CNC turning, as an essential processing technology, has long broken through the limitation of simple rotary cutting. It is in the process of becoming a high-precision system that integrates online measurement & control and digital twin technology.

When presented with an array of custom machined metal parts that necessitate micron-level tolerances, or small batch CNC turning operations with the mandate to deliver product development cycles in 72 hours or less, it will become paramount for you to fully comprehend the abilities offered by modern CNC turning centers and the benefit of precision CNC turning services.

This handbook will assist you to comprehend the technological core and business logic for CNC turning in 2025, which will show you how to accomplish outstanding flexible manufacturing with CNC turning with intelligent manufacturing partners all around the globe.

Core Answer Table

| Core Topics | Technical Challenges and Market Myths | JS Precision Solutions and Value Proposition |

| Dimensional Accuracy Control | Errors caused by heat deformation, tool wearout, and clamping inaccuracies make for poor batch quality. | Process-Aware Closed-Loop Control: The integration of online measurement and real-time compensation in CNC turning centers shifts the control of accuracy from prior testing to the process. |

| Cost and Value Optimization | Just considering the cost per unit overlooks the total cost incurred in material usage, tool life, and lead times. | Total Cost of Ownership (TCO) Analysis: We enable cost analysis and optimization on the entire value chain, ranging from CNC turning of aluminum 7075 parameter optimization to process planning. |

| Precision Grade Definition | The imprecise definition used for “precision” prevents proper correlation between the definition of drawings and the corresponding levels of processes. | Standard Precision Capability Matrix: The definition involving clear tolerance zones, roundness, and cylindricity on a commercial to ultra-high level of precision offers a strong basis for your projects. |

| Flexible Manufacturing Support | Traditional assembly lines are changeover slow and unadaptable to meet current iteration rates required for small batch and variety production. | Modular Rapid Response System: Through standardized equipment, modular programs, and digital management, flexible manufacturing with CNC turning is achieved, reducing changeover time by 70%. |

Why Choose This Guide? Core Experience In JS Precision CNC Turning

As a professional with over 15 years of experience with precision CNC turning services, JS Precision has seen many developments in CNC turning technology and evolving demands from industries.

We have more than 12,000 completed projects for custom machining, and our customers come from a wide scope of industries: aerospace, medical equipment, robots, cars, and many others. The minimum machined diameters are only 0.3mm, with a maximum precision of ±0.003mm. Also, the precision CNC turning for aluminum 7075 has been tested on more than 500 projects.

We have dealt with everything, starting from individual prototypes to production runs of 10,000 custom machined metal parts. We completely understand the need for rapid response as in small batch CNC turning and have learned how to optimise costs on a mass production scale.

Our machining processes completely follow ASME B18.3-2019 “Threaded Fasteners – Quality Assurance and Performance.”

This guide is more than a set of theories, it is the embodiment of the combined experience that my crew and I accumulated over the years through endless process changes and problem-solving meetings. Each recommendation is directly applicable, ensuring that you do not fall into common traps while doing CNC turning.

To view industry-specific case studies from JS Precision, fill out the form and submit your industry type and processing needs for the free case studies. In addition, a senior engineer will offer you a starting plan for the CNC turning process.

How To Achieve Micron-Level Consistency In CNC Turning?

It is in total process control, starting from error sources to their compensation in the closed-loop, that the secret to micron-level accuracy in CNC turning resides. This, in nutshell, holds the key to the competitiveness of precision CNC turning services.

Systematic Error Source Identification and Control

Thermal Stability Management: Each part with the ratio >10:1 is sensitive to the thermal expansion caused by spindle operation or environmental temperatures. In JS Precision, there is temperature-controlled workshop environment with an ambient temperature that is precision-managed at 20±1℃. Thermal deformation error correction is done through spindle preheating programs.

Intelligent Tool Management: Contrary to passive tool replacement, we make use of a cutting force observation system and a timer in order to provide an anticipatory compensation in order for the tool to always remain in its optimal state while CNC turning.

Latest Clamping Technology: For deformable components, like thin-walled components, hydraulic clamping and diaphragm chucks help provide a uniform force, thus preventing deformation of the components. This is one of the most important factors that help create high-quality precision CNC turning services.

Closed Loop Manufacturing: From Detection to Compensation

On-Line Measurement/Feedback: The incorporation of contact probes in the CNC turning center enables measurement of the dimension during machining. The data is automatically fed back to the control system for correction of the cutter offset to prevent production of defective products.

Result Analysis and Process Optimization: We apply data analysis to form SPC statistical process control charts. Through trend analysis, we optimize maintenance, improving and refining CNC turning precision with each passing process.

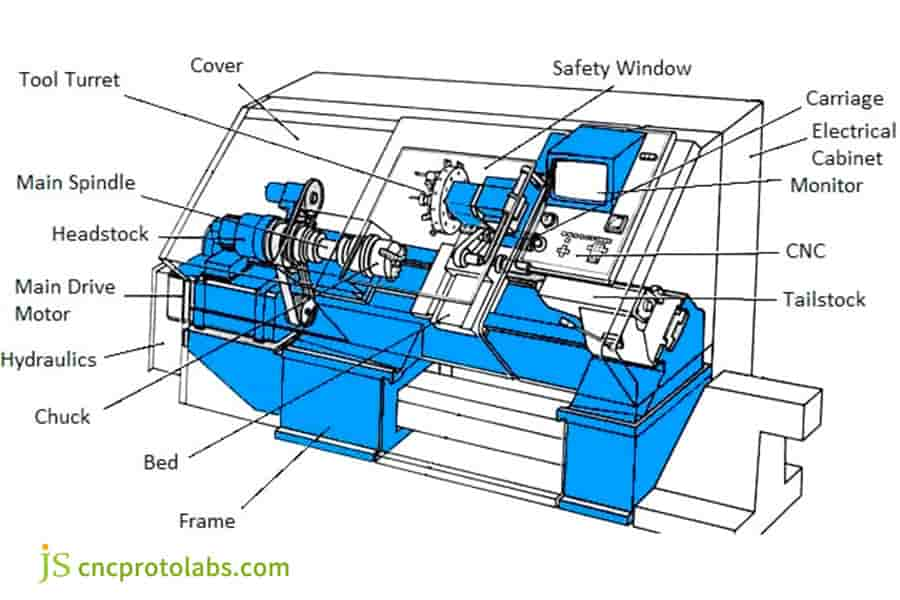

The Brain And Brawn Of Modern Production: Key Functions Of Today's CNC Turning Centers

The CNC turning center remains at the forefront of CNC turning and is reliant on CNC turning functions for efficiency and product accuracy. CNC turning machines are often referred to as “the brain and brawn of modern production.”

Combined and Multifunctional

The combination of turning and milling, Y-axis machining, secondary spindle linkage, and power turret configuration enable the CNC turning center to achieve "one-time clamping, complete completion", completely changing the process selection logic of CNC turning vs CNC milling. It can complete the full machining of parts with rotation and milling features without transferring equipment.

Intelligent and Interconnected

Real-time monitoring of machine tool conditions, wireless program transmission, and digital twin interfaces create a solid data basis for flexible manufacturing with CNC turning. Through the system, I can check the running status of the equipment, make changes in the production plans accordingly, and minimize downtime.

Focus on humans, high efficiency

The protection functions against collisions not only protect equipment from damage during operations, but also reduce the complexity of programming and improve ease of use, and quick-change turrets help reduce the tool-changing times. All these aspects not only improve equipment efficiency but also enable competitive production through CNC turning.

Looking for a high-efficient CNC turning center for machining parts? Please share the parameters and requirements for your parts, and JS Precision will introduce the most suitable resources and solutions for you through an advanced CNC turning center.

Figure 1 A turning center usually refers to a machine tool that integrates milling or drilling functions, or a machine tool with a secondary spindle for performing secondary machining.

What Really Drives The Cost Of Custom Machined Metal Parts?

Custom machined metal parts prices pose a challenge for all their consumers. CNC turning prices are complex, and understanding their underlying drivers can play an essential role in cost control.

Material Cost and Utilization:

The costs begin with material procurement in round bar stocks. Depending on the diameter and dimensions of the component, a specific amount of waste is incurred.

Take, for instance, making φ20x50mm shaft components from φ25mm round bar stocks, for which only 64% of resources are utilized.High specialization alloys, including inconel and titanium, are 5-10 times more costly than regular steel. Higher specialization introduces higher costs.

Processing complexity "tax":

Deep hole processing (hole depth greater than 5 times the aperture), slender shafts (aspect ratio greater than 15:1), small threads (pitch less than 0.5mm), and surface smoothness requirements below Ra 0.2 μ m all exponentially increase programming difficulty and processing time, leading to a significant increase in single piece costs.

Batch effect curve:

This affects the unit cost, which is pronounced differently with varying sizes of the batch, as demonstrated in the table that follows:

| Batch Size Range | Unit Cost (USD) | Main Cost Components |

| 1-10 pieces | 150-300 | Programming, clamping, equipment debugging |

| 11-50 pieces | 80-150 | Material, machining time |

| 51-500 pieces | 40-80 | Machining time, tool wear |

| 501-1000 pieces | 30-40 | Material, batch machining efficiency |

It is clear that the cost per unit for small batch CNC turning is high, but the cost reduces drastically once the orders are over 50. The economic size of the batches is paramount.

Looking to cut costs associated with machined prices for custom machined metal parts? Simply upload your part design drawings and production volume requirements to JS Precision, and they will be able to identify areas to achieve 10-30% savings.

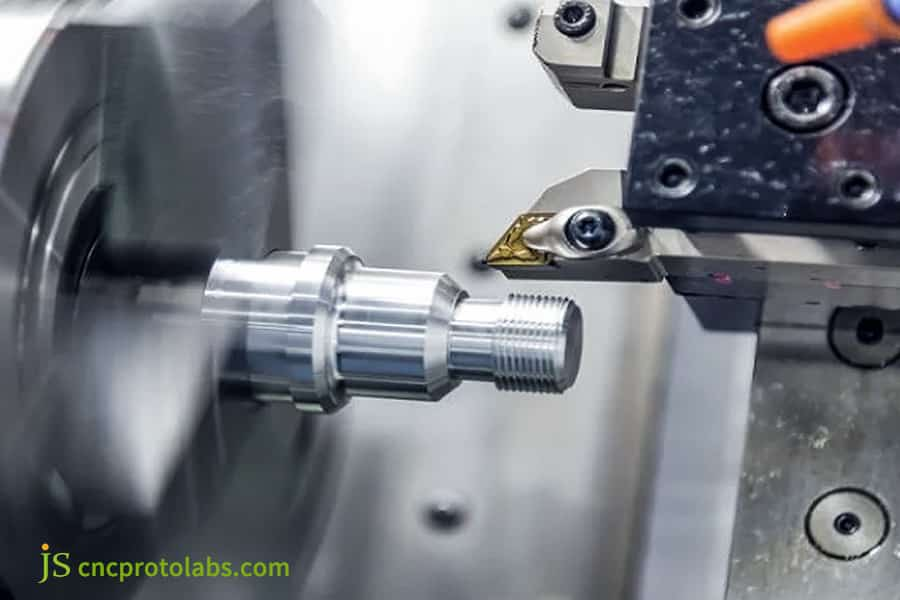

Parameter Mastery: Optimizing CNC Turning For The Demands Of Aluminum 7075

Aluminum 7075 has high strength and lightweight, and is widely used in the aerospace and robotics fields. However, its cutting performance is poor, and CNC turning for aluminum 7075 requires targeted parameter optimization. All aluminum 7075 materials, as chosen for our machining process, comply with the standards of the ASTM B211-19.

Material characteristics and processing challenges:

The strength of 7075 aluminum alloy is over 500 MPa, but because of high viscosity and sticking to the tool, which causes built-up edge, there are specific machining difficulties.

The procedure for selecting the 'golden parameter:'

- For roughing, the aim is efficiency, with spindle speed ranging from 2000 to 3000 rpm, feed rate ranging from 0.2 to 0.3 mm/rev, and the depth of cut set between 2 and 3 mm.

- For finishing, the major aim is surface finish, with the spindle speed increased to 3000-5000 rpm, the feed rate decreased to 0.05-0.1 mm/rev, and the depth of cut maintained at 0.1-0.3 mm. For high-efficient machining, parameter matching must take place.

Cutting tool and cutting fluid:

The use of sharp PCD or TiAlN coated carbide cutting tools with a positive rake angle will reduce the cutting force exerted on the material and prevent the sticking of cutting tools. The use of high-pressure emulsion cutting fluid or cutting oil will significantly improve the quality and efficiency of CNC turning for Aluminum 7075.

Looking for effective machining of Aluminum 7075 components? The presence of “7075 turning” is important, and JS Precision is the point of contact. We will provide you with exclusive CNC turning for aluminum 7075 parameter solutions and tool selection recommendations.

Figure 2:7075 aluminum alloy is one of the strongest aluminum alloys and an ideal choice for CNC machining.

How To Specify And Evaluate Precision CNC Turning Services

To select a trustworthy precision CNC turning services, you have to understand precision specifications and learn scientific techniques to assess them correctly so that you are not deceived by deceptive promises.

Accuracy level pyramid

| Precision Grade | Tolerance Range | Use Cases |

| Commercial Grade | ±0.05mm | General structural components, non-critical load bearing components. |

| Precision Grade | ±0.015mm | Main transmission parts and other mechanical parts. |

| High Precision Grade | Below 0.005mm | Hydraulic parts, optical parts, core parts for medical devices. |

Evaluating a Supplier's "Chain of Evidence"

While considering precision CNC turning services, do not rely solely on what a vendor promises. Instead, actively seek verification of three evidence points:

- Reports of regular machine tool calibrations to verify equipment capability and precision.

- Process control data that indicate ongoing production consistency.

- Part inspection results, primarily focused on key measurements such as roundness and cylindricity.

The Strategic Choice: Making The Right Call Between CNC Turning Vs CNC Milling

Comparing CNC turning vs CNC milling, both being processes used for various applications in the manufacturing sector. None of these processes is better than the other, what matters is matching them to the product.

"Natural Assignment" of Geometric Features

Rotational components like shafts, sleeves, and discs are adequately machined on a turning operation on a CNC lathe and hence efficient and precise. Complex shapes, cavities, and pieces with a multitude of non-rotational features are best machined on a milling operation on the CNC milling machine.

Cost-Effectiveness Crossroads

In those cases where there are many rotary features and a few milling features, economic efficiency may be gained through the use of a CNC turning center rather than the combination of CNC turning followed by transferring the workpiece to the milling machine. Such procedures eliminate the possibilities of secondary positioning error due to setups, hence shortening the production process.

Design-Guided Decisions

Taking into consideration manufacturing in the design phase of a concept can lead to considerable savings and performance enhancements. For instance, maximizing small non-rotational detail on a part into a turnable semblance can tap into the efficiency provided by CNC turning.

How Small Batch CNC Turning Enables Rapid Prototyping And Launch

Based on rapid response speed, small batch CNC turning services have emerged as a crucial operating paradigm to support prototype development and smaller batches of market entry.

Digital Production Line:

JS Precision initiates a digital production flow that extends from online quoting and automated programming right through to smart scheduling. Once you enter your requirements, the software swiftly retrieves a quote that has been programmed by the software team with tool paths by the CAD/CAM software, and smart scheduling gives priority to small batch CNC turning.

Standardized Process Library:

A valid standardized parameter and tool path library for common materials, such as aluminum alloys, stainless steel, titanium alloys, typical features, such as external diameters, internal holes, threads, etc., has been developed, which reduces process re-tuning and cuts process preparation time considerably.

Flexible Production Cells:

The flexible production cells for small lot production have high equipment flexibility and quick changeover. The switching capability between products can be maintained within 30 minutes by employing a quick tool change system and modular tooling.

Figure 3:Prototype production and small batch production require flexibility, speed, and precision, and CNC turning can meet these requirements.

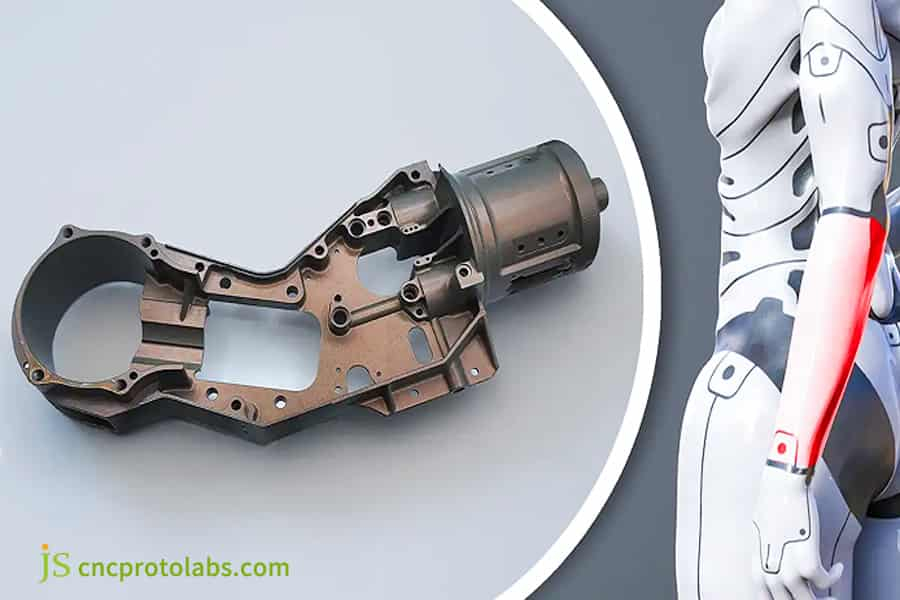

Case Study: From 14 To 3 Days – Accelerating Robotic Actuator Shaft Production By 79%

In the case of precision CNC turning services, the quick response time offered by small batch CNC turning assisted a robotics business in overcoming challenges in R&D, resulting in a substantial gain in efficiency.

Customer Challenges

This robotics manufacturer’s actuator shaft made out of Aluminum 7075 has a tolerance measure of ±0.01mm, making it a precision component.

Previously, the supplier they chose used traditional processing methods, which required multiple clamping and equipment replacement, resulting in a prototype iteration cycle of up to 14 days, seriously slowing down the product development progress and affecting the launch plan.

JS Precision Solution

Process Restructuring: Based on the analysis of the component parts, my group combined the original three assemblies into one part that could then be turned on one machine pass on the mill-turning CNC turning center.

Fast Track Implementation: This project was introduced into the small batch CNC turning rapid response environment where pre-tuned tooling and toolkits were used, thus eliminating the lengthy process of debugging.

Digital Collaboration: This facilitated collaboration between the customer and Miebach, where the customer had access to the machining process information and inspections done in real time. This helped avoid rework.

Quantifiable Results

This was achieved through various optimizations. The single iteration countdown time was cut from 14 days to 3 days, with an optimization of 79%. At the same time, the combined approach resulted in a weight reduction of 20% in components, as well as a cost savings of 15%. Through all these, the customer was able to launch his product 4 months before the scheduled time.

Looking to realize this efficiency gain yourselves? Get in contact with JS Precision, and we can tailor an efficiency gains program based on the needs of your components and the difficulties you are currently experiencing, by leveraging the expertise of precision CNC turning services and small batch CNC turning.

Figure 4:Precision Actuator Interfaces

Agile By Design: Leveraging Flexible Manufacturing With CNC Turning For Product Iteration

Under the rapidly accelerating product development paradigm, the need for flexible manufacturing with CNC turning has become an absolute necessity for businesses to maintain their agility. The particular prototypes developed through this method require less time.

Modular Tooling System: JS Precision employs a modular tooling system that has a zero point positioning quick change chuck as well as standardized V-blocks. It decreases the time required for clamping preparation work from several hours to mere minutes. Additionally, the company can easily change the design and resume operations.

Program and Tool Management: We have established a version managed processing program library and shared tool list. For different versions of part designs, only minor adjustments need to be made based on the original program to immediately put them into production, avoiding duplicate programming.

Partner Agility: Selecting a partner such as JS Precision, that takes flexible manufacturing with CNC turning as a core competence, is an important factor. The agility we possess and our level of collaboration, more so than our hardware, matter because we make suggestions in terms of process during design, and then modify that easily if something changes.

FAQs

Q1: What is the standard lead time for small batch turning (e.g., 50 pieces)?

JS Precision takes 7-10 business days, including process preparation, machining, inspection, and preparation of logistics, to complete orders for 50 pieces for small-batch CNC turning jobs of standard materials and manageable complexity, and this can also be processed as an urgent order.

Q2: Can you turn parts with diameters smaller than 1mm?

Yes. We own Swiss type lathes and precision lathes that come equipped with guide sleeves, allowing us to perform micro-turning. This makes it feasible to machine sub-millimeter shafts that have a diameter of 0.3mm or larger, serving the micro-part machining requirement in the medical and electronics sectors.

Q3: Do you provide turning services for plastics like PEEK or ULTEM?

Yes. Based on engineering plastics like PEEK and ULTEM, we also have designed tool shapes and machining parameters specifically for such materials, efficiently eliminating the risk of melting, burrs, or dimensional instability during machining.

Q4: How do you handle long, thin shafts to prevent bending during turning?

In this, a follow rest and center rest is utilized to assist in supporting long and thin shafts. Additionally, "scraping" machining parameters with a small depth of cut, a high speed, and a larger feed rate are utilized. Stress relief operations are also carried out when required to prevent the bending of the parts at various angles.

Q5: What surface roughness (Ra) can be consistently achieved in precision turning?

With Standard Precision CNC Turning Services, we can guarantee surface roughness of Ra values of Ra 0.8μm. However, if required, we can also provide Ra values of Ra 0.2μm and even lower surface roughness values by using turning, grinding, and polishing techniques.

Q6: How does your flexible manufacturing system handle urgent order changes?

Our online scheduling system incorporates an "urgent order insertion" logic. Together with process packages and tooling, it is capable of promptly reacting to any change in orders, normally starting the adjusted production process within 24 hours.

Q7: What is the maximum turning diameter and length your machines can handle?

Our CNC turning centers have a variety of capabilities. They can turn parts as large as a diameter of 500mm and a length of 1500mm. They can turn micro parts as well as large shaft parts. We can check the possibility based on your drawings.

Q8: What are the benefits of choosing a China-based supplier like JS Precision?

We provide a unique benefit with our blending of Western precision manufacturing standards with an efficient Chinese supply chain system. We provide a guarantee of premier quality precision CNC turning services with more competitive pricing and faster turnaround times, allowing you to achieve optimal quality at reduced costs.

Conclusion

CNC turning is no longer just a mechanical machining process, but a strategic tool that drives product innovation, optimizes production costs, and shortens the time to market.

Whether it is ultimate dimensional stability or incredibly fast time-to-market, JS Precision is dedicated to being the most reliable, professional, and valuable link in your worldwide flexible manufacturing with CNC turning.

Define new possibilities for your next turn-around project.

→ Upload your drawings and start experiencing the intelligent quoting system based on DFM Analysis today

→ Schedule a tech seminar with our turning application engineers for a customized solution to optimize your industry (robotics, medical, automotive, etc.).

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com