In a competitive market, one single precision-machined part can either make or destroy the success of your product. Choosing a 5-Axis CNC Machining supplier is much more than just comparing prices—it's a quality, efficiency, risk, and total cost of ownership decision.

A misdecision will result in project delays, cost overrun, and potentially catastrophic product quality. The best partner can be an extension of your R&D department, however, and can assist in keeping costs down, becoming more efficient, and grabbing market opportunity.

This article will reveal the deep logic behind evaluating suppliers and why technology partners like JS Precision can provide you with the maximum cost benefits that are not just costs.

Summary of Key Answers

| Evaluation Criteria | Low-Cost Vendor | JS Precision - Value Partner Vendor |

| Quotation Core | Focused its attention entirely on machining time, resulting in a reduced up-front cost. | Includes full-process cost factors (DFM optimization, material usage, and post-processing efficiency) trying to minimize total cost. |

| Technical Capability | Possible confusion between 3+2 and 5-axis linkage, outdated equipment. | Actual 5-axis masters, quality equipment, and proficiency at machining difficult surfaces and long parts. |

| Quality System | Relying on final-stage inspection, with open-and-shut quality control procedures. | End-to-end quality control (IQC, IPQC, FQC), full-dimensional test reports, and efficient traceability. |

| Communication and Cooperation | Late to respond, only after drawings but without making suggestions. | Extensively involved engineering staff, actively providing design for manufacturability suggestions, with efficient clear communication. |

| Reliability of Delivery | Erratic delivery schedules, on-time delivery the exception. | Ship on time, with open production tracking to keep tabs on your progress on our project. |

| Long-Term Value | One-time relationship. | Strategic partner, progressively lowering cost and improving product performance. |

JS Precision Avoidance Guide Of Pitfalls: Key Points To Maximize Value Of 5-Axis Machining

JS Precision takes pride in having over 15 years of practical experience in 5-Axis CNC Machining which has been offered to over 500 clients in high-demand sectors such as aerospace, medical, and automotive. We have over 20 5-axis CNC machines with repetition capability for 5-axis CNC machining parts to a tolerance of ±0.005mm on a daily basis.

For example, we just machined a sophisticated impeller part for an aerospace client. It minimized the 5-axis simultaneous machining path, enhancing the efficiency of the machining process by 25% with scrap rates less than 1%.

We also customized stainless steel casings for surgical equipment for a healthcare client, eradicating the problem of deformation through conventional machining.

This comes from our thousand-project experience and can assist in establishing a service provider's process capability, preventing communication pitfalls, and avoiding pitfalls in 5-axis CNC machining partnerships.

JS Precision's fault guide is based on real-world project experience. If you require 5-axis CNC machining parts, we offer free process consultation to help with risk reduction and maximizing the value of 5-axis CNC machining.

Why Supplier Choice Is Among Your Top Business Decisions?

Choosing a 5-axis CNC machining service provider directly affects your project cost and competitiveness as it involves four essential costs:

- Cost of Quality: Precision is required in 5-axis CNC machining, an error of 0.01mm means that a part will have to be scrapped. One of the customers had $20,000 worth of 5-axis CNC machining parts scrapped because one of his suppliers was not precise enough. That is a hidden cost of over $5,000 compared to the $5,000 saved on the cost of machining.

- Time Cost: A new product that loses a primary trade show or holiday season due to supplier delay will lose millions of dollars in business, an investment far greater than the machining fees.

- Cost of Communication: Communication breakdowns drain energy from the team, clog schedules, and impact engineers' core work.

- Risk Cost: Inexperienced supplier will leak designs or compromise contract terms, leading to lawsuits and project delay.

Key Point: The most cost-effective choice is to minimize your total cost of ownership, not the one with the lowest quote.

To avoid such hidden expenses as quality and time, JS Precision can provide you trustworthy 5-axis CNC machining parts services. Simply email your drawings to us, and we'll perform a Design for Manufacturing (DFM) analysis initially before having a plan to minimize your total cost of ownership.

Six-Dimensional Evaluation Technique: Cope With Marketing Jargon To Identify True Experts

With so many "professional 5-axis CNC machining" service providers, the below six-dimensional evaluation technique can help you identify true experts:

1.Technical Equipment and Process Expertise

Key Questions: What kind of 5 axis CNC machine do you have? Can it produce the required precision? Can you explain how the difference between 3+2 positioning and 5-axis simultaneous machining is made?

For example, for components with deep holes, 3+2 positioning is recommended in order to reduce costs, while for continuous curved surface components, 5-axis simultaneous machining is recommended to maintain precision.

2.Quality Assurance and Certification System

Key Questions: Is the organization ISO 9001/AS9100 certified? How are in-process and first-article inspections handled? Can reports of testing be provided? Dependable service providers conduct full-size inspection of first-article parts before each batch and conduct in-process sampling to check part quality.

3.Engineering Support and Teamwork

Key Questions: Do they actively check drawings and provide DFM comments? Can they diagnose complex process issues? For example, a great service provider can point out an "over-tolerancing" issue, so that you can optimize the process and reduce the 5-axis CNC machining price.

4.Transparency and Communication Efficiency

Key Questions: Is the quote properly outlined? Does a project manager specifically designated to this task exist? Can production progress be tracked? Professional service providers typically provide an online tracking system for the progress of production, so you can track part production status in real-time.

5.Production Capacity and Delivery Reliability

Key Questions: What is the true production capacity? What is the on-time delivery percentage? How do you manage urgent matters? For instance, some service providers have an on-time delivery percentage of more than 98% and provide 72-hour rush service.

6.Intellectual Property Protection Measures

Key Questions: Are there tight NDAs and information security controls in place? Are design files kept encrypted? These measures ensure your 5-axis CNC machining parts designs are not leaked out.

JS Precision is optimal in all six dimensions. We offer online 5-axis CNC machining services, and you can monitor production progress at any time. Our professional team will also provide impromptu feedback on design optimization suggestions for enhancing project efficiency.

Figure 1:Five axis machined turbine blades with smooth and glossy streamlined surfaces.

Comparison Of Top Suppliers: An In-Depth Analysis Of The Cost-Effectiveness Of JS Precision And Xometry

When choosing a 5-axis CNC machining company, the Xometry and JS Precision models vary:

| Comparison Dimensions | Xometry | JS Precision |

| Operating Model | Manufacturing Platform (matchmaking). | Vertical Integrated Manufacturer (in-house manufacturing). |

| Complex Part Quotes | Platform commission of 15%-20%, low cost-performance (e.g., an impeller part quote of $600 with a $90 commission). | No commission, high cost-performance (same impeller part quote of $500 with a $30 DFM optimization fee). |

| Delivery Stability | Based on partner factory production capacity, with an on-time delivery percentage of approximately 85%. | Separately operated production capacity, with an on-time delivery percentage of >98%, with daily compensation of 0.5% of the order value. |

| Minimum Order Quantity | 10 pieces, with an additional 50% small order fee for orders below 10 pieces. | 1 piece, no small order fee, prototype and production prices the same. |

| Payment Terms | 30% Advance payment, balance due prior to shipping. No credit terms. | 50% Advance payment, balance 30 days from date of shipping. Long-term customers can apply for credit terms of 45 days. |

| Urgent Fee Ratio | On the basis of regular delivery time, an additional 50% -80% will be charged, with no fixed standard. | 72-hour expedited service has a 20% surcharge, 48-hour expedited service has a 35% surcharge. Fees are clear. |

Xometry Model Analysis

- Advantages: Platform-based, fast quotes (within 24 hours), able to quote simple parts (e.g., metal brackets).

- Disadvantages: Order distribution to unknown factories, thus unable to have any control over the quality, 15%-20% commissions, and complex parts have exorbitant quotations, no extensive supporting engineering.

JS Precision Model Analysis

- Advantages: Factory production internally with quality control, the engineers tweak and keep the cost low, and overall cost saving and reliability of complex parts considerably better than that of the platform model.

Comparative Conclusion: For high precision, complex components, JS Precision's "expert services" yield greater long-term return on value than Xometry's "matchmaking."

For complex custom 5-axis CNC machining manufacturing requirements, JS Precision is more reliable than platform mode. Contact us to upload an RFQ, and we will answer with a comprehensive quote and Design for Manufacturing (DFM) report within 24 hours or less to help you control cost.

Why The Price Difference: Why Are 3+2-Axis And 5-Axis CNC Machining Differently Priced?

The price difference is broad in 5-axis CNC machining between 3+2 positioning and 5-axis simultaneous due to inherent process, application, and cost differences:

| Comparison Dimensions | Comparison Dimensions | 5-Axis Simultaneous Machining |

| Principle | The workpiece is held by two rotary axes, three-axis machining is effectively "indexed" machining. | Five axes move together to place the tool in the most favorable posture. |

| Programming Difficulty | Low (open to common programmers). | High (require engineers with 5 years or more of experience). |

| 5-axis CNC Machine Price Reference (per-processing fee) | 100-300 | 300-800 |

| Minimum Processing Batch | 5 pieces or more | 3 pieces or more |

| Payment Cycle | 30 day monthly settlement. | 45 day monthly settlement. |

| Surface Treatment Surcharge | $50/piece | $80/piece |

| Rework Charges After Sales | Customer pays 30%. | JS Precision pays 100%. |

JS Precision's wisdom: Recommend best practice based on part nature, e.g., using 3+2 positioning on cavities or 5-axis simultaneous machining on curved surfaces, in a way to reach quality with minimal 5 axis cnc machine price.

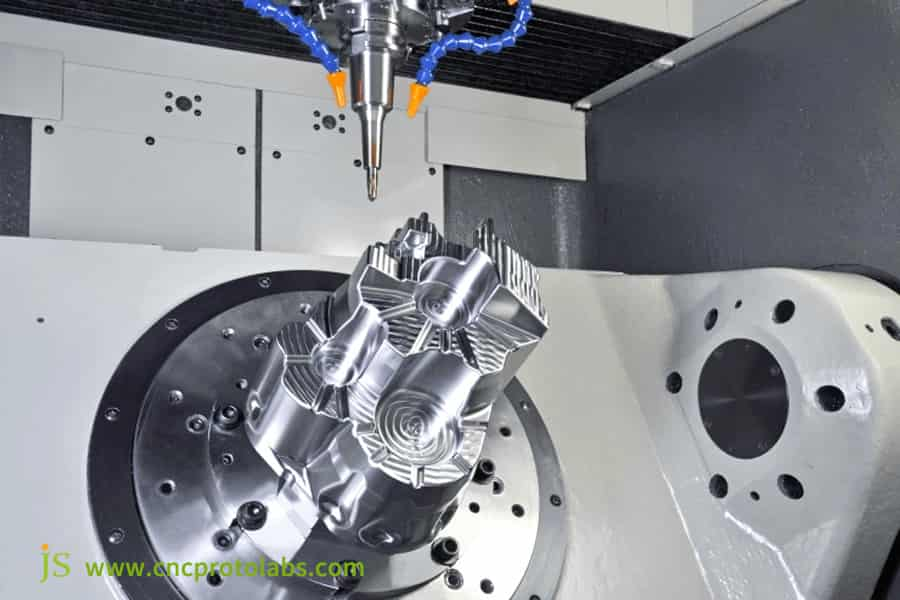

Figure 2:Five axis machine tool for machining aluminum alloy engine cylinder block.

Global Perspective: A Reasonable Trade-Off Between Chinese And American Suppliers

When choosing a supplier of 5-axis CNC machining, there are characteristics of both Chinese and American suppliers:

| Comparison Dimensions | US Suppliers | High-End Chinese Supplier (JS Precision) |

| Cost Advantage | Labor cost 35-50/hour, high part price (stainless steel parts $500, including 15% profit margin). | Labor cost 8-12/hour, good part price (stainless steel parts $350, including 12% profit margin). |

| Communication Efficiency | English-speaking, 1-2 hour response time. | Chinese and English-speaking team, 24-hour response time. |

| Supply Chain Support | Rapid local shipping (3-5 days), costly shipping ($500/shipping, excluding tariffs). | One-stop supply chain: Ocean freight $100/shipping (inclusive of customs clearing, excluding tariffs), air freight $300/shipping (inclusive of customs clearing). |

| Technical Team | Skilled, but communication costs are high (video conferencing adds an additional $100/session). | 10 years experience with background in 5-Axis CNC Machining, free video conferencing, no additional fees. |

| Minimum Order Quantity | $5000, an additional 20% small order fee will be charged for orders below the amount. | $1,000, no small order charge, and trial runs of small lots are allowed. |

| Payment terms | Up to 15 days, approved by credit. | New customers have a 30 day payment term, and customers who have cooperated for 6 months can apply for a 60 day payment term. |

Overcoming Ancient Concerns

- Quality: We are certified as ISO 9001/13485, implement imported test equipment, and implement full-process quality control in achieving Europe-American comparable quality.

- Communication: Project teams of both Chinese and English guarantee 24-hour response time for avoiding miscommunication caused by languages.

- IP Protection: Conduct an international NDA, and design files are encrypted for access by authorized personnel only.

As a leading Chinese supplier of high-end 5-axis CNC machining services, JS Precision's intelligent supply chain model has been featured on TechBullion. Through process digitization, we persist in lowering the collaboration hurdle with international suppliers while maintaining cost competitiveness.

By choosing a high-end Chinese supplier like JS Precision, you will have top-class manufacturing quality and service at a lower price.

Practical Guide: Seven-Step Practical Guide To Selecting 5-Axis Services For Your Precision Parts

Having understood evaluation and cost, the following seven-step guide will take you through selecting a 5-axis CNC machining service provider:

- Define your requirements clearly: Create drawings, 3D models (have them send STEP/IGES preferred), and material and precision requirements. The clearer your specifications, the more accurate your quote.

- Screen suppliers first: Select 3-5 candidate suppliers based on technical strengths, company reputation, and case studies.

- Send RFQ and evaluate: Look for breakdown prices and engineer questions. Experts will identify potential design errors in the drawings.

- Request a DFM report: Good suppliers will provide design optimization suggestions to allow you to reduce cost and scrap.

- Investigate commitment to quality: Ask about the inspection documents and quality control processes, and request prior reports for ensuring quality capabilities.

- Validate communication experience: Check whether the company responds within 24 hours and can answer process questions.

- Careful Decision: Balanced selection based on technology (30%), quality (30%), service (20%), and price (20%).

By following this seven-step method to select a service provider, JS Precision is your best bet. We react promptly to RFQs, present comprehensive Design and Measurement (DFM) reports, assist you in negotiating 5-axis CNC machine price, and deliver on time. Please do not hesitate to reach out to our project team while you go through the steps.

Figure 3:Five axis machine tool milling silver workpieces with spiral texture.

Is JS Precision The One For You? This Is The Value We Guarantee

If the following issues are important to you in your 5-Axis CNC Machining partnership, JS Precision is the perfect fit for you:

1.An engaged engineering partner: Our engineers will thoroughly review your 5-axis CNC machining parts drawings to decide how to maximize them (e.g., simplify machining steps and minimize waste), allowing you to cut costs without compromising performance.

2.Secure supply chain and delivery: By owning our own manufacturing facilities and raw material inventory, we cut down on the lag in delivery due to capacity constraints or availability of raw material at outside factories, with on-time delivery rate of over 98%.

3.High-end Part Machining Capabilities: We have over 20 imported 5-axis CNC machines capable of machining intricate parts to ±0.005mm accuracy. We have solved most of the industry challenges faced by customers in the medical and aviation sectors.

4.Open Collaboration Reduces Overall Cost: Our quotations completely itemize raw materials, processing, and testing fees without any hidden fees. We also help reduce concealed costs (e.g., scrap and delays) through Design for Material Design (DFM) optimization and process improvements.

JS Precision has expert 5-axis CNC machines and technical expert staff. We don't simply offer custom 5-axis cnc machining manufacturing services, we guarantee success for your products.

Case Study: How JS Precision Lowered Total Costs For A Medical Customer By 35% With 5-Axis Machining And DFM

Pain Points of Customers

An opportunity existed to produce stainless steel surgical instrument housings for one European medical device company. The parts were 316L stainless steel, 1.2mm thin wall thickness, and an accuracy tolerance of ±0.01mm. ISO 13485 certification was required. Original supplier quoted $450 per part with 30% scrap and eight-week lead time, resulting in a market delay.

JS Precision Solution

When we got the request, we proposed a solution in three dimensions:

1.DFM analysis in-depth:

The engineer noticed, upon reviewing the drawings, that three of the non-critical ribs on the component were being produced too thin (0.8mm), one of the prime reasons for deformation.

We proposed changing the thickness of those ribs to 1.0mm and aligning the corner radius. This layout not only retained the personality of the instrument but also offered a dramatic enhancement in structural stiffness under machining.

2.Enhanced machining process:

We employed 5-axis CNC machining involving a spiral tool path to achieve uniform cutting forces (avoiding localized deformation caused by excessive force). We actually came up with vacuum fixtures for gripping the workpiece securely in place using negative pressure, reducing vibration during machining.

3.Process monitoring:

In advance of mass production, we conduct full-size three-dimensional coordinate measurement (on a Zeiss CMM) on the initial part to make sure that accuracy is on standards before mass production. On mass production, we conduct sampling inspections every 10 pieces in order to guarantee uniform accuracy for all 5-axis CNC machining parts.

Comparison of Results

| Indicators | Current Local Supplier | JS Precision |

| Unit Price | $450 per piece (including $30 surface treatment charge). | $382.50 per piece (forgoing of $20 surface treatment charge, 15% discount). |

| Scrap Rate | 30% (repeated of scrapped parts with additional $13,500 charge). | Less than 0.5% (no additional charge). |

| Lead Time | 8 weeks (rush order at additional $100/unit charge). | 4 weeks (no rush charge, 4 weeks prior delivery). |

| Quality Certification | No ISO 13485 certification (customer test necessary, $5,000 charge). | ISO 13485 certification (test report provided free of charge, no additional charge). |

| Total Cost of Project (100 units) | $64,350 (additional reproduction cost of $13,500 + $5,000 additional testing cost). | $38,632.50 (additional testing cost) $1,632.5 (no rework cost). |

| Warranty after Sale | Warranty is zero. Rework at customer's cost of $200 per unit. | 3-month warranty, JS Precision will bear all costs for rework (including international logistics fees)。 |

Customer Review: "JS Precision's professionalism is unthinkable. Not only did they materialize the drawings, but with their skill in 5-axis CNC machining, they shipped our products to us in perfection. 15% savings on cost were added to by even higher underlying cost savings—e.g., opportunity costs to the market due to scrap loss and delay. Overall cost savings to us was 35% in total."

Figure 4:CNC machining of stainless steel surgical instrument parts

FAQs

Q1: JS Precision's minimum order quantity is what?

JS Precision does not have a minimum order quantity for its online 5-axis CNC machining services. We can take single prototype or batch orders of thousands. From five pilot run R&D test samples to 500 mass-produced structural parts, we provide trustworthy service. We also do full-scale inspection on prototypes, never wavering from quality control practices.

Q2: What information must be provided for a quote?

We recommend providing a 3D model (where available in STEP, IGES, or X_T format), engineering 2D diagrams, part material (for example, 316L stainless steel), production lot size, surface finish requirements, and required delivery term. The more data you provide us, the more real your 5-axis CNC machining price quotation will be, and some process optimization suggestions are also included.

Q3: Can my design be protected as intellectual property?

We will have a close 3-year NDA signed by us prior to working together. Your 5-axis CNC machining parts design files are stored on an AES-256 encrypted server with two-factor authentication only accessible to authorized engineers. Staff sign on hiring a secrecy agreement and receive regular training to prevent any type of leak.

Q4: What if my part needs changing?

Just call your dedicated project manager, provide your changeover specifications (e.g., size changes) and new drawings. Our engineers will inspect the impact within 24 hours and provide a report with a revised 5-axis CNC machining cost quote and delivery date. Production will be started as soon as agreed upon, within 12 hours, avoiding project delays.

Summary

The choice of a 5-axis CNC machinist is war of value, faith, and accuracy. The most cost-effective answer is always hidden behind the quotation—in the vendor's engineering savvy, the strength of their quality system, and how well they can adapt with you.

The next time you require a manufacturing partner for that key project, don't just send a request for quote. Send an invitation to partnership and select an extended team that will be in a position to create real value for you.

Experience JS professional online 5-axis CNC machining services!

Submit your part drawing today and receive not only an instant, transparent quote, but also a Design for Manufacturability and Cost Optimization Proposal from our experienced engineers. Let us help you manage 5 axis cnc machining price and 5 axis cnc machining price, and let us draw on our expertise to show you that true cost-effectiveness starts with the first contact with JS Precision.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com