CNC Machining Milling is the key to solving the difficult problem of precision part machining.

When an ordinary metal blank is precisely cut by rotating CNC milling bits under the drive of CNC commands, gradually transforming into precision components for aerospace engines or core parts for medical devices, this is a perfect demonstration of CNC machining milling technology.

Quality, cost, and delivery efficiency of parts are directly linked to the technology of CNC milling. Herein, JS Precision summarized the process breakdown from process, tooling, and design perspectives that will help in solving challenges from design through production and finding suitable machining solutions.

Core Answer Summary

| Technical Dimension | Core Considerations | JS Precision's Professional Solutions |

| Machining Principles and Tools | Material removal mechanisms, cutting mechanics, tool geometry, and materials science. | A professional selection database of CNC milling bits based on material properties in order to optimize the cutting parameters. |

| Part Design and Optimization | Feature accessibility, rigidity, tolerances, and surface quality requirements. | Providing manufacturing design analysis to optimize the structure of CNC milling machining parts, improve quality, and reduce costs. |

| Equipment and Precision | Rigidity of machine tool, dynamic performance, control system, and precision compensation. | By using high-precision machine tools with strict process control, the consistency of CNC milling machining parts is high. |

| Cost-Value | Investment in equipment, tool wear, time, and material use. | Transparency of CNC milling machine price for an optimum cost-performance relationship by optimizing the process. |

The Authoritative Guide To CNC Machining And Milling: Precision Manufacturing Secrets From JS Precision

With 15 years of deep involvement in the field of CNC Machining Milling, JS Precision has been serving more than 500 customers around the world, covering 12 core industries such as aerospace, medical devices, and automotive precision components.

We have processed more than 40 types of materials, including aluminum alloy, titanium alloy, and composite materials, and completed more than 10,000 projects of precision parts. The pass rate of aerospace-grade parts has always been more than 99.5%. We once reduced the machining cycle of a complicated impeller for a client by 42%.

Our quality system follows the International Organization for Standardization (ISO) best practice framework for quality management, ensuring the standardization and traceability of processes. The 99.5% parts qualification rate achieved by JS Precision in the aerospace field is a reflection of the implementation of this strict standard.

In addition, our engineering team has more than 8 years of average CNC milling experience, capable of solving various technical challenges from micro-milling to high-speed hard milling.

This is not a simple theoretical compilation but rather a concentrated outcome of our 15-year practice that has been confirmed in real productions, from the selection of tools to five-axis equipment configuration. That being said, please have full confidence in the professionalism and practicality of this guidebook.

Whether for the aerospace or medical field, JS Precision has the experience in providing a broad array of CNC machining milling services. Feel free to contact us with your specific requirements, and we will be able to expedite the order process to meet parts quality and efficient delivery.

How Does CNC Machining Milling Transform Raw Material Into Precision Parts?

After learning about JS Precision, you must be wondering how raw materials are turned into high-precision CNC milling parts using CNC Machining Milling. The following analysis is presented with three stages.

Digital Subtractive Manufacturing:

Our design consists of making a 3D CAD model according to part requirements, importing it into CAM software for programming, setting parameters like cutting paths and spindle speeds, and simulating anti-interference.

Then, import the program into the CNC system and control the machine tool to cut the raw material to get a CNC Machining Milling part that fits the requirements.

Principles of Motion Control:

Five-axis machine tools link the X, Y, and Z linear axes with two rotary axes to enable multi-angle machining of impellers and other complex parts. Linear interpolation controls the straight-line movement of a tool to ensure flatness. Circular interpolation controls a circular trajectory to machine curved surfaces. Both ensure that the CNC machining paths are accurate.

Material Removal Mechanisms:

In CNC machining milling, contact between a tool and raw material generates cutting force. If too great, this can wear the tool and deform the workpiece. If chip removal isn't timely, the surface finish goes down, if the cutting heat isn't effectively dissipated, it changes the metallographic structure of the material.

JS Precision optimizes the control by improving cutting parameters and choosing an appropriate cooling method to guarantee the quality of CNC milling parts.

How To Select The Perfect CNC Milling Bits For Different Materials?

The right choice of the CNC milling bits is important for ensuring quality in CNC machining milling. Most customers increase their costs by choosing the wrong tool because they do not understand tool material, parameters, and coatings. The following are three dimensions that will help in the selection of appropriate tools.

Tool Material Selection

Different tool materials have their respective applicable scenarios and costs, as detailed in the table below.

| Tool Material | Applicable Material | Cost-Benefit Analysis |

| Carbide | Steel, Aluminum Alloy, Titanium Alloy | Longer life, medium price, high cost-effectiveness, suitable for batch processing. |

| High-Speed Steel | Low Carbon Steel, Non-Ferrous Metals | Low cost, shorter lifespan, suitable for small-batch processing of simple parts. |

| Ceramics | High Temperature Alloy, Hardened Steel | Resistant to high temperature and durable. Higher cost. For machining high-hardness materials. |

| CBN/PCD | Superhard Materials, Non-Metallic Materials | High precision, extremely long life, high price, used for precision part processing. |

The Decisive Role of Geometric Parameters

The geometric parameters of the CNC milling bits have a direct effect on machining results.

- Rake Angle: The large rake angle leads to low cutting force, which is suitable for soft materials such as aluminum. In contrast, a small rake angle leads to high rigidity in cases where hard material is involved, like steel or titanium.

- Clearance Angle: With a large clearance angle, the friction will be low and wear is slow but rigidity will be low. A small clearance angle gives high rigidity but fast wear.

- Helix Angle: Larger helix angles have better chip removal and are suitable for aluminum and copper, while smaller helix angles offer better stability and are suitable for hard steel.

- Number of Flutes: More flutes will increase efficiency but will have less chip removal space, and vice versa. Example: For aluminium, 4 flutes are used, for deep cavities, 2 flutes are used.

Coating Technology Enhancement

Coatings improve the lifespan and performance of CNC milling bits:

- TiN Coating: Hard, wear-resistant, suitable for steel, increases tool life 2-3 times.

- TiAlN Coating: Resistant to high temperatures, stable above 800℃, suitable for titanium alloys and high-temperature alloys.

- DLC Coating: Low friction, hence less cutting force, suitable to cut aluminum and copper because it prevents tool sticking.

JS Precision is capable of matching the best CNC milling bits for you in regard to the materials you are machining. Whether it's a carbide tool or specially coated, it ensures the cutting performance and life, reducing your tool replacement costs.

Figure 1: Different tool materials have different applicable scenarios.

Designing For Manufacturability: How To Optimize Your CNC Milling Machining Parts?

Most customers' designs of CNC milling machining parts exist in such a way that deformation, substandard accuracy, and even redesign are not taken into consideration in the CNC milling process. The following are key points of optimization:

Internal Corner Radius:

Because CNC milling bits have radii, it is impossible to machine corners that are perfectly sharp. JS Precision suggests always designing something with a standard fillet radius (0.5mm, 1mm, 2mm) to avoid machining difficulties or even tool wear altogether.

Deep Cavities and Holes:

Deep cavity/hole machining, with a depth-to-diameter ratio over 5:1, easily causes tool overload and vibration that affects the accuracy of the product. The design shall, as much as possible, control the depth-to-diameter ratio.

When adjustment cannot be done, JS Precision will use long-neck tools and optimized parameters to reduce the vibration and ensure the quality of CNC milling machining parts.

Thin Wall Feature:

Thin-walled parts are prone to deformation due to poor rigidity. Minimum wall thickness should be guaranteed in the design: aluminum ≥ 0.8mm, steel/titanium alloy ≥ 1mm, for even thinner parts, JS Precision uses specialized fixtures to reduce cutting forces and prevent deformation.

Principle of Unified Datum:

Parts requiring multi-clamping/multi-process operations need unified datums, such as planes or holes that avoid positioning errors. JS Precision's DFM service optimizes these datums and makes sure accuracy is maintained.

JS Precision's DFM Service:

With our DFM service, we intervene early in the design phase by optimizing the part structure according to the milling process of CNC machining to offer a quotation with a lower cost, shorter cycle time, and balancing quality with efficiency.

Figure 2: To ensure your parts can be milled in the most efficient way possible, consider the DFM principles during the design phase.

What Configurations Truly Impact the Cost Of CNC Milling Machine?

Many customers, when inquiring about CNC milling machining service, are concerned about the cost and price of a CNC milling machine. Different equipment configurations result in significant differences in price and processing quality. The following analysis addresses this from three aspects.

Core Cost Analysis

The cost of a CNC milling machine mainly depends on three parts, which are represented in the table below.

| Core Items | Influencing Factors | Impact on the Cost of CNC Milling Machine |

| Machine Body | Structural rigidity, stroke range, guideway/screw type. | High rigidity + large stroke + ball screw, 30%-50% higher in cost. |

| CNC System | Brand (Siemens/Fanuc), performance level. | High-end systems cost 2-3 times more than basic systems. |

| Key Optional Equipment | Tool magazine capacity, spindle speed, probe. | 24 tool positions+15000rpm spindle+probe, cost increases by 20%. |

Return on Investment Perspective

While the high-configuration CNC milling machine price is higher (5-axis is 50% plus higher than 3-axis), long-term unit costs are lower. A customer in the aerospace industry once manufactured a bracket with a three-axis CNC machine, resulting in 5 setups, taking 10 days per piece at $2500 each.

Changing to a five-axis machine reduced the time to 5.8 days per piece and $1550 per piece and enabled recouping the price difference in six months.

Our Equipment Strategy

JS Precision has invested in multiple top-of-the-line CNC machine tools, including 10 five-axis and 20 three-axis machines, equipped with Siemens 840D systems, 24-tool magazines, and online probes. The spindles can achieve speeds of up to 20,000 rpm, which offer stable CNC milling machining service for customers.

JS Precision's equipment balances the cost of CNC milling machine with processing efficiency, offering you a cost-effective CNC milling machining service. You can contact us to learn about specific service plans and quickly start your machining project.

Why Is 5-Axis CNC Milling Machining A Game Changer For Complex Parts?

Some complex CNC milling machining parts, like aerospace impellers and medical implants, are hard to machine by 3-axis CNC milling, while 5-axis CNC milling machining can solve this problem easily. We will analyze below its advantages, application scenarios, and the capabilities of JS Precision.

In-Depth Analysis of Technical Advantages

- Single-setup machining: This avoids positioning errors from multiple setups, significantly improving the overall accuracy.

- Complex surface machining: Optimal tool angle cutting avoids interference, ensuring accuracy and finish on the surface.

- Optimal tool orientation: this makes use of shorter tools for maximum rigidity, less vibration, and longer tool life.

Application Scenarios

5-axis CNC milling machining is suitable for aerospace (structural parts, impellers), medical devices (artificial joints), high-precision molds (cavities, cores), and other fields.

Our 5-Axis Capabilities

JS Precision has 10 5-axis machine tools that can handle parts with a maximum size of 1500×800×600mm. It supports micro-milling, with a minimum tool diameter of 0.1mm and high-speed hard milling at HRC60+. We have helped clients increase turbine blade yield from 85% to 99.5%, and have reduced cycle time by 42%.

Figure 3: 5 axis mills.The configuration of a five axis milling machine is more diversified, used for machining more complex geometric shapes, such as turbine blades, integral disks, and complex surfaces.

The Precision Premium: How Does CNC Milling Machine Price Correlate With Accuracy?

Many customers could not help but wonder why different types of CNC milling machines have such huge price differences. In fact, accuracy is the key influencing factor: the higher the accuracy, the higher the price of the equipment. Below, we analyze the relationship of the two and the accuracy guarantee from JS Precision.

Accuracy Grade Cost Composition:

The regular precision CNC milling machine price(± 0.025mm) is approximately 50000 to 80000 US dollars. For a higher precision machine-let's say, ±0.005mm-the figure rises to US$150,000-US$200,000. This is because high precision machines are fitted with high-precision guideways and spindles, making assembling and calibration more difficult.

Thermal Stability and Dynamic Accuracy:

Thermal compensation systems are installed in high precision machine tools, with real-time temperature control to reduce component deformation. High-quality servo systems improve dynamic accuracy - all adding up to increased equipment cost.

Accuracy Value Consistency:

JS Precision calibrates the equipment monthly, maintains the workshop temperature at 20±2℃, and makes online measurement compensations during machining. It ensures that the accuracy deviation of each CNC milling machining part is ≤±0.003mm.

JS Precision ensures precision in controlling the CNC milling machine price, therefore providing you with high-precision CNC milling machining parts. You can contact us to confirm your precision requirements, and we will match up with appropriate equipment for machining.

What Are The Technical Demands For CNC Milling Machining Service On Complex Parts?

Handling complicated CNC milling machining parts requires higher technical demands. Below goes an analysis of the required technical capabilities, quality control, and JS Precision service positioning.

Beyond Conventional Technical Capabilities

- Micro-milling: It can achieve an accuracy of ±0.002mm and machine features as small as 0.5mm for medical micro-parts and optical parts.

- High-speed hard milling: The technology can machine HRC60+ hardened steel directly, reducing die cycle time by 30 percent and improving die accuracy.

- Turn-milling combination: This combines turning with milling, thereby completing the process in one clamping operation, reducing clamping errors.

End-to-End Quality Control

Simulation-based toolpath interference prevention during programming, online measurement and real-time compensation using probes during machining. After completion, a three coordinate detection report will be generated to ensure quality throughout the entire process.

JS Precision's Service Positioning

A professional CNC milling machining service provider, we have a team of 10+ people specializing in complex projects with members averaging 10+ years of experience. We have helped medical clients machine micro-implants with a 99.8% pass rate.

Case Study: Achieving 38% Cost Reduction On Aerospace Bracket With 5-Axis CNC Milling

Below, a real-world case study will give an intuitive understanding of the value of 5-axis CNC machining milling technology and how JS Precision helps clients solve machining challenges and reduce costs.

The Challenges Faced by the Client

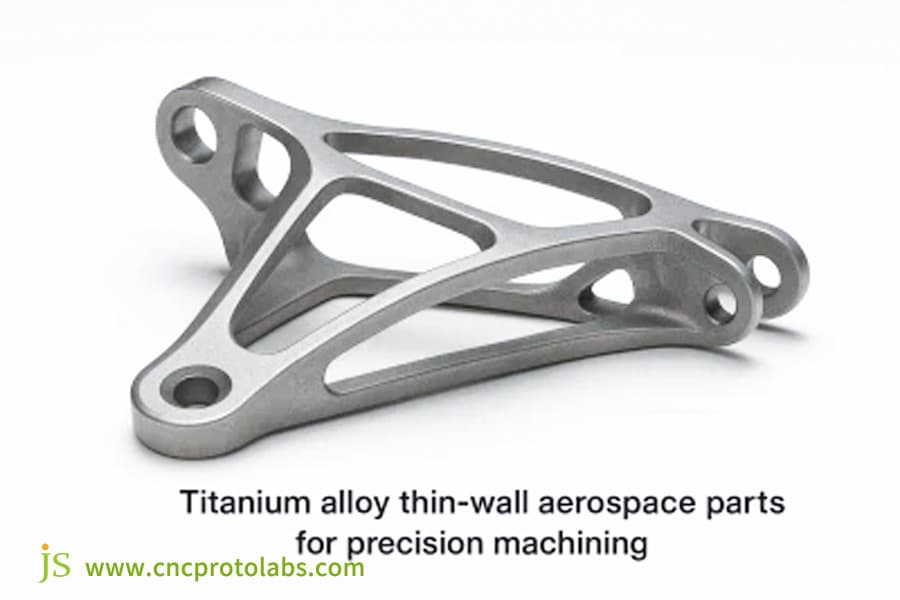

An aerospace customer needed to machine a batch of bracket CNC milling machining parts made of titanium alloy (TC4) with a precision requirement of ±0.01mm.

The client originally used a three-axis CNC machining milling process, requiring 5 clamping operations, 3 sets of specialized fixtures, and a single-part machining time of up to 10 days.

More seriously, the cumulative errors caused by multiple clamping operations resulted in a part pass rate of only 85%, with 20 parts scrapped per month, leading to direct economic losses of approximately $50,000 and failing to meet the delivery cycle requirements.

JS Precision Solution

After receiving the project, we analyzed the part structure and machining difficulties and developed a five-axis CNC machining milling solution accordingly:

- Redesigned the special fixtures for machining of all the part surfaces in one clamping to avoid repeated positioning errors.

- Improve toolpaths, select TiAlN-coated carbide tools, and optimize the cutting parameters: spindle speed at 8000 rpm, feed rate at 150 mm/min to improve machining efficiency and extend tool life.

- An online measuring probe is applied to perform dimensional calibration every 5 parts that have been machined, which can compensate for the machining error in real time and guarantee stability in accuracy.

Final Quantitative Results

By applying these methods, the project achieved remarkable results:

- The single-piece machining time was reduced from 10 to 5.8 days, with an increase in machining efficiency of up to 42%.

- The overall cost (including materials, labor, equipment depreciation, and tool consumption) decreased from $2500/piece to $1550, a 38% drop.

- The part qualification rate rose from 85% to 99.5%, and only 1 part was scrapped in a month.

- The customer recorded a saving of over $250,000 every year while guaranteeing on-time order delivery.

Up until now, the customer has signed a 3-year long-term cooperation agreement with JS Precision.

Figure 4: Titanium alloy aerospace bracket

Local Expertise Or Global Standard? Decoding The 'CNC Milling Near Me' Dilemma

While looking for the CNC milling machining service, many customers often search for "CNC milling near me," believing this is convenient. However, in the processing of complex CNC milling machining parts, geographical location is not the most important factor.

Advantages and Limitations of Localized Services

The benefits of services provided locally include convenient communication and probably shorter delivery cycles due to proximity.

However, most local suppliers lack technologies like five-axis machining and micro-milling, and their equipment precision and quality systems cannot meet high-precision requirements. It is hard to find the right service provider by simply relying on "CNC milling near me".

Technical Capability First Principle

For complex parts, more important than the geographical location of the supplier is technical capability and quality system. Advanced equipment such as five-axis machine tools with professional teams can guarantee quality even from a distance, while insufficient local technology can easily lead to project failure and waste of costs.

JS Precision Solutions

JS Precision caters to customers worldwide, driving hyperlocal value with effective communication and supply chain management.

- The web platform enables clients to track the progress, report, and have technical discussions through video conferencing, hence mitigating communication problems due to distance.

- Global logistics partners ensure optimal transportation options with US client delivery times of 7-10 days.

- On-site support is provided at key clients to resolve parts usage issues by local technical personnel.

Be it "CNC milling near me," JS Precision's service can reach anywhere. We make sure that communication is well-established with the support of digital tools, and provide you with the best CNC milling machining service.

FAQs

Q1: What is the typical tolerance achievable with CNC milling?

The overall accuracy of the CNC milling is ±0.025mm. In high-precision applications that require as high as ±0.005mm, special processes can be used depending on the part characteristics and the material being machined.

Q2: How do I choose between 3-axis and 5-axis CNC milling?

3-axis CNC milling can be used to process plate-shaped and simple three-dimensional parts. If the part has multiple machined surfaces or complex curved surfaces, then 5-axis CNC milling will improve accuracy and efficiency to better meet the requirements.

Q3: What are the most important factors affecting surface finish in milling?

The major factors impacting milling surface finish include cutting parameters, tool selection, machine tool rigidity, and toolpath strategy. In particular, finishing strategy and tool vibration control have to be considered.

Q4: Can CNC milling be used for prototyping?

Absolutely possible. CNC milling is capable of making functional prototypes with high precision and strength rather quickly, hence, it is one of the preferred methods in prototyping.

Q5: How does material choice impact the CNC milling process?

Hardness, toughness, and thermal conductivity influence directly tool selection, cutting parameters, machining forces, and thermal deformation in CNC milling, thus affecting machining costs and cycle time.

Q6: What is the difference between milling and turning?

The principal movement during milling is the rotation of the tool, and the workpieces are stationary or fed. On the contrary, turning is done by rotating the workpiece and feeding the tool. Both are suitable for parts with different geometric features.

Q7: How do you handle deep cavity milling challenges?

Deep cavity milling problems can be solved with long-neck tools, reduced cutting parameters, and high-speed milling strategies, ensuring proper chip removal and cooling. In some cases, this means milling in layers.

Q8: Can you machine hardened steels with CNC milling?

Yes, this machining process is called hard milling. Within this process, special tools are required, and specific adaptation strategies need to be considered. Hard milling is among the most common machining processes within the mold manufacturing industry.

Summary

CNC Machining Milling is not just about "cutting materials," but accurate collaboration in the whole chain, from the design of parts to the selection of tools and equipment configuration down to service delivery. JS Precision is your reliable partner along this precision machining chain.

With 15 years of practical experience, we secure your CNC milling machining needs and turn "difficult problems" into "easily implemented results." Let us work together in transforming your designs into tangible products boasting better quality and competitiveness.

Embark on precision manufacturing with Uiz today!

→ Click to upload your part drawings for professional quotation and manufacturing analysis

→ Contact our application engineering team to discuss the specific technical solution for your project

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com