economical Than Continuous Five-Axis?

3+2 axis machining, and Simultaneous 5-Axis Machining are both kinds of 5-axis CNC machining. The following is a comparison of their process applicability and cost:

Process Applicability Analysis

- Polyhedral parts: Fixed-axis machining is completed quickly and does not require complicated programming, which suits box-type and support-type parts.

- Deep cavity and deep hole parts: High rigidity, convenient chip removal, reduced vibration impact.

- Special angle feature parts: Adjust the posture for one-time processing, with low programming difficulty and low cost.

Cost-Effectiveness Comparison

| Comparison Dimensions | 3+2 Axis Machining | Simultaneous 5-Axis Machining | Difference Ratio |

| Programming Complexity | Low (CAM programming time about 2-4 hours). | High (CAM programming time about 6-10 hours). | Programming time saving: 60%-80%. |

| Machining Cycle | Medium (taking a box-shaped part as an example, machining time approximately 5 hours). | High (machining time for the same part approximately 3 hours). | Machining time increase: 40%. |

| Equipment Occupancy Cost | Low (equipment hourly rate approximately $80/hour). | High (equipment hourly rate approximately $150/hour). | Equipment cost saving 47%. |

If your parts are simple or moderately complex, 3+2 axis machining is more economical. JS Precision offers two machining capabilities, and the solution can be tailored based on part characteristics. For further information, please contact our process engineers.

Figure 3:5-Axis and 3+2 axis machining.The main difference between five axis linkage machining and three-axis+two axis machining lies in the usage of each axis during the machining process.

Understanding Quotation Structure And Lead Times In 5-Axis CNC Machining Services

Quotation and delivery time are the major concerns of customers when it comes to 5-axis CNC machining services. Details are as follows.

Quotation Breakdown

- Machining Time Cost: Calculated based on part size, complexity, and precision. Simple parts: 2 hours / $300, complex parts: 8 hours / $1200.

- Material Cost Optimization: Standard blanks are preferred. For example, using standard blanks for precision shaft parts saves a manufacturing company $50 per piece.

- Auxiliary Process Costs: Greater quantities have lower costs amortized while smaller batches have higher amortized costs. For instance, tooling costs of $1000 are amortized at $100 per piece for 10 pieces and $10 per piece for 100 pieces.

Delivery Cycle and Production Batch Relationship Table

| Production Batch | Part Type | Delivery Cycle (Working Days) | Expedited Delivery Cycle (Working Days) | Expedited Fee (Additional Percentage) |

| Single Piece (Prototype) | Aluminum Alloy Parts | 5-7 | 2-3 | 50% |

| Single Piece (Prototype) | Titanium Alloy Parts | 7-10 | 3-5 | 60% |

| Small Batch (5-50 Pieces) | Aluminum Alloy Parts | 10-15 | 5-7 | 40% |

| Small Batch (5-50 Pieces) | Titanium Alloy Parts | 15-20 | 7-10 | 50% |

| Medium Batch (50-500 Pieces) | Aluminum Alloy Parts | 20-30 | 10-15 | 30% |

| Medium Batch (50-500 Pieces) | Titanium Alloy Parts | 30-40 | 15-20 | 40% |

How Does Complex Contour 5-Axis Machining Excel In Deep Cavity And Steep Profile Workpieces?

Complex contour 5-axis machining represents one of the important applications of Simultaneous 5-Axis Machining, offering significant advantages in machining deep-cavity and steep-walled parts:

Technical Advantages in Depth

- Optimized Tool Posture: Shortened overhang length due to real-time adjustment, and hence reduced vibration assure accuracy.

- Improved Surface Quality: Uniform cutting parameters achieve a surface roughness below Ra0.4μm.

- Breakthrough in Machining Efficiency: Optimized machining parameters include increasing the cutting speed of deep-cavity and steep-walled parts from 100m/min to 150m/min, meaning a 50% increase in efficiency.

Comparison of Cost and Efficiency for Complex Contour Machining

| Part Type | Machining Method | Machining Time (hours) | Unit Cost (USD) | Surface Roughness (Ra) | Accuracy Compliance Rate |

| Deep Cavity Mold | Complex Contour 5-axis Machining | 6-8 | 900-1200 | ≤0.4μm | 99% |

| Deep Cavity Mold | Traditional 3-axis Machining | 12-15 | 1200-1500 | 1.6-3.2μm | 90% |

| Steep Wall Bracket | Complex Contour 5-axis Machining | 4-6 | 600-800 | ≤0.4μm | 99% |

| Steep Wall Bracket | Traditional 3-axis Machining | 8-10 | 800-1000 | 1.6μm | 92% |

Where Does The Premium For High Precision 5-Axis CNC Services Manifest Compared To Conventional Five-Axis?

High precision 5-axis CNC services are more expensive than conventional five-axis services, and the premium is reflected in three aspects:

Value of the Precision Premium

- Equipment Investment Difference: the cost of a high-precision simultaneous 5-axis machining center is $800,000-$1,500,000, while a standard model costs $400,000-$700,000, a difference of 50%-100%.

- Process Control Requirements: Investment in constant temperature and humidity (20±0.5℃), vibration isolation, etc., increases the costs by 15%-25%.

- Technical Team Configuration: Investment in senior engineers increases costs by 30%-40%.

Price Comparison Table for High Precision and Standard 5-Axis Services

| Service Type | Precision Level | Single-Piece Machining Fee (USD) | Equipment Investment (USD Ten Thousand) | Equipment Investment (USD Ten Thousand) | Technical Team Cost (Additional Percentage) |

| Standard 5-Axis Service | ±0.01mm | 400-600 | 40-70 | 5%-10% | 10%-15% |

| High Precision 5-Axis CNC Service | ±0.005mm | 800-1200 | 60-100 | 20%-25% | 30%-35% |

| High Precision 5-Axis CNC Service | ±0.002mm | 1500-2000 | 80-150 | 30%-35% | 40%-45% |

What Special Strategies Are Required For 5-Axis Machining Titanium Alloy?

Machining of titanium alloy is difficult, the 5-axis machining of titanium alloy requires a special process:

Optimization of Cutting Parameters:

Based on a tool-material matching database, JS Precision develops specific parameters for titanium alloys such as Ti-6Al-4V and Ti-5553. For example, the cutting speed is 60-80 m/min, feed rate 0.1-0.15 mm/r, and depth of cut 0.5-1 mm during the machining of Ti-6Al-4V, which reduces work hardening and prolongs tool life.

Tool Technology Selection:

Optimized groove shapes on titanium alloy-specific tools reduce cutting forces, TiAlN/AlCrN coatings improve heat and wear resistance, extending tool life by 3-5 times compared with ordinary tools.

Innovative Cooling Strategies:

By employing different methods, such as high-pressure internal cooling, mist cooling, and low-temperature cooling, selecting the best solution based on the scenario-a leading example being 100bar high-pressure internal cooling for deep-cavity parts-reduces the cutting temperature by 30%-40% and minimizes tool wear and part deformation.

JS Precision has much experience in 5-axis machining titanium alloy for many aerospace companies. We strictly follow the ASTM B265 standard to process titanium alloy parts. If you need it, please contact our technical team immediately for process plans and quotations.

Case Study: 68% Time Saving In Aerospace Impeller Manufacturing Through 5-Axis Strategies

Project Background

An aerospace company needs to machine a batch of titanium alloy aero-engine impellers. These impellers are made of Ti-6Al-4V titanium alloy, with 12 blades, a blade thickness of only 2mm, a surface accuracy requirement of ±0.03mm, and a surface roughness requirement of Ra0.4μm.

Traditional multistep processes involving several machines with reclamping after each operation can take as much as 280 h per processing cycle. The blade deformation caused by the traditional process is high, reaching a scrap rate of up to 8%.

Technical Challenges

- Thin Blade Deformation Control: The thin blades are easily deformed by cutting forces, which impacts the accuracy.

- Assurance of Complex Surface Accuracy: The surface of the impeller blade is complicated and requires accurate simultaneous machining.

- Material Work Hardening Control: Work hardening easily occurs during the machining of titanium alloys. Hence, further machining is rendered increasingly difficult with an already worn tool.

JS Precision Solution

- Optimize toolpaths using a complex contour 5-axis machining strategy: Through five-axis simultaneous motion, the optimum cutting angle between the tool and the blade surface is maintained at all times, minimizing the cutting forces to avoid blade deformation.

- Develop dedicated 5-axis machining titanium alloy cutting parameters. The optimum cutting speed, feed rate, and depth of cut were determined based on characteristics for Ti-6Al-4V titanium alloy, effectively reducing work hardening.

- In-machine measurement and adaptive machining technology implement real-time monitoring of the dimensional accuracy of the blades during machining, according to the monitoring results, automatic adjustments of cutting parameters are made to ensure machining accuracy.

Final Results

- Machining time has been reduced from 280 hours to 90 hours, saving 68% of machining time.

- Blade thickness accuracy was controlled within ±0.03mm, which fully met customer requirements.

- The surface roughness Ra0.4μm achieved a 100% compliance rate, significantly improving part surface quality.

- Reduced scrap rate from 8% to 1%, with the unit cost down by 45%, thus saving the customer millions in production costs.

This case fully illustrates the advantages of simultaneous 5-axis machining in the machining of complex titanium alloy parts. If you also face similar machining challenges, JS Precision can provide you with customized solutions to help you reduce costs and increase efficiency.

Figure 4:Aerospace Impeller

How To Start Your Project With Our Professional 5-Axis Machining Services?

1.Technical Requirements Analysis:

You need to provide a complete 3D model (supporting STEP, IGES, STL, etc.) and technical requirements, including dimensional accuracy, surface roughness, materials, and batch size. JS Precision has standardized the requirements template, filling it out according to the template guarantees completeness of information.

2.Process Solution Review:

Our professional engineering team will carry out the DFM analysis and work out a detailed process solution, including machining flow, tool selection, etc. A review report will be provided within 3 business days, followed by communication and confirmation.

3.Confirmation of Project Plan:

After confirming the process solution, we will create a visual schedule plan, including key milestones, and clearly define the time nodes for each stage. This will enable you to track progress in real time and ensure timely completion of the project.

FAQs

Q1: What is the typical positioning accuracy of your 5-axis centers?

Our simultaneous 5-axis machining center achieves a positioning accuracy of ±0.002mm and a repeatability of ±0.001mm, which can meet the processing requirements for most high-end precision parts in many fields such as aeronautics, medical equipment, and more.

Q2: How do you handle vibration in long tool overhang situations?

We apply a triple approach to ensure machining stability: active vibration damping toolholders, optimized cutting parameters, and adjusted tool posture. Active vibration damping toolholders absorb the vibration of the tool, optimized cutting parameters reduce the cutting forces, while the adjusted tool posture shortens the overhang length.

Q3: What is the cost difference between 3+2 and simultaneous 5-axis machining?

3+2 axis machining is generally more cost-effective than simultaneous 5-axis machining, roughly 20-40 percent lower in cost, depending on part complexity and batch size. This advantage is more visible when simple parts are being worked on rather than those requiring complex curved surfaces.

Q4: Can you machine both prototypes and production quantities?

Yes, we support full-scale 5-axis CNC machining services that range from single-piece prototypes to mass production. Be it small-batch prototypes of less than 5 pieces or large-batch production of over 500 pieces, we are capable of providing efficient and precise machining service.

Q5: How do you regulate thermal deformation throughout prolonged machining processes?

There are several ways to ensure stability in the process: thermal compensation of the machine tool, control over ambient temperature, and cutting fluid temperature control.

Q6: Can you provide complete machining from raw material to finished part?

Yes, we provide end-to-end manufacturing services from raw material procurement to finished product delivery. This includes raw material selection, machining, heat treatment, surface treatment, and inspection. You will not have to contact a number of suppliers and invest precious time in it.

Q7: What experience do you have with aerospace certification requirements?

We are familiar with the AS9100 system and provide numerous aerospace companies with our certified parts manufacturing services. Our production processes are strictly in line with aerospace industry quality standards, meeting customer certification requirements and ensuring the quality of parts.

Q8: Why choose JS Precision over other 5-axis machining suppliers?

Instead of simple contract manufacturing, we offer deeper technical services starting from process development to mass production. We employ a professional technical team, together with advanced equipment and a comprehensive quality assurance system, which altogether allow us to provide customized solutions for our clients.

Summary

Simultaneous 5-axis machining in complex parts manufacturing is more than a choice of technology, it's a strategic decision that can affect product performance and development efficiency.

Equipped with an advanced simultaneous 5-axis machining center, JS Precision has professional complex contour 5-axis machining process experience and strict high-precision 5-axis CNC quality control. It is becoming the preferred partner in the high-end manufacturing field.

Experience professional precision 5-axis machining services now!

→ Upload your complex part's 3D model and get a detailed process plan and quotation within 24 hours.

→ Book a technical exchange and go in-depth on machining strategies with our five-axis experts.

→ Contact a project consultant now to arrange specialist machining options for your line of work.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com